Stainless steel slag treatment method

A treatment method and technology for stainless steel slag, which are applied in the direction of recycling technology and process efficiency improvement, can solve the problems of high energy consumption, unenvironmental protection and large area of stainless steel slag treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

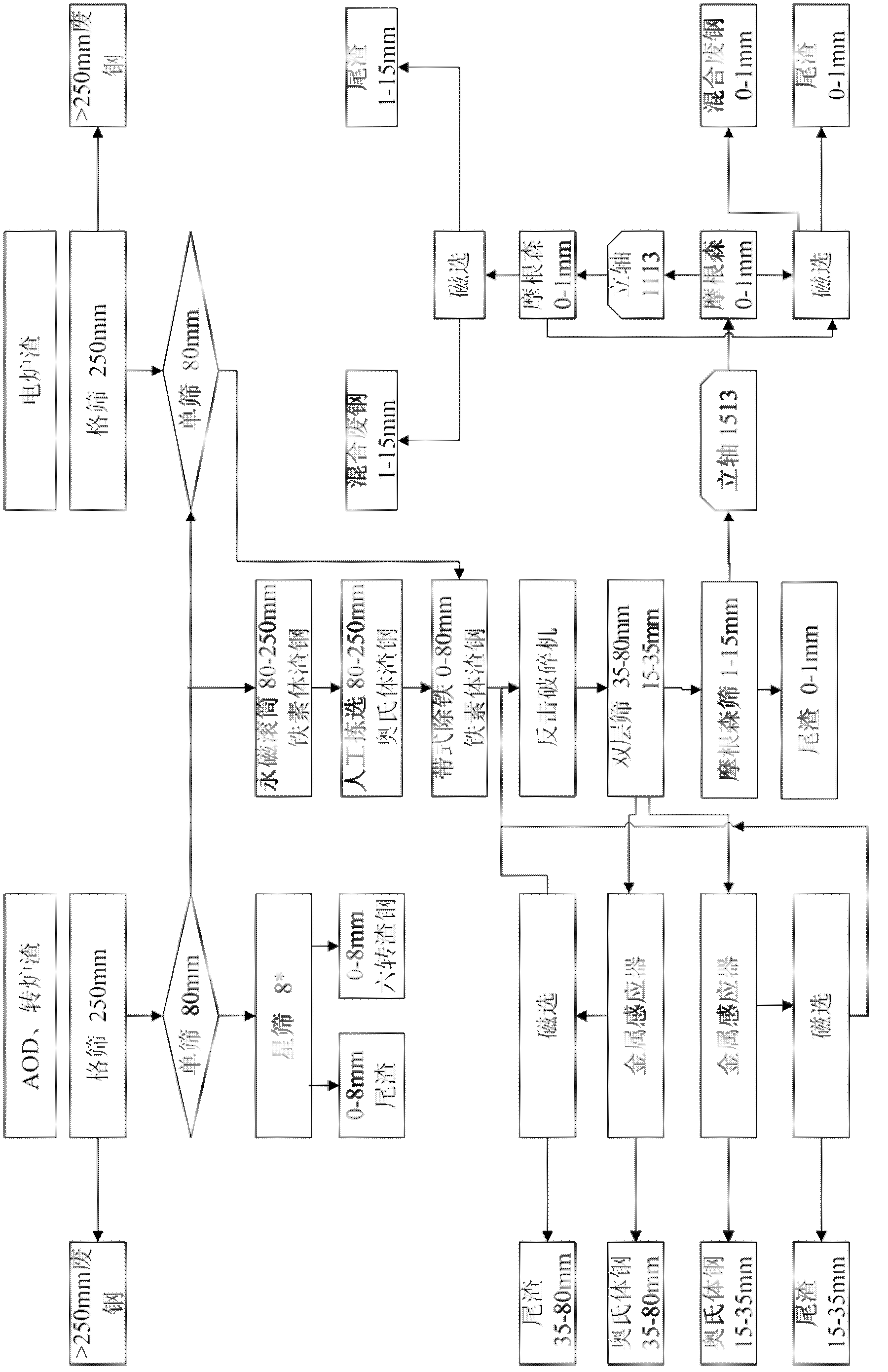

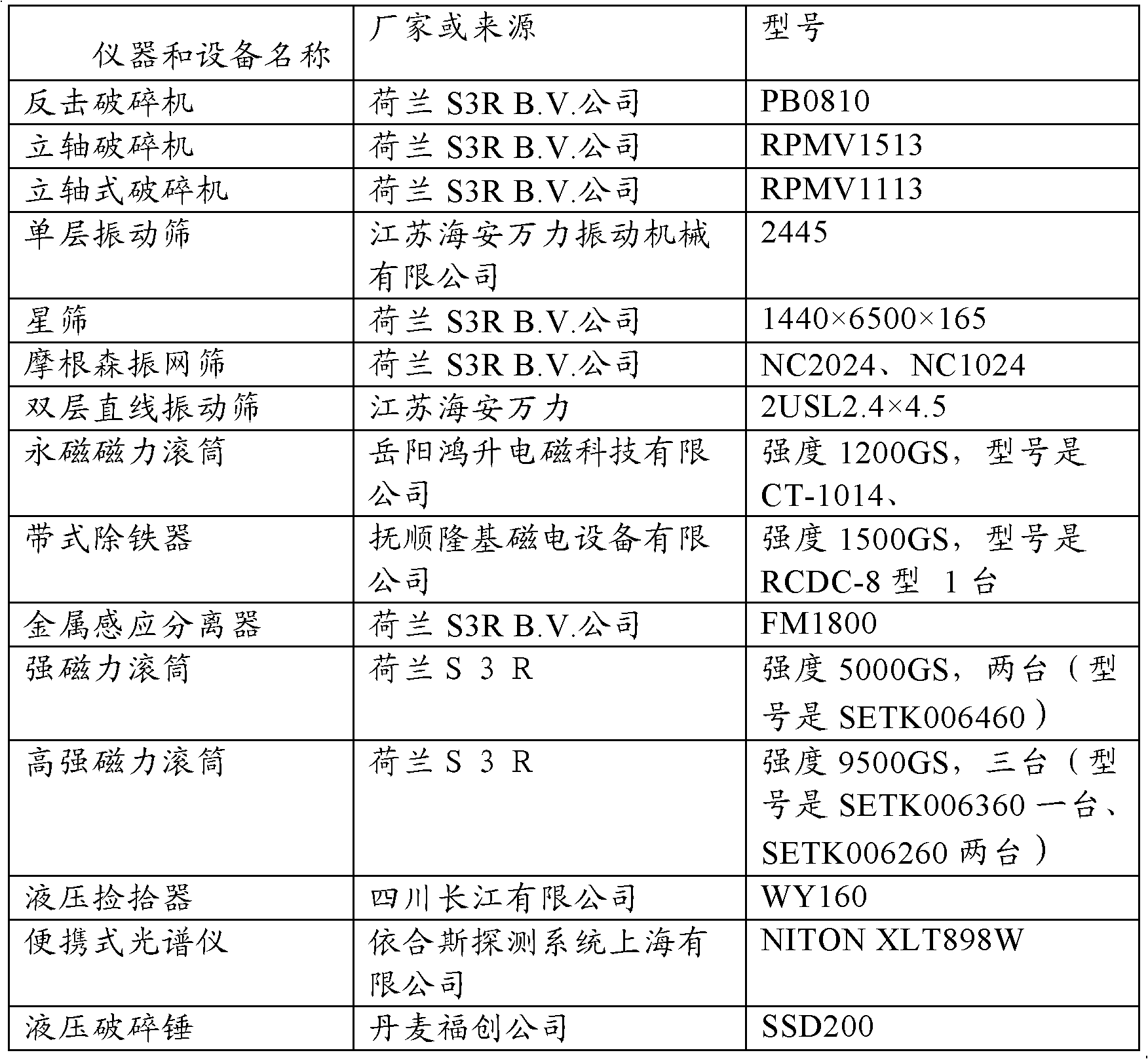

[0125] Schematic diagram of combined stainless steel slag treatment line figure 2 , the concrete treatment steps of stainless steel slag are:

[0126] (1) Add modifier

[0127] The stainless steel slag (AOD stainless steel slag, converter stainless steel slag and electric furnace slag) tank from the steel factory is added with a boron modifier, and its composition is mainly borax, containing more than 0.5% B 2 o 3 .

[0128] (2) cooling

[0129] First, it is transported to the steel slag cooling workshop through the railway line, and the slag tank is unloaded to the slag tank cooling area by a special spreader. The slag tank is cooled by water spraying in the cooling area for about 1.5 days, and then transported to the tank dumping area. The steel slag is further sprayed with water in the tank dumping area for cooling, and the tank is dumped after cooling to below 80°C (intermittent and regular temperature measurement to meet the process requirements). The steel slag aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com