Patents

Literature

45results about How to "Meet energy saving and emission reduction requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

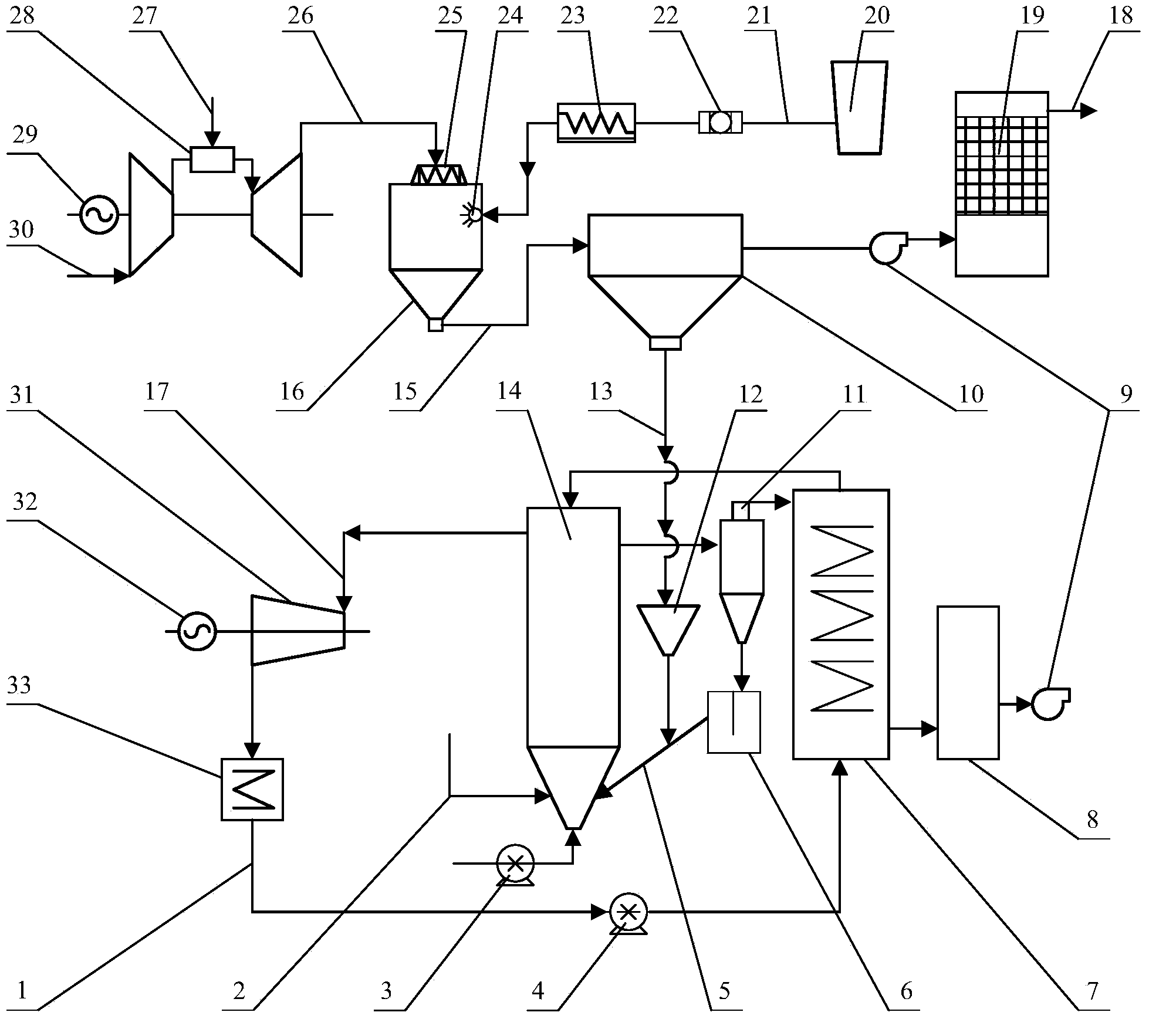

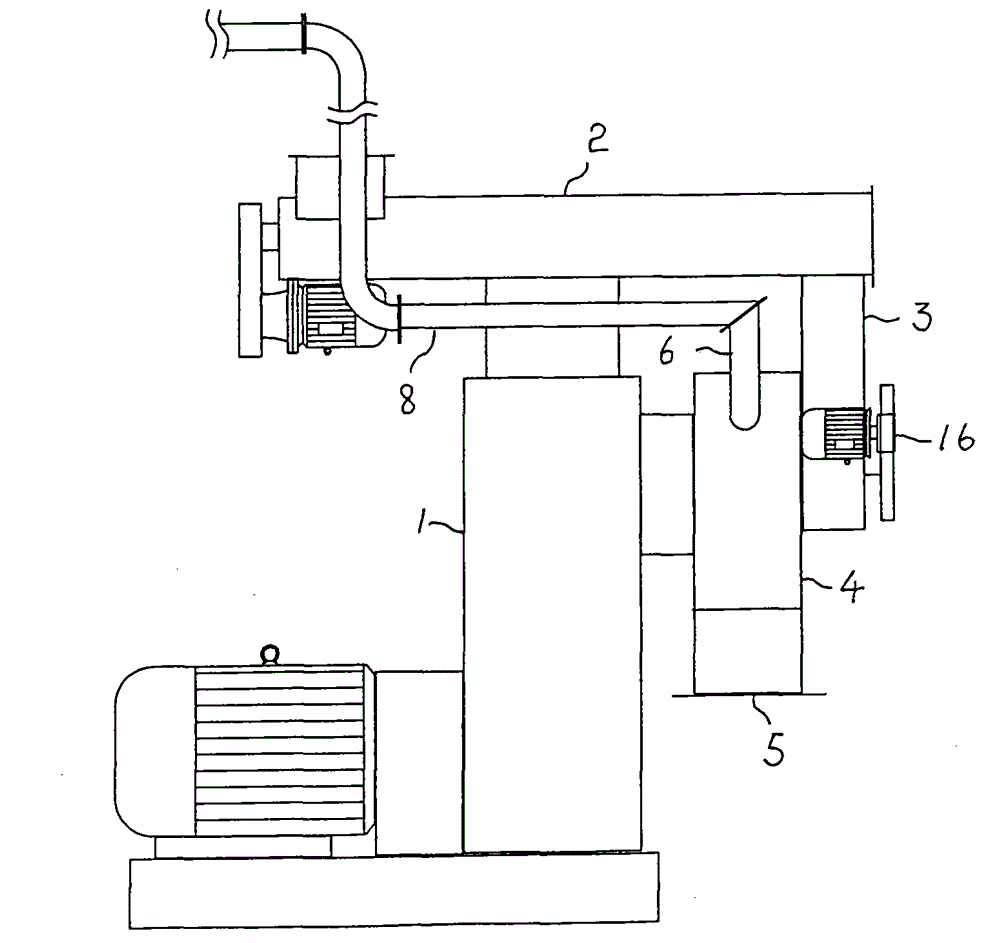

Integrated system and method for generating electricity employing drying and burning of sludge

InactiveCN103539332ASolve the emission problemImprove thermal efficiencyFluidized bed combustionSludge treatment by de-watering/drying/thickeningSludgeNitric oxide

The invention provides an integrated system and method for generating electricity employing drying and burning of sludge. A gas turbine is connected with a generator; a smoke outlet of the gas turbine is communicated with a sludge drying device; an outlet of the sludge drying device is connected with a gas-solid separating device; a dry sludge outlet of the gas-solid separating device is communicated with a hopper; the hopper is communicated with a feed pipe of a fluidized bed boiler; the smoke outlet of the fluidized bed boiler is communicated with a separator; a solid outlet of the separator is communicated with a feeding hole of the fluidized bed boiler through a return feeder; smoke afterheat of the gas turbine is utilized as a heat source for drying the sludge; gradient utilization of an energy source and high thermal efficiency are achieved; the problem of emission of sulfur dioxide, nitric oxide, dust and the like generated by burning fire coal to dry the sludge is avoided; the problem of polluting underground water and the environment caused by sludge landfill and soil utilization is effectively avoided; the moisture content of the dried sludge is greatly reduced; stable combustion can be achieved inside the fluidized bed boiler; auxiliary fuel does not need to be added; a highly toxic pollutant dioxin is avoided.

Owner:HANGZHOU LANZHENG ENVIRONMENTAL ENG

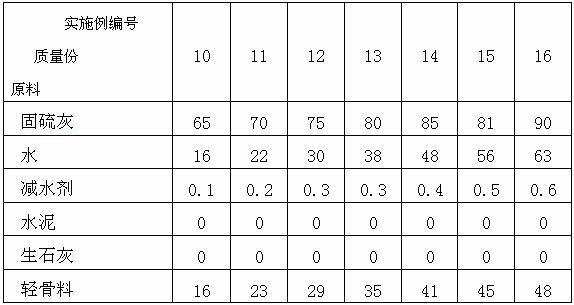

Method for preparing circulating fluidized bed fuel coal solid-state sulfur slag light concrete

InactiveCN102617074AMeet energy saving and emission reduction requirementsLow costSolid waste managementSlagThermal coefficient

The invention discloses a method for preparing circulating fluidized bed fuel coal solid-state sulfur slag light concrete. The method is characterized by comprising the following steps of: pre-treating raw materials, namely grinding solid-state sulfur slag and quick lime; mixing, namely taking 60 to 95 mass parts of solid-state sulfur slag, 0 to 15 mass parts of cement, 0 to 20 mass parts of quick lime, 15 to 65 mass parts of water, and 0.1 to 0.6 mass part of water reducer which are taken as raw materials; adding water into a stirrer, sequentially adding solid-state sulfur slag, cement, quick lime and water reducer, and stirring to obtain slurry; and adding light-weight aggregate and mixing, namely adding 15 to 50 mass parts of light-weight aggregate into the stirrer, and stirring and mixing for 1 to 5 minutes to obtain the circulating fluidized bed fuel coal solid-state sulfur slag light concrete. The concrete prepared by the method has the characteristics of light weight, high intensity, low thermal coefficient, high heat insulation performance and the like; and the recycling of resources is facilitated, the pollution of stacking of the solid-state sulfur slag to environment is reduced, and environment is protected.

Owner:SOUTHWEAT UNIV OF SCI & TECH

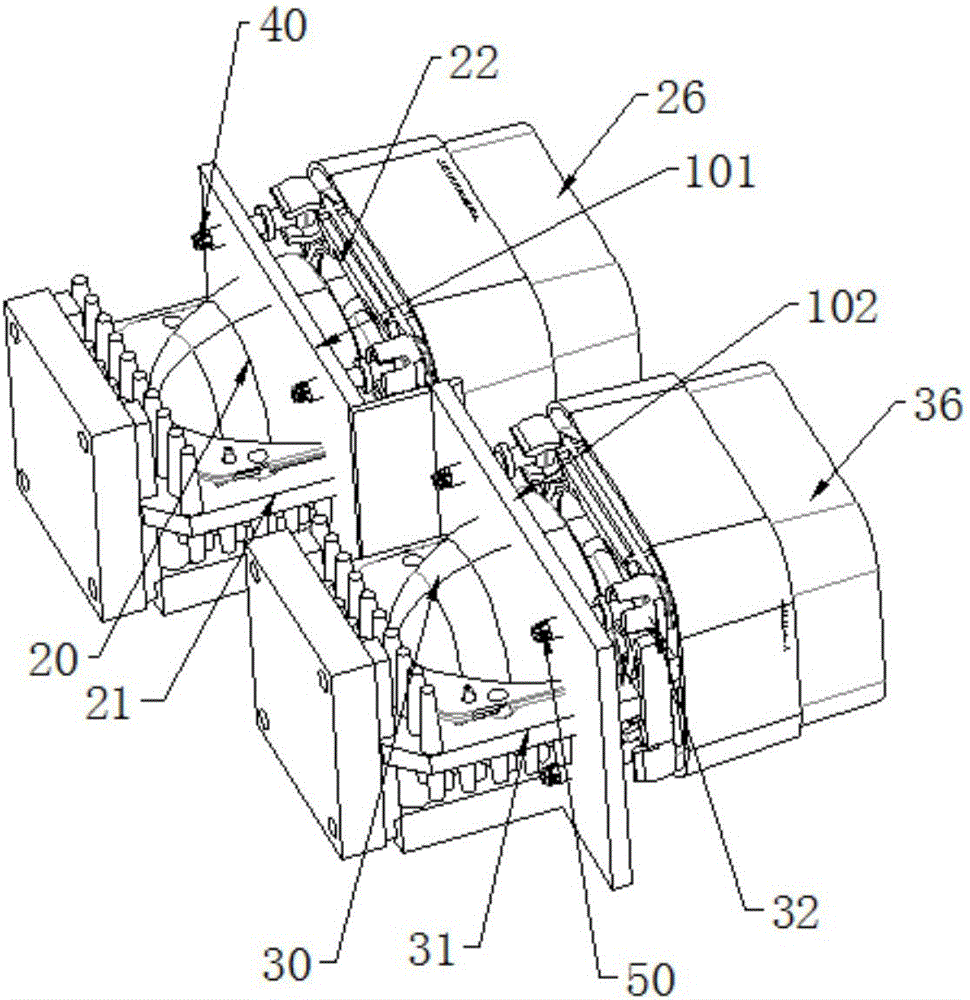

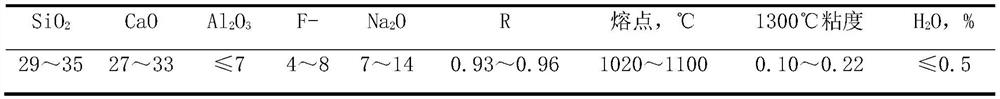

Low-cost production method for container steel casting blanks

InactiveCN103436654ASolve quality problemsHigh yieldManufacturing convertersProcess efficiency improvementAlkalinityPhosphorus utilization

The invention discloses a low-cost production method for container steel casting blanks. The method is characterized in that a 100 to 120-ton system comprises molten iron (106-110 tons) and waste steel (12 tons); a 150 to 180-ton system comprises the molten iron (132-140 tons) and the waste steel (20 tons); the converter terminal alkalinity is controlled to be 1.6-2.5; a slag reservation operation is adopted; in the secondary cooling process, the 120-ton system has the specific water flow of 0.7-1.0 L / kg and the 150-ton system has the specific water flow of 0.7-1.1 L / kg; the tundish temperature is controlled to be 1529-1543 DEG C; and the drawing speed is controlled to be 1.45-1.10 m / min according to different cross sections (1000-1800 mm) of a casting machine. The method has the advantages that the molten steel yield is increased, the iron loss is reduced, the molten iron phosphorus utilization rate is increased, the production cost is greatly reduced, the consumption of slag-making materials is lowered, the environmental pressure is reduced, and the national energy-saving and emission-reducing requirements are met.

Owner:LIUZHOU IRON & STEEL

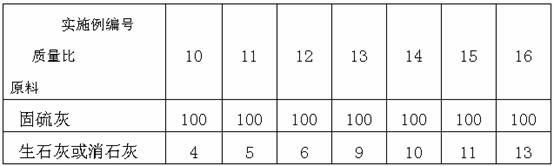

Method for preparing hydraulic cementing material by utilizing sulfur fixation ash

The invention discloses a method for preparing a hydraulic cementing material by utilizing sulfur fixation ash. The method is characterized by comprising the following steps of grinding raw materials, namely grinding the sulfur fixation ash serving as a raw material until the fineness (d50) of the sulfur fixation ash is less than or equal to 14 mu_m, and grinding calcined lime serving as another raw material until the fineness of the calcined lime is 80 mu_m and the screening residue of a standard screen is less than or equal to 10 percent; burdening, namely taking the raw materials according to a proportion that every 100 parts by weight of sulfur fixation ash is doped with 3 to 14 parts by weight of calcined lime or slaked lime or 1 to 3 parts by weight of CaSO4.2H2O; mixing the raw materials, namely uniformly mixing and stirring the raw materials, thus obtaining the hydraulic cementing material. According to the method, waste is turned into wealth, so that environment pollution is reduced; and the hydraulic cementing material prepared by the method can be used as a component of cement concrete, artificial aggregate, a steamed building block, a filling structure and a roadbed and has the advantage of high performance.

Owner:SOUTHWEAT UNIV OF SCI & TECH

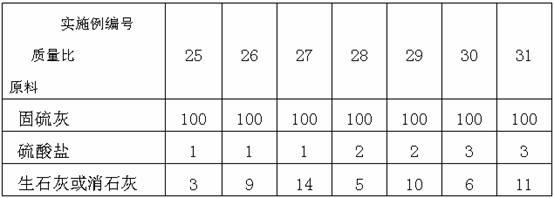

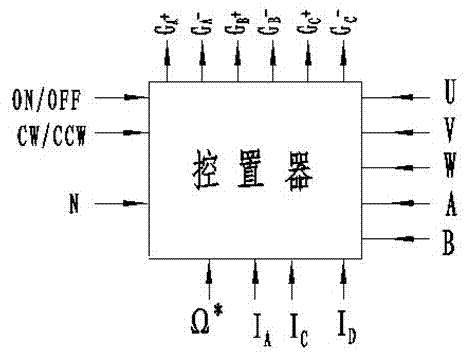

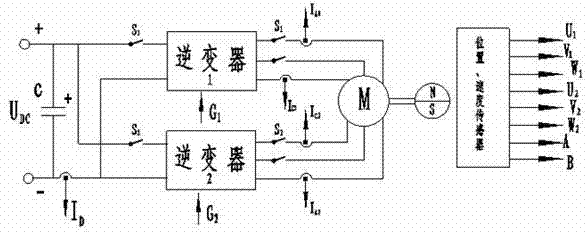

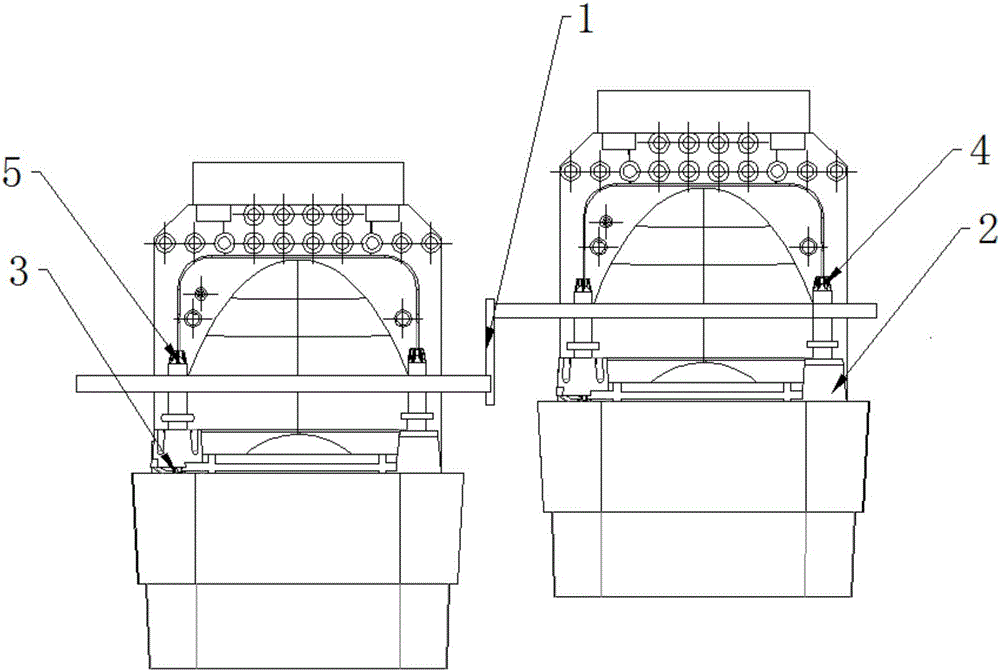

Multi-phase permanent magnet brushless direct current square wave motor capable of replacing Z4 series motors

InactiveCN102780432AReduce volumeReduce weightSingle motor speed/torque controlMultiple dc dynamo-electric motors controlElectronic switchControl theory

The invention discloses a multi-phase permanent magnet brushless direct current square wave motor capable of replacing Z4 series motors and relates to a direct current motor. The motor consists of four parts, namely a motor body, a position sensor, a speed sensor and an electronic switch control circuit; the multi-phase permanent magnet direct current motor is integrated by multiple three-phase permanent magnet brushless direct current motors in the same set of mechanical component, and comprises the motor body, a motor stator, a motor rotor, rotor magnetic steel, a combined sensor stator, a combined sensor rotor and a fan, wherein the stator winding is wound in a three-phase, or six-phase, nine-phase or multi-phase mode; and tile-shaped magnetic steel is attached to the outer side of the axial surface of the rotor, and the permanent magnetic steel is formed by pole pairs. An electric brush is canceled, the electronic commutation is performed, and the motor is integrally regulated by a controller, so that the average efficiency of the motor is over 94 percent, the load rate is within 25 to 125 percent, the multi-phase permanent magnet brushless direct current square wave motor is a motor driving system in a high-efficiency area, the Z4 series motors can be replaced, and the requirements of energy conservation and emission reduction are met.

Owner:沈阳永磁电机制造有限公司

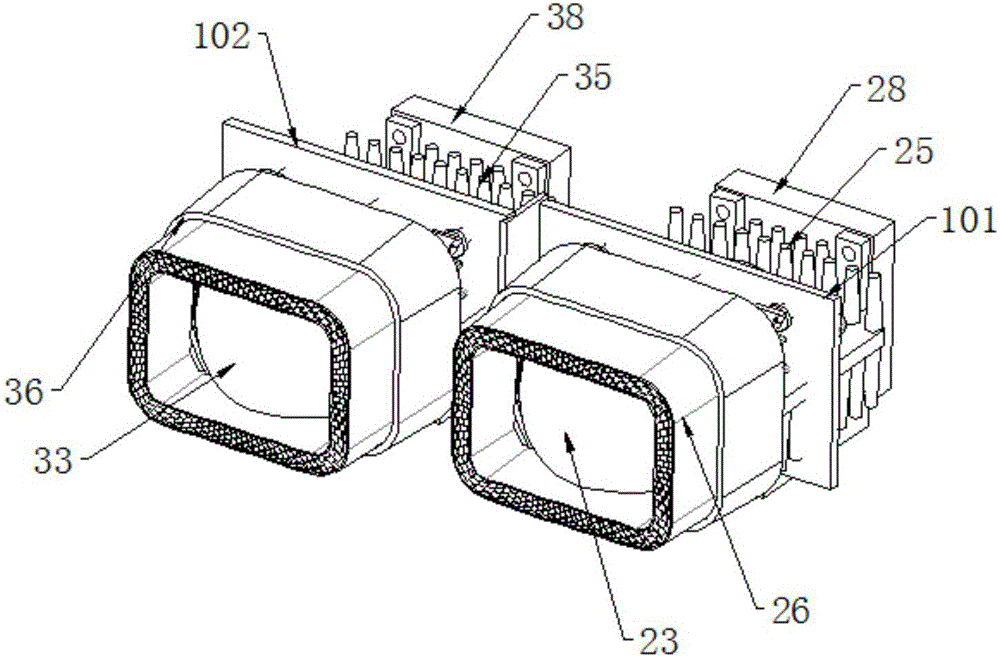

Car lamp module and car comprising same

PendingCN106678695AAchieve independent regulationEasy to adjustVehicle headlampsFixed installationEffect lightLight reflection

The invention relates to the technical field of car lighting, in particular to a car lamp module and a car comprising the same. The car lamp module comprises a module support, a near-light module and a far-light module, wherein the near-light module and the far-light module are installed on the module support; the near-light module comprises a near-light reflection lamp bowl, a near-light inner support and a near-light adjusting support, the near-light reflection lamp bowl is installed on the near-light inner support connected with the near-light adjusting support, and a near-light adjusting assembly is arranged between the near-light adjusting support and the module support; and the far-light module comprises a far-light reflection lamp bowl, a far-light inner support and a far-light adjusting support, the far-light reflection lamp bowl is installed on the far-light inner support connected with the far-light adjusting support, and a far-light adjusting assembly is arranged between the far-light adjusting support and the module support. According to the car lamp module, a near-light lamp and a far-light lamp are used for achieving modularization and are independently adjusted, installation and detaching are convenient, positioning is convenient and accurate, and light adjustment is simple.

Owner:鲸蓝激光科技(天津)有限公司

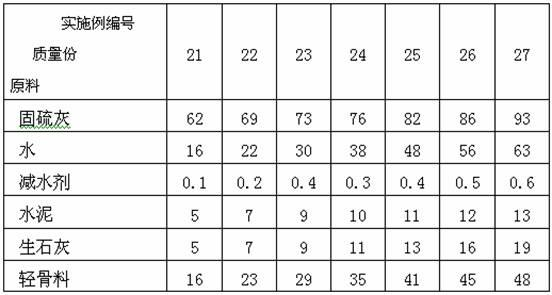

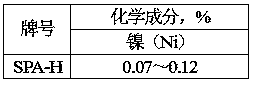

Production method of nickel-free copper-phosphorus weathering steel casting blank

ActiveCN112760550AReduce consumptionReduce iron lossProcess efficiency improvementSmelting processMaterial consumption

The invention provides a production method of a nickel-free copper-phosphorus weathering steel casting blank. The production method of the nickel-free copper-phosphorus weathering steel casting blank is characterized in that the nickel-free copper-phosphorus weathering steel casting blank comprises the following components of 0.05wt% to 0.10wt% of C, 0.30wt% to 0.50wt% of Si, 0.40wt% to 0.55wt% of Mn, 0.07wt% to 0.15wt% of P, less than or equal to 0.005wt% of S, 0.3wt% to 0.5wt% of Cr, 0.2wt% to 0.5wt% of Cu, 0.020wt% to 0.050wt% of Alt; less than or equal to 0.035wt% of Ti; no Ni alloy, and the balance Fe and inevitable trace elements, and the production method of the nickel-free copper-phosphorus weathering steel casting blank sequentially comprises the following process routes of molten iron desulfurization pretreatment, converter molten steel smelting, LF furnace molten steel refining and straight arc type slab casting machine continuous casting. According to the method, slag making material consumption and iron loss in the smelting process are reduced, a molten iron phosphorus utilization rate is increased, and the problems of unsmooth pouring of nickel-free copper-phosphorus weathering steel and poor casting blank surface quality are solved.

Owner:广西柳钢华创科技研发有限公司 +1

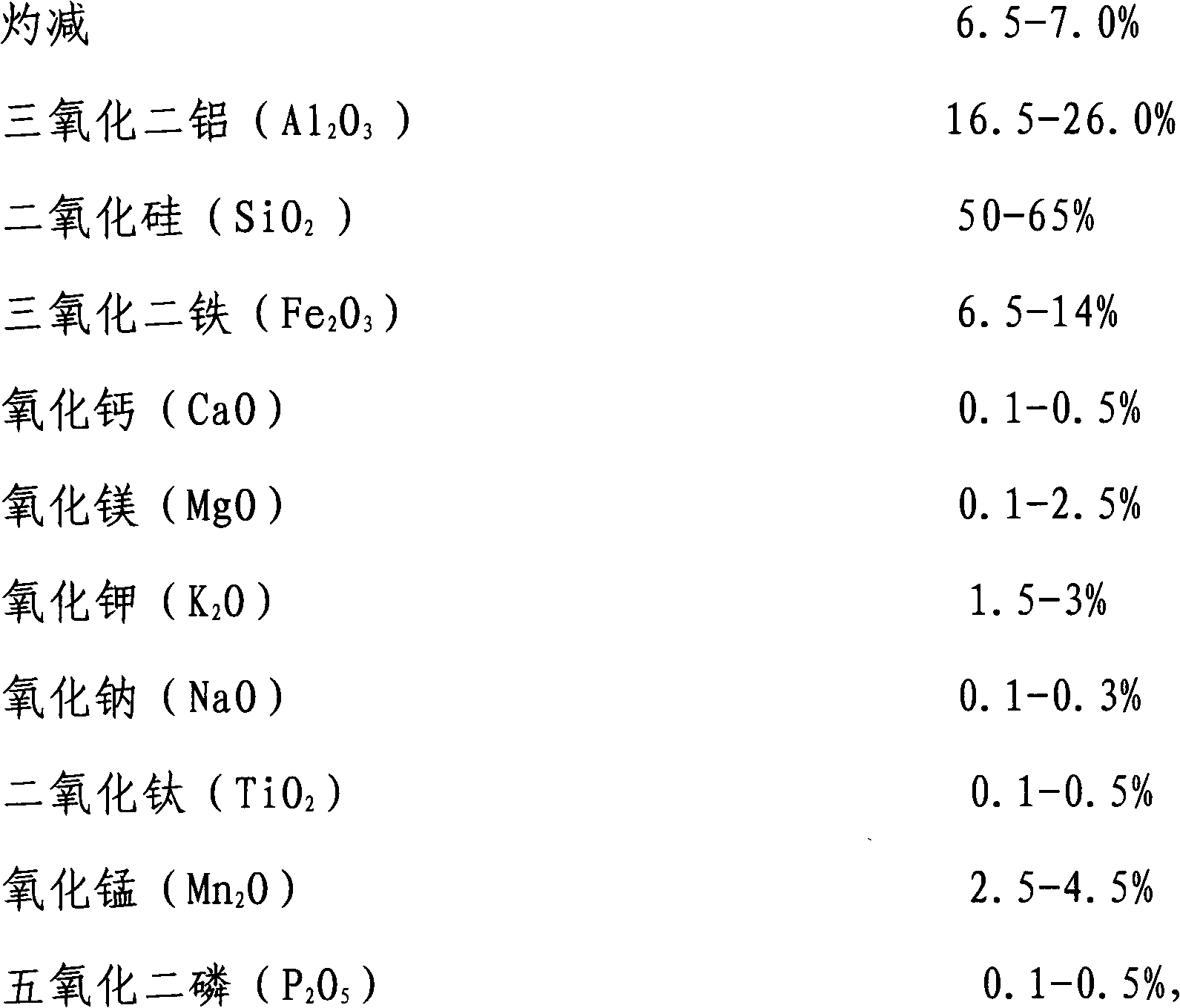

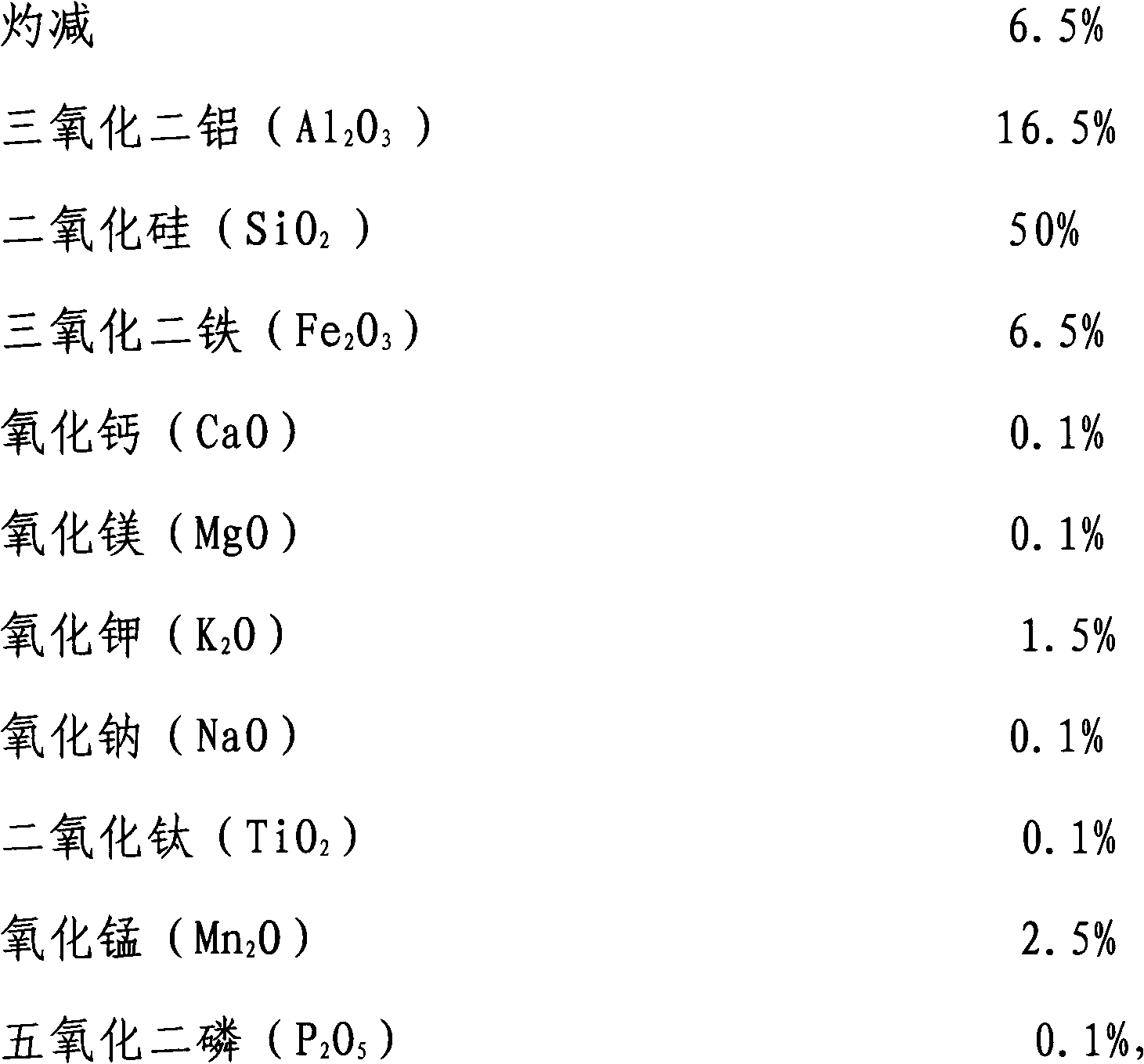

Method for preparing conductive admixture from pyrite smelting slag

ActiveCN101935176AMeet energy saving and emission reduction requirementsLow costSolid waste managementMass ratioSlag

The invention relates to a method for preparing a conductive admixture from pyrite smelting slag. The method is characterized by comprising the following steps: grinding a raw material ( the pyrite smelting slag) and a reducing agent (pulverized coal) into powder with the grain diameter less than or equal to 0.1mm; weighing and mixing the pyrite smelting slag and the pulverized coal according to the mass ratio of 50:10-25; placing the mixture into a high temperature furnace under the reducing atmosphere, roasting, heating to 600-800 DEG C at the heating rate of 6-8 DEG C / min, and roasting for 60-120min at a constant temperature; cooling the roasted material to room temperature under the reducing atmosphere, taking out and levigating to prepare the conductive admixture finished product; or molding the mixture into pieces or blocks, and then roasting. By adopting the method of the invention, the wastes can be turned into things of value; the cost is low; and the prepared conductive admixture has lower resistivity, can be used for preparing conductive concrete or conductive mortar and also can be used in other building materials.

Owner:SOUTHWEAT UNIV OF SCI & TECH

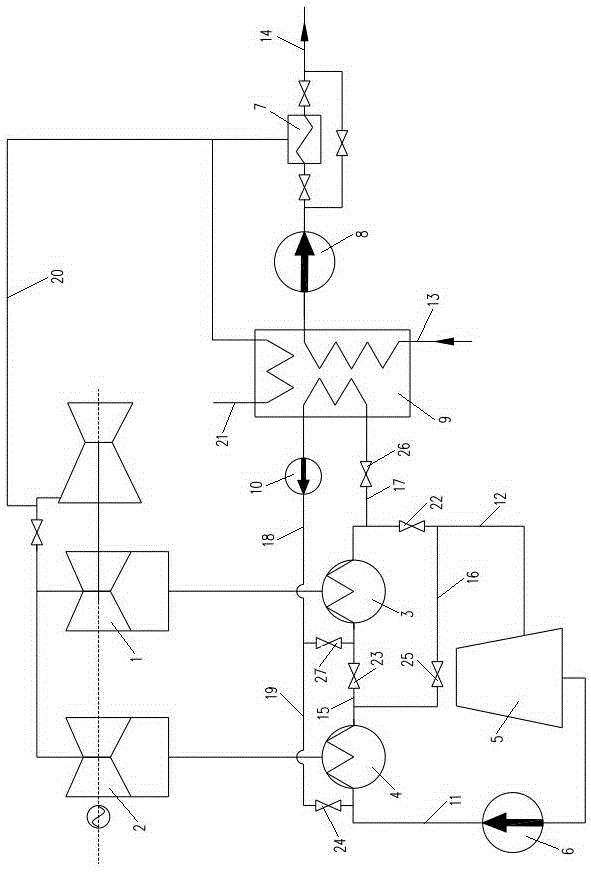

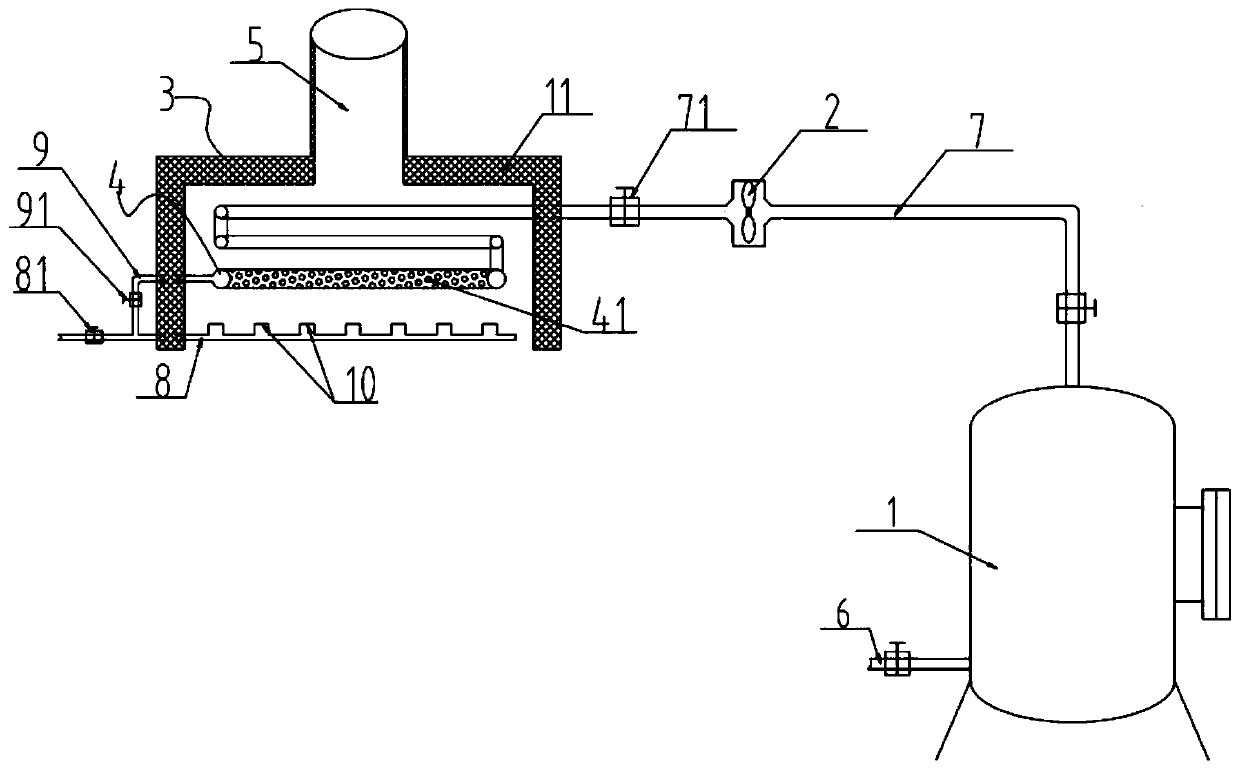

Low-temperature afterheat using system and afterheat using method

ActiveCN104807245AReasonable structural designUnique ideaHeating fuelClimate change adaptationCooling towerWater flow

The invention relates to a low-temperature afterheat using system and an afterheat using method. At present, the afterheat using system and the afterheat using method capable meeting requirements of energy-saving and emission reduction, and slightly influencing on the power generation are not existed. The low-temperature afterheat using system is characterized by comprising a 1# low-pressure cylinder, a 2# low-pressure cylinder, a 1# condenser, a 2# condenser, a circular water outlet mother pipe and a hot pump water inlet branch pipe; the 1# low-pressure cylinder is connected with the 1# condenser, and the 2# low-pressure cylinder is connected with the 2# condenser; one end of the hot pump water inlet branch pipe is connected to the circular water outlet mother pipe. The afterheat using method is characterized in that when the outside hot load demand at the beginning and last periods of heat supply is low; according to temperature of circular water entering an absorbing type hot pump, the circular water flow of an upper cooling tower is adjusted through controlling the opening degree of an isolating valve of the circular water outlet mother pipe. The low-temperature afterheat using system can be flexibly arranged and switched at any time, so that the requirements of saving energy and reducing emission are satisfied, and the influence on the power generation amount is small.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

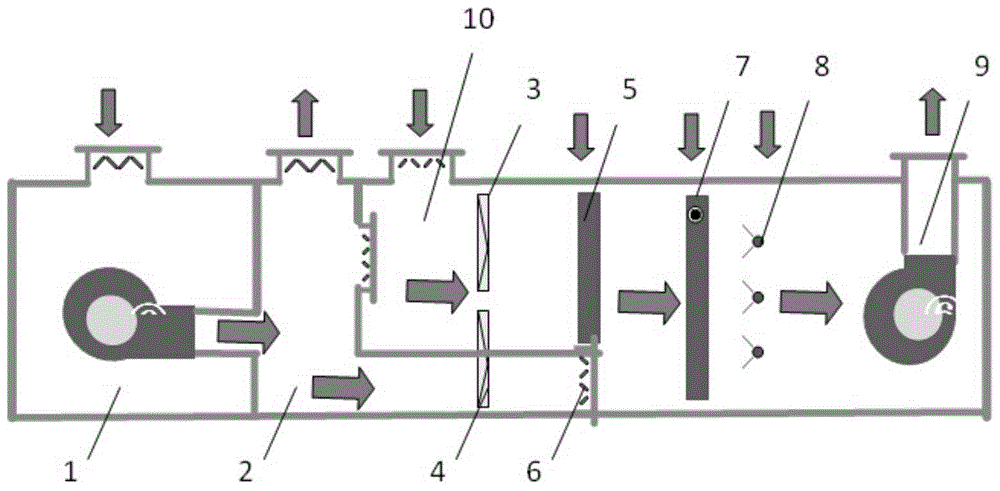

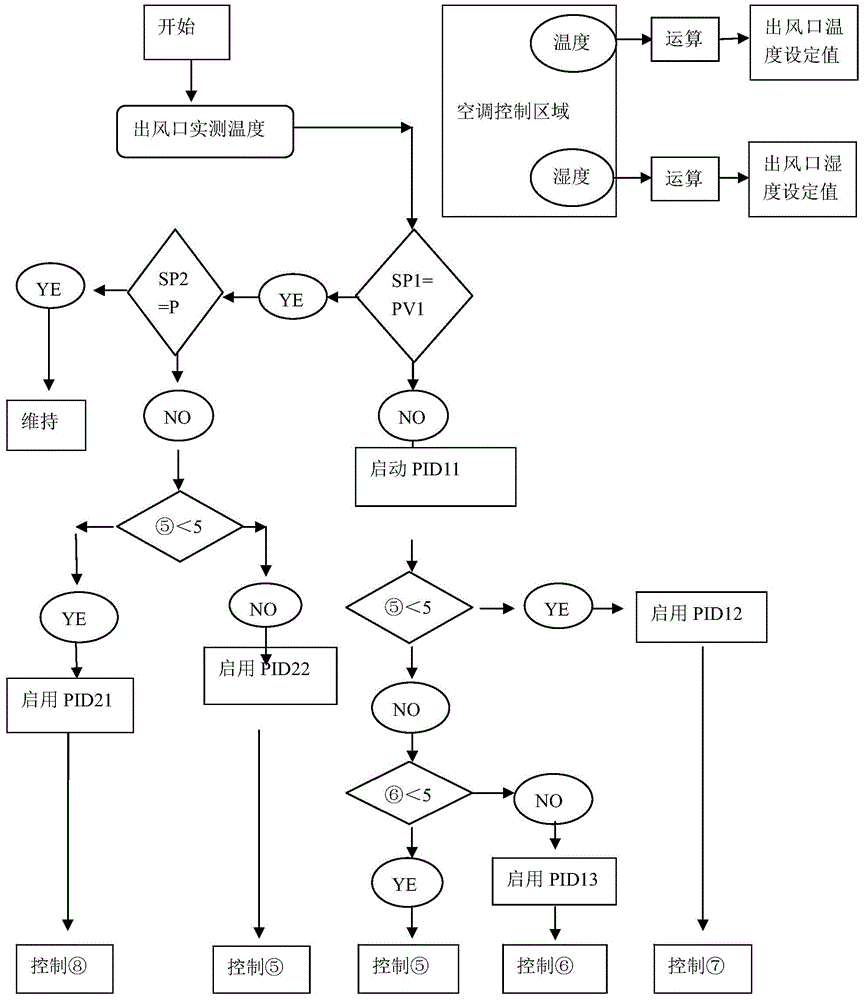

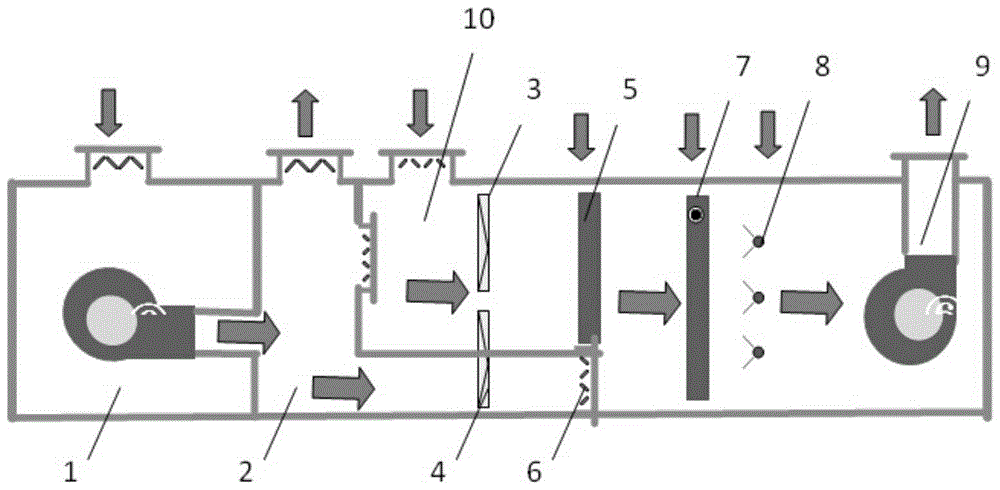

Two-channel return air air-conditioning case and temperature control method thereof

ActiveCN104456726AIncrease energy saving potentialReach air temperatureMechanical apparatusSpace heating and ventilation safety systemsSurface coolingTemperature control

The invention relates to a two-channel return air air-conditioning case. The two-channel return air air-conditioning case comprises a return fan section, an air exhaust section, a fresh return air mixing section, a filter section A, a surface cooling section, a heating section, a humidifying section, a forced draft fan section, a filter section B and a control air valve. A return air port is formed above the return fan section, the return fan section is connected with the air exhaust section, an air exhaust port is formed above the air exhaust section, the upper section the air exhaust section is connected with the fresh return air mixing section, a fresh air port is formed above the fresh return air mixing section, the fresh return air mixing section is connected with the filter section A, the filter section A is connected with the surface cooling section, a chilled water connector is arranged above the surface cooling section,, and the surface cooling section is connected with the heating section. The lower section of the air exhaust section is connected with the filter section B through a partition pipe, the filter section B is connected with the control air valve, and the control air valve is connected with the heating section. The heating section is connected with the humidifying section, and the humidifying section is connected with the forced draft fan section. The two-channel return air air-conditioning case improves the energy-saving potential of an air-conditioning system and meets the energy-saving and emission-reducing requirements.

Owner:CHINA TOBACCO ZHEJIANG IND

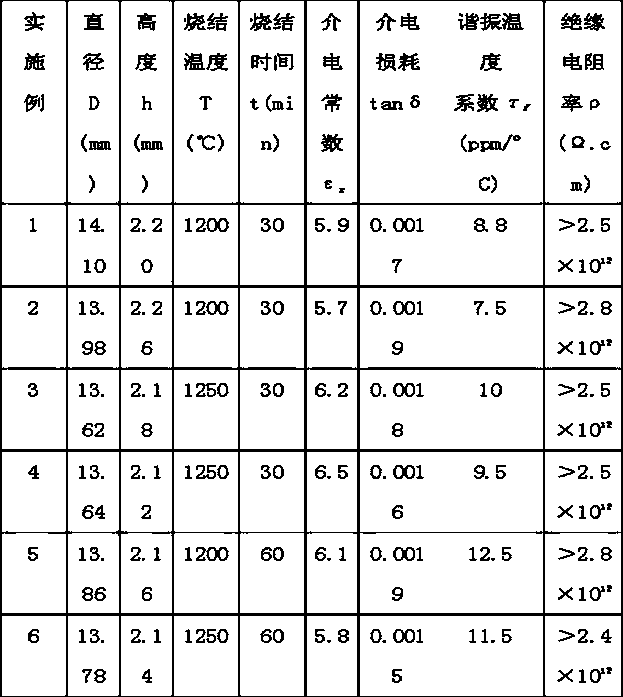

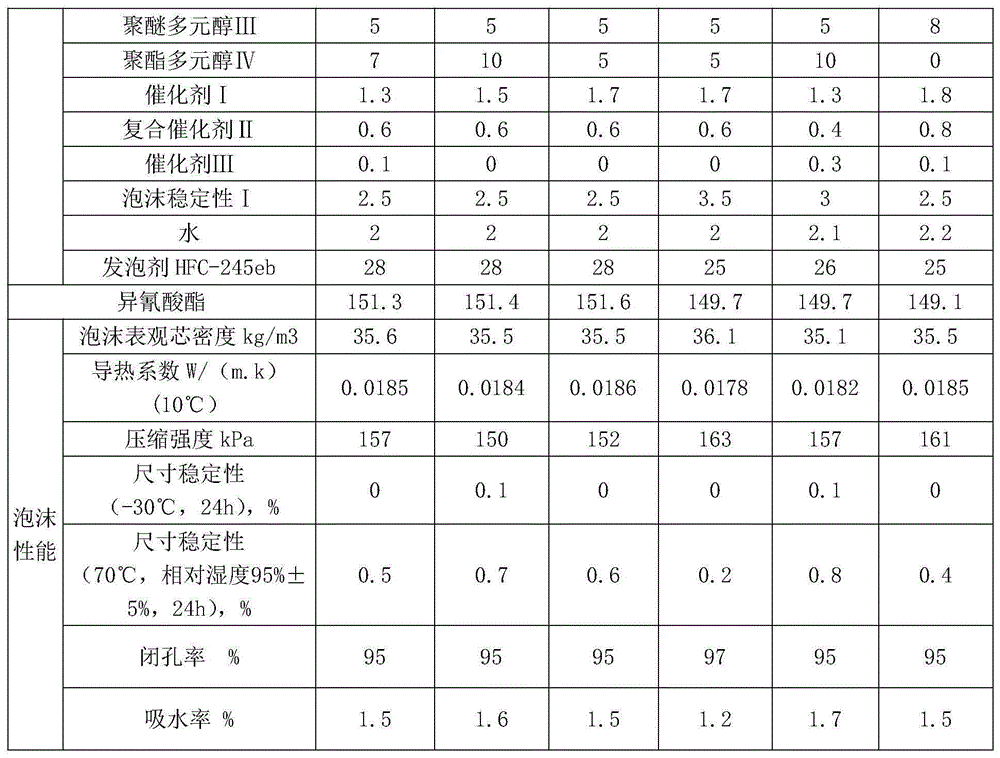

Method for preparing intermediate-temperature microwave dielectric ceramic material

The invention discloses a method for preparing an intermediate-temperature microwave dielectric ceramic material. The method comprises the steps: step S1, washing kaolin by water, removing impurities, and drying to obtain kaolin powder; step S2, based on percentage by weight, adding 87-93.5 percent of the kaolin powder, 3-5 percent of MgO, 1-3 percent of CaO, 0.5-1 percent of ZnO, 2-3.5 percent of B2O3 and 0-0.5 percent of SnO2 into a ball-milling tank, and carrying out ball milling for 12-16 hours by using a planetary ball mill to uniformly mix and finely mill the materials, wherein the MgO, the CaO, the ZnO, the B2O3 and the SnO2 form a modifying agent. Due to adoption of conventional equipment, the intermediate-temperature microwave dielectric ceramic material is formed by once firing without roasting and melting, and by introduction of the modifying agent, the temperature is reduced from the primary 1400-1450 degrees centigrade to 1200-1250 degrees centigrade, thus the production cost is lowered, and the requirements on energy conservation and emission reduction are satisfied. The intermediate-temperature microwave dielectric ceramic material disclosed by the invention has a dielectric constant within 5.7-6.5@1MHz-3GHz, and simultaneously has low microwave dielectric loss and a small temperature coefficient of resonance frequency.

Owner:YUNNAN INFINE NEO MATERIAL

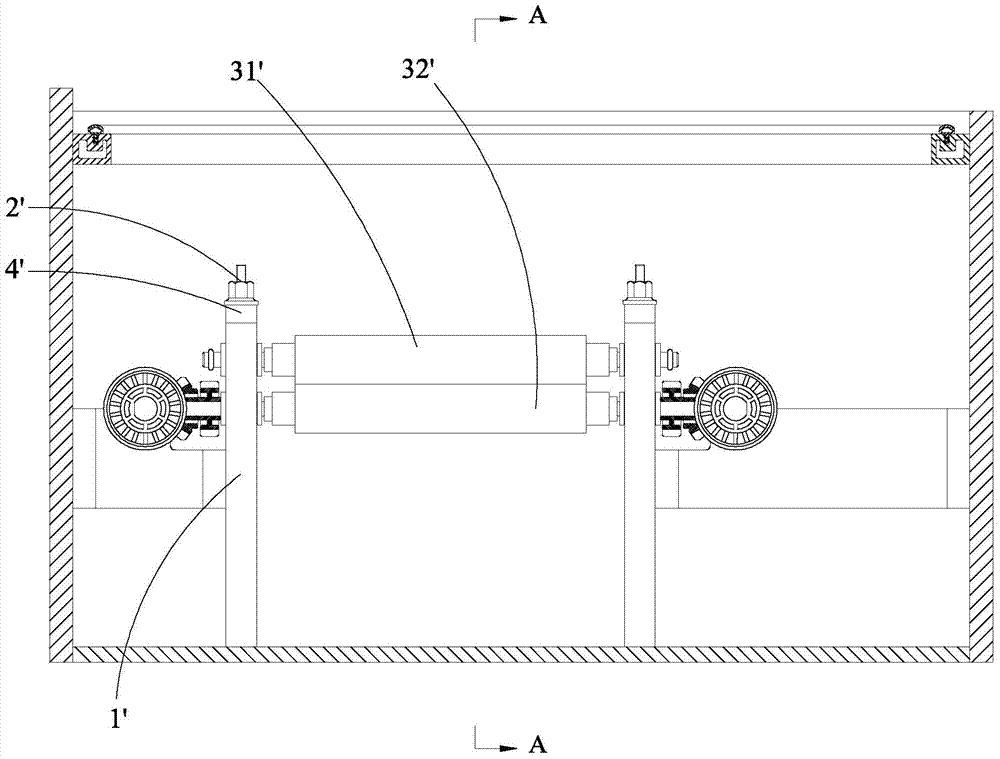

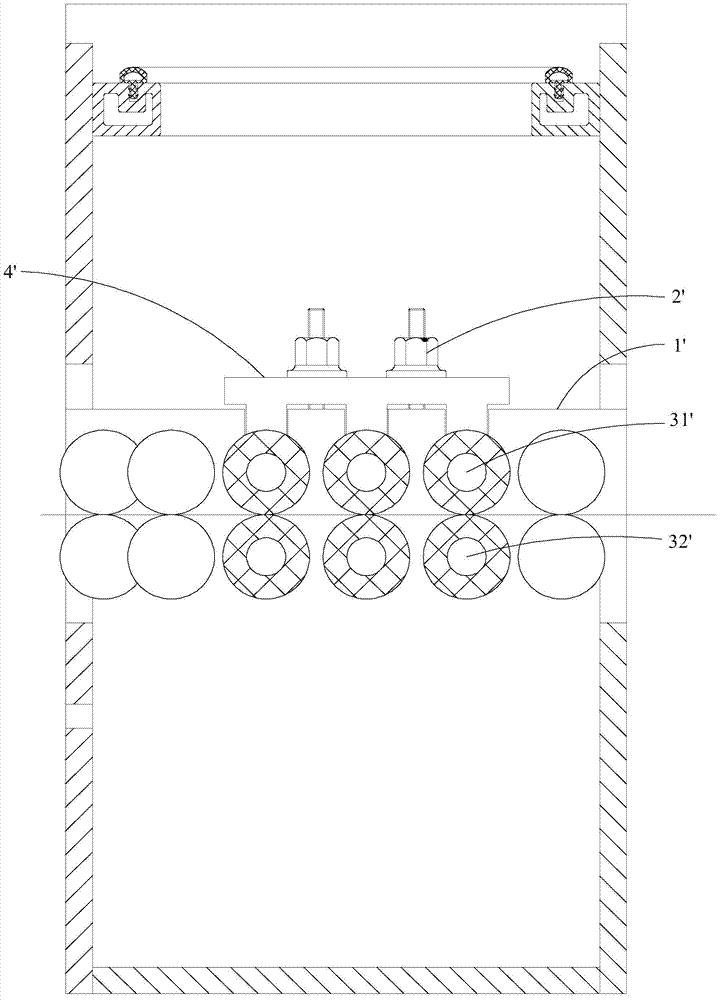

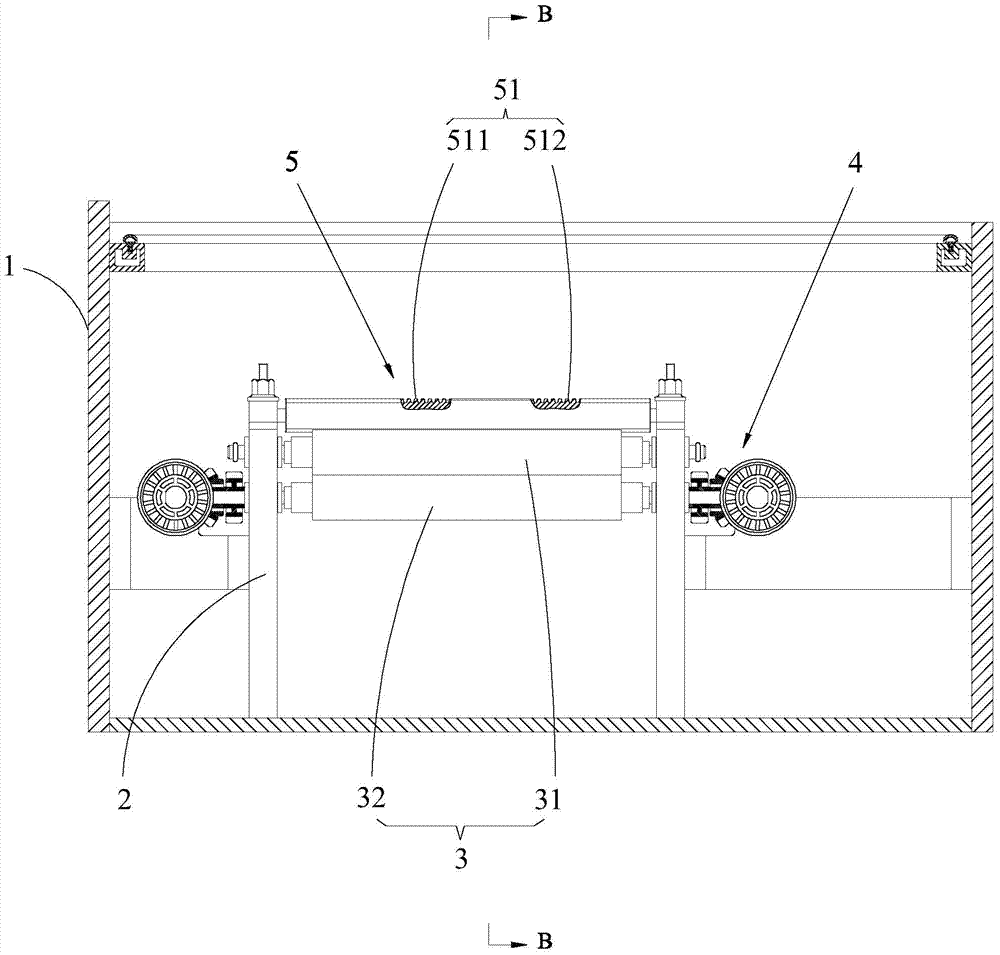

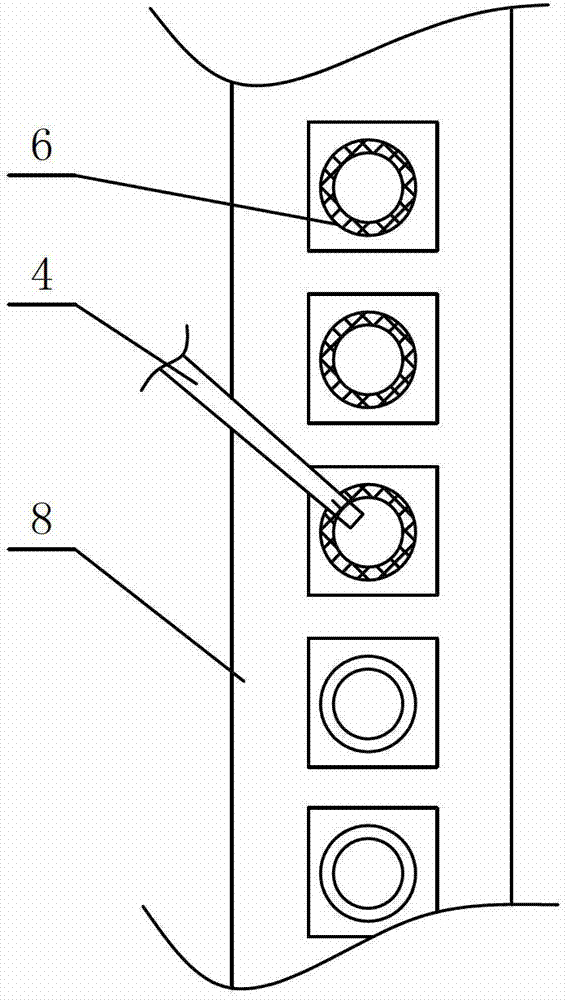

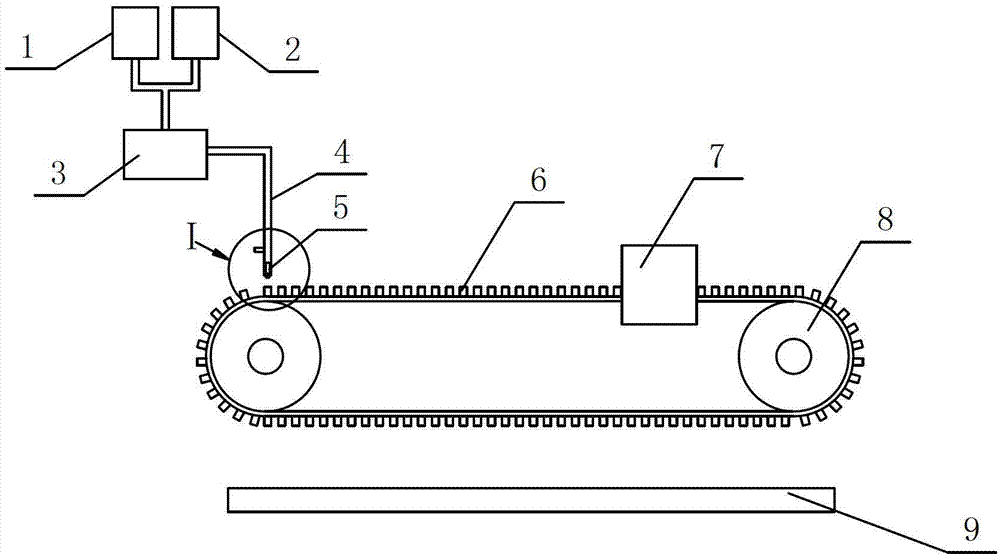

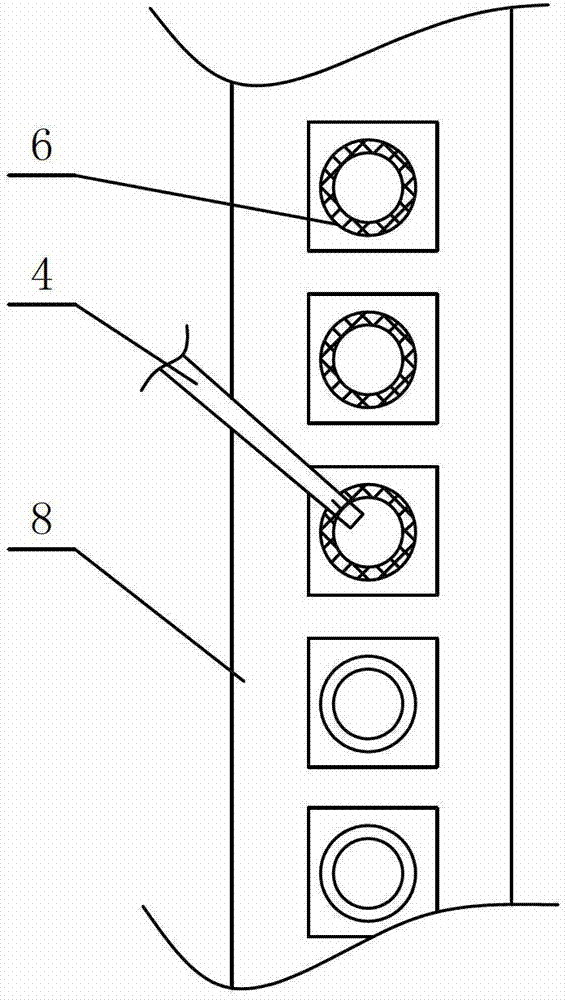

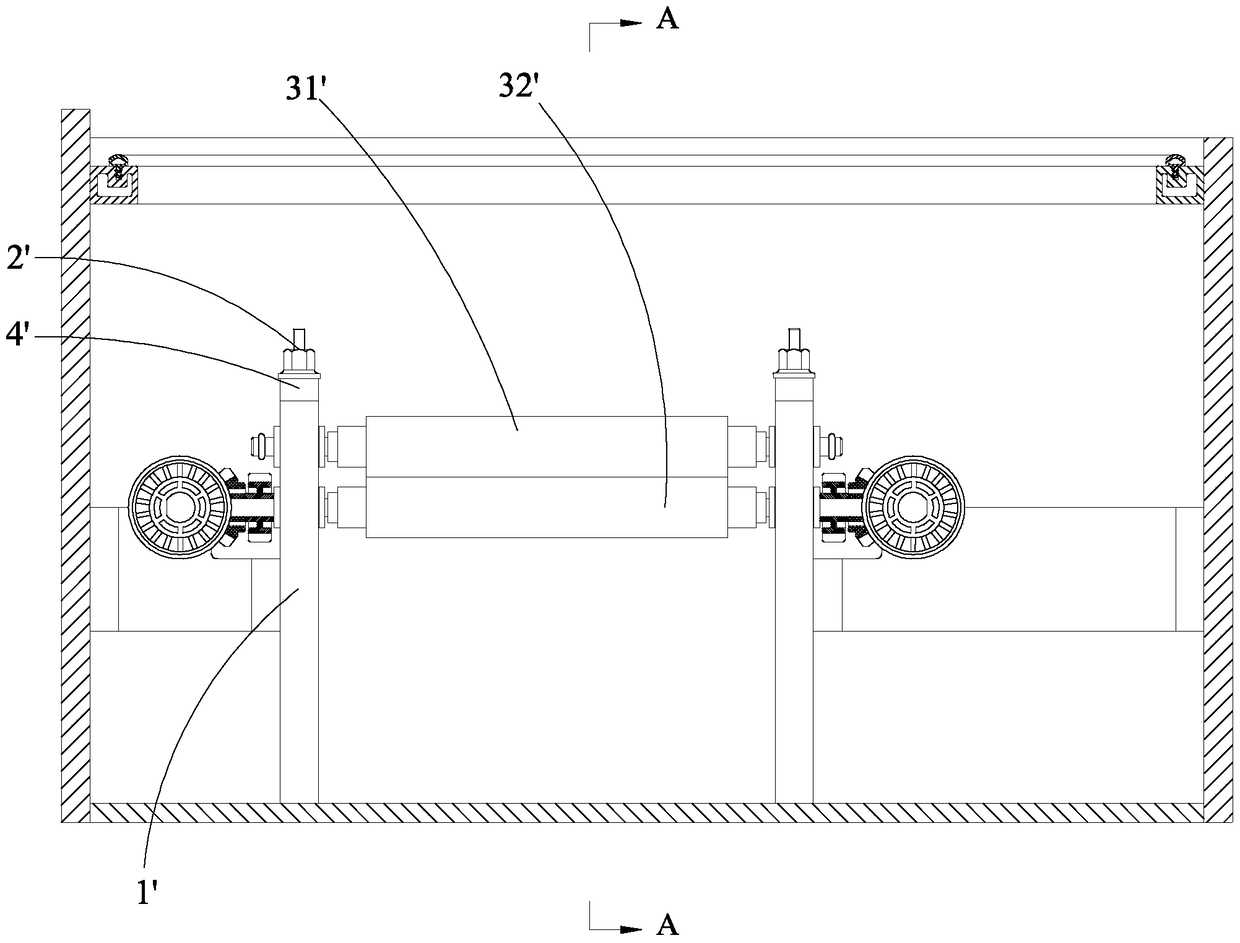

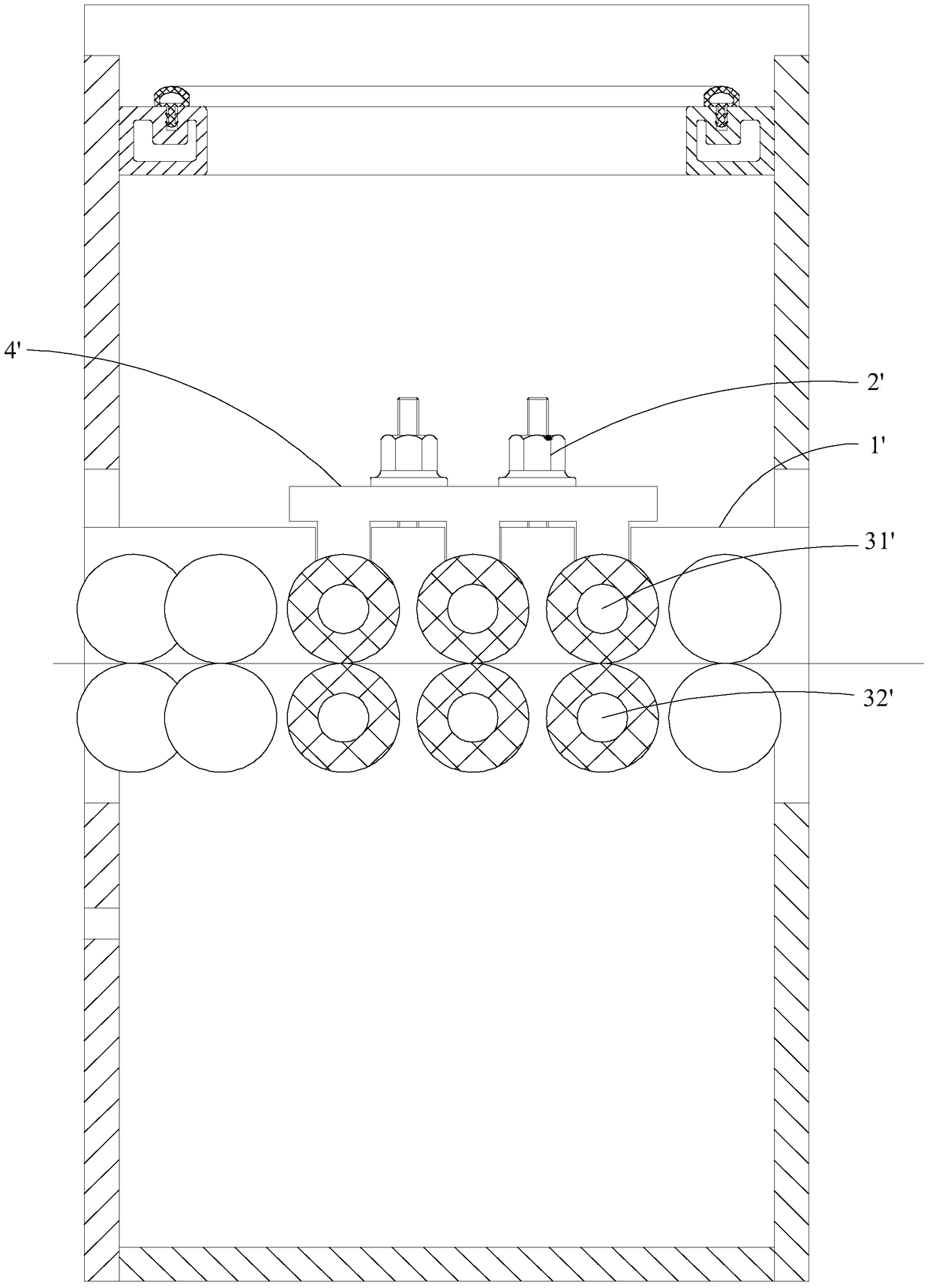

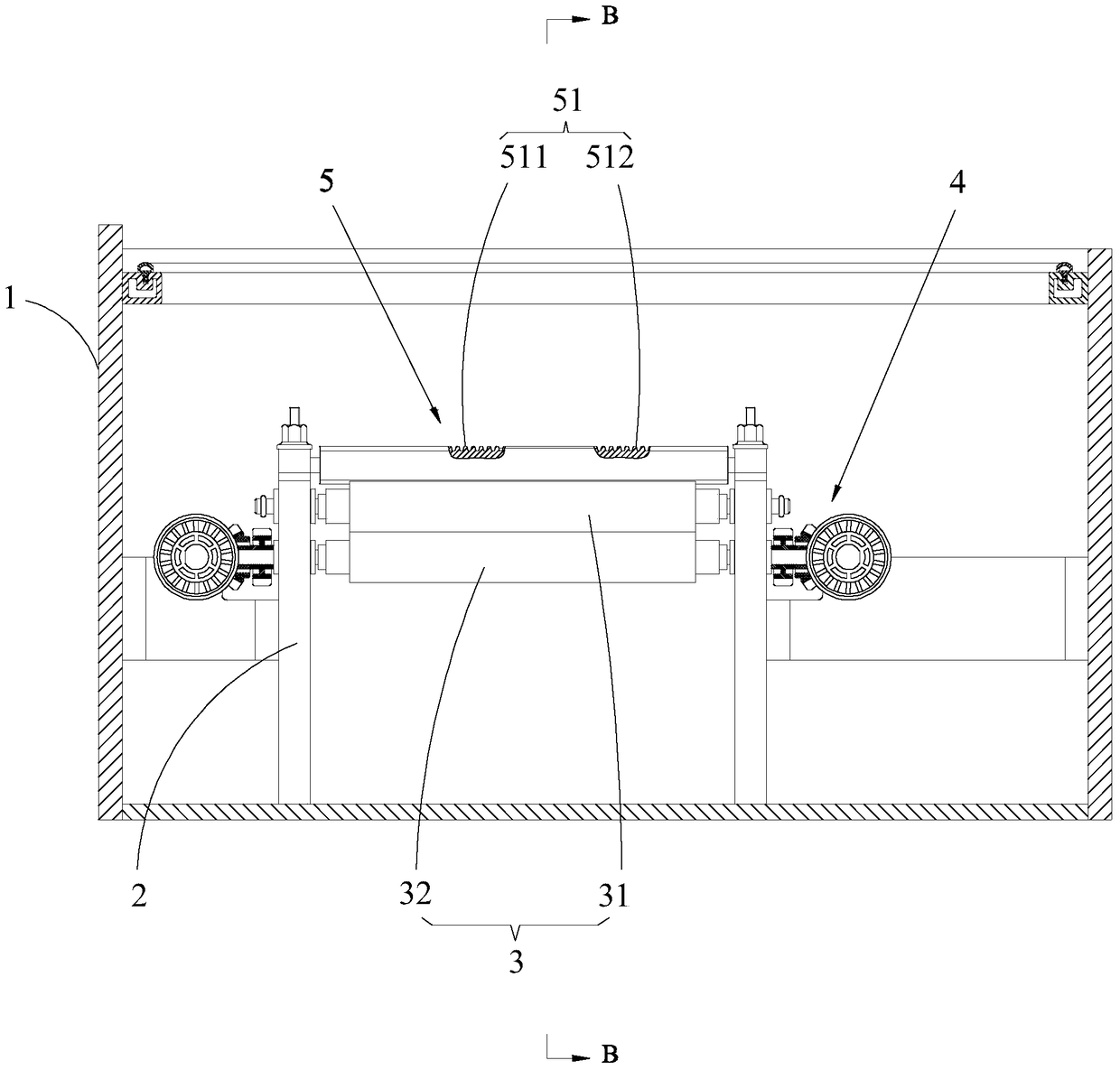

Water suction windlass device

ActiveCN104754872AImprove the phenomenon of the posterior bandImprove the phenomenonConductive pattern polishing/cleaningEngineeringExtrusion

The invention relates to the technical field of water washing equipment for circuit boards and discloses a water suction windlass device used for extruding, sucking and etching liquid on the circuit board. The water suction windlass device comprises an isolation groove, a stand firmly arranged in the isolation groove, a water suction windlass group arranged on the stand and used for extruding and sucking the liquid on the circuit board, and a transmission device arranged on the stand and used for driving the water suction windlass group to rotate axially, and moreover, the stand is provided with a water press windlass for extruding the water suction windlass group, an angle is formed between the water press windlass and the water suction windlass group, and spiral water extrusion threads are formed in the outer wall of the water press windlass. According to the water suction windlass device, the water press windlass with water extrusion threads is arranged at the oblique upper side of the water suction windlass group, the water suction windlass group is extruded through the water press windlass, the liquid sucked by the water suction windlass group is extruded towards the two ends through the water extrusion threads, the post-liquid taking phenomenon is reduced, the energy saving and emission reduction demands are satisfied, the circuit board surface oxidization chance is reduced, and the circuit board quality is improved.

Owner:UNIVERSAL P C B EQUIP SHENZHEN

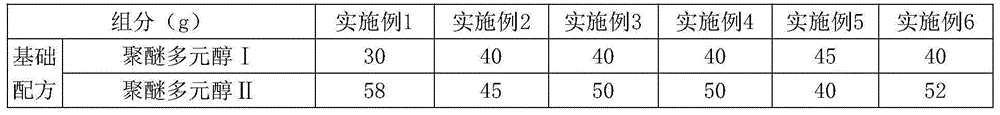

HFC-245eb type composite polyether for refrigerator polyurethane plastic and preparing method of HFC-245eb type composite polyether

InactiveCN105085970AGood insulation performanceLow costChemical industryChemistryRefrigerated temperature

The invention discloses HFC-245eb type composite polyether for refrigerator polyurethane plastic and a preparing method of the HFC-245eb type composite polyether. The HFC-245eb type composite polyether for the refrigerator polyurethane plastic comprises, by mass, 30-140 parts of polyether polyol, 0.7-6 parts of catalyst, 0-5 parts of foam stabilizer, 1-3 parts of water and 10-60 parts of foaming agent HFC-245eb. According to the HFC-245eb type composite polyether for the refrigerator polyurethane plastic, the hard refrigerator polyurethane foam plastic prepared through the foaming agent HFC-245eb has the good heat preservation performance, mechanical strength and dimension stability, is an ideal heat preservation material in the field of heat preservation of household electric appliances of refrigerators, is safe and environmentally friendly, and meets the national energy-conservation and emission-reduction requirements in the household electric appliance field of refrigerators.

Owner:JIANGSU LIHONG TECH DEV CO LTD

Iron-manganese heat resistant cooker and production technology thereof

The invention belongs to the technical field of ceramic materials, and provides a novel iron-manganese heat resistant cooker and a production technology thereof. A low expansion coefficient raw material such as spodumene is not required in the formula of the product; the heat conductivity coefficient of the ceramic ware is greatly improved by improving the heat conductivity coefficient and the thermal shock resistance of ceramic; the sintering temperature is low, and the maturing temperature is wide in range and is 1,160 to 1,230 DEG C; the product is high in superior quality, can be quickly sintered, can tolerate the heat exchange of 500 to 20 DEG C without cracking, has the advantages of low energy consumption, high heat conductivity, high impact strength, thermal shock resistance and the like, and can be used for directly steaming, boiling, stewing and stir-frying food over a heat source; and the cooker keeps the cooking flavor of the conventional ceramic ware, does not decompose nutritional components in the food, and is an ideal multifunctional cooking ware for modern families, hotels and restaurants.

Owner:邱东烽

Nitride ceramic ammonia gas tail gas treatment system and treatment method thereof

InactiveCN110986063AMeet energy saving and emission reduction requirementsMeet environmental protection requirementsIncreasing energy efficiencyIncinerator apparatusPtru catalystCombustion

The invention discloses a nitride ceramic ammonia gas tail gas treatment system and a treatment method thereof. The structure comprises a nitriding furnace, a pipeline fan, a hearth and an ammonia gaspreheating pipeline. A gas inlet of the nitriding furnace is connected with an ammonia gas pipeline. A gas outlet of the nitriding furnace is connected with a connecting pipeline. The pipeline fan isarranged on the connecting pipeline, the other end of the connecting pipeline is connected with the ammonia gas preheating pipeline. A catalyst is arranged in the ammonia gas preheating pipeline, theother end of the ammonia gas preheating pipeline is connected with a nitrogen-hydrogen mixed gas pipeline, the hearth is provided with a combustion pipeline, the nitrogen-hydrogen mixed gas pipelineis connected with the combustion pipeline, the combustion pipeline is connected with a natural gas source, the combustion pipeline is provided with a plurality of combustion openings, and an exhaust pipeline is arranged in the middle of a top end of the hearth. By adopting the structure, an ammonia gas tail gas is treated by a catalytic cracking method to obtain a combustible nitrogen-hydrogen mixed gas, and heat generated after ignition can maintain energy required by ammonia gas cracking and water and carbon dioxide are generated through combustion so that requirements of energy conservation, emission reduction and environmental protection are met.

Owner:福建立亚新材有限公司

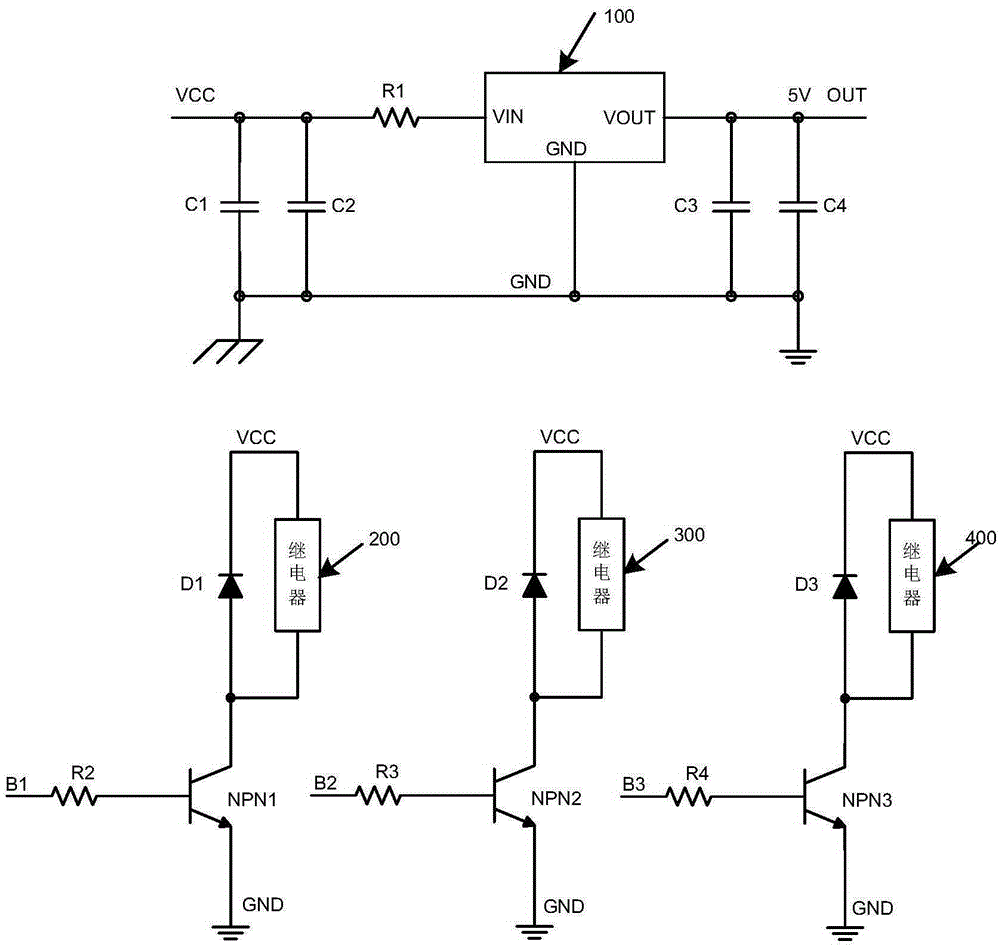

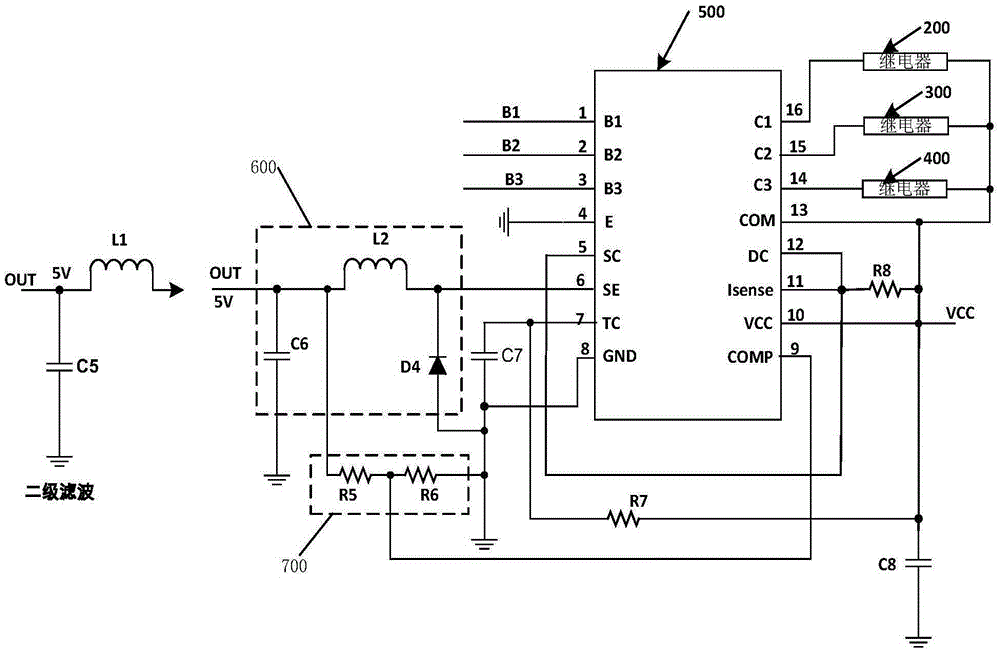

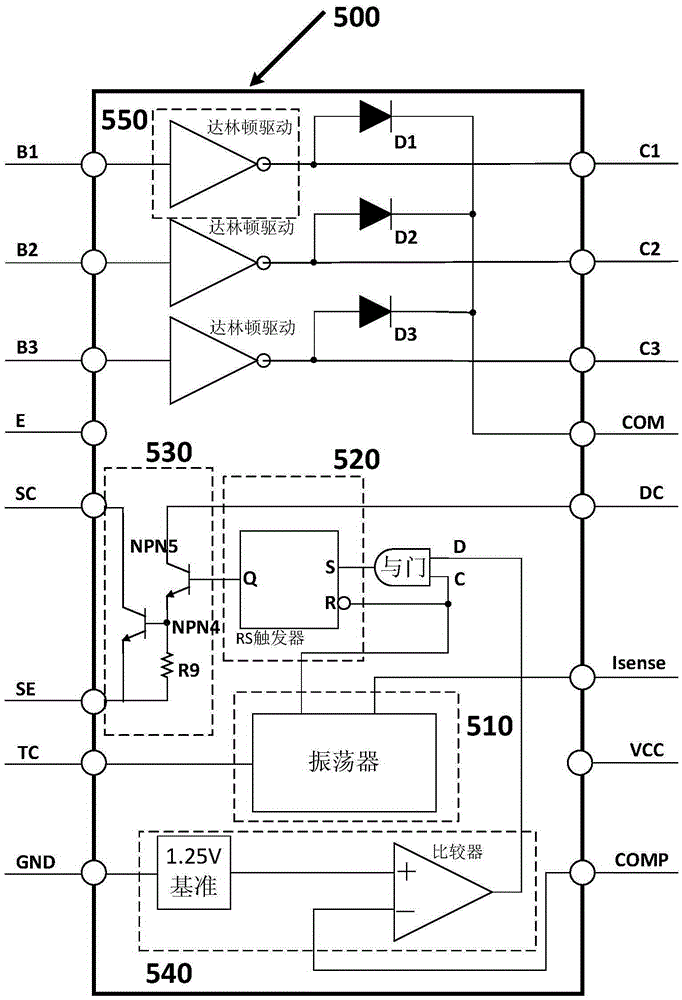

DC-DC converter integrated circuit and application circuit thereof

ActiveCN105406714AReduce standby power consumptionImprove power conversion efficiencyEfficient power electronics conversionDc-dc conversionIntegrated circuitStandby power

The invention discloses a DC-DC converter integrated circuit. The DC-DC converter integrated circuit comprises an oscillation unit which generates an oscillating pulse signal; a triggering unit which is connected with the oscillation unit and regards the received oscillating pulse signal as one triggering signal; a switch driving unit which is connected with the triggering unit; a comparing unit; and at least a Darlington driving unit. The signal output end of the switch driving unit is led outwards to connect with a voltage output unit; the voltage output unit outputs a driving voltage used for driving a load; a reference voltage signal is arranged in a path of signal input; and the other path of signal input is voltage signals which are sampled from the voltage output unit through a sampling unit; the comparing unit outputs a first electric level signal which serves as another triggering signal of the triggering unit based on the sizes of the two paths of the voltage signals; and the comparing unit is connected with the triggering unit. As a DC-DC converter and a Darlington driver are arranged in the integrated circuit, units of a relay waiting for driving can be directly driven while standby power consumption is reduced, and the DC-DC converter integrated circuit is convenient to use.

Owner:SINOTECH MIXIC ELECTRONICS

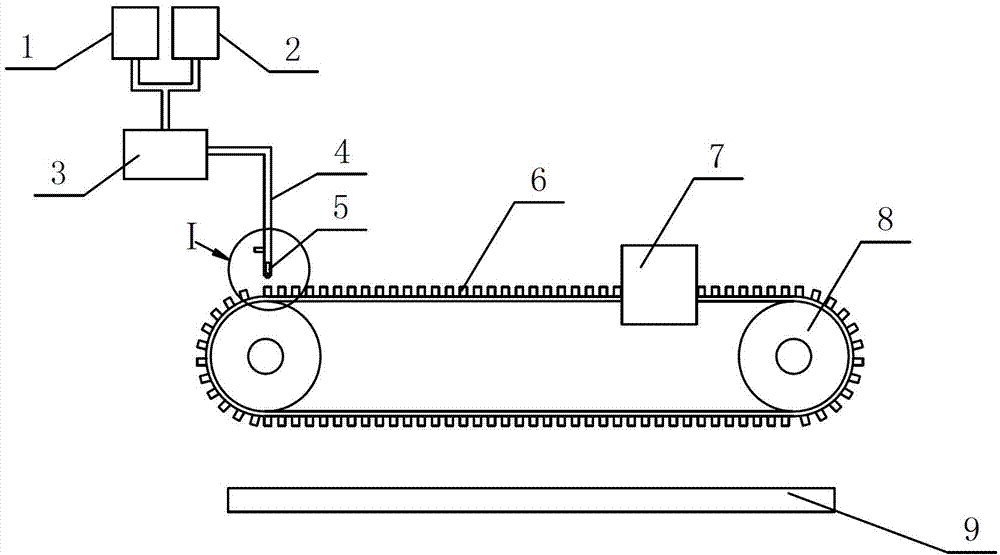

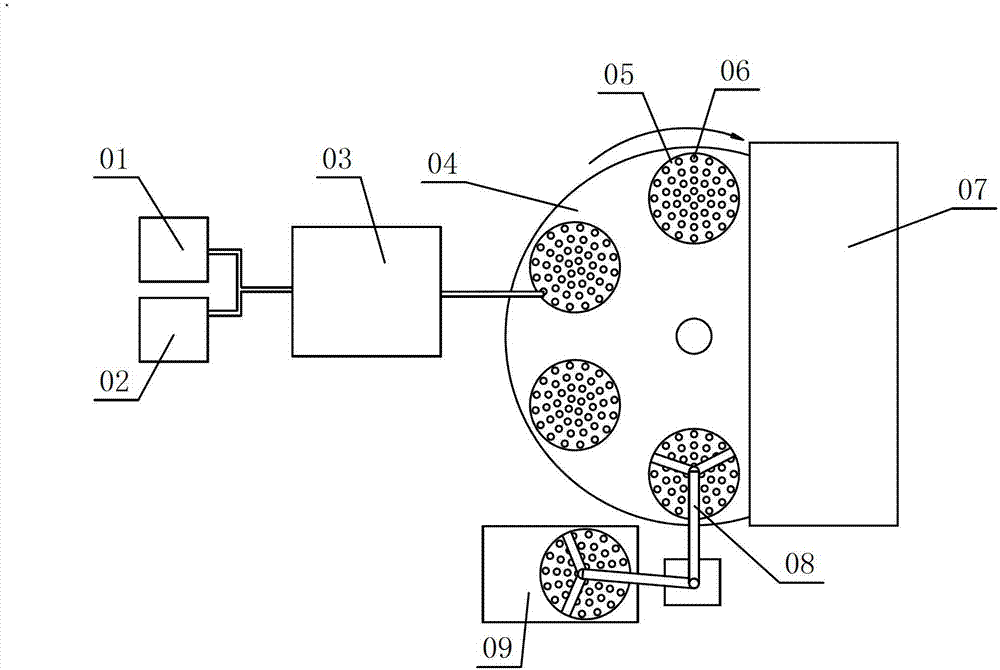

Production process of foaming headset sleeve

InactiveCN102857855AReduce production processImprove molding qualityElectrical transducersMixed materialsMaterials science

The invention discloses a production process of a foaming headset sleeve, and the production process comprises the following steps of a, preparation of materials: placing a well mixed material A and a well mixed material B respectively into a mixing kettle to be stirred; b, mixing: simultaneously placing the material A and the material B into the mixing kettle to be adequately stirred and mixed to form a mixed material; c, injection: continuously injecting the mixed material into a plurality of molds which are matched with each headset sleeve in shape through a mixing reaction kettle, arranging the molds in a single row in the transverse direction, and realizing automatic circular work through a transmission device; d, baking: automatically feeding the molds with the mixed material into a baking box to be baked through the transmission device; and e, demolding: pouring out the headset sleeves from the molds through the transmission device so as to enable the headset sleeves to be separated from the molds after baking is completed. Compared with the prior art, the production process of the foaming headset sleeve has the advantages of simplicity in production equipment, few in manufacturing procedures, simplicity in mold structure, long in service life, capability of being formed in one step, good forming quality, low production cost and low energy consumption.

Owner:刘天镐

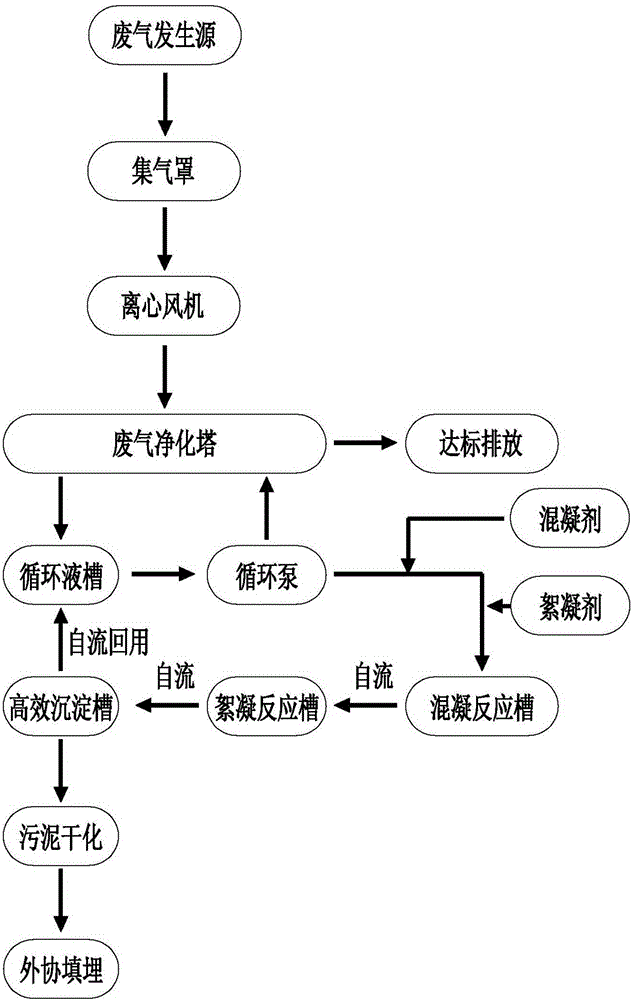

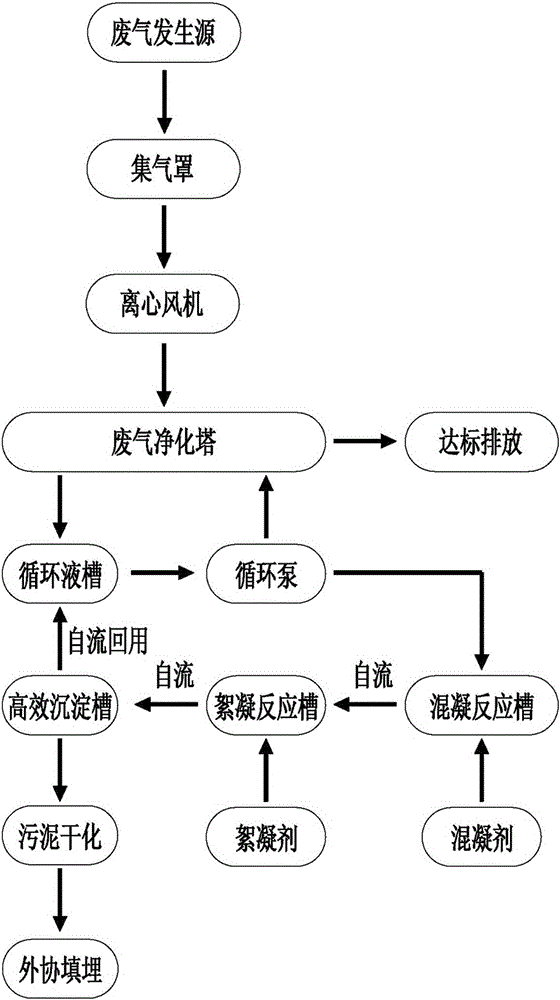

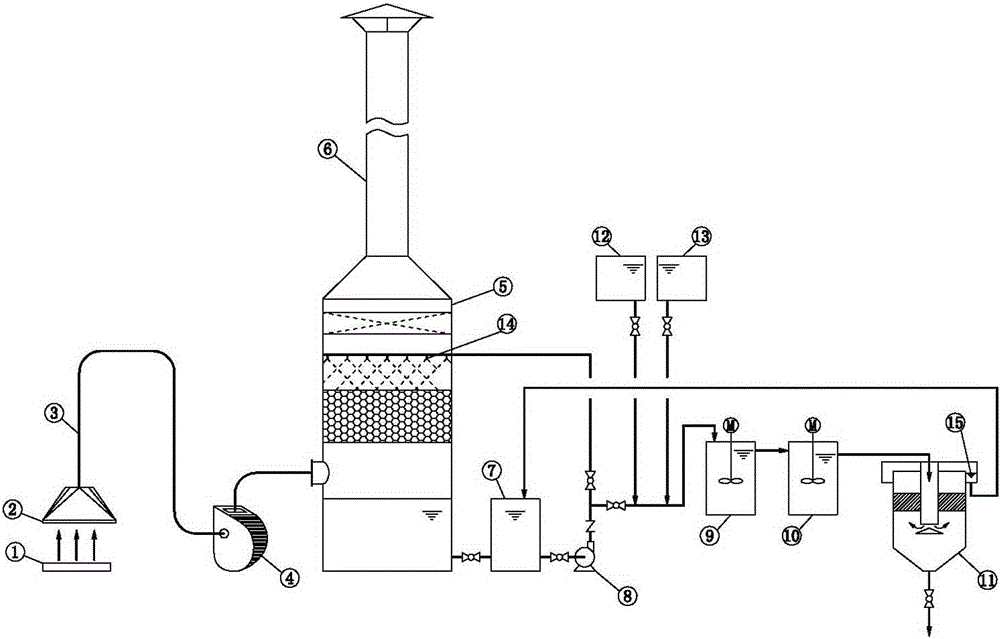

Waste gas purifying treatment technology for reusing internal circulation solution

InactiveCN105233648AReduce secondary pollutionGood environmental benefits and operation and maintenance benefitsDispersed particle separationSmall footprintPrecipitation

The invention discloses a waste gas purifying treatment technology for reusing an internal circulation solution. The purifying treatment technology comprises the following steps: 1, collecting target treatment waste gases generated by a waste gas generation source by a gas collection hood, and conveying the collected waste gases to a waste gas purifying tower through a main gas tube, and allowing the waste gases to upward flow from the lower portion of the waste gas purifying tower and to be purified by a downward flowing circulation solution, wherein the circulation solution is repeatedly recycled until saturation and failure; and 2, lifting a failure circulation solution in a circulation solution tank to a coagulation reaction tank through a circulating pump, carrying out a coagulation reaction, allowing the coagulated failure circulation solution to automatically flow into a flocculation reaction tank, carrying out a flocculation reaction, allowing the flocculated solution to automatically flow into a high efficiency sedimentation tank, and allowing the purified circulation solution to flow into the circulation solution tank. The failure circulation solution is coagulated, flocculated and deposited to obtain the purified circulation solution, and the purified circulation solution is reused, so the cost is saved, pollution is reduced, and energy saving and emission reduction requirements are met; and the technology also has the advantages of concise flow, stable recycling and small occupied area.

Owner:JIANGSU NANFANG COATING & ENVIRONMENT PROTECTION EQUIP

Method for preparing conductive admixture from pyrite smelting slag

ActiveCN101935176BMeet energy saving and emission reduction requirementsLow costSolid waste managementSlagCoal

The invention relates to a method for preparing a conductive admixture from pyrite smelting slag. The method is characterized by comprising the following steps: grinding a raw material ( the pyrite smelting slag) and a reducing agent (pulverized coal) into powder with the grain diameter less than or equal to 0.1mm; weighing and mixing the pyrite smelting slag and the pulverized coal according to the mass ratio of 50:10-25; placing the mixture into a high temperature furnace under the reducing atmosphere, roasting, heating to 600-800 DEG C at the heating rate of 6-8 DEG C / min, and roasting for60-120min at a constant temperature; cooling the roasted material to room temperature under the reducing atmosphere, taking out and levigating to prepare the conductive admixture finished product; ormolding the mixture into pieces or blocks, and then roasting. By adopting the method of the invention, the wastes can be turned into things of value; the cost is low; and the prepared conductive admixture has lower resistivity, can be used for preparing conductive concrete or conductive mortar and also can be used in other building materials.

Owner:SOUTHWEAT UNIV OF SCI & TECH

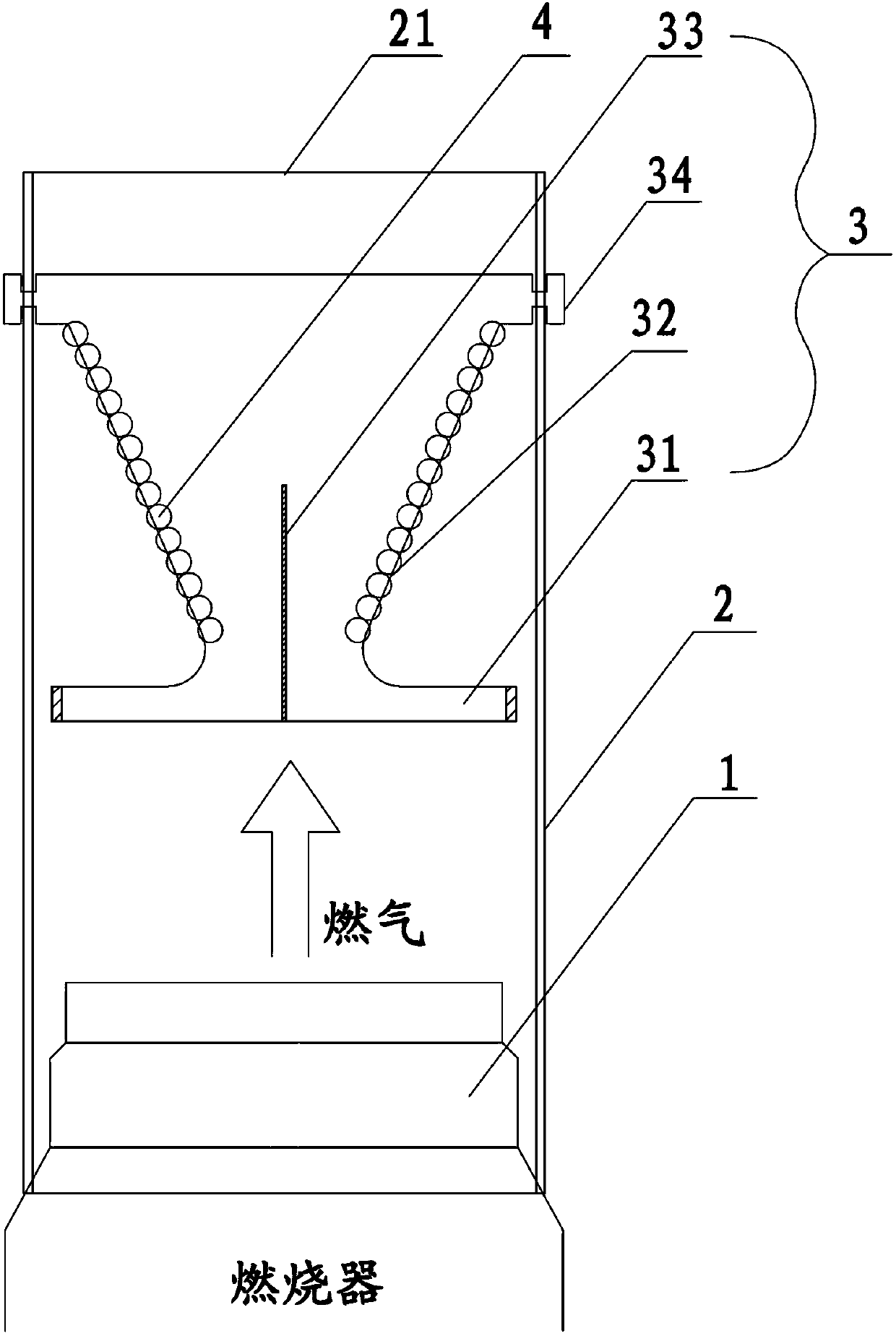

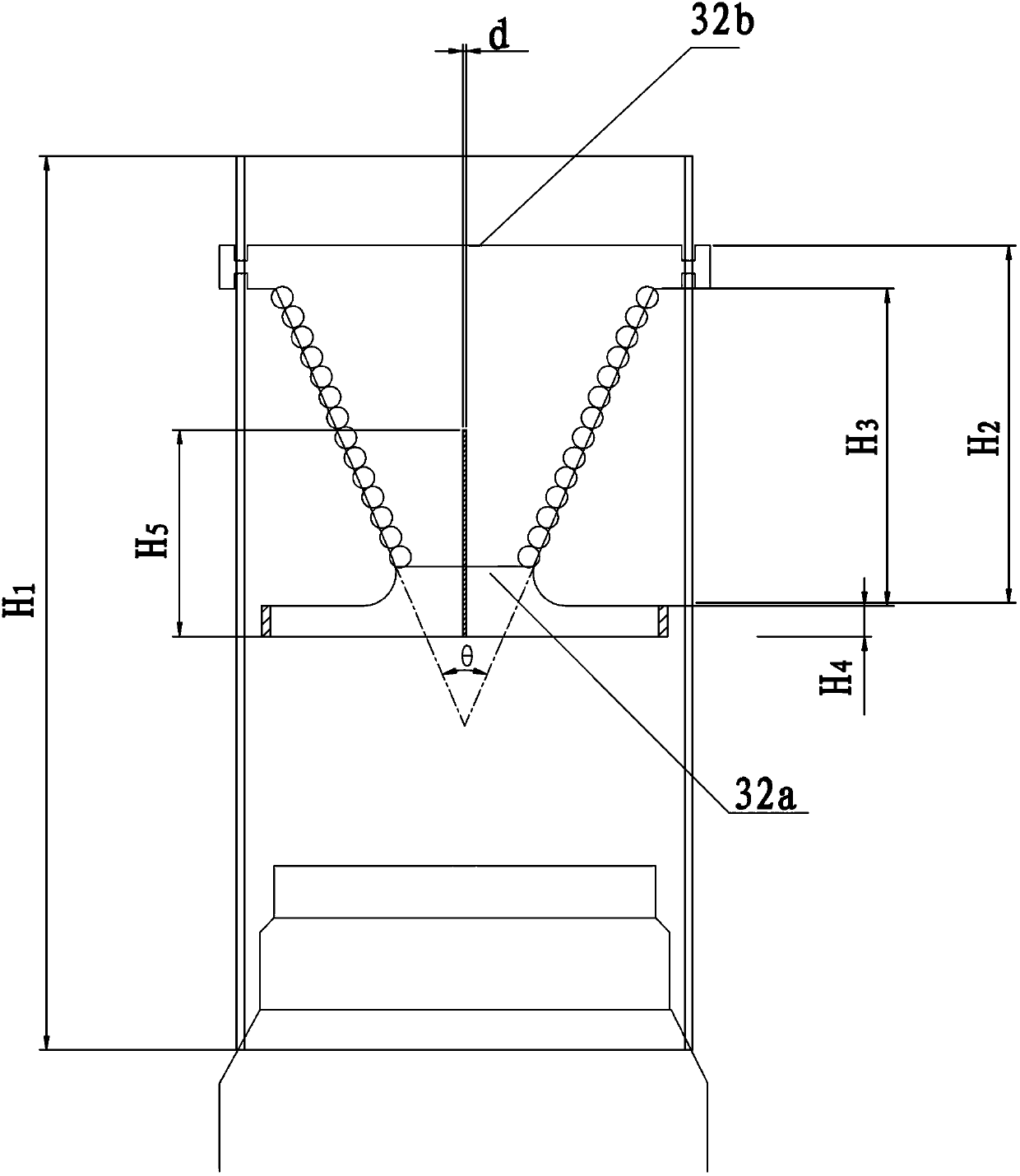

Energy-saving device of burner

InactiveCN103123114AImprove efficiencyImprove actual utilizationBurnersBiomedical engineeringCombustor

The invention relates to an energy-saving device of a burner, and belongs to the technical field of configuration of the burner. The energy-saving device of the burner comprises a burner head and a furnace cover, wherein the furnace cover and the burner head are installed in a matched mode, a support ring is arranged right in front of the burner head, the support ring is in a hollow structure, and a metal wire is wound on the outer surface of the support ring. The support ring comprises a support body and a clamping buckle, wherein the support body is conical, the conical top of the support body extends along the horizontal direction to form a support sheet, the clamping buckle is arranged at the conical bottom position of the support body, the support ring is installed on the furnace cover through the clamping buckle, and the metal wire is wound on the support body. The energy-saving device of the burner has the advantages of being high in burning efficiency, saving energy, reducing emission, and the like, and can be applied to equipment such as a boiler, a kiln furnace, a drying oven and a steaming box.

Owner:浙江绍兴世纪能源有限公司

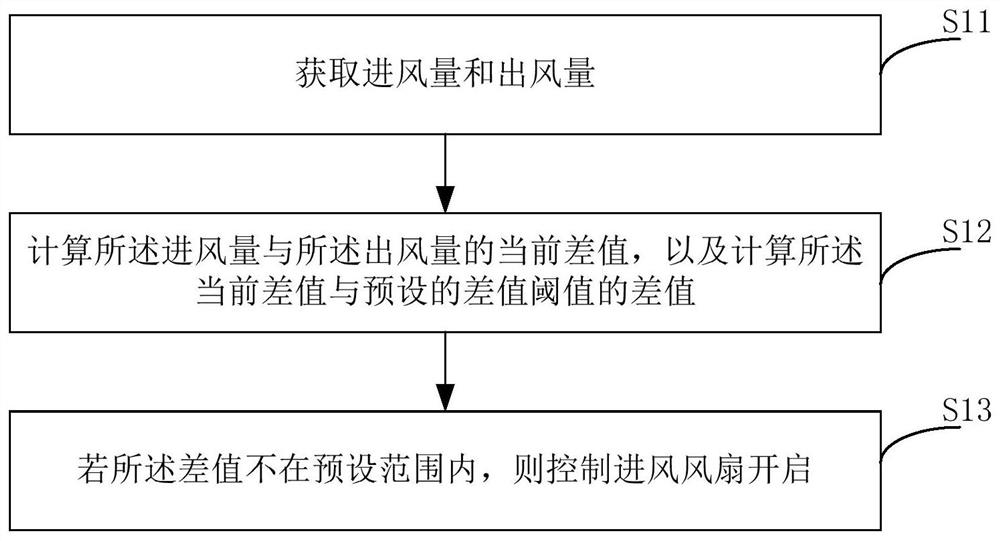

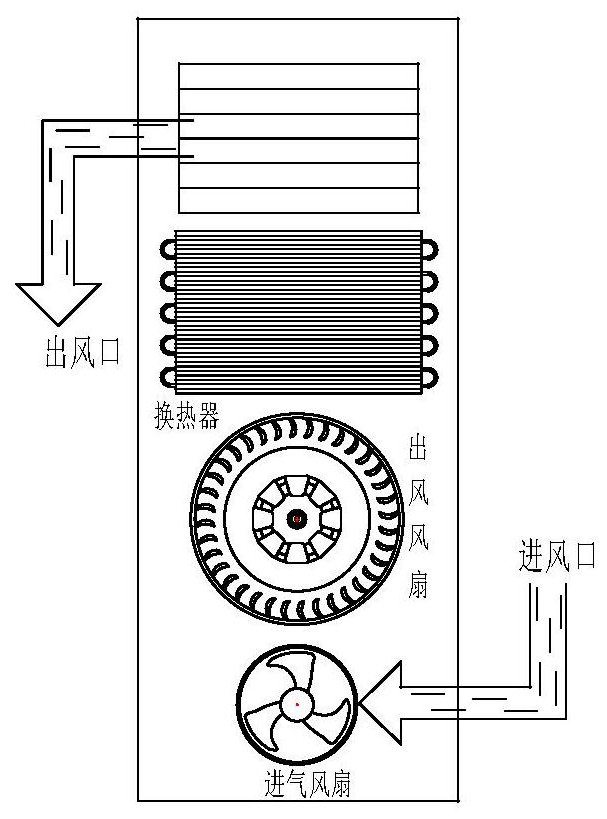

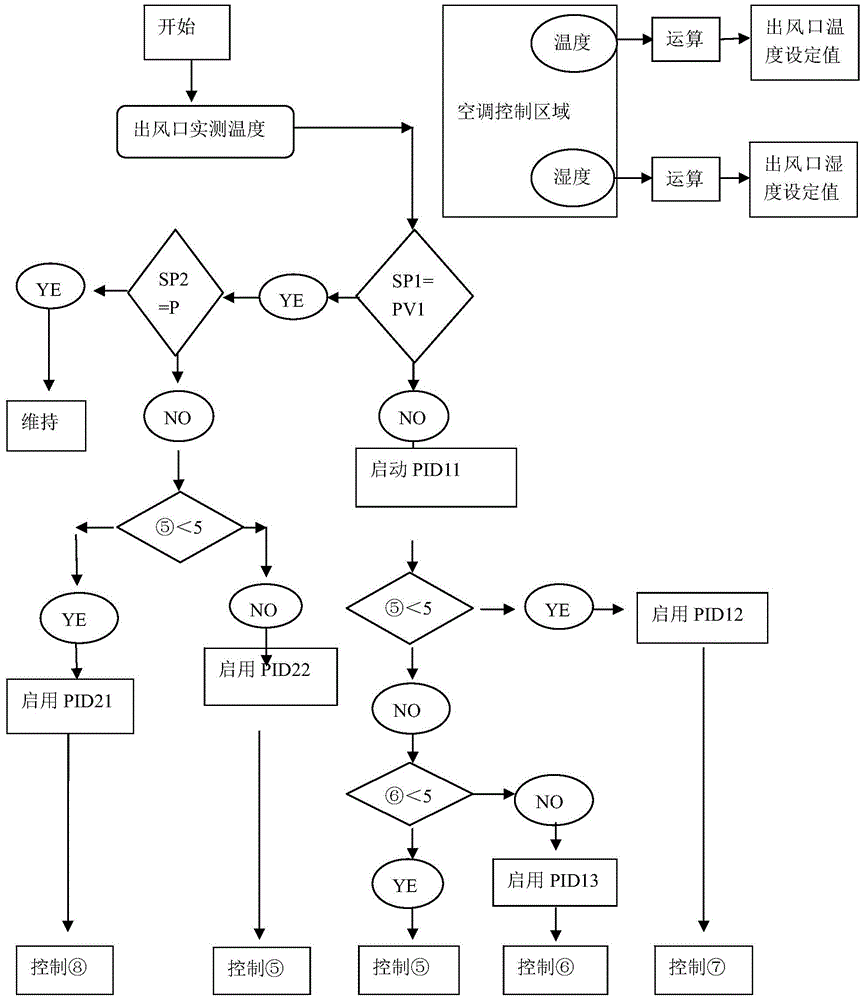

Air conditioner control method, device and air conditioner

ActiveCN112484249BReduce loadAvoid high load operationMechanical apparatusEfficient regulation technologiesAir volumeElectric machinery

The application provides an air conditioner control method, device and air conditioner, which belong to the field of electrical equipment. The air-conditioning control method includes obtaining the air intake volume and the air output volume; calculating the current difference between the air intake volume and the air output volume, and calculating the difference between the current difference value and a preset difference threshold; if the difference value If it is not within the preset range, the intake fan is controlled to be turned on. This method can improve the energy efficiency of the air conditioner and prolong the life of the motor.

Owner:GREE ELECTRIC APPLIANCES INC

Method for preparing light ceramic particle from pyrite cinder

InactiveCN102295467BMeet energy saving and emission reduction requirementsLow costSolid waste disposalCeramicwarePolymer scienceSulfur

The invention provides a method for preparing light ceramic particle from pyrite cinder. The method comprises the following steps: 1) pretreating; 2) preparing materials; 3) mixing; 4) forming; 5) firing; and 6) preparing a finished product. The light ceramic particle prepared by the preparation method has low cost and can be used for preparing light concrete, heat insulation mortar, heat insulation loose filling material and refractory concrete, and by the adoption of the method, wastes are turned into wealth.

Owner:云南常青树投资有限公司

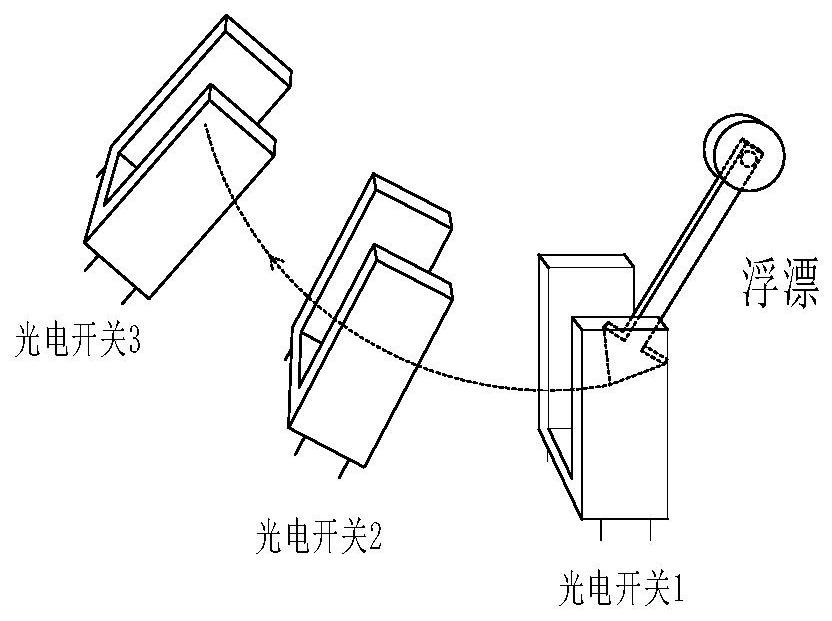

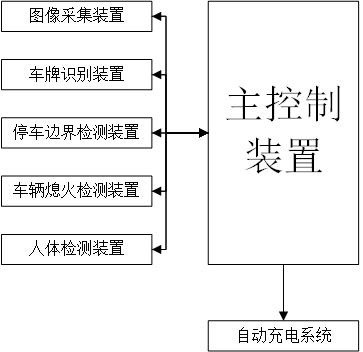

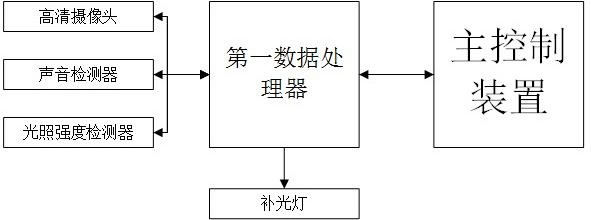

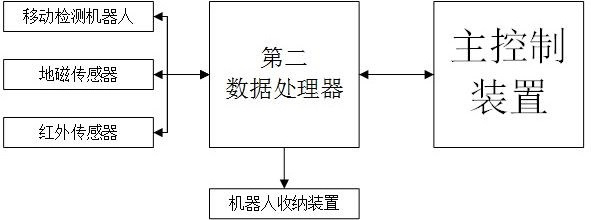

New energy vehicle battery pack charging switching system and method based on image acquisition

ActiveCN113246768BReduce consumptionImprove efficiencyCharging stationsMeasurement devicesParking areaNew energy

The invention belongs to the technical field of new energy vehicle charging, and discloses a new energy vehicle battery pack charging switching system and method based on image acquisition, including an image acquisition device, a license plate recognition device, a parking boundary detection device, a vehicle flameout detection device, and a human body detection device. Device, main control device, automatic charging system; check in order whether a car enters the charging station, whether it is a new energy vehicle, whether it is parked in the standard parking area of the charging station, whether the new energy vehicle is turned off, and whether there is anyone in the standard parking area of the charging station , and finally start the automatic charging, the efficiency is high and there is no potential safety hazard; at the same time, only when the previous detection is completed, the next detection is restarted to meet the energy saving and emission reduction requirements in the new energy field and further reduce energy consumption.

Owner:DEYANG HENGBO STRAW OIL TECH

Method for preparing conductive ceramic product from pyrite cinder

InactiveCN106187093ALow costMeet energy saving and emission reduction requirementsNon-conductive material with dispersed conductive materialCeramic materials productionElectromagnetic shieldingPower equipment

A method for preparing a conductive ceramic product from pyrite cinder comprises the following steps: 1) pretreatment; 2) batching; 3) mixing; 4) moulding; 5) roasting; and 6) preparation of a finished product. By the preparation technology of the invention, electrical resistivity of a conductive ceramic product can reach 0.6 Omega.m and above, compressive strength of the conductive ceramic product can be adjusted within the range of 5-120 MPa, and use amount of pyrite cinder is greater than 80%. The conductive ceramic product can be used as a building structural material, and also can be used in electrotechnics, resistance to electromagnetic interference, electromagnetic shielding, industrial electrostatic prevention, electric heaters, power equipment grounding engineering and steel bar cathodic protection. The conductive ceramic product is a multifunctional intelligent product.

Owner:无锡市华东电力设备有限公司

A dual-channel return air-conditioning box and its temperature control method

ActiveCN104456726BIncrease energy saving potentialMeet energy saving and emission reduction requirementsMechanical apparatusSpace heating and ventilation safety systemsSurface coolingFresh air

Owner:CHINA TOBACCO ZHEJIANG IND

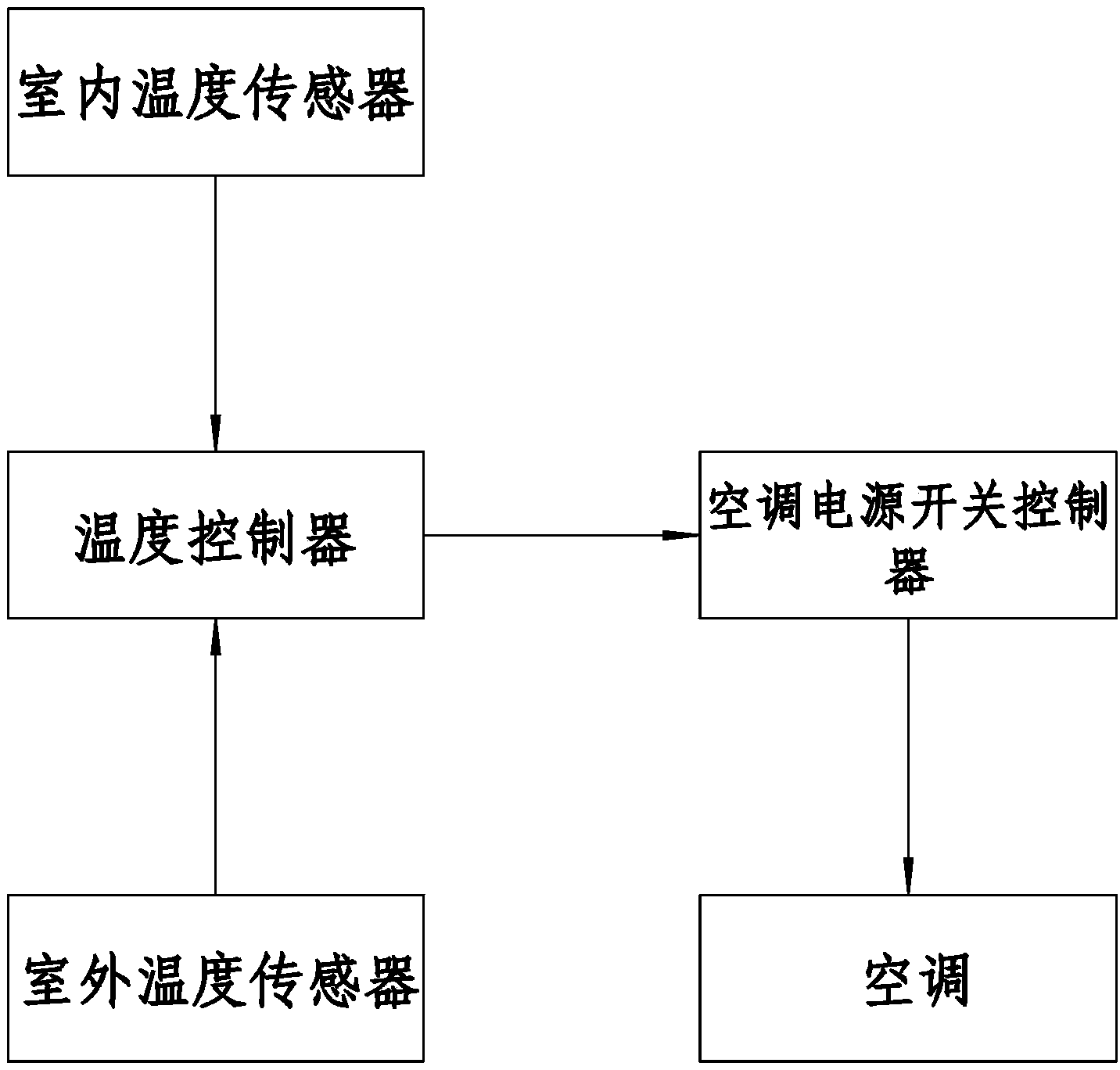

Temperature control device of air conditioner

InactiveCN103411296ASimple structureLow costSpace heating and ventilation safety systemsLighting and heating apparatusTemperature controlControl signal

A temperature control device of an air conditioner is characterized by comprising an indoor temperature sensor, an outdoor temperature sensor, a temperature controller and an air conditioner power switch controller, wherein the indoor temperature sensor is arranged in an indoor unit of the air conditioner; the outdoor temperature sensor is arranged in an outdoor unit of the air conditioner; the indoor temperature sensor and the outdoor temperature sensor transmit an indoor temperature value signal and an outdoor temperature value signal to the temperature controller respectively; the temperature controller compares the received indoor temperature value signal with outdoor temperature value signal and then outputs a control signal to the air conditioner power switch controller; and the power switch controller controls an air conditioner power supply to be connected and disconnected according to the control signal. The device is simple in construction, low in construction cost, easy to implement, convenient, rapid, practical, efficient and energy-saving, and meets the requirements for energy conservation and emission reduction and achieves the purpose of environmental protection at the same time.

Owner:张一达

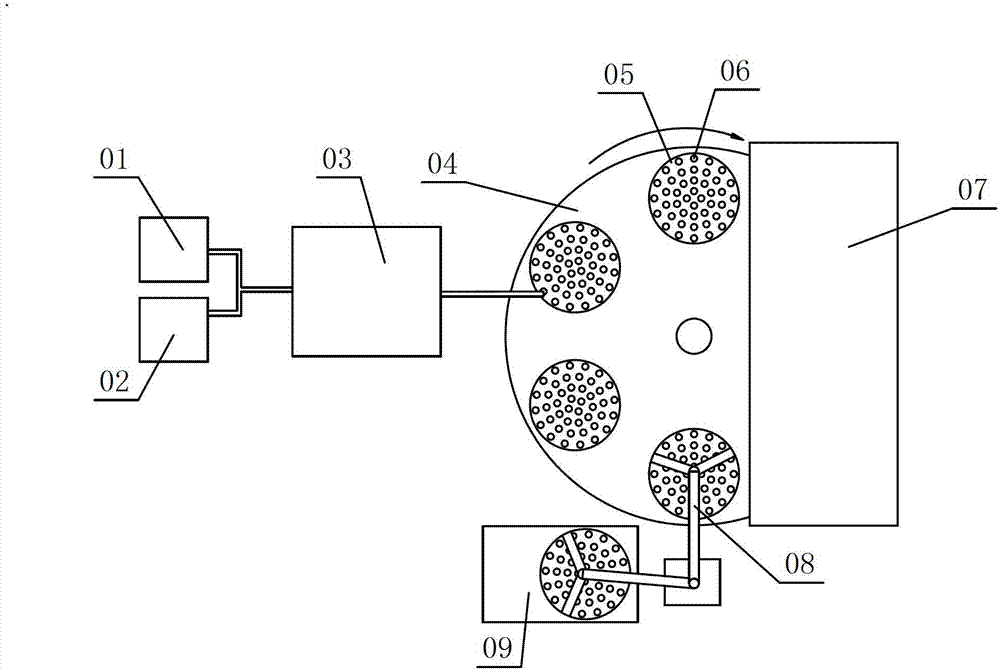

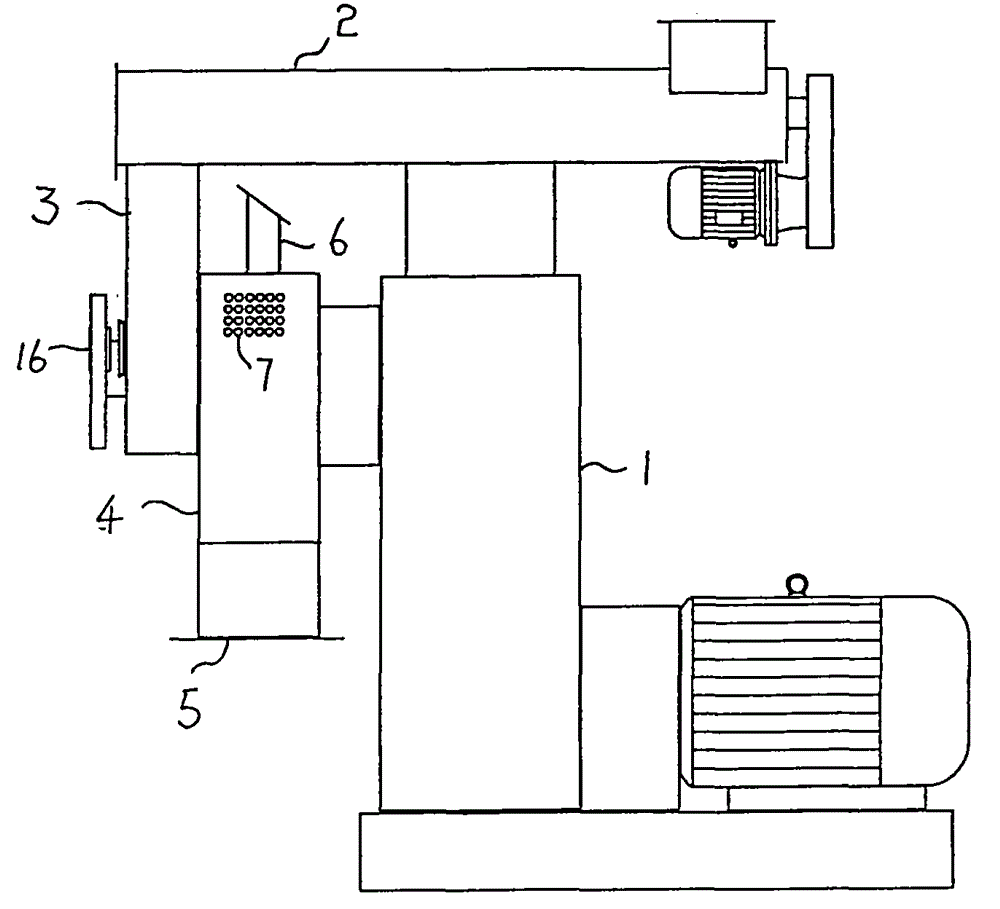

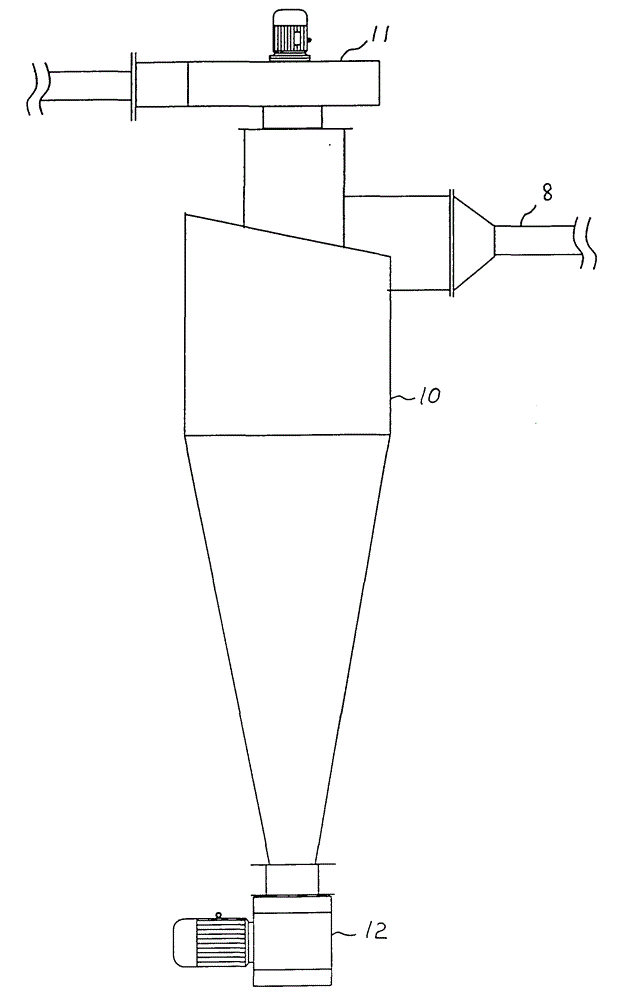

Air-cooled dedusting system of biomass granulator

InactiveCN101700482BExtended service lifeIncrease productionDirt cleaningGranulation by pressingEngineeringProduct gas

An air-cooled dedusting system of a biomass granulator is used for forming air convection environment in a granulation room (4). The air-cooled dedusting system of the biomass granulator comprises the granulation room (4), of which the lower end is provided with a discharging opening (5); the air-cooled dedusting system of the biomass granulator is characterized in that the granulation room (4) is provided with at least one air opening, the air opening and / or the discharging opening (5) are connected to a blasting device or a drafting device. The inventive air-cooled dedusting system of the biomass granulator utilizes wind-force to produce air flow in the granulation room, can effectively temperature in the granulation room by the air-cooled form, realize cold pressing forming, and simultaneously dedust the fly ash and powder bits produced in the granulation process and recycle the discharged powder, thus saving cost, greatly enhancing service life of the granulator and yield of granulation, which is a significant renovation in the field of granulation.

Owner:溧阳市华生机械厂

Production process of foaming headset sleeve

InactiveCN102857855BReduce production processImprove molding qualityElectrical transducersMixed materialsMaterials science

The invention discloses a production process of a foaming headset sleeve, and the production process comprises the following steps of a, preparation of materials: placing a well mixed material A and a well mixed material B respectively into a mixing kettle to be stirred; b, mixing: simultaneously placing the material A and the material B into the mixing kettle to be adequately stirred and mixed to form a mixed material; c, injection: continuously injecting the mixed material into a plurality of molds which are matched with each headset sleeve in shape through a mixing reaction kettle, arranging the molds in a single row in the transverse direction, and realizing automatic circular work through a transmission device; d, baking: automatically feeding the molds with the mixed material into a baking box to be baked through the transmission device; and e, demolding: pouring out the headset sleeves from the molds through the transmission device so as to enable the headset sleeves to be separated from the molds after baking is completed. Compared with the prior art, the production process of the foaming headset sleeve has the advantages of simplicity in production equipment, few in manufacturing procedures, simplicity in mold structure, long in service life, capability of being formed in one step, good forming quality, low production cost and low energy consumption.

Owner:刘天镐

A suction roller device

ActiveCN104754872BImprove the phenomenon of the posterior bandImprove the phenomenonConductive pattern polishing/cleaningEngineeringWindlass

The invention relates to the technical field of water washing equipment for circuit boards and discloses a water suction windlass device used for extruding, sucking and etching liquid on the circuit board. The water suction windlass device comprises an isolation groove, a stand firmly arranged in the isolation groove, a water suction windlass group arranged on the stand and used for extruding and sucking the liquid on the circuit board, and a transmission device arranged on the stand and used for driving the water suction windlass group to rotate axially, and moreover, the stand is provided with a water press windlass for extruding the water suction windlass group, an angle is formed between the water press windlass and the water suction windlass group, and spiral water extrusion threads are formed in the outer wall of the water press windlass. According to the water suction windlass device, the water press windlass with water extrusion threads is arranged at the oblique upper side of the water suction windlass group, the water suction windlass group is extruded through the water press windlass, the liquid sucked by the water suction windlass group is extruded towards the two ends through the water extrusion threads, the post-liquid taking phenomenon is reduced, the energy saving and emission reduction demands are satisfied, the circuit board surface oxidization chance is reduced, and the circuit board quality is improved.

Owner:UNIVERSAL P C B EQUIP SHENZHEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com