Production process of foaming headset sleeve

A production process and technology for earphone covers, which are applied to electrical components, sensors, etc., can solve the problems that the baking area of the oven cannot be fully utilized, the structure of the earphone cover forming mold is complex, and the energy saving and emission reduction plan cannot be met, and the reduction of The effect of cutting and screening process, low mold cost and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

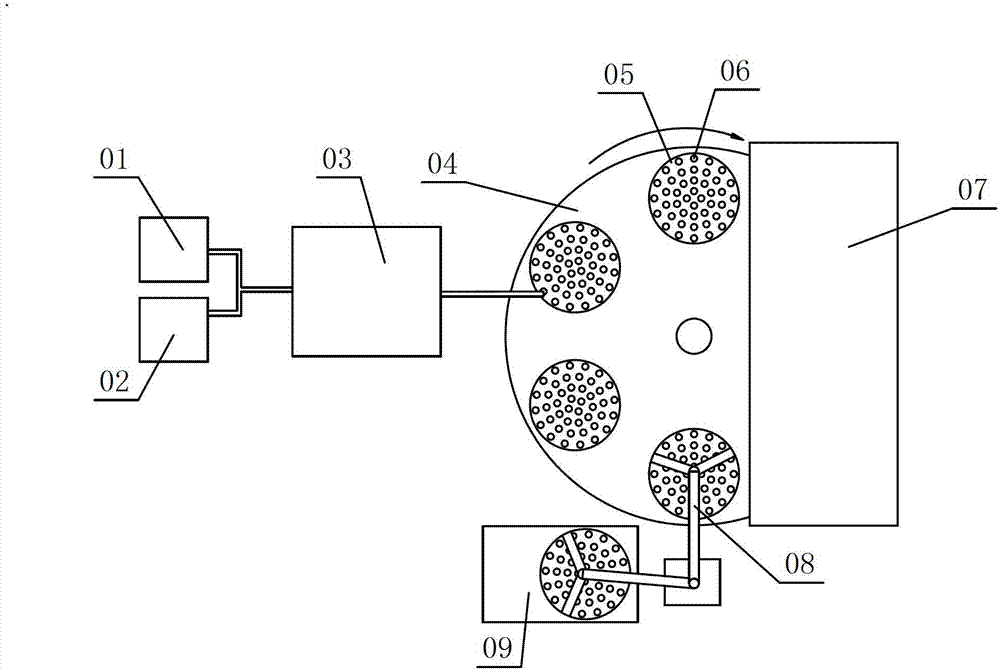

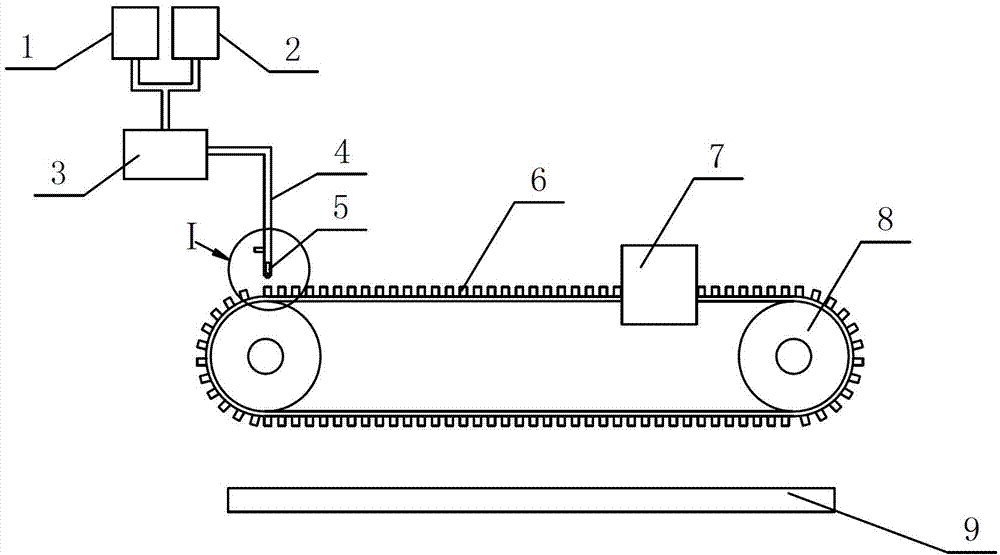

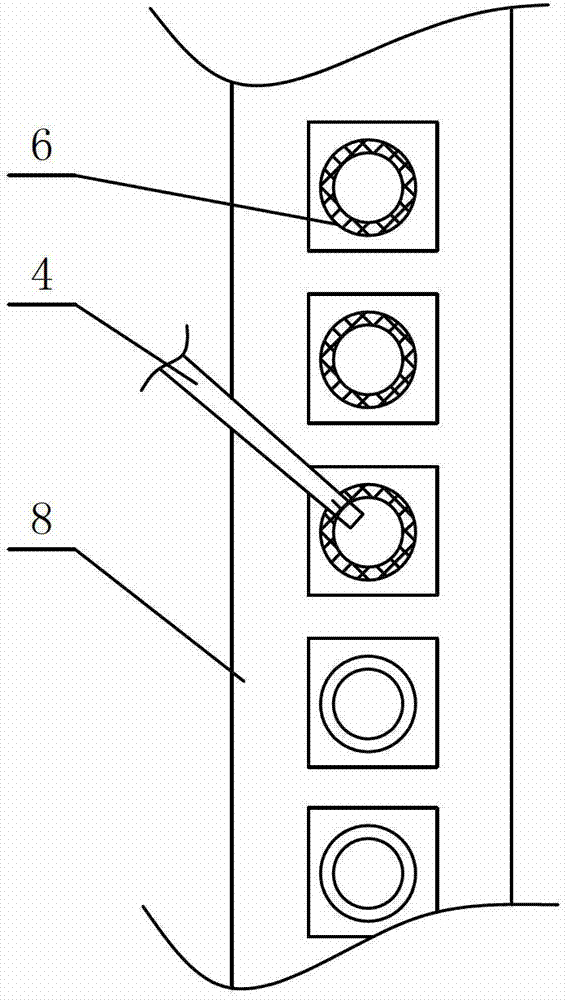

[0059] Such as Figure 2~3 As shown, the production process of the foam earphone cover described in the present embodiment comprises the following steps:

[0060] The first step: material preparation

[0061] (1) Material batching, each component in material A and material B for producing foam earphone cover is weighed and batched separately;

[0062] (2) Feeding, put the prepared material A and material B into the first batching kettle 1 and the second batching kettle 2 respectively;

[0063] (3) For the first time mixing, start the stirring devices in the first batching kettle 1 and the second batching kettle 2 respectively, and simultaneously stir material A and material B respectively to complete the first mixing, and the time for this mixing is 0.5 h;

[0064] (4) Heating, start the heating devices in the first batching kettle 1 and the second batching kettle 2 respectively, and heat the mixed materials in each batching kettle, and the heating temperature is 45°C;

[...

Embodiment 2

[0085] Such as Figure 4 As shown, the production process of the foam earphone cover described in the present embodiment comprises the following steps:

[0086] The first step: material preparation

[0087] (1) Material batching, each component in material A and material B for producing foam earphone cover is weighed and batched separately;

[0088] (2) Feeding, put the prepared material A and material B into the first batching kettle 101 and the second batching kettle 102 respectively;

[0089] (3) For the first time mixing, start the stirring devices in the first batching kettle 101 and the second batching kettle 102 respectively, and simultaneously stir material A and material B respectively to complete the first mixing, and the time for this stirring is 1h ;

[0090] (4) Heating, start the heating devices in the first batching kettle 101 and the second batching kettle 102 respectively, and heat the mixed material in each batching kettle, and the heating temperature is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com