Air-cooled dedusting system of biomass granulator

A technology of biomass particles and dust removal system, which is applied in the direction of removing smoke and dust, extrusion granulation of molds, presses, etc., can solve the problems of threatening the service life of ring die, lack of effective lubrication of press rollers, and large damage to press roller bearings. , to achieve the effect of improving the service life and granulation output, good economic and social benefits, and meeting the requirements of energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

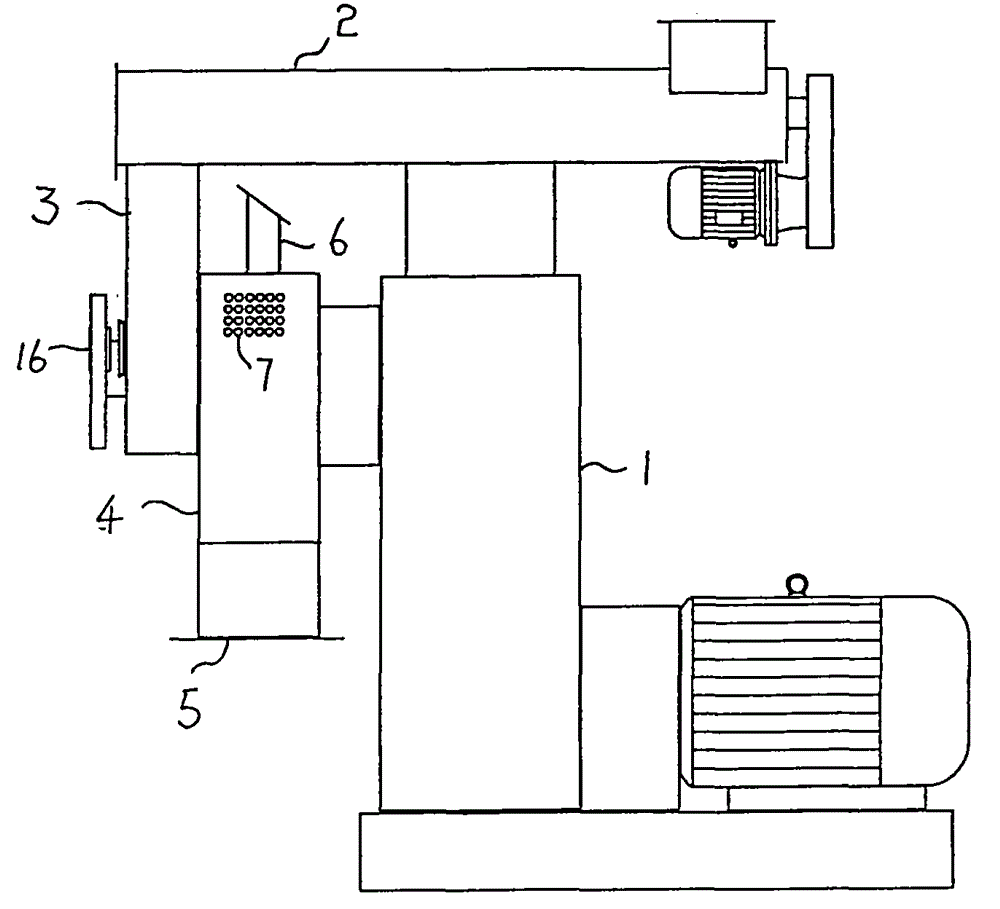

[0036] This embodiment realizes the air-cooling mode that the upper part of the granulation chamber 4 draws air and the lower part takes in air.

[0037] An air-cooled dust removal system for a biomass particle granulator is used to form a gas convection environment in the granulation chamber 4, which includes a granulation chamber 4, and a discharge port 5 is provided at the lower end of the granulation chamber 4, and is characterized in that the The granulation chamber 4 is provided with at least one air duct 6, and the corresponding position of the opening of the air duct 6 is provided with a heat dissipation hole 7, and the heat dissipation hole 7 can be provided through a sieve plate or a screen mesh.

[0038] The air pipe 6 is connected to the exhaust equipment through the air delivery pipeline 8, and the exhaust equipment is a cyclone separator 10 or a negative pressure blower. The air pipe 6 is used as an air outlet, and the discharge port 5 at the lower end of the gra...

Embodiment 2

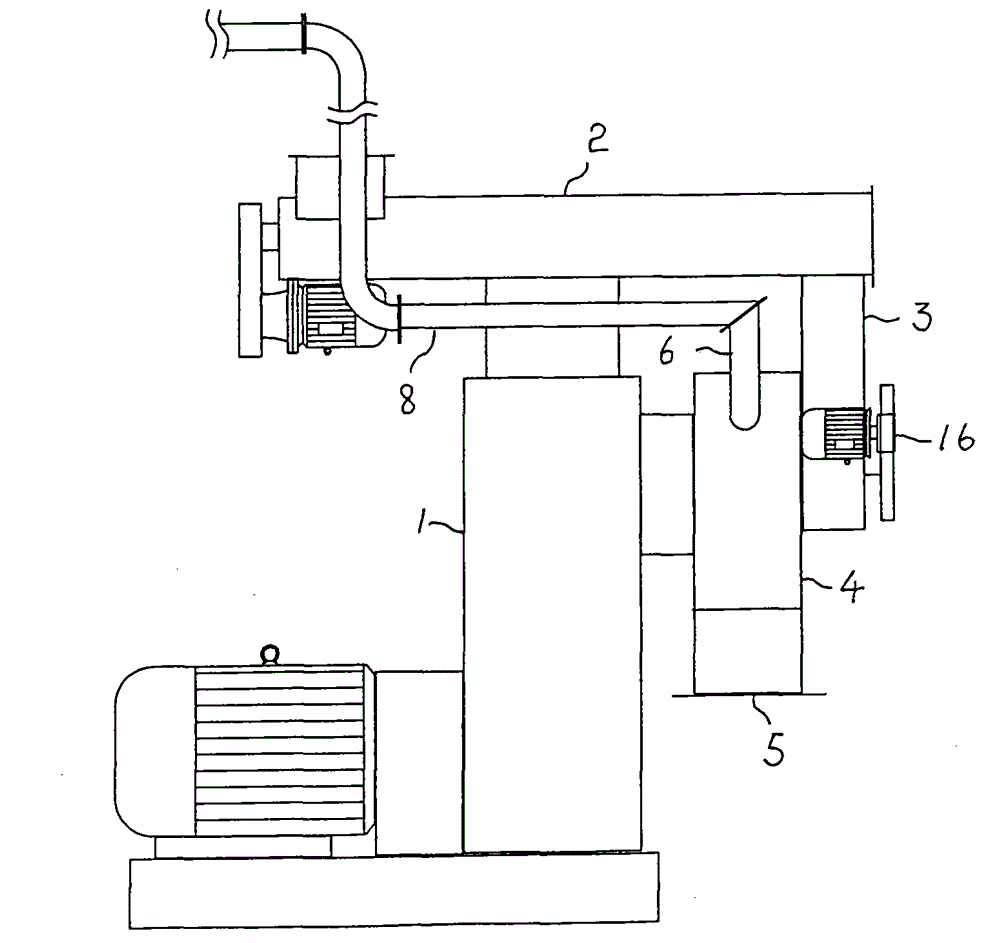

[0040] This embodiment realizes the air-cooling mode of air intake from the upper part of the granulation chamber 4 and exhaust air from the lower part.

[0041] An air-cooled dust removal system for a biomass particle granulator is used to form a gas convection environment in the granulation chamber 4, which includes a granulation chamber 4, and a discharge port 5 is provided at the lower end of the granulation chamber 4, and is characterized in that the The granulating chamber 4 is provided with a cooling hole 7, which can be a relatively large opening, or can be provided through a sieve plate or a screen.

[0042] The discharge port 5 is connected to the airtight cabin 13, and the airtight cabin 13 is provided with a main air delivery pipe 9, and the main air delivery pipe 9 is connected to the ventilation equipment.

[0043] The cooling hole 7 is used as the air inlet of the upper part, and the discharge port 5 at the lower end of the granulation chamber 4 is used as the a...

Embodiment 3

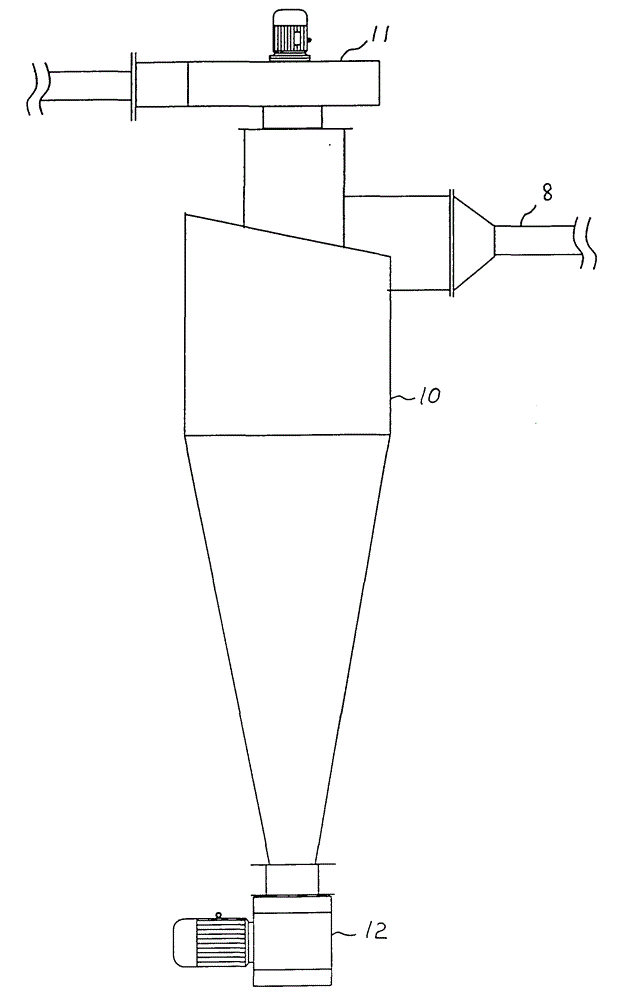

[0045] This embodiment realizes the air-cooling mode in which the upper part of the granulation chamber 4 blows air and the lower part blows air.

[0046] An air-cooled dust removal system for a biomass particle granulator is used to form a gas convection environment in the granulation chamber 4, which includes a granulation chamber 4, and a discharge port 5 is provided at the lower end of the granulation chamber 4, and is characterized in that the The granulation chamber 4 is provided with at least one air duct 6 .

[0047] The air duct 6 is directly connected to the blast equipment through the air delivery pipeline 8, and the blast equipment is a blower fan. The air duct 6 is used as a blowing outlet, and the discharge port 5 at the lower end of the granulation chamber 4 is used as an air outlet to realize the air-cooling mode in which the upper part is blasted and the lower part is discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com