HFC-245eb type composite polyether for refrigerator polyurethane plastic and preparing method of HFC-245eb type composite polyether

A technology of hfc-245eb and combined polyether, which is applied in the field of polyurethane foam, can solve the problems of hydrocarbon foaming agents such as flammability and explosion, high raw material requirements, poor dimensional stability, etc., achieve good thermal insulation performance, and simple preparation method , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

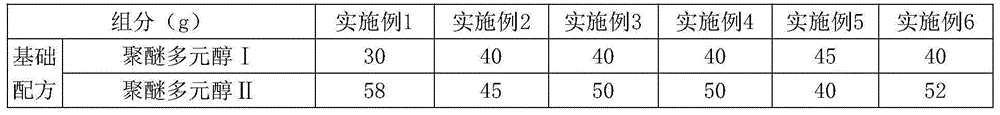

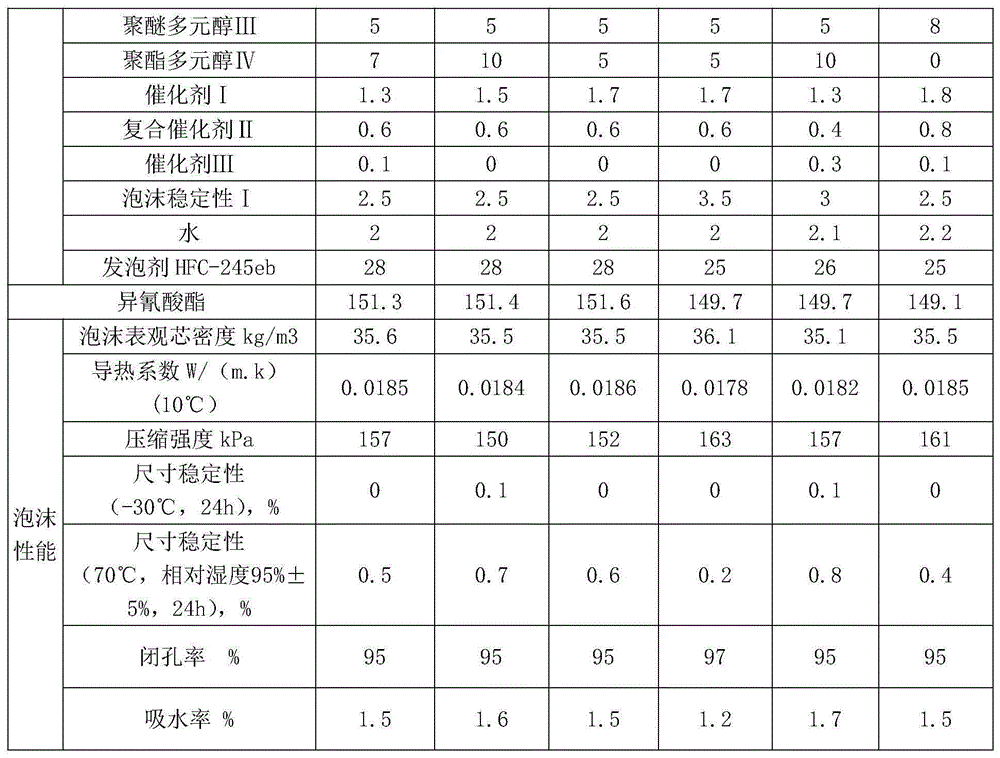

[0028] The raw materials used in each embodiment are as follows:

[0029] Polyether polyol I (named 600A, hydroxyl value 421mgKOH / g, functionality 5, viscosity (25°C) 11500cp), polyether polyol II (named 8238, hydroxyl value 395mgKOH / g, functionality 5.2, viscosity ( 25°C) 7350cp) are all produced by Shaoxing Hengfeng Polyurethane Industrial Co., Ltd.; polyether polyol III (called VOANOLCP450, hydroxyl value 378mgKOH / g, functionality 3, viscosity (25°C) 330cp) is produced by Dow Chemical; Polyester polyol IV (named 400A, hydroxyl value 425mgKOH / g, functionality 2.2, viscosity (25°C) 2950cp) is produced by Zhangjiagang Nanguang Chemical Co., Ltd.;

[0030] Catalyst Ⅰ is N,N-dimethylcyclohexylamine; the manufacturer is Jiangdu Dajiang Chemical Plant; composite catalyst Ⅱ is triethylenediamine and 1,3,5-bis(dimethylaminopropyl)hexahydrotriazine The mass ratio is 1: (1.5) mixture, the manufacturer is Jiangdu Dajiang Chemical Plant; the catalyst III is pentamethyldiethylenetriamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com