Patents

Literature

32results about How to "Reduce screening process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-human MSLN (mesothelin) monoclonal antibody

ActiveCN110698562AGood water solubilityImprove patienceImmunoglobulins against cell receptors/antigens/surface-determinantsAntibody ingredientsAntiendomysial antibodiesPharmaceutical drug

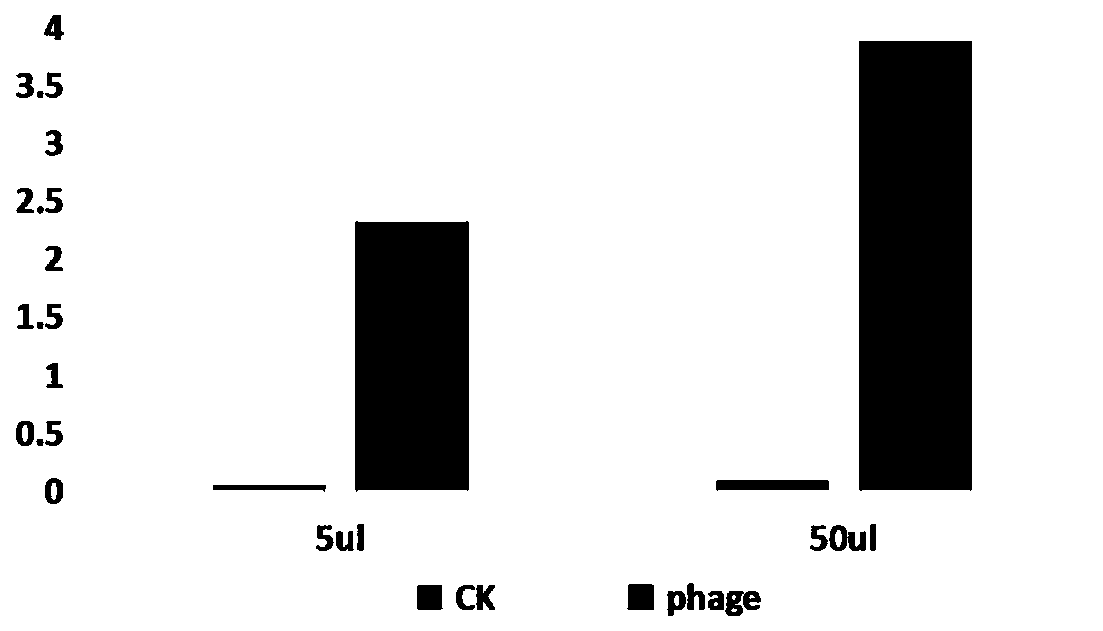

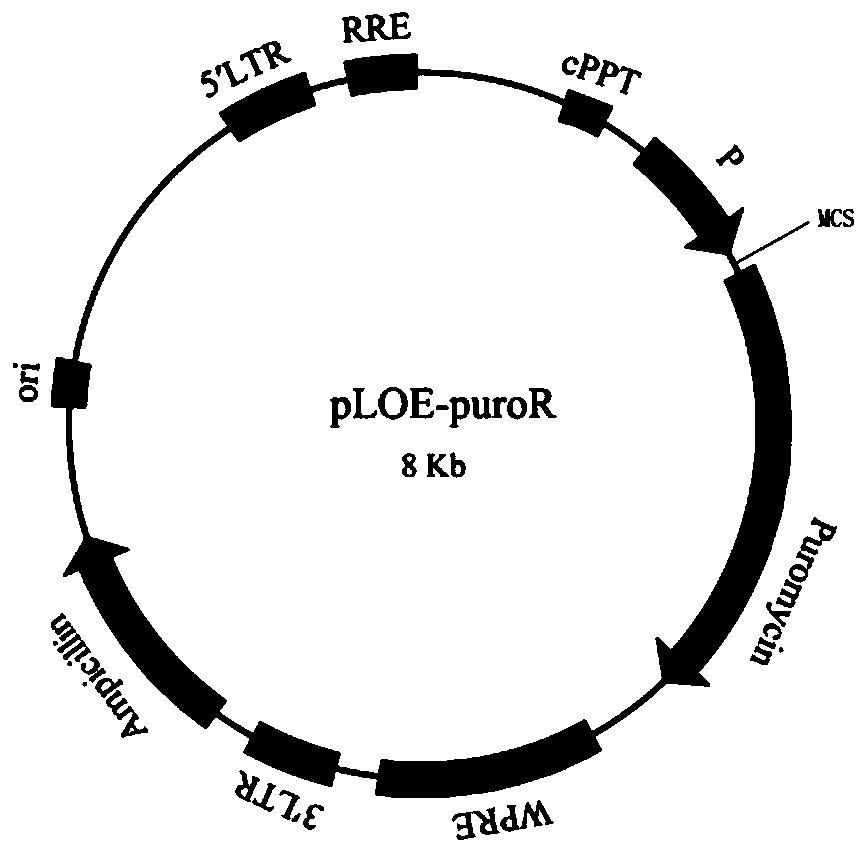

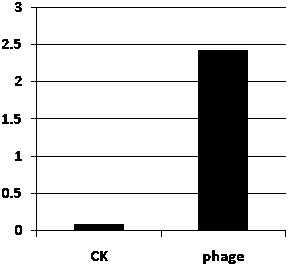

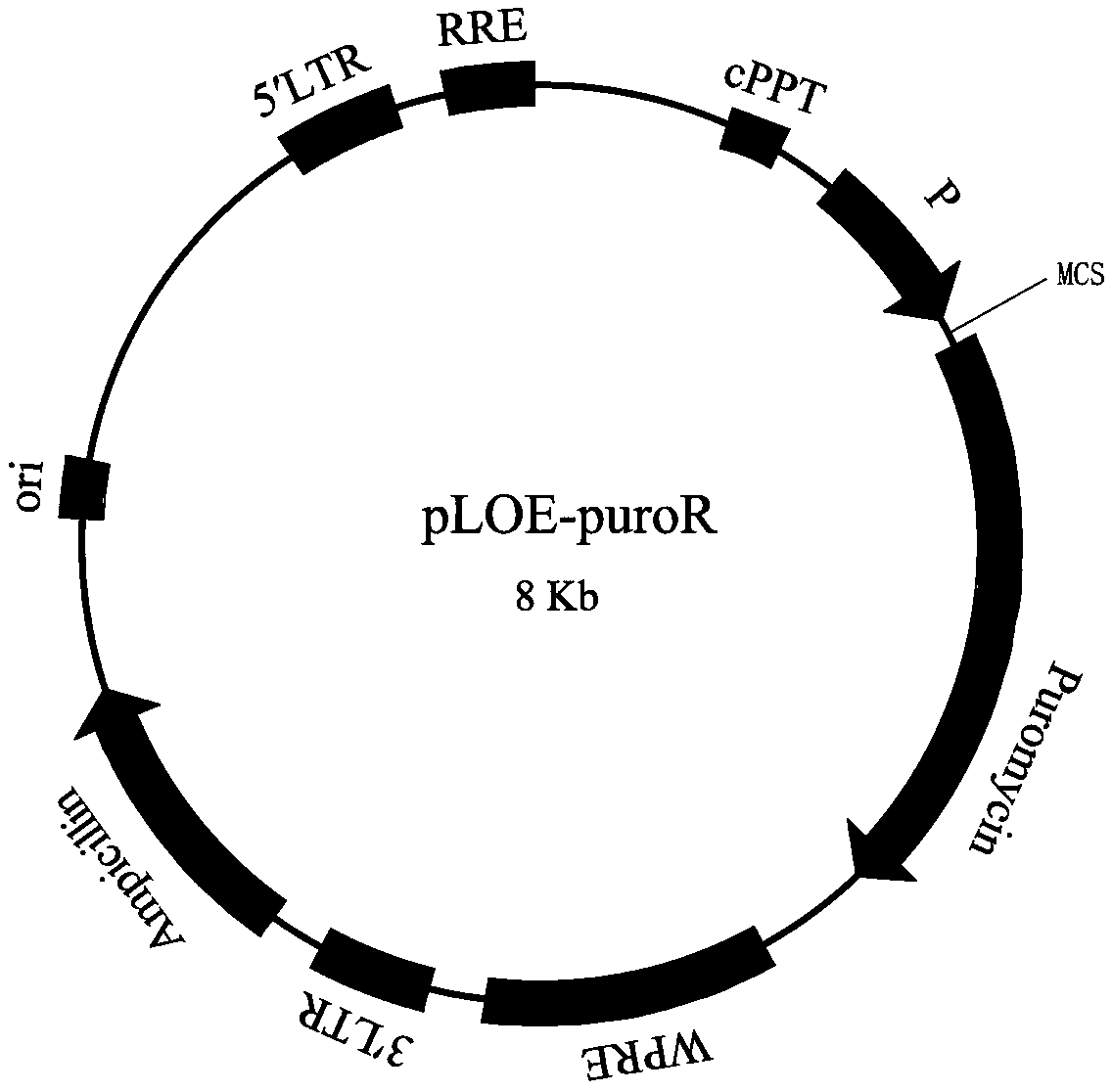

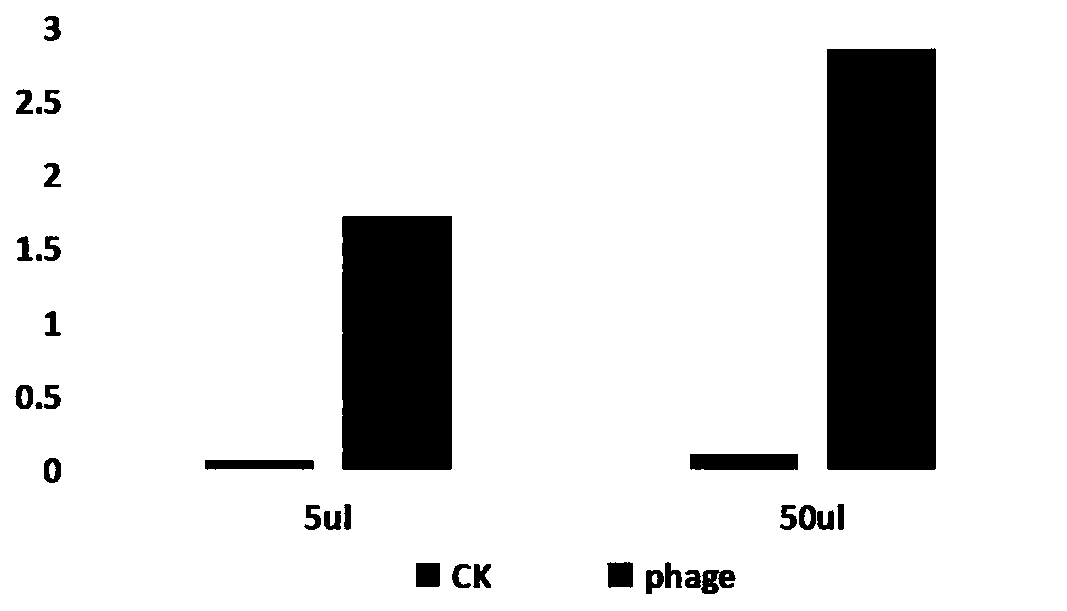

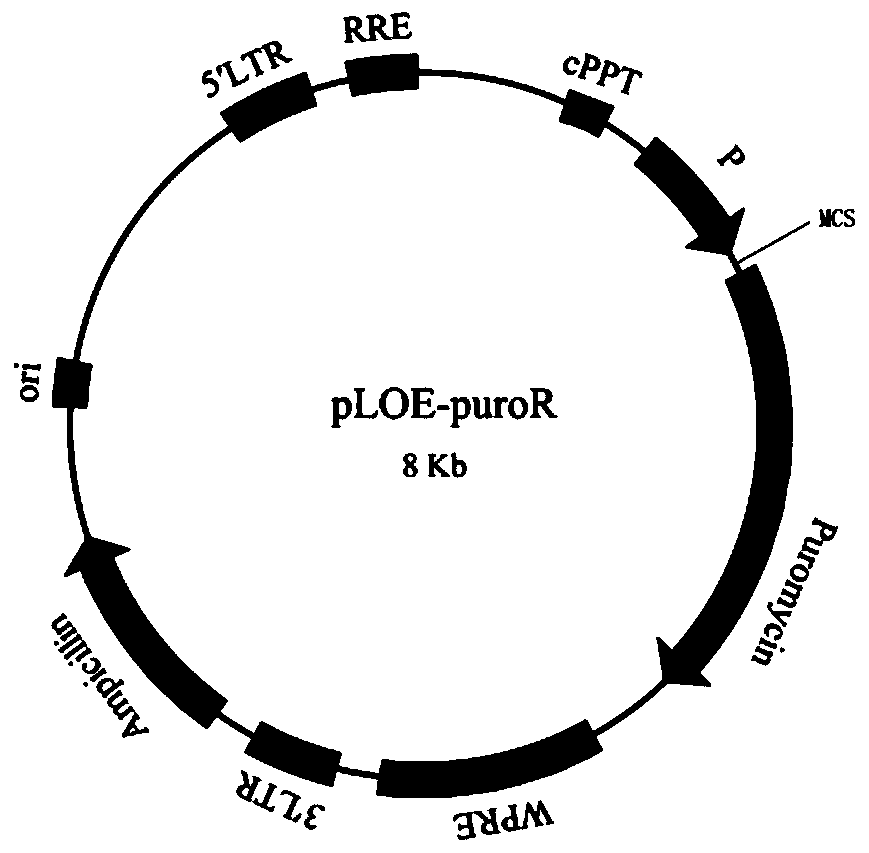

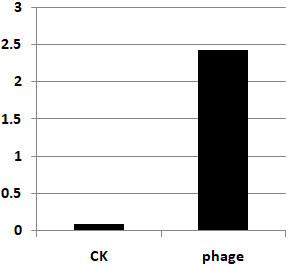

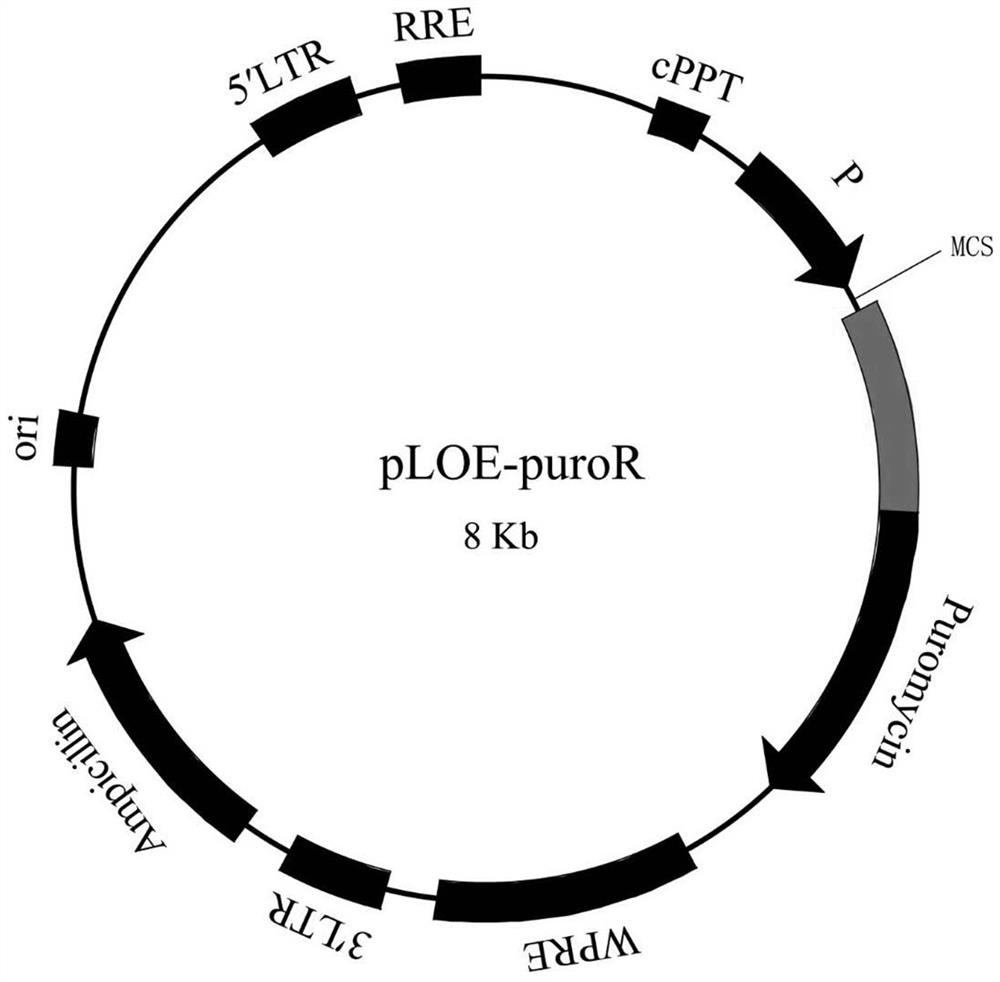

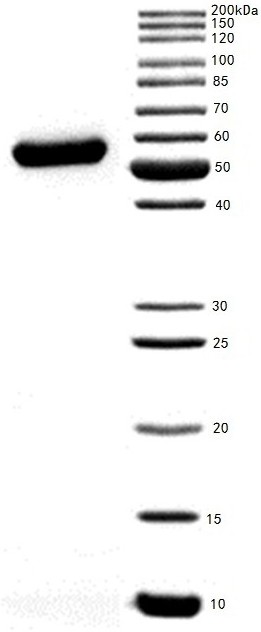

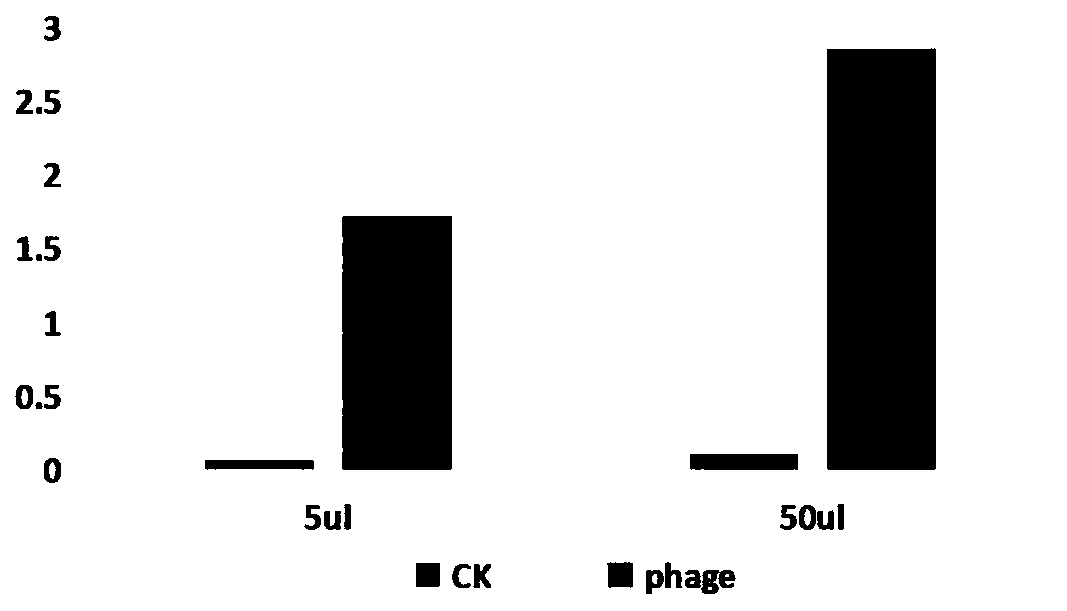

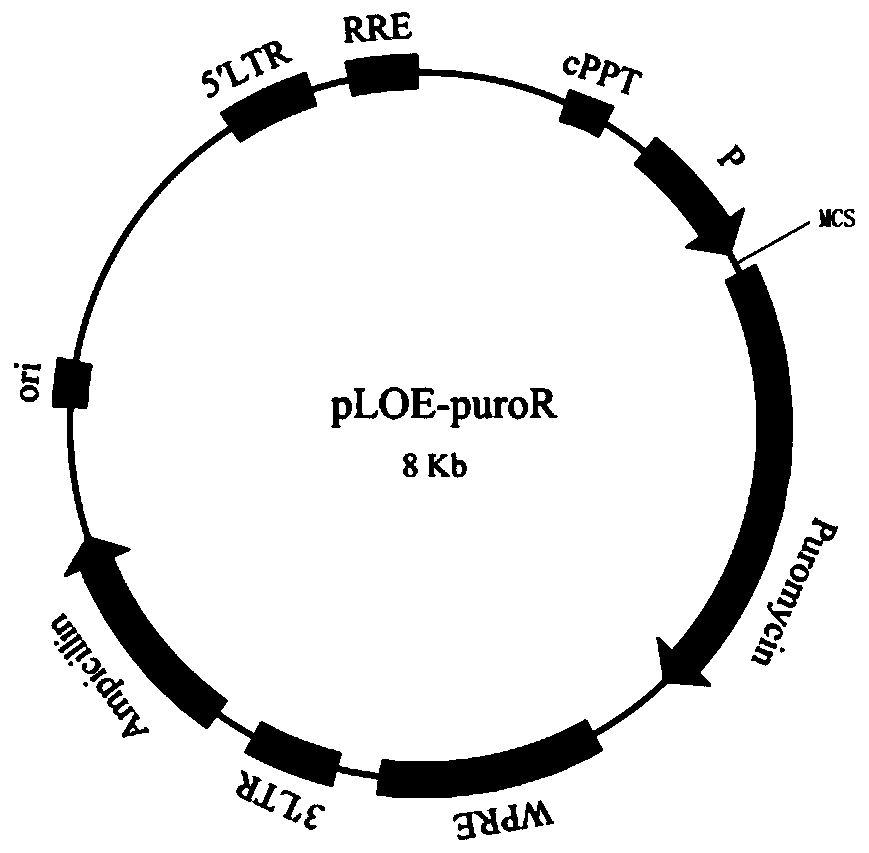

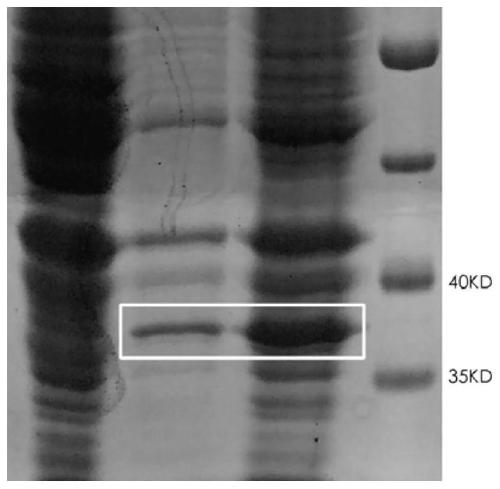

The invention discloses an anti-human MSLN (mesothelin) monoclonal antibody, which is a specific high-affinity nano antibody developed by taking human MSLN as a target and based on a phage display technology. Compared with the prior art, the invention allows the anti-human MSLN monoclonal antibody to be successfully prepared, which is good in specificity, high in affinity and capable of binding tohuman MSLN expressed on the cell surface, and the anti-human MSLN monoclonal antibody is a potential drug for tumor immunotherapy.

Owner:ZHEJIANG BLUE SHIELD PHARM CO LTD

Preparation of zircite tube

The invention relates to a preparation method for a zirconia tube. The method comprises the following steps: firstly, the preparation of ceramic slurry: ceramic powder, microcrystalline wax, polyethylene or polypropylene and oleic acid are fully mixed; secondly, injection molding: suitable particles required for injection molding are produced through a granulating machine, and finally the blank of the zirconium tube of an oxygen sensor is produced; thirdly, low-temperature dewaxing: low-temperature heating treatment is performed for a long term, in order to discharge the paraffine resin adhesive; fourthly, isostatic cool pressing: the stress to the blank is uniform in all directions, in order to eliminate the gap reserved in the blank after dewaxing; fifthly, high temperature sintering: the zirconia tube is sintered. The invention provides a preparation method which can effectively enhance the compactness of the zirconia tube with high rate of finished products.

Owner:浙江通源环保科技有限公司

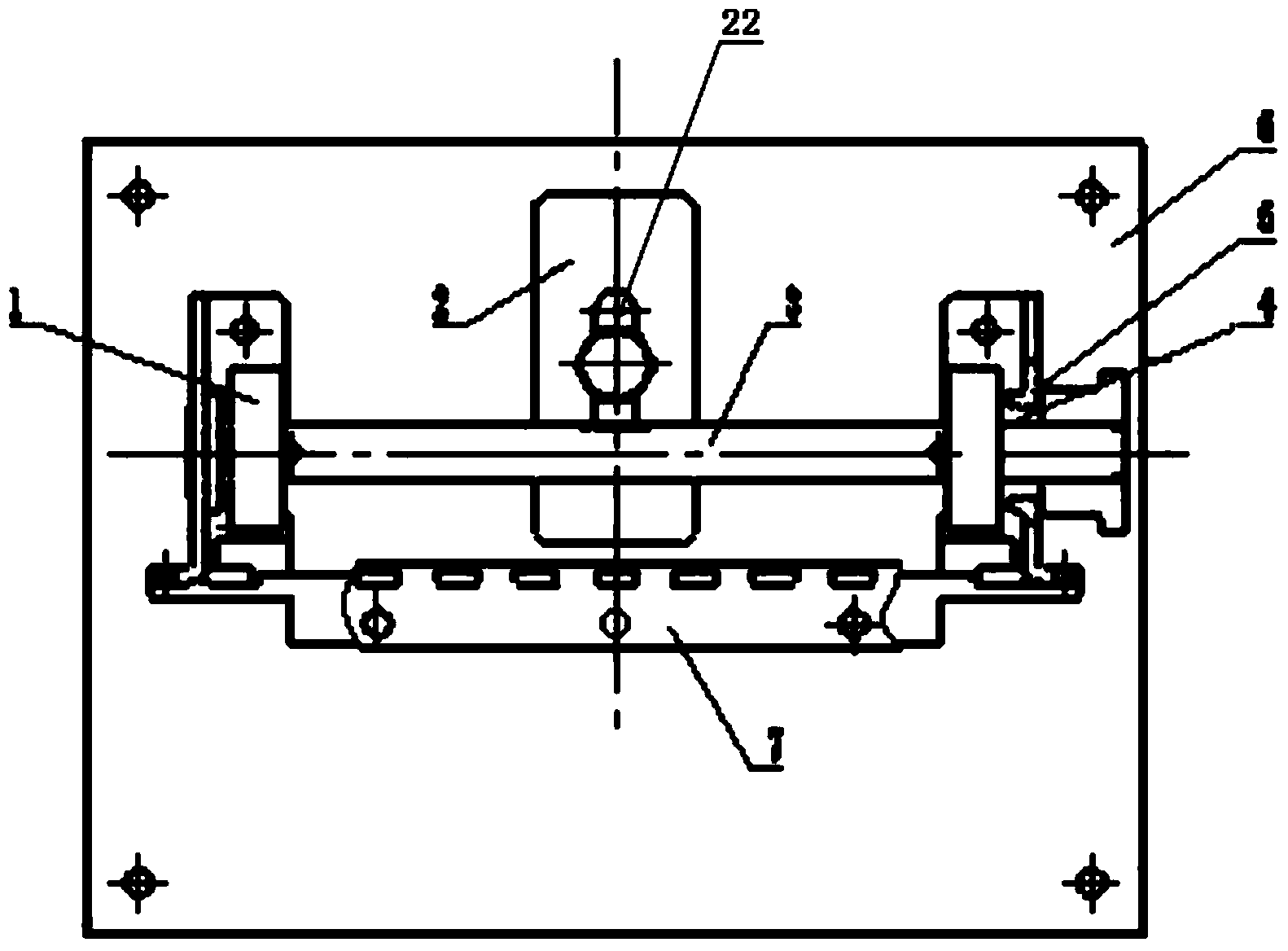

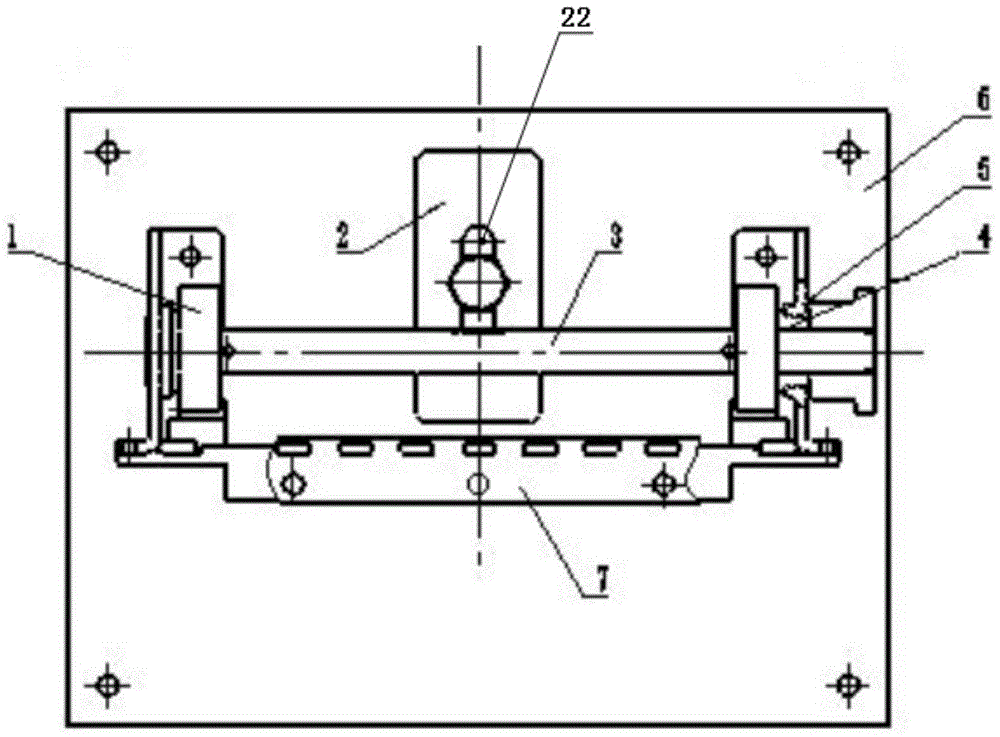

Device for rapidly preparing stability test samples of gunpowder and explosives

ActiveCN104330295AExtended use timeNot easy to producePreparing sample for investigationGunpowderEngineering

The invention discloses a set of device for rapidly preparing stability test samples of gunpowder and explosives, and solves the problems that the stability test samples of the gunpowder and the explosives are low in preparation efficiency, long in consumed time and difficult to collect. The device comprises a knife rest part, a base part and a sample collecting part. According to the device, the samples can be prepared with the specification and size required by testing regulations once in continuous feeding and intermittent shearing stress manners; by virtue of a drawer type sample collector, the spattering of gunpowder particles can be effectively prevented. The device has the beneficial effects that the operation is easy, the time and the labor are saved, the test cycle can be greatly shortened, and the working efficiency is improved.

Owner:XIAN MODERN CHEM RES INST

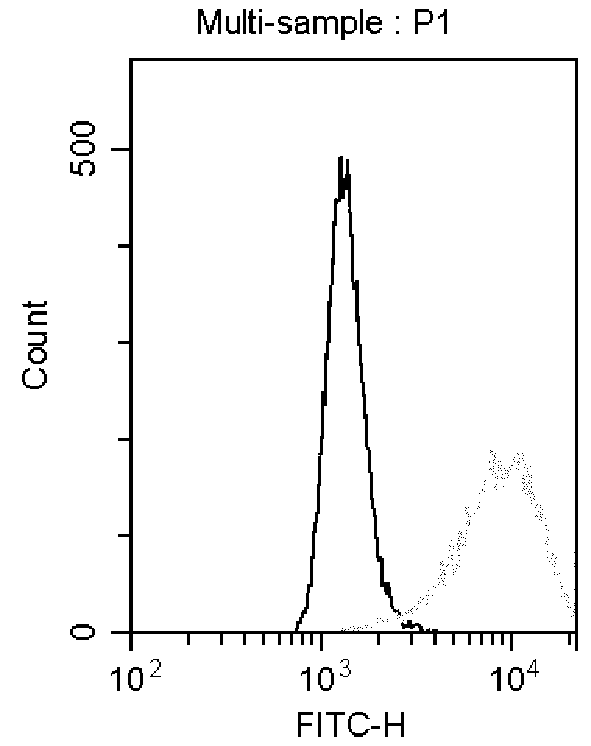

Anti-human MSLN monoclonal antibody and application thereof

ActiveCN111349165AReduce volumeStrong tissue penetrationImmunoglobulins against cell receptors/antigens/surface-determinantsAntibody ingredientsSingle-Chain AntibodiesAntiendomysial antibodies

The invention discloses an anti-human MSLN monoclonal antibody and an application thereof, and is a specific and high-affinity single-chain antibody developed by taking human MSLN as a target based ona phage display technology. Compared with the prior art, the anti-human MSLN monoclonal antibody is successfully prepared, the antibody is good in specificity and high in affinity and can be combinedwith human MSLN expressed on the surface of a cell, and the anti-human MSLN monoclonal antibody is a potential drug for tumor treatment.

Owner:NANJING BLUE SHIELD BIOTECH CO LTD

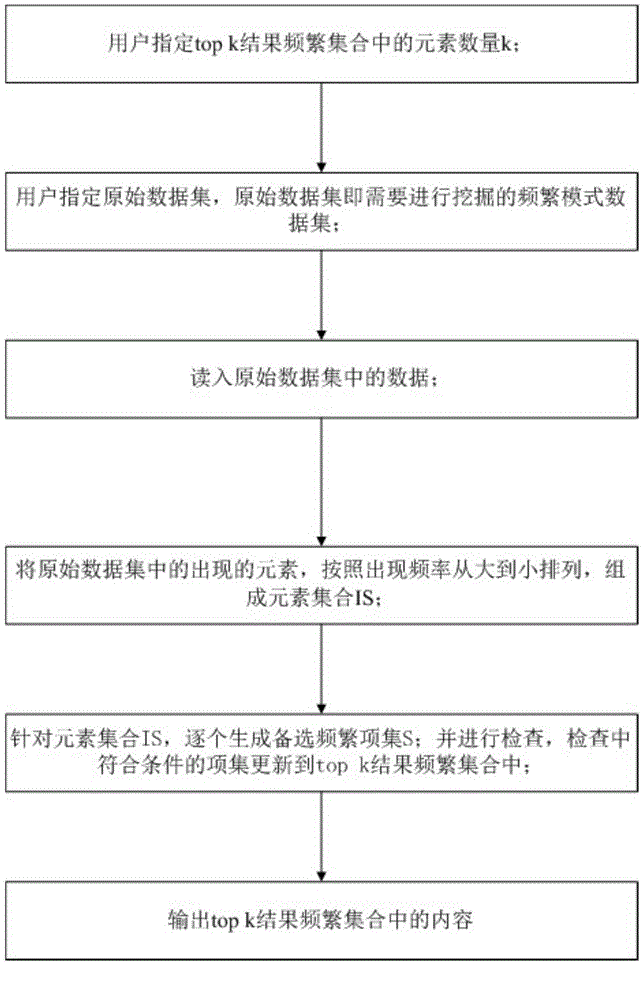

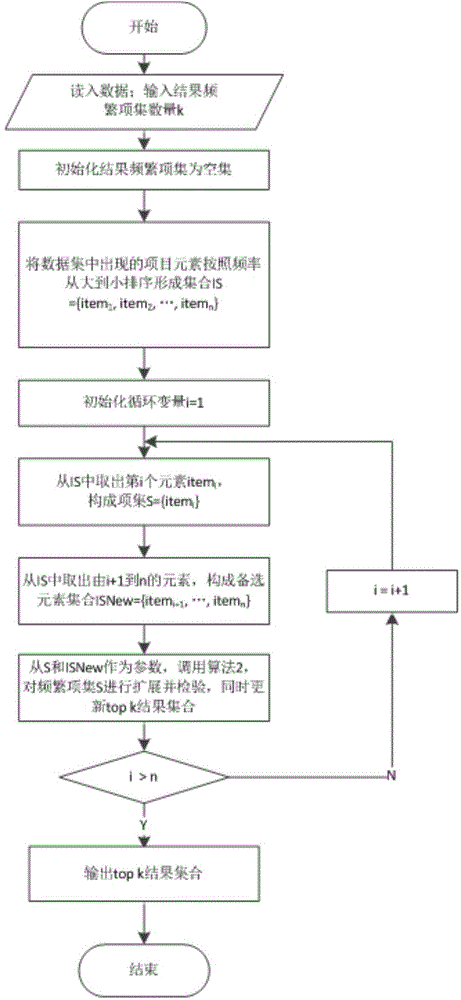

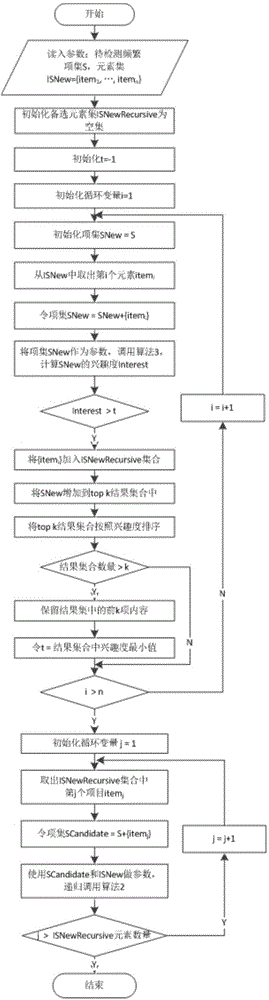

Frequent mode mining method based on interesting measure

InactiveCN104834708AImprove practicalityEasy to useSpecial data processing applicationsData setOriginal data

The invention discloses a frequent mode mining method based on interesting measure. The frequent mode mining method is characterized by comprising the following steps of 1, enabling a user to designate the number k of elements in a top k result frequent set; 2, enabling the user to designate an original data set, wherein the original data set is a to-be-mined frequent mode data set; 3, reading the data in the original data set; 4, sequencing the elements in the original data set from large to small according to the emerging frequency, and combining into an element set IS; 5, according to the element set IS, gradually generating a candidate frequent item set S; checking, and updating the item set meeting the conditions into the top k result frequent set; 6, outputting the content in the top k result frequent set. The method has the advantages that the interesting measure is used as the evaluation reference of the frequent mode mining result, so the practicality of the mining result is improved; the number of algorithm inputting parameters is reduced, and the convenience is realized for user.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

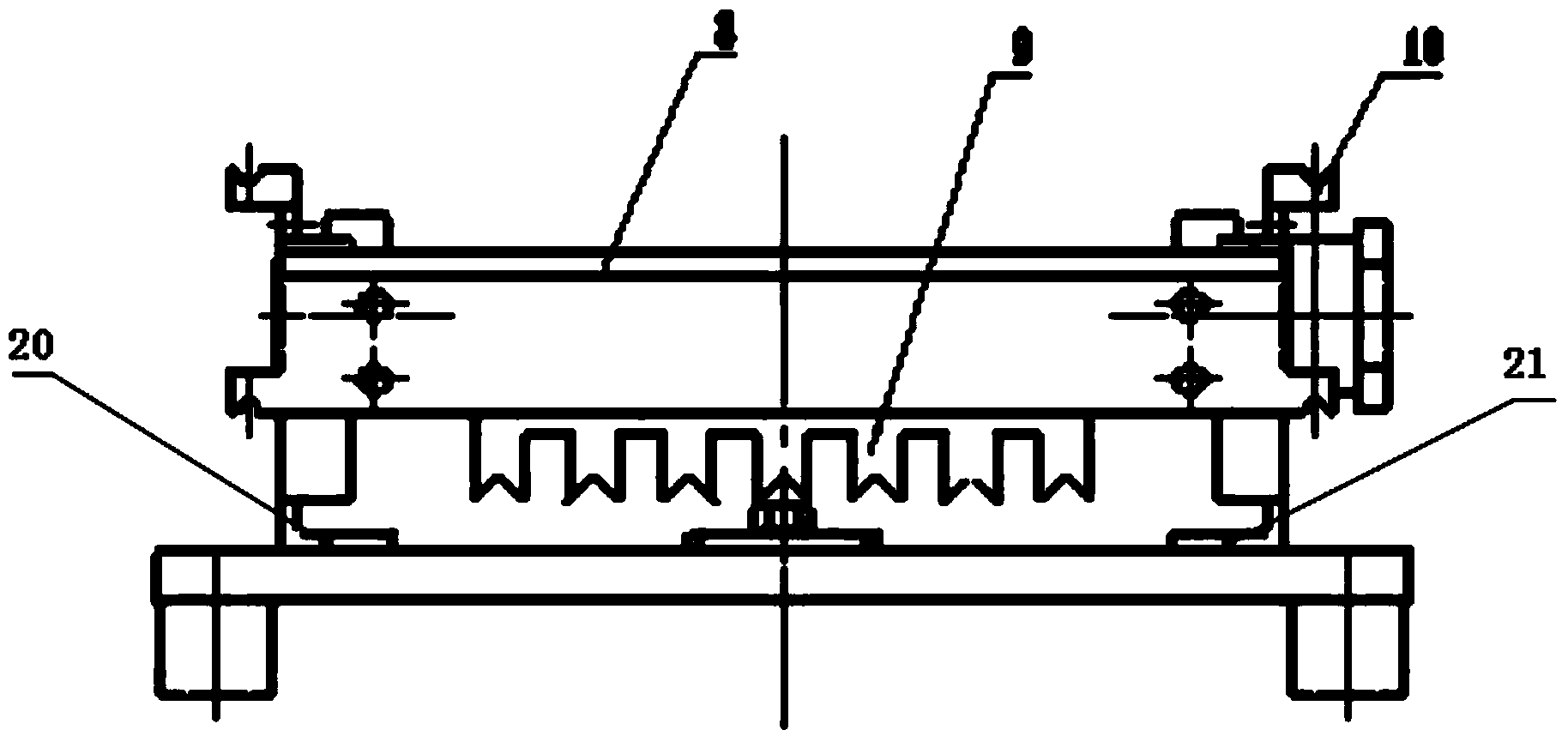

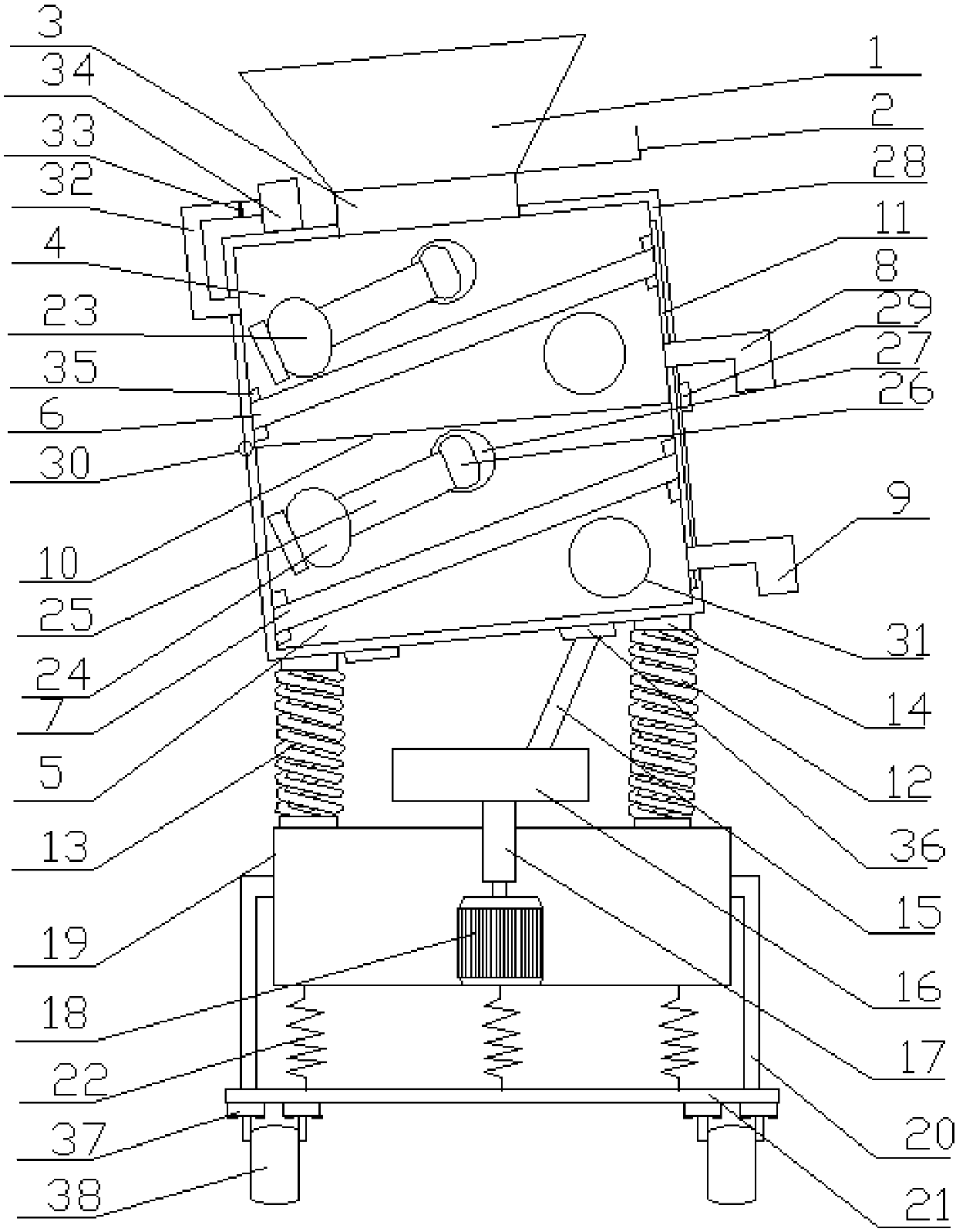

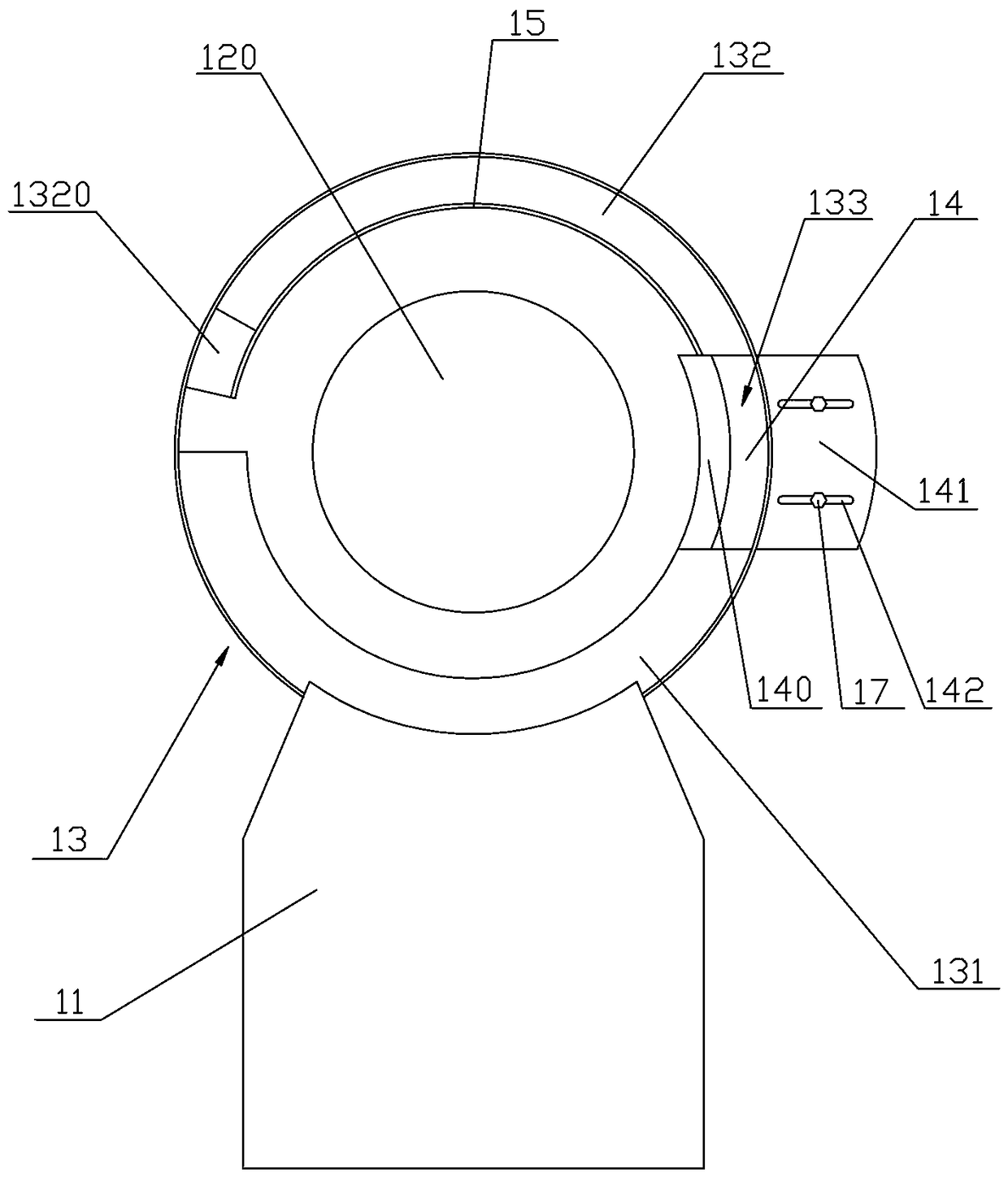

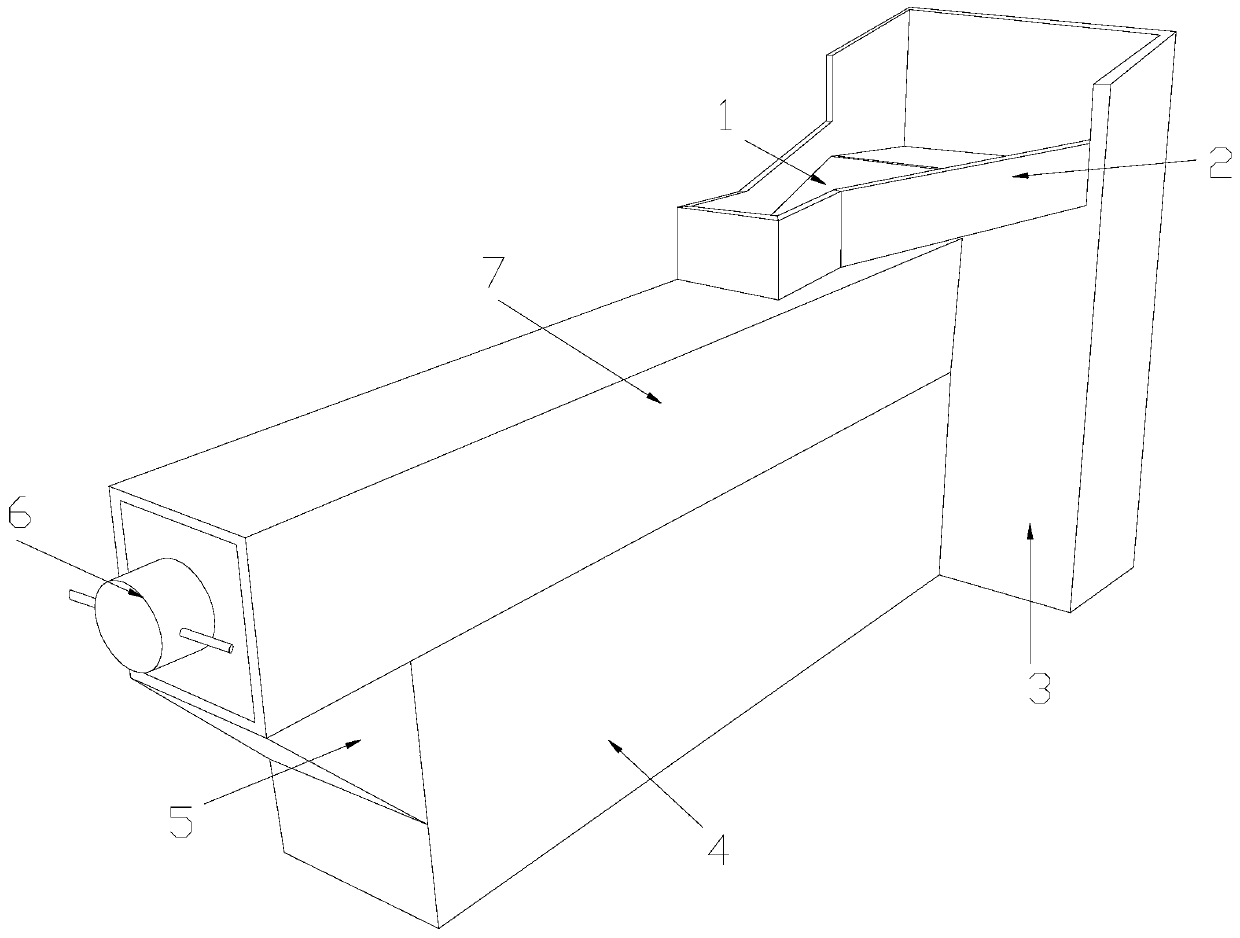

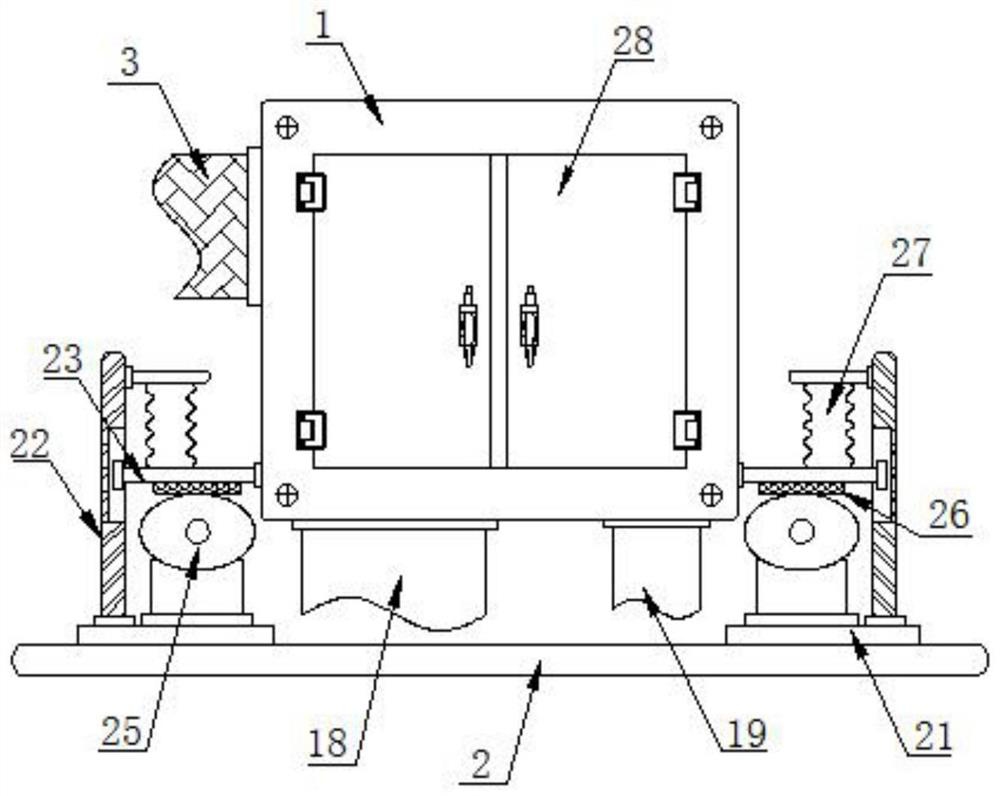

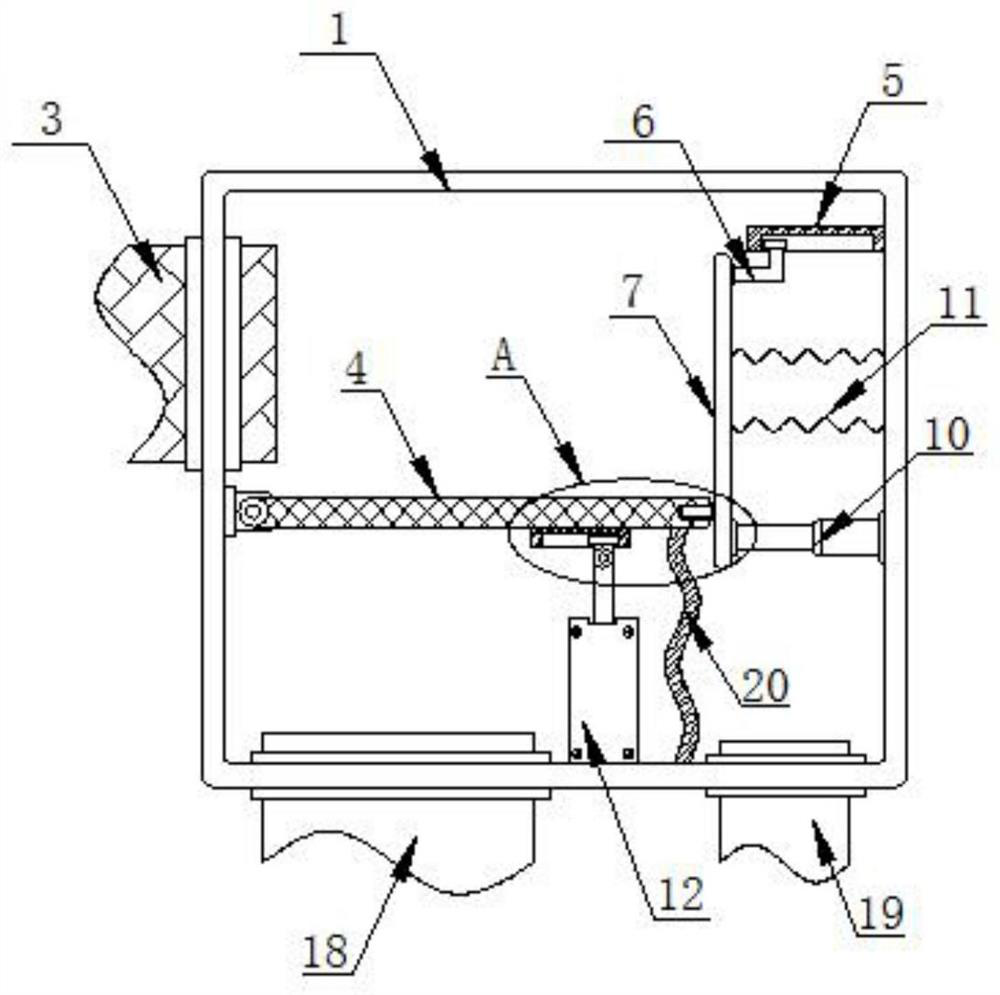

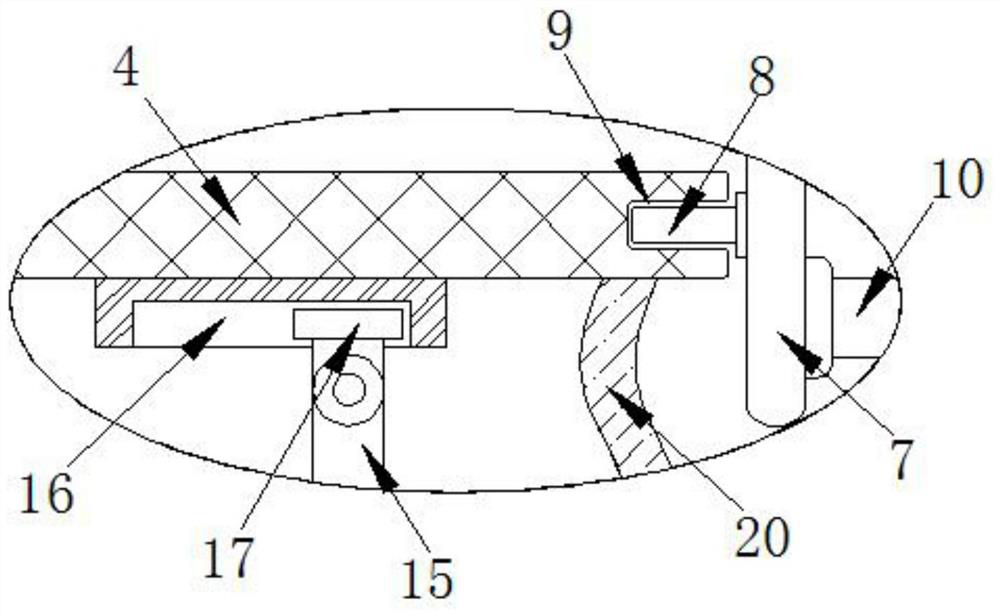

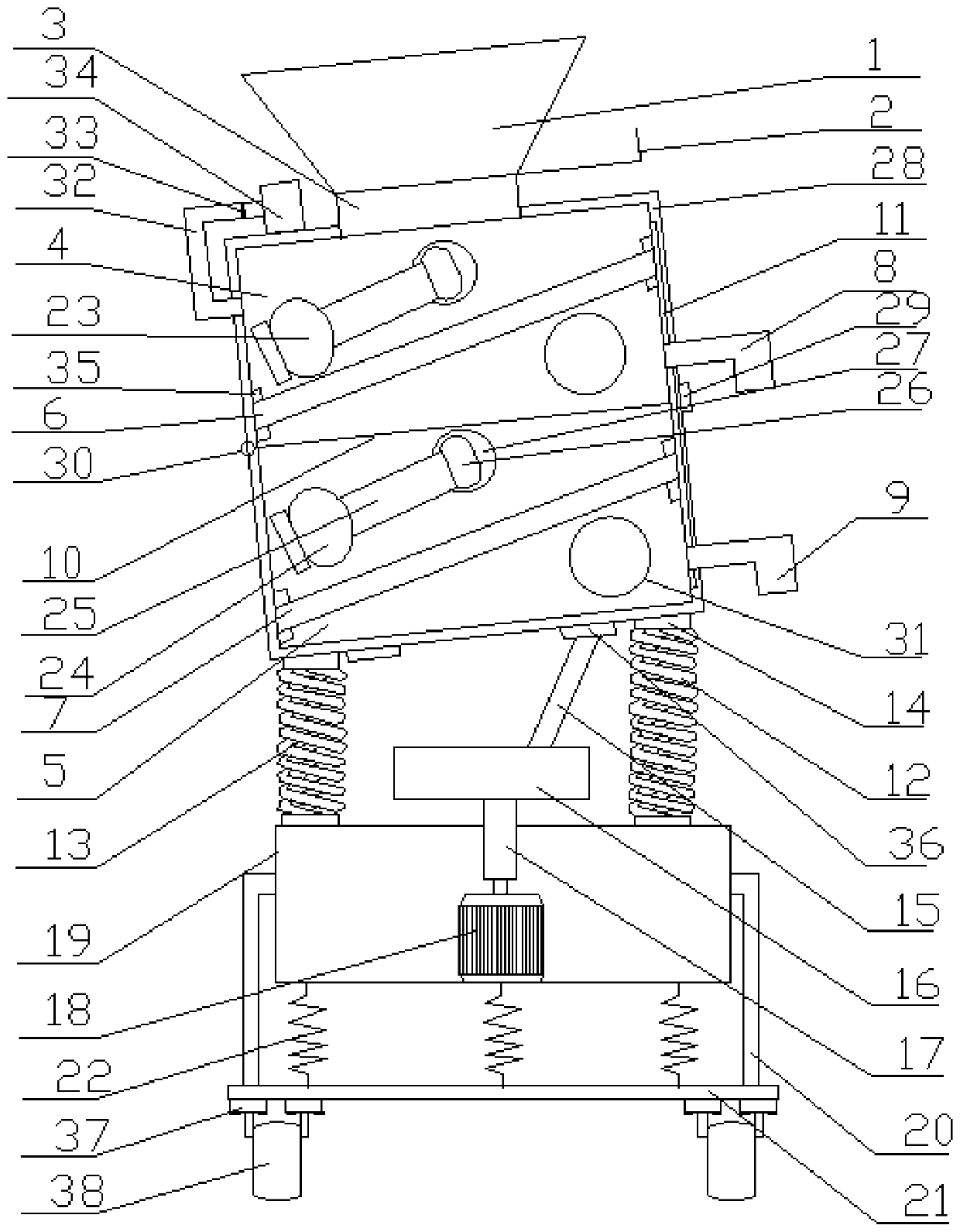

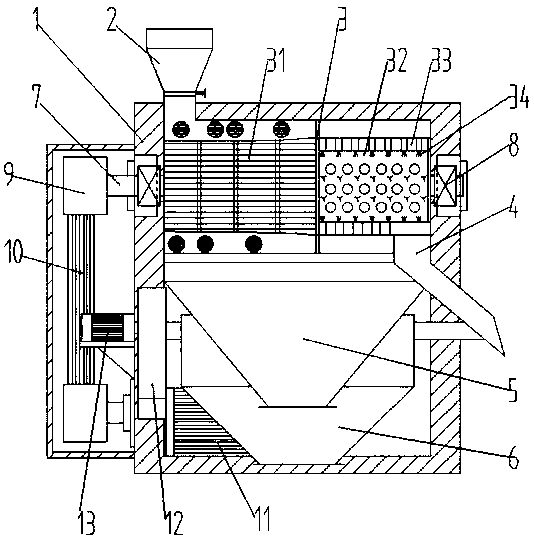

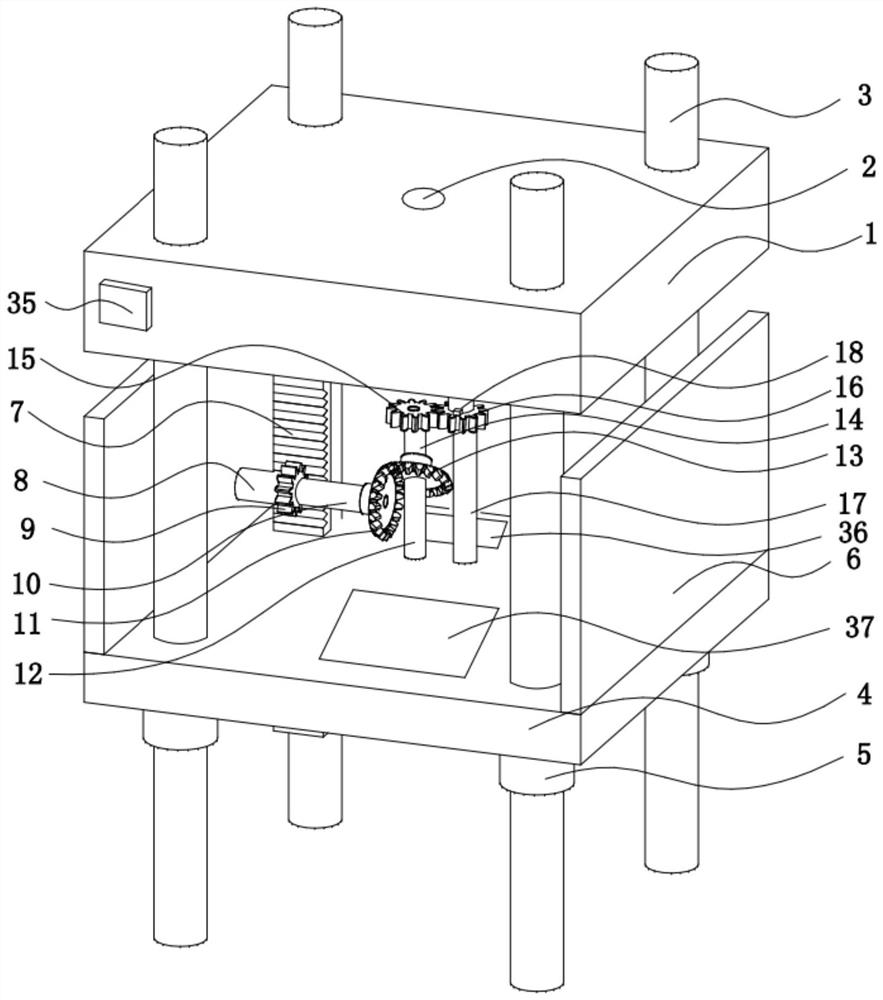

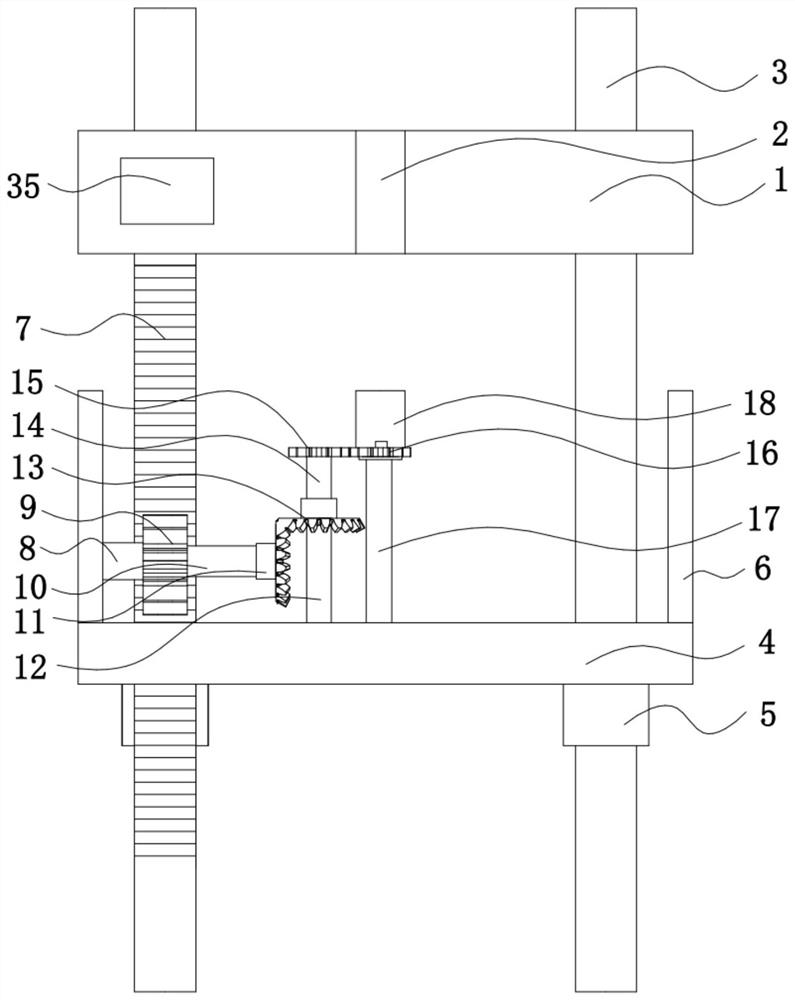

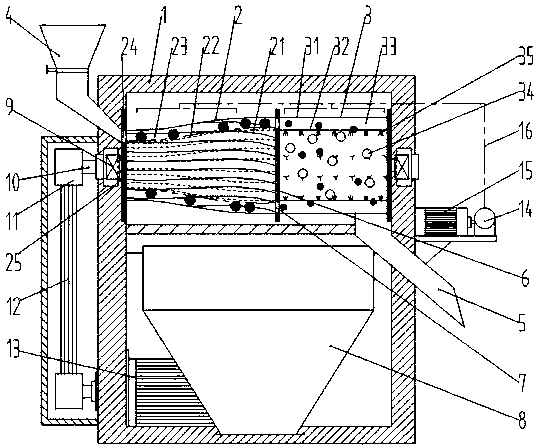

Powder vibrating screen

ActiveCN108043712APrevent splashShort contact distanceSievingScreeningScreening proceduresElectric machinery

The invention discloses a powder vibrating screen. The powder vibrating screen comprises a feeding device, a screening device, a driving device and a cushioning device. The area of a top opening of abuffer hopper is larger than that of a bottom opening of the buffer hopper. The buffer hopper is arranged above a feeding inlet. The axis of the buffer hopper coincides with that of the feeding inlet.A feeding slide door penetrates through the feeding inlet in the horizontal direction and further extends out of the feeding inlet. The buffer hopper is in an inverted pyramid shape. Materials can slide into the feeding inlet along the oblique plane of the buffer hopper, and the phenomenon of material splashing caused when the materials are directly poured into the feeding inlet in the vertical direction of the bottom of the feeding inlet is avoided. The feeding slide door plays the effects of opening the feeding inlet and adding the materials, and meanwhile the effects of closing the feedinginlet and preventing the materials from splashing in the screening operation process can be achieved. The screening process of the coarse powder material and the screening process of the fine powdermaterial are both driven by a driving motor, so that screening efficiency is guaranteed, the screening procedure is omitted and the applied range is made wider.

Owner:湖南太子新材料科技有限公司

Anti-human GPC3 monoclonal antibody

ActiveCN110627904AImprove water solubilityHigh resistance and stabilityImmunoglobulins against cell receptors/antigens/surface-determinantsAntibody ingredientsImmunotherapyPhage display

The invention discloses an anti-human GPC3 monoclonal antibody which is a specific high-affinity nanometer antibody developed by using human GPC3 as a target on the basis of a phage display technology. Compared with the prior art, the anti-human GPC3 monoclonal antibody is successfully prepared; the antibody has high specificity and high affinity, and can be combined with the human GPC3 expressedon the cell surfaces; and the anti-human GPC3 monoclonal antibody belongs to potential medicine for tumor immunotherapy.

Owner:NANJING BLUE SHIELD BIOTECH CO LTD

A sintering method for sintering base material

The invention discloses a sintering bedding material, and a manufacturing method and sintering method thereof, relating to the technical field of ferrous metallurgy. The sintering bedding material comprises the following components in parts by weight: 48-52 parts of sintering dust, 20-24 parts of gas ash, 14-16 parts of gas sludge, 11-12.8 parts of converter dust and 1.0-1.2 parts of bentonite. The particle size of the sintering bedding material is 7-20mm, and the thickness of the sintering bedding material is 25-35mm. The technique can save abundant finished sinter and lump ore resources, greatly enhance the sintered ore yield and output and lower the fuel consumption and production cost. The sintering bedding material can sufficiently utilize various iron-containing dust and sludge generated in the steel production process, thereby changing wastes into valuable substances and reducing the environmental pollution. The technique has favorable effect, is simple and easy to implement, only needs to add one iron-containing dust and sludge pelletizer, and has the advantages of high feasibility for popularization and application and high practical value.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

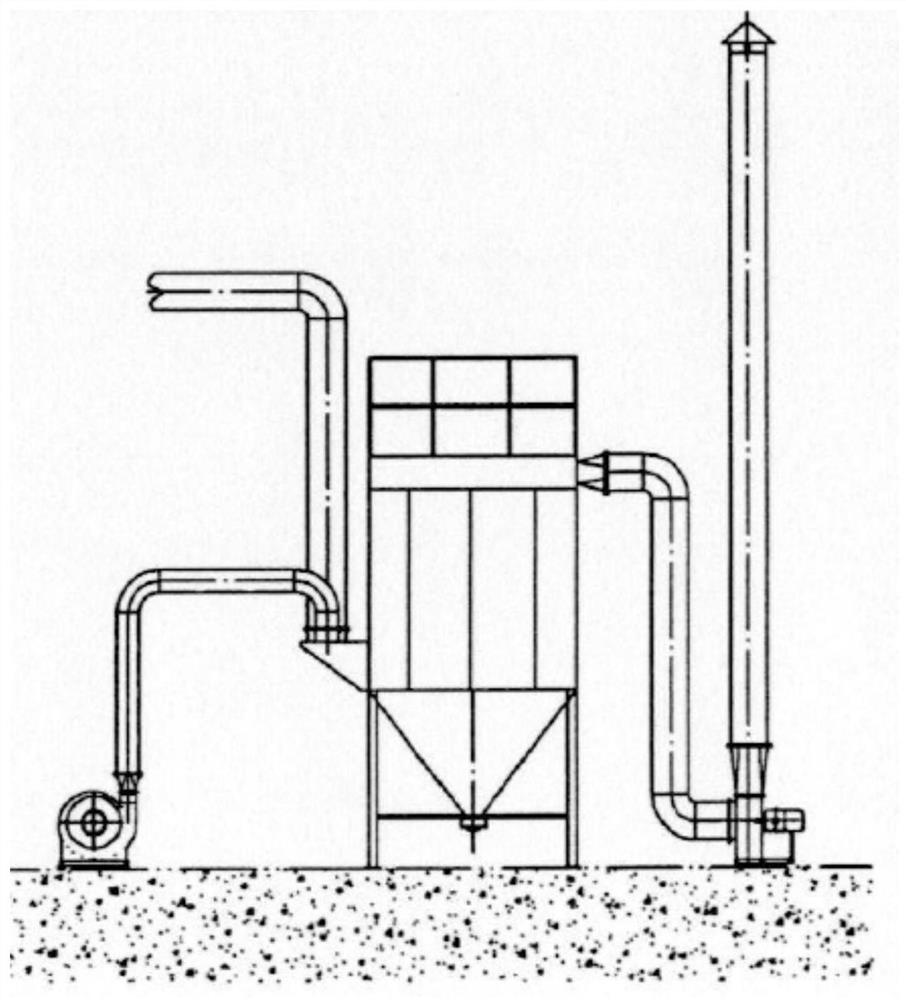

Solid waste crushing treatment system

ActiveCN113751173AImprove selection rateSmall output volumeSievingScreeningPhysical chemistryMetal impurities

The invention provides a solid waste crushing treatment system. The solid waste crushing treatment system comprises a first crushing device, a second crushing device and a magnetic separation device; the first crushing device is used for primary crushing of solid waste to generate first particles, and the particle size of at least 90% of the first particles is smaller than or equal to 150 mm; the second crushing device is used for crushing the first particles to generate second particles, and the particle size of the second particles is smaller than or equal to 100 mm; and the magnetic separation device is arranged between the first crushing device and the second crushing device and is used for removing metal impurities in the first particles. According to the solid waste crushing treatment system, the solid waste crushed particles generated by the system are stable in combustion, and the production process is high in automation degree and environmentally friendly.

Owner:TIANJIN GREEN AID ENVIRONMENTAL TECH CO LTD +1

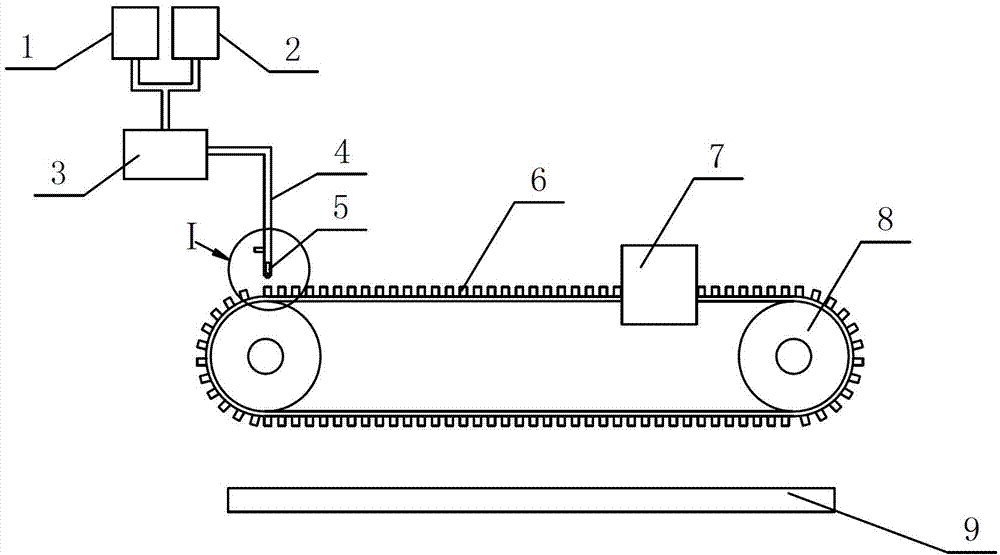

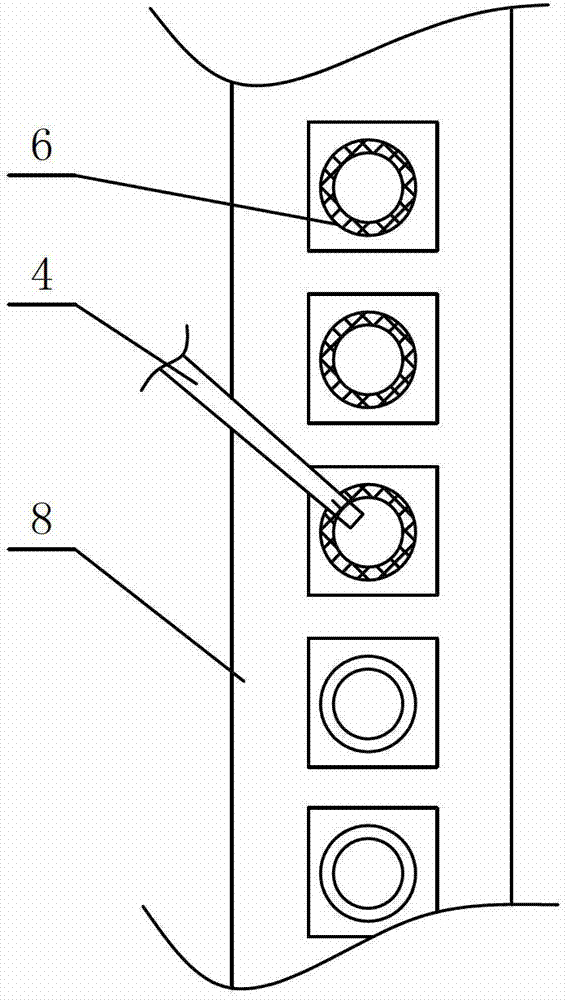

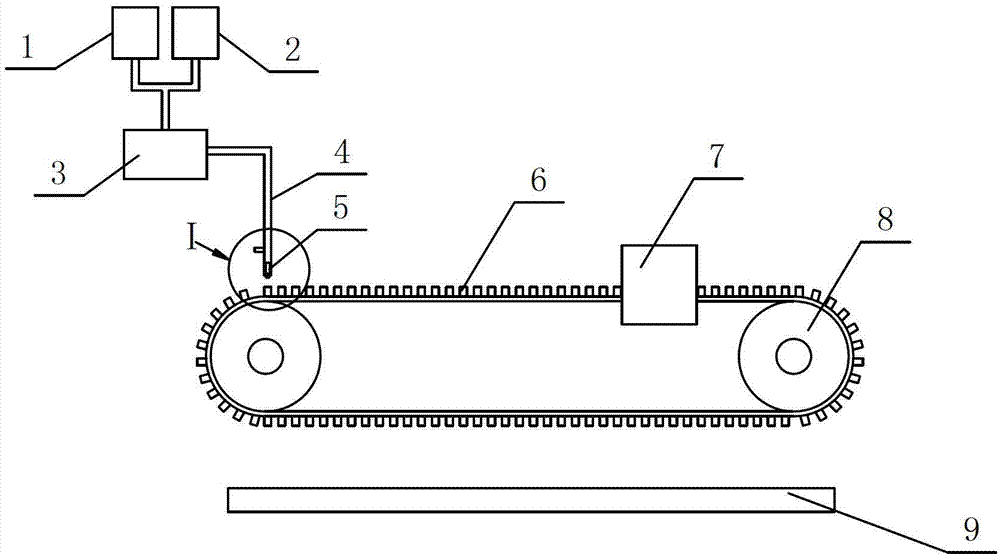

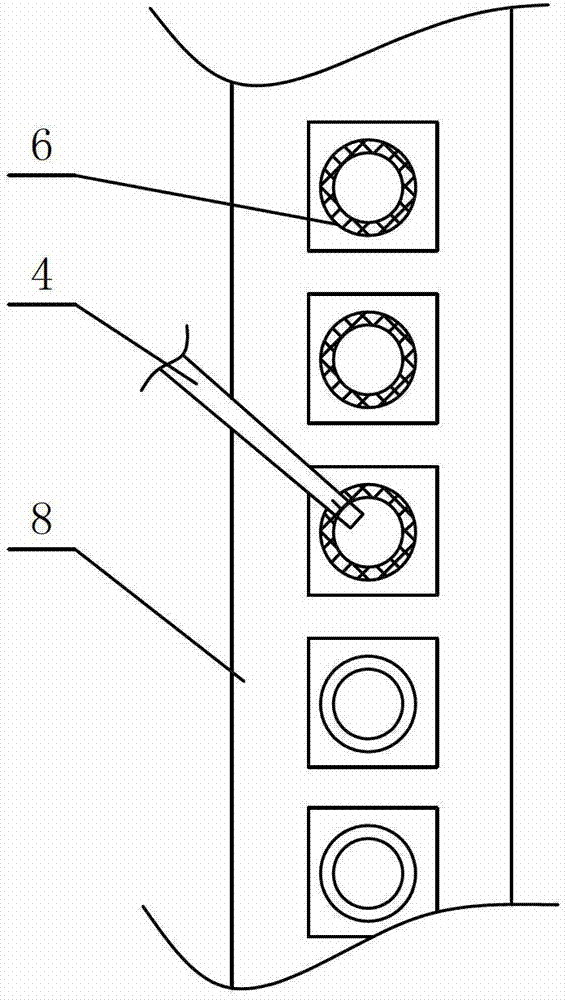

Production process of foaming headset sleeve

InactiveCN102857855AReduce production processImprove molding qualityElectrical transducersMixed materialsMaterials science

The invention discloses a production process of a foaming headset sleeve, and the production process comprises the following steps of a, preparation of materials: placing a well mixed material A and a well mixed material B respectively into a mixing kettle to be stirred; b, mixing: simultaneously placing the material A and the material B into the mixing kettle to be adequately stirred and mixed to form a mixed material; c, injection: continuously injecting the mixed material into a plurality of molds which are matched with each headset sleeve in shape through a mixing reaction kettle, arranging the molds in a single row in the transverse direction, and realizing automatic circular work through a transmission device; d, baking: automatically feeding the molds with the mixed material into a baking box to be baked through the transmission device; and e, demolding: pouring out the headset sleeves from the molds through the transmission device so as to enable the headset sleeves to be separated from the molds after baking is completed. Compared with the prior art, the production process of the foaming headset sleeve has the advantages of simplicity in production equipment, few in manufacturing procedures, simplicity in mold structure, long in service life, capability of being formed in one step, good forming quality, low production cost and low energy consumption.

Owner:刘天镐

Plastic granulation equipment

The invention provides plastic granulation equipment. The equipment comprises a tilted guide plate, a containing frame, a pulverizing controlling table, a placing supporting box, a uniform mixing cyclic internal clearing device, a maintaining sealing member and a melted material granulating tube; the tilted guiding plate is arranged in the containing frame, the right end of the containing frame is fixedly connected with the top of the pulverizing controlling table by electric welding, and the bottom of the melted material granulating tube is fixedly installed in the placing supporting box. According to the equipment, plastic materials have certain plasticity when just being cut and shaped, the plastic materials are divided and hit a sector section on a condense concave-convex grinding plate when dropping due to the pumping and sucking on internal heat air flow by an air suction device, so that sharp edges of the plastic granules are grinded when roll down from the top to ensure the uniform size of the plastic granules, a uniform mixing switching mechanism is controlled by the passive braking of a pressing drawing and switching mechanism to regulate an impacting air hole switching mechanism to allow the plastic granules blocked on the condense concave-convex grinding plate to drop in batches, the appearance is more attractive, and the screening procedure needed before packaging and selling can be directly omitted.

Owner:泰州市曙明塑胶有限公司

Grate cooler head cover blanking device capable of improving production efficiency

ActiveCN112444132AIncrease productivityQuality assuranceHandling discharged materialClinker productionEngineeringMechanical engineering

The invention discloses a grate cooler head cover blanking device capable of improving the production efficiency. The grate cooler head cover blanking device comprises a head cover, a bottom mountingplate and a cooling cylinder; one end of the cooling cylinder is communicated with one side of the head cover; one side of an inner cavity of the head cover is rotationally connected with a filteringplate through a rotating piece; the right side of the inner cavity of the head cover is fixedly connected with a first chute plate; and a sliding rod is slidably connected into the first chute plate.The grate cooler head cover blanking device capable of improving the production efficiency relates to the technical field of cement processing equipment. According to the grate cooler head cover blanking device capable of improving the production efficiency, during blanking, cement materials can be screened, the cement materials with qualified particle sizes are rapidly guided out, meanwhile, thecement materials with unqualified particles are collected, the cement processing quality is guaranteed, meanwhile, the subsequent screening procedure is omitted, the working efficiency is improved, when a cooler carries out blanking, the head cover can be shaken, the filtering plate and a blanking channel are prevented from being blocked, and meanwhile the material filtering efficiency is improvedto a large extent.

Owner:湖北宜飞复合新材料有限公司

Production process of foaming headset sleeve

InactiveCN102857855BReduce production processImprove molding qualityElectrical transducersMixed materialsMaterials science

The invention discloses a production process of a foaming headset sleeve, and the production process comprises the following steps of a, preparation of materials: placing a well mixed material A and a well mixed material B respectively into a mixing kettle to be stirred; b, mixing: simultaneously placing the material A and the material B into the mixing kettle to be adequately stirred and mixed to form a mixed material; c, injection: continuously injecting the mixed material into a plurality of molds which are matched with each headset sleeve in shape through a mixing reaction kettle, arranging the molds in a single row in the transverse direction, and realizing automatic circular work through a transmission device; d, baking: automatically feeding the molds with the mixed material into a baking box to be baked through the transmission device; and e, demolding: pouring out the headset sleeves from the molds through the transmission device so as to enable the headset sleeves to be separated from the molds after baking is completed. Compared with the prior art, the production process of the foaming headset sleeve has the advantages of simplicity in production equipment, few in manufacturing procedures, simplicity in mold structure, long in service life, capability of being formed in one step, good forming quality, low production cost and low energy consumption.

Owner:刘天镐

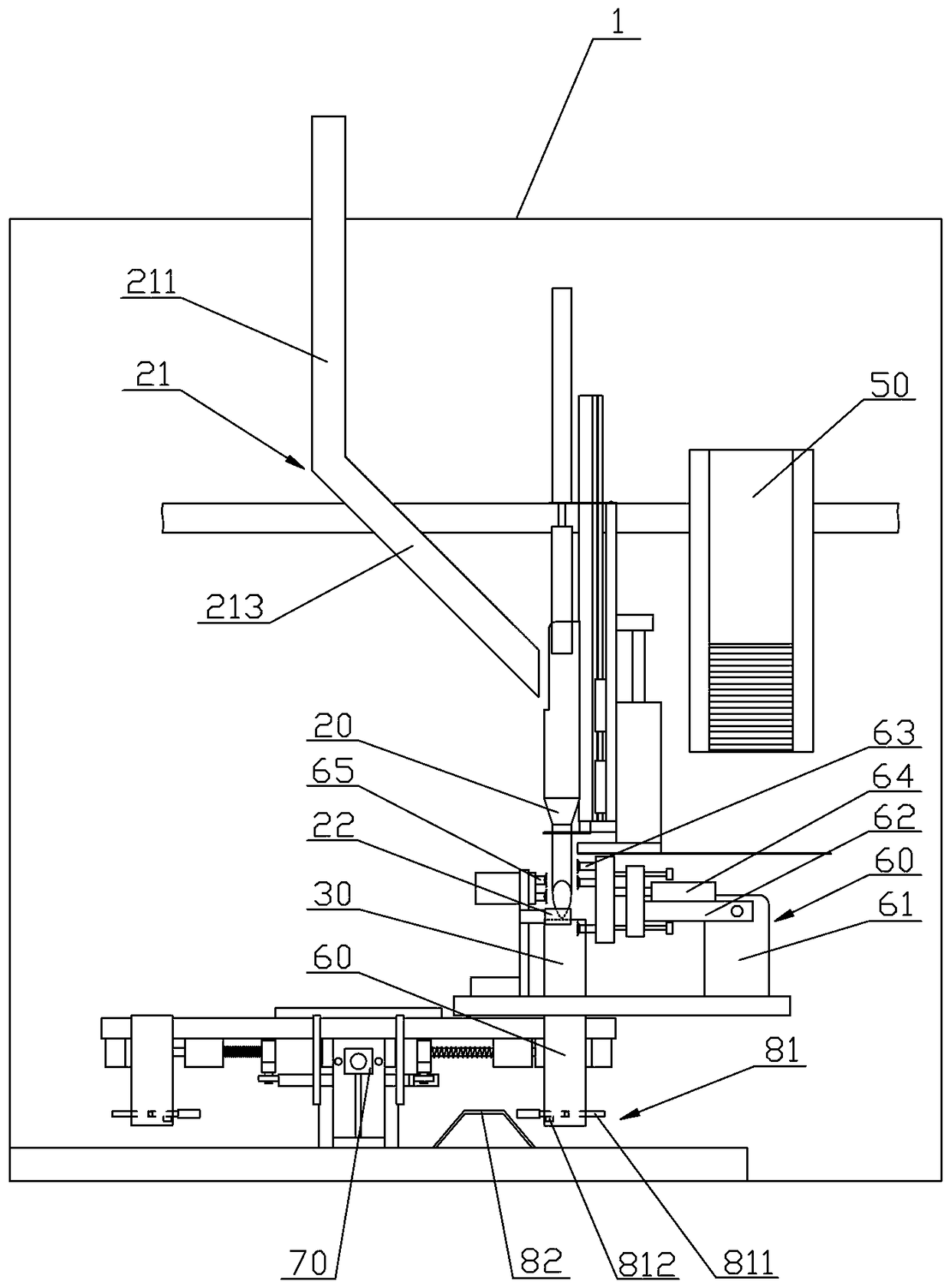

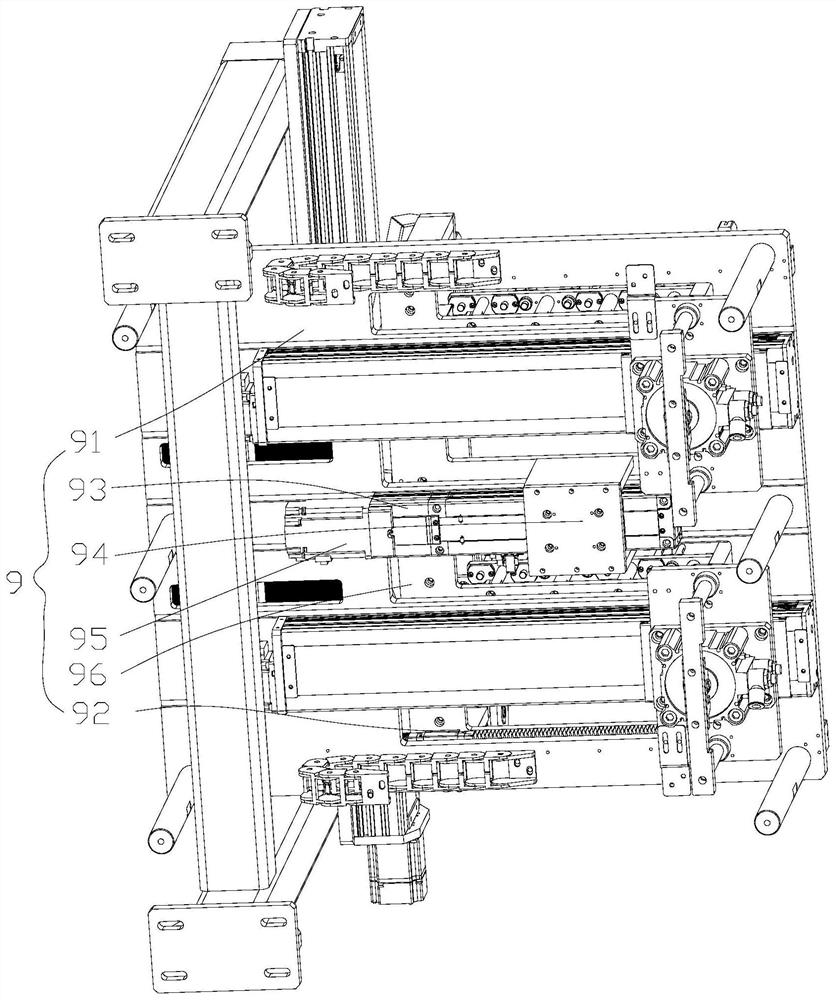

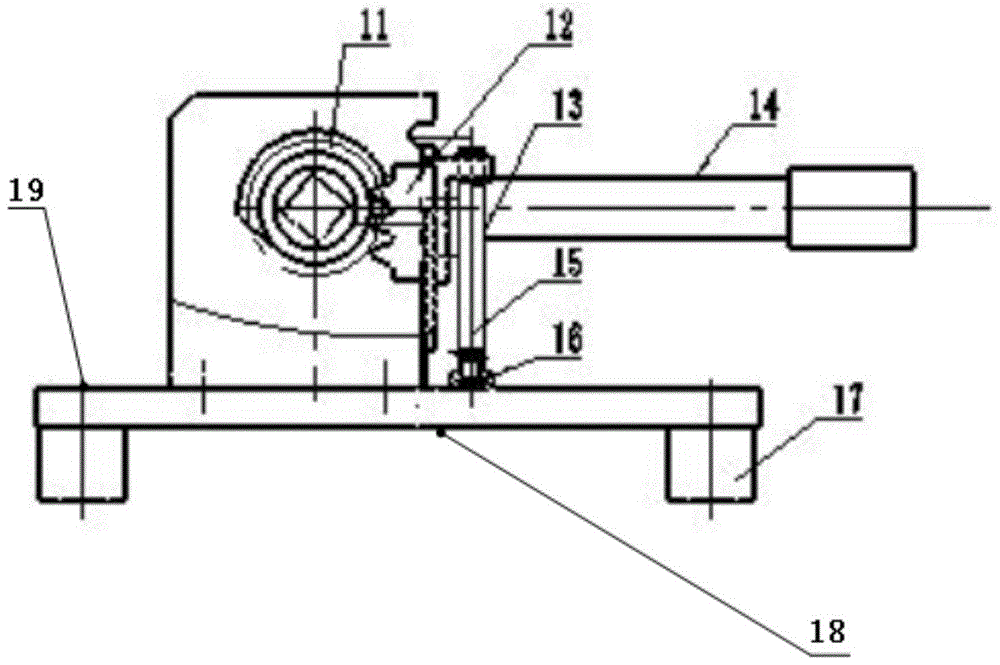

Full-automatic multi-bar feeding and cutting device and method

PendingCN113953954AGuaranteed cutting accuracyImprove cutting efficiencyGrinding drivesGrinding machinesBar stockWaste material

The invention is suitable for the field of cutting devices, and provides a full-automatic multi-bar cutting device. The full-automatic multi-bar cutting device comprises a first support and a cutting module, further comprises a feeding module, the feeding module comprises a material pressing assembly used for pressing the first ends of multiple bars and a feeding assembly used for pressing the second ends of the multiple bars and pushing the multiple bars to the pressing assembly, the feeding module further comprises a material supporting plate assembly used for loading a plurality of bars, the material pressing assembly and the feeding assembly are arranged at the two ends of the material supporting plate assembly correspondingly, and the cutting module comprises a cutting sliding rail arranged on a first support and a cutting part capable of sliding along the cutting sliding rail and used for cutting the bars. The invention further provides a full-automatic multi-bar cutting method. According to the full-automatic multi-bar feeding and cutting device and method, full-automatic feeding and cutting of the multiple bars are achieved, the cutting precision and efficiency are high, the bars with cut middle sections can be separated from head and tail waste, and time and labor are saved.

Owner:SHENZHEN JINZHOU PRECISION TECH

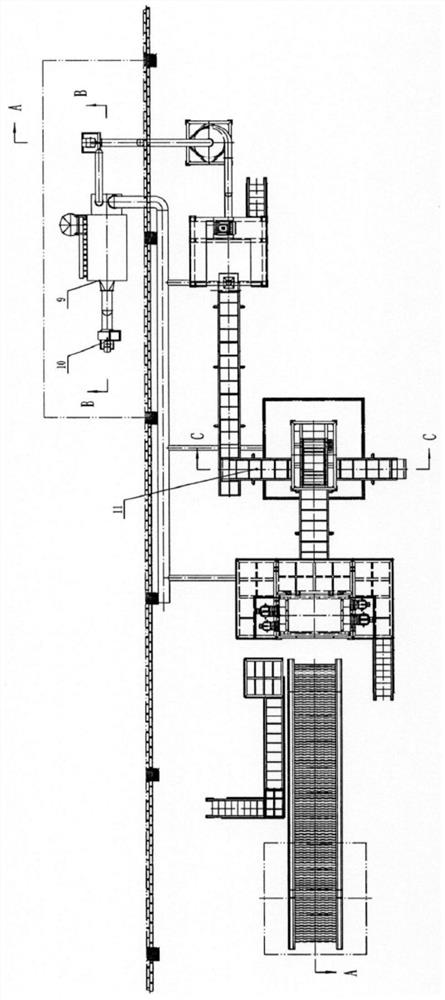

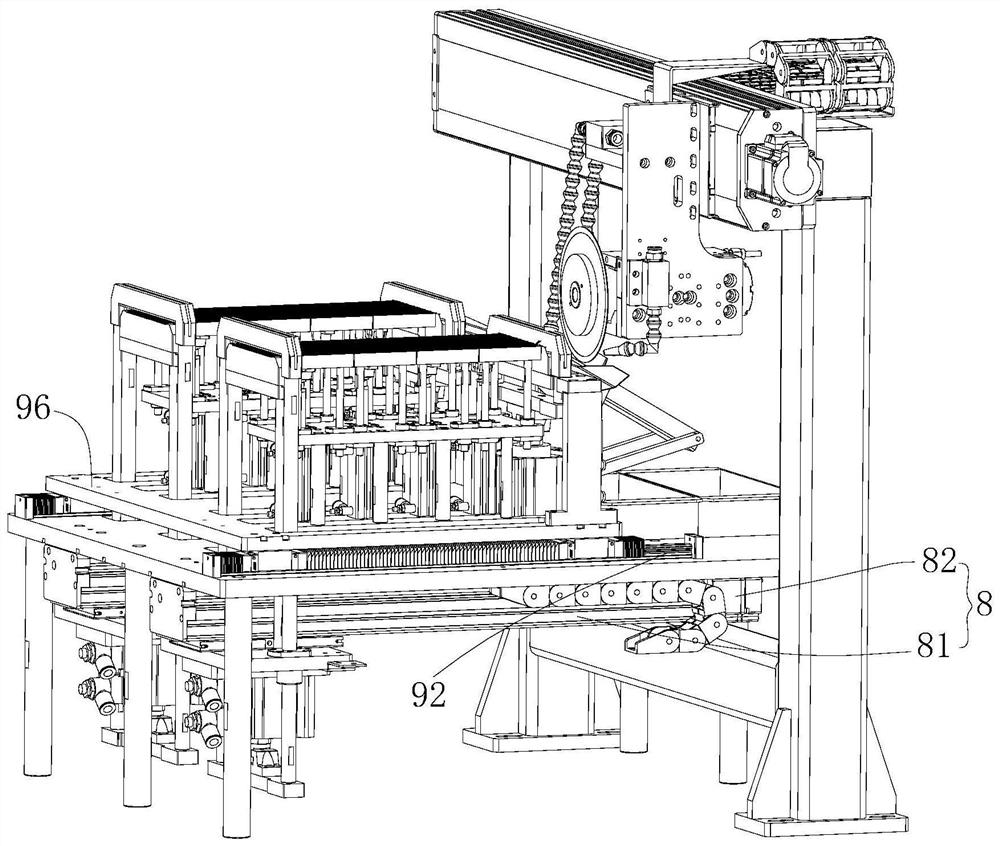

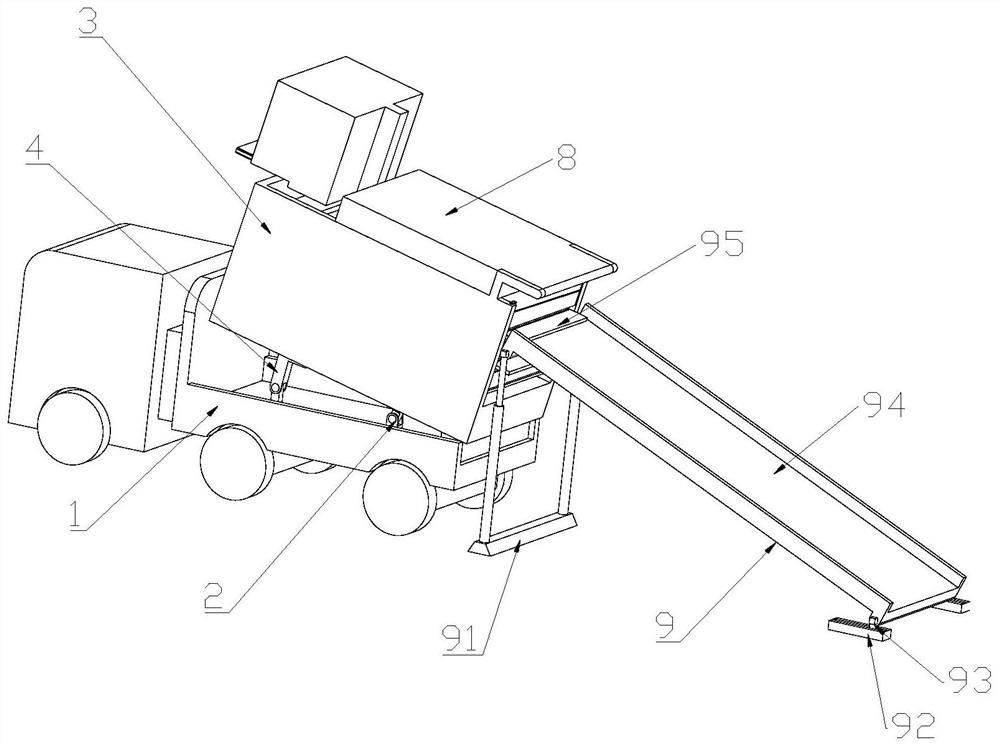

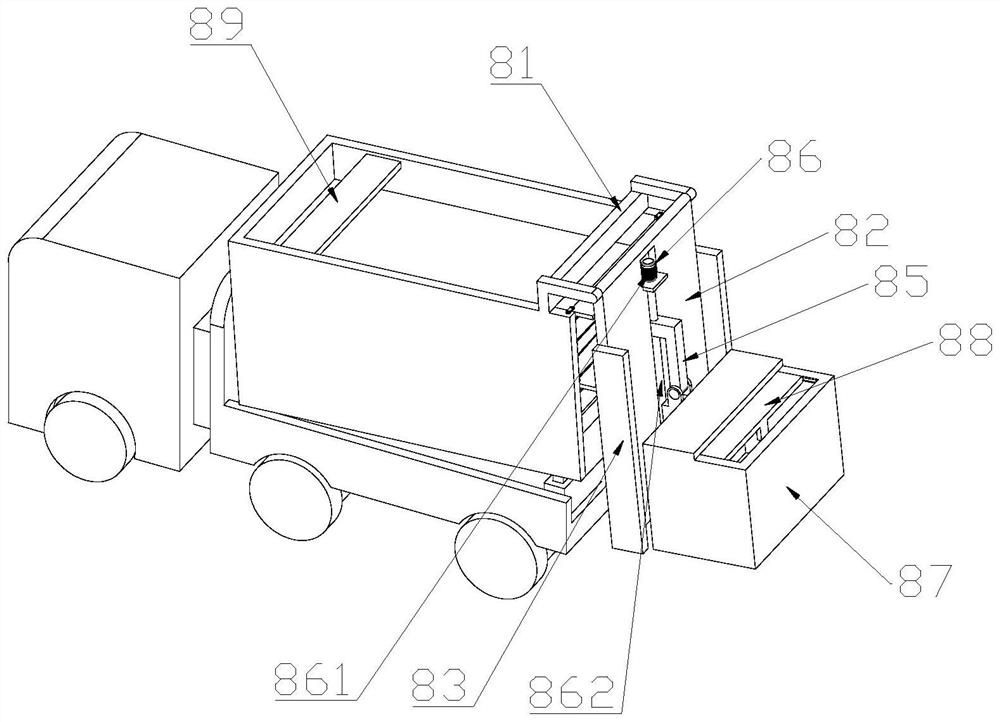

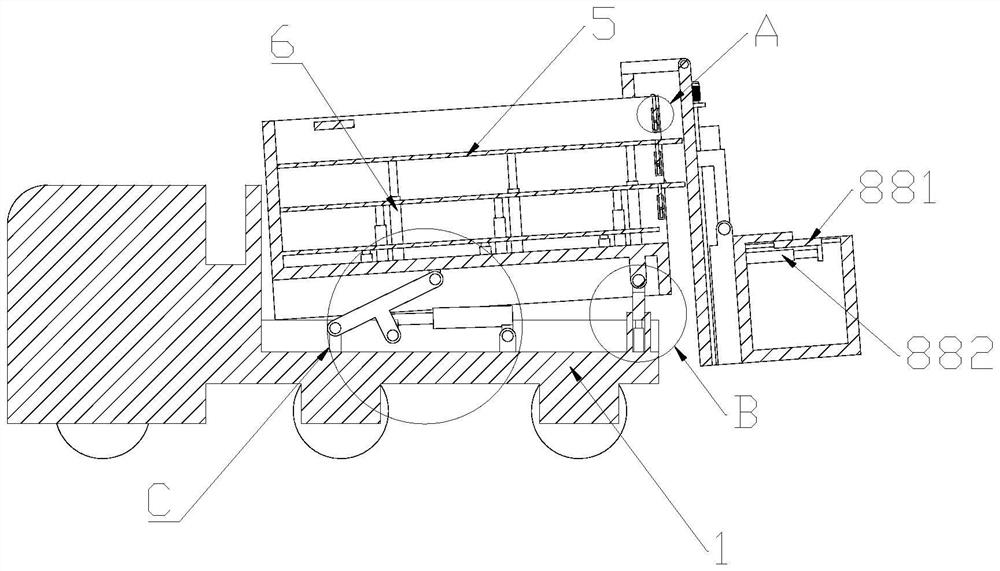

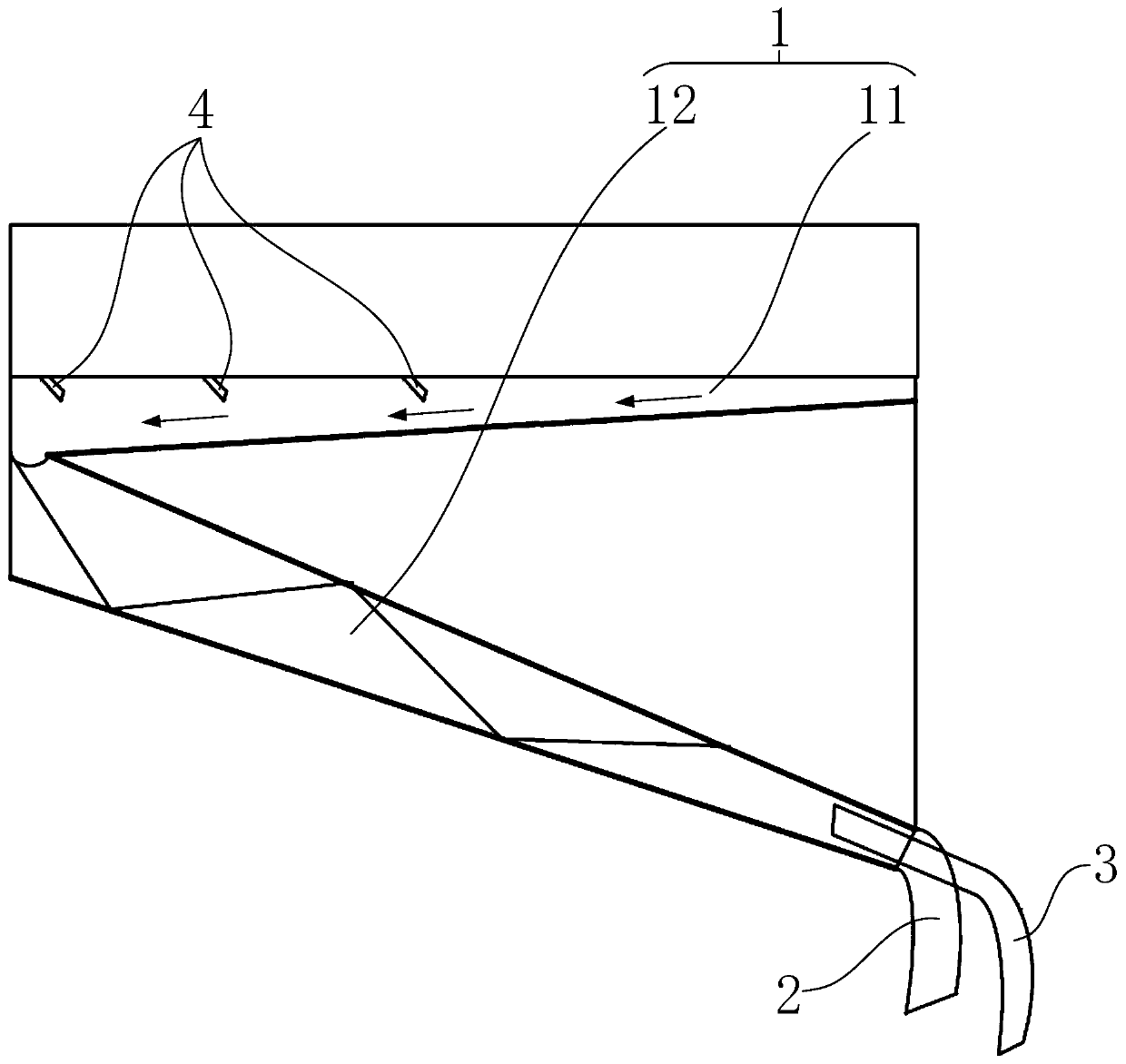

Dumper for sorting and transferring engineering ores

ActiveCN113997848AEvenly distributedReduce screening processSievingScreeningCarriageIndustrial engineering

The invention discloses a dumper for sorting and transferring engineering ores, which comprises a chassis, a first lifting device is arranged on the chassis, a carriage is rotatably arranged on the first lifting device, a second lifting device for driving the carriage to rotate is arranged on the chassis, and the second lifting device is slidably connected with the carriage. A plurality of layers of filter sieves are arranged in the carriage, a feeding device is arranged on the carriage and comprises a cover plate support fixed above the carriage, the cover plate support is located at the position close to the tail of the carriage, a cover plate is rotatably arranged on the cover plate support, and an L-shaped support is slidably arranged on the cover plate. According to the dumper, by arranging the first lifting device and the second lifting device, the carriage can incline towards the two sides, when the carriage inclines towards the side close to the truck head, ore can flow towards the truck head side in the feeding process, it can be guaranteed that the ore is evenly distributed, and the ore with the small specification can be screened into the filter sieve on the lower layer.

Owner:安徽省青阳县荣华炉料有限公司

Anti-human msln monoclonal antibody and its application

ActiveCN111349165BReduce volumeStrong tissue penetrationImmunoglobulins against cell receptors/antigens/surface-determinantsAntibody ingredientsSingle-Chain AntibodiesTumor therapy

The invention discloses an anti-human MSLN monoclonal antibody and an application thereof, which is a specific and high-affinity single-chain antibody developed based on phage display technology with human MSLN as the target. Compared with the prior art, the present invention has successfully prepared an anti-human MSLN monoclonal antibody, which has good specificity and high affinity, and can bind to human MSLN expressed on the cell surface. potential drugs.

Owner:NANJING BLUE SHIELD BIOTECH CO LTD

A powder vibrating sieve

ActiveCN108043712BPrevent splashShort contact distanceSievingScreeningScreening proceduresElectric machinery

The invention discloses a powder vibrating screen. The powder vibrating screen comprises a feeding device, a screening device, a driving device and a cushioning device. The area of a top opening of abuffer hopper is larger than that of a bottom opening of the buffer hopper. The buffer hopper is arranged above a feeding inlet. The axis of the buffer hopper coincides with that of the feeding inlet.A feeding slide door penetrates through the feeding inlet in the horizontal direction and further extends out of the feeding inlet. The buffer hopper is in an inverted pyramid shape. Materials can slide into the feeding inlet along the oblique plane of the buffer hopper, and the phenomenon of material splashing caused when the materials are directly poured into the feeding inlet in the vertical direction of the bottom of the feeding inlet is avoided. The feeding slide door plays the effects of opening the feeding inlet and adding the materials, and meanwhile the effects of closing the feedinginlet and preventing the materials from splashing in the screening operation process can be achieved. The screening process of the coarse powder material and the screening process of the fine powdermaterial are both driven by a driving motor, so that screening efficiency is guaranteed, the screening procedure is omitted and the applied range is made wider.

Owner:湖南太子新材料科技有限公司

A kind of efficient method for manufacturing ferrite rubber plastic magnetic powder

ActiveCN111370215BImprove performanceReduce screening processIron compoundsMagnetic core manufactureSlurryWet grinding

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

anti-human gpc3 monoclonal antibody

ActiveCN110627904BGood water solubilityImprove patienceImmunoglobulins against cell receptors/antigens/surface-determinantsAntibody ingredientsPharmaceutical drugBacteriophage

Owner:NANJING BLUE SHIELD BIOTECH CO LTD

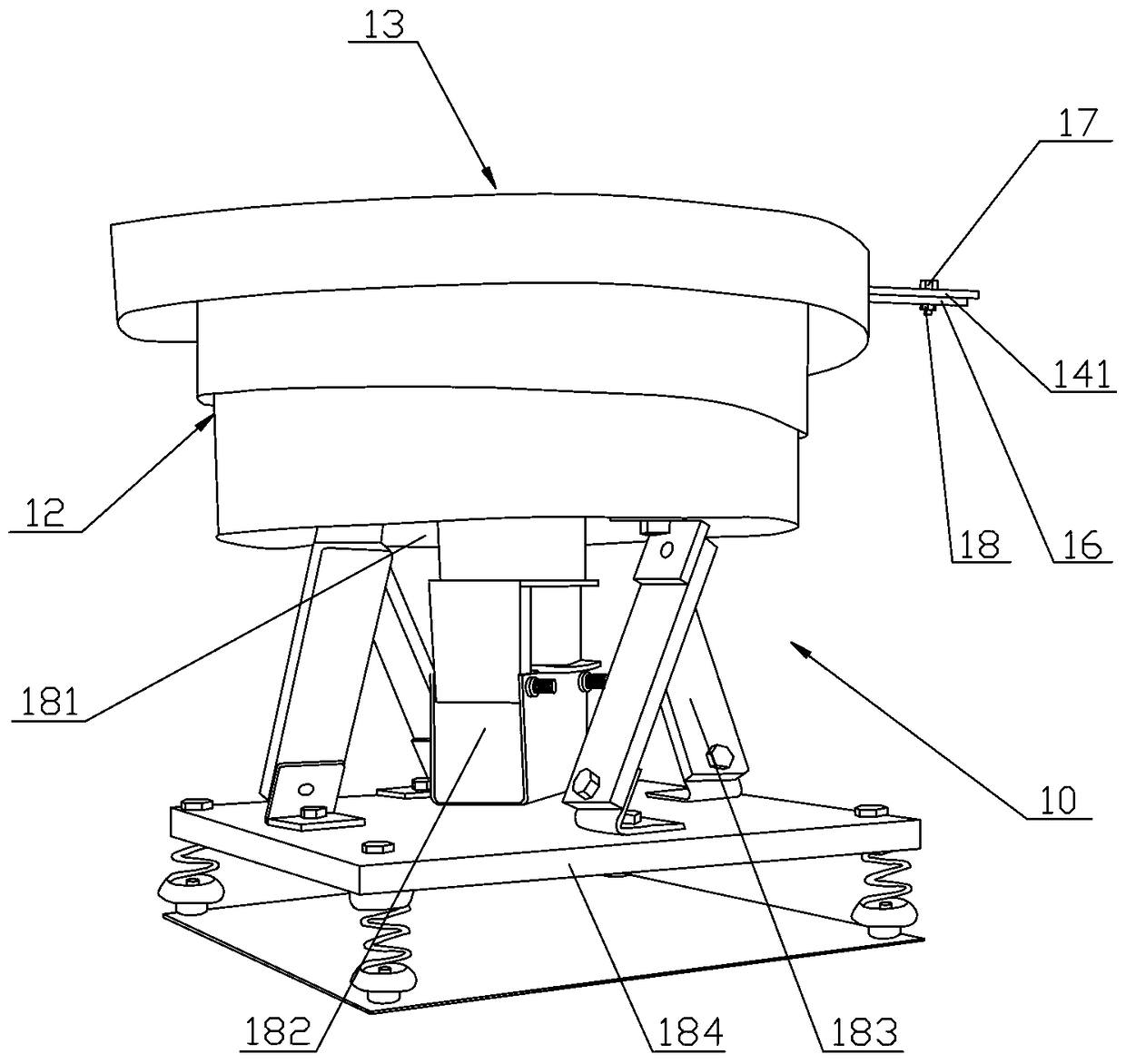

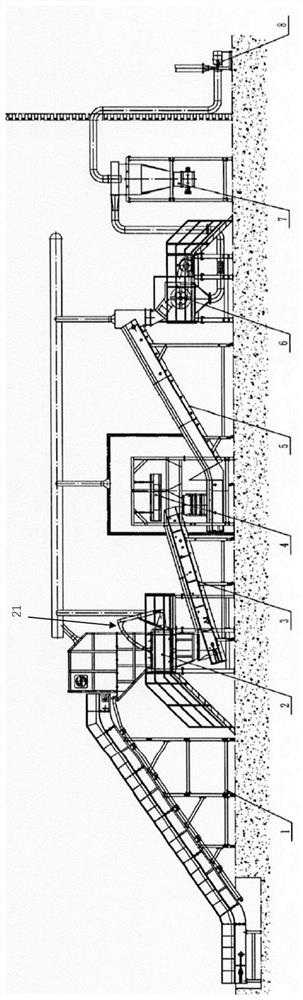

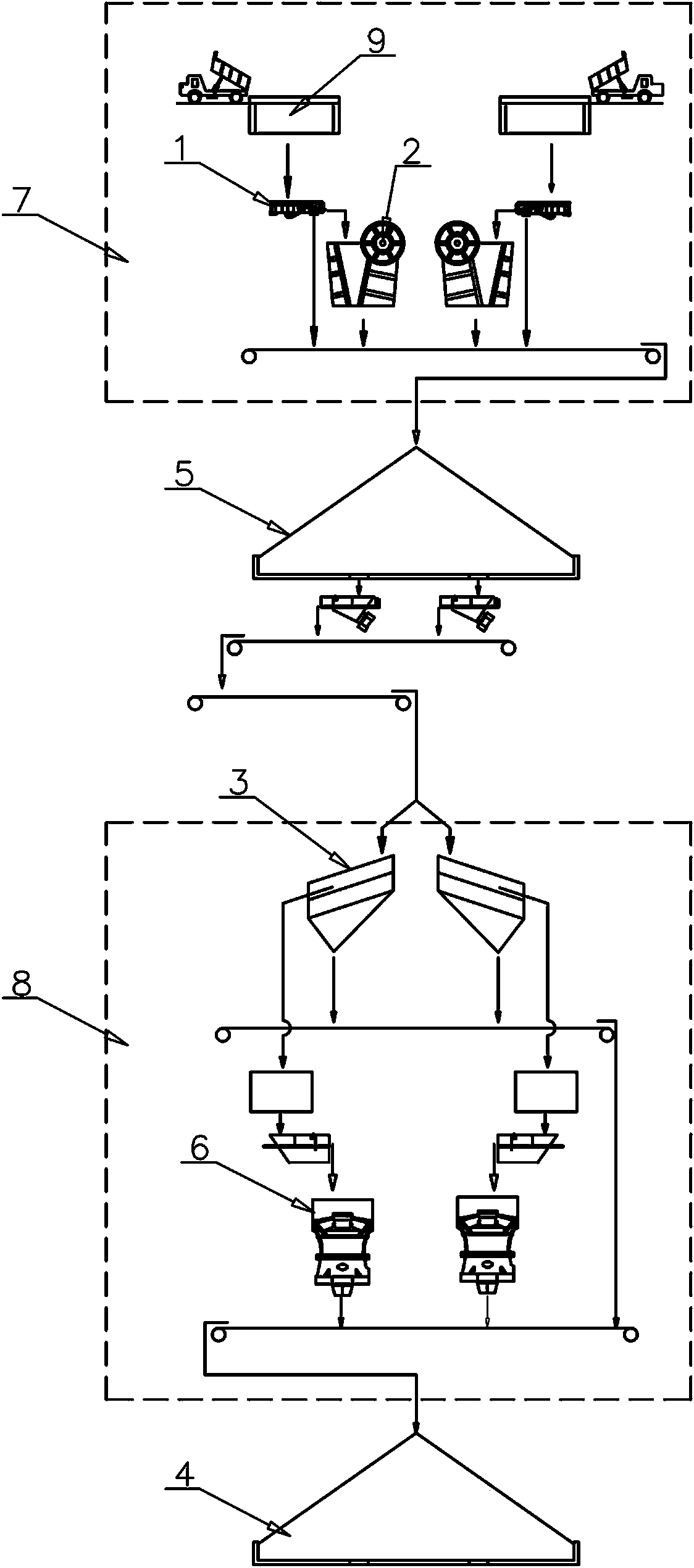

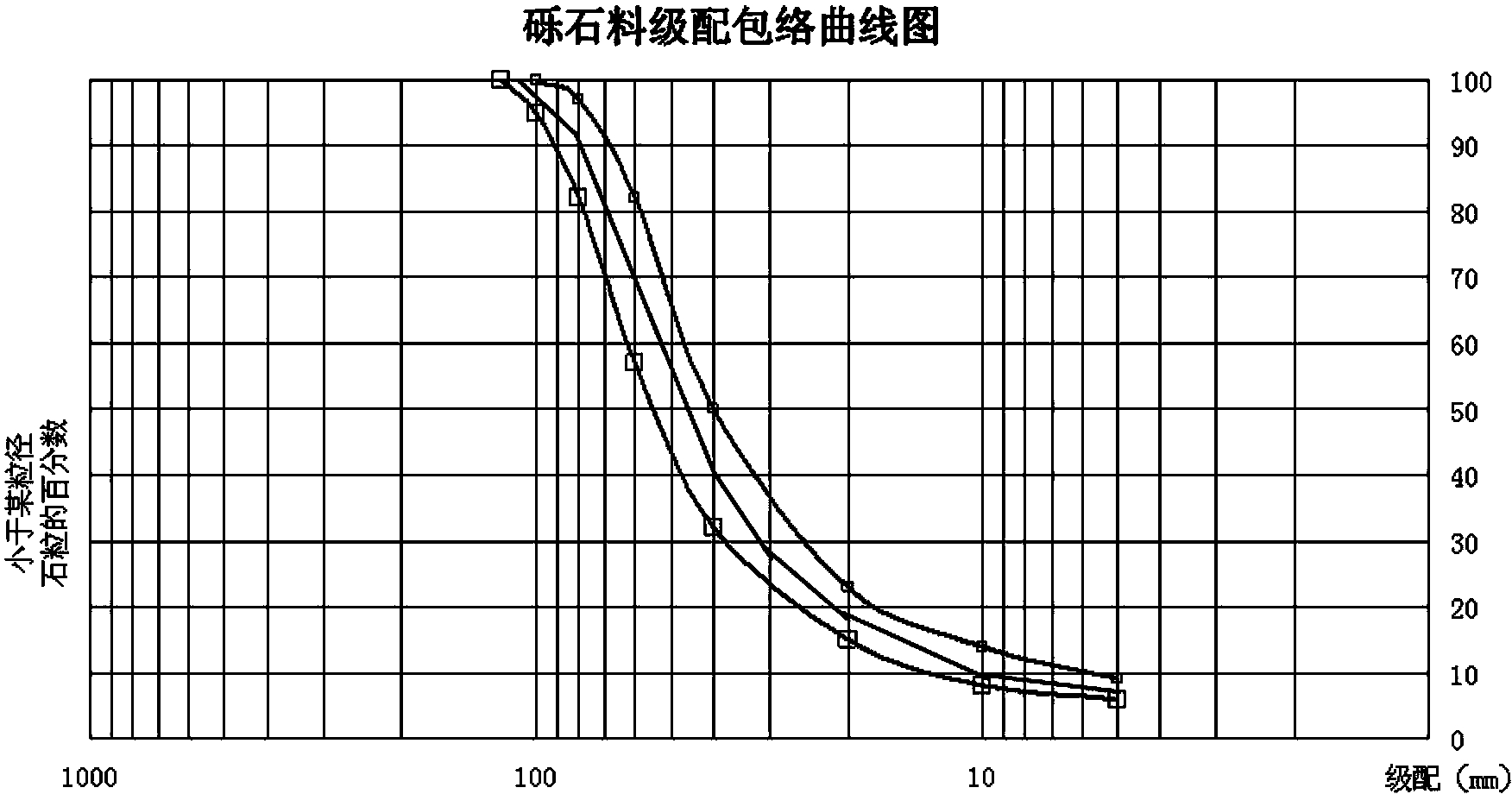

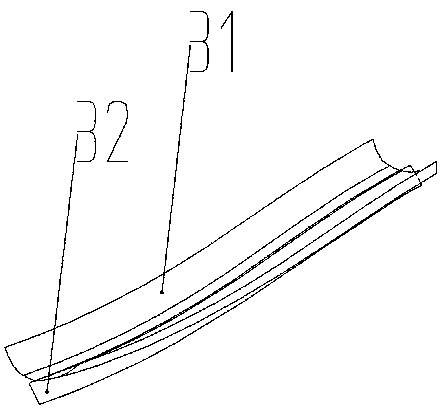

Dam core wall gravel-doped stone preparation system and method

InactiveCN102274783BReduce breakageReduce screening processGrain treatmentsScreening proceduresEngineering

The invention relates to a dam core wall gravel-doped stone preparation system. A bar type feeding machine is arranged under a receiving bin; a plus sieve of the bar type feeding machine is connected with a jaw type crusher; a minus sieve of a bar type feeding machine and a discharging opening of the jaw type crusher are connected with a gravel semi-finished product storage yard by a belt conveyor; the gravel semi-finished product storage yard is connected with a screening machine by the belt conveyor; the minus sieve of the screening machine is connected with a gravel finished product storage yard by the belt conveyor; the plus sieve of the screening machine is connected with a cone crusher; and an outlet of the cone crusher is connected with the gravel finished product storage yard by the belt conveyor. The invention realizes the aim of obtaining grading curve gravel meeting the design requirement just by two-stage crushing and one-stage screening by the set matching of rough crushing and intermediate crushing technologies. By reasonably configuring equipment and reducing the crushing and screening procedure, the content of particles smaller than 5mm in a gravel finished product does not exceed 8 percent and meets the process requirement of smaller than 10 percent; and an isolating screen of 5mm is not arranged, and the invention has no discarded materials.

Owner:CHINA GEZHOUBA GROUP NO 5 ENG

Preparation of zircite tube

The invention relates to a preparation method for a zirconia tube. The method comprises the following steps: firstly, the preparation of ceramic slurry: ceramic powder, microcrystalline wax, polyethylene or polypropylene and oleic acid are fully mixed; secondly, injection molding: suitable particles required for injection molding are produced through a granulating machine, and finally the blank of the zirconium tube of an oxygen sensor is produced; thirdly, low-temperature dewaxing: low-temperature heating treatment is performed for a long term, in order to discharge the paraffine resin adhesive; fourthly, isostatic cool pressing: the stress to the blank is uniform in all directions, in order to eliminate the gap reserved in the blank after dewaxing; fifthly, high temperature sintering: the zirconia tube is sintered. The invention provides a preparation method which can effectively enhance the compactness of the zirconia tube with high rate of finished products.

Owner:浙江通源环保科技有限公司

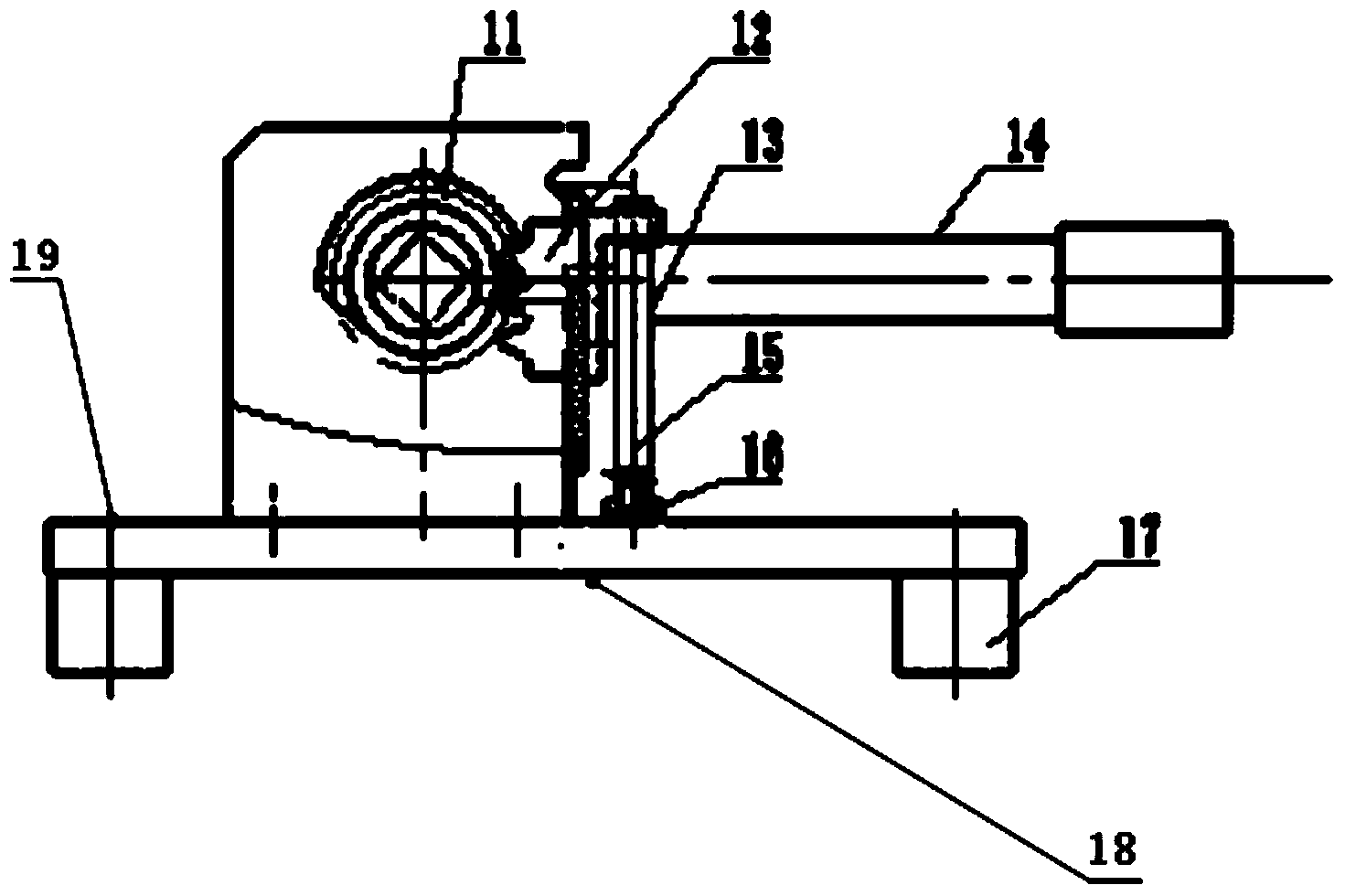

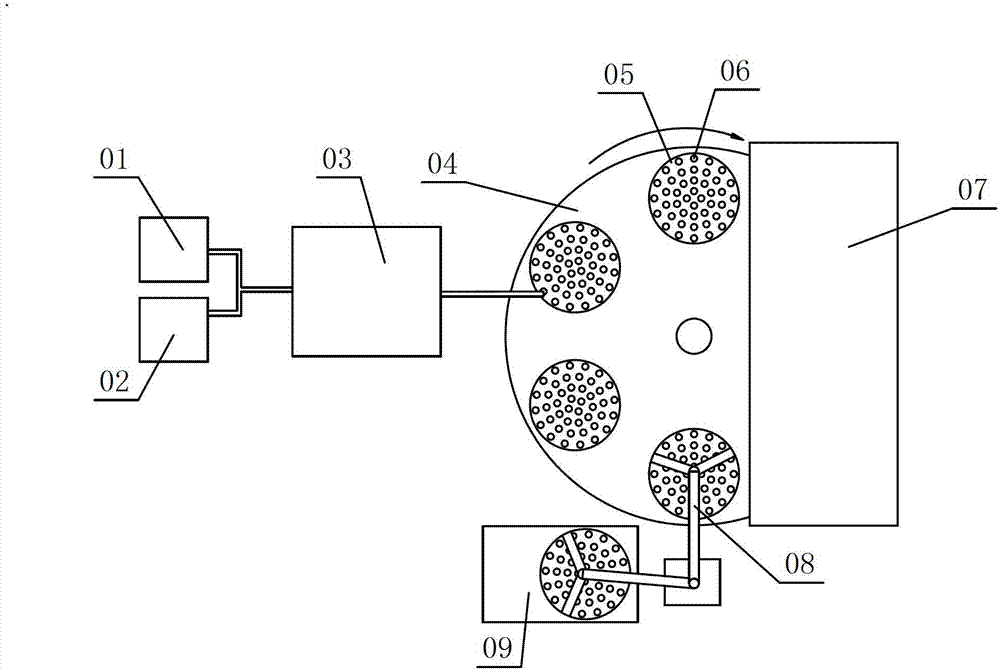

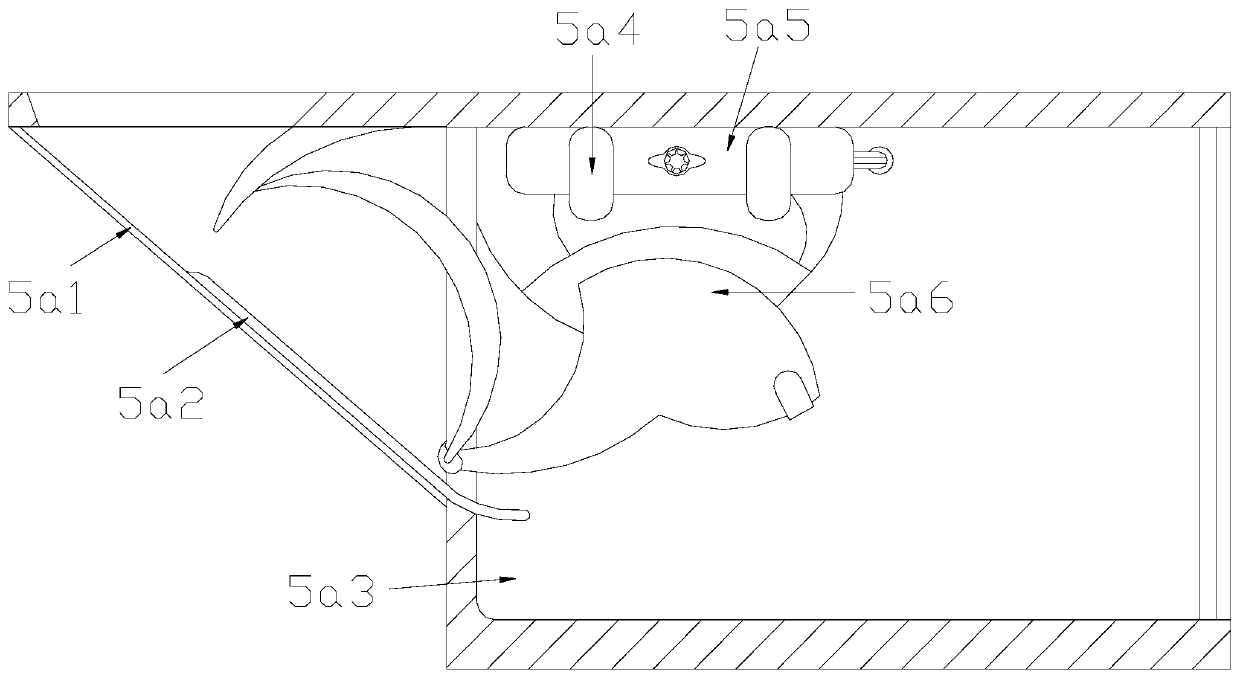

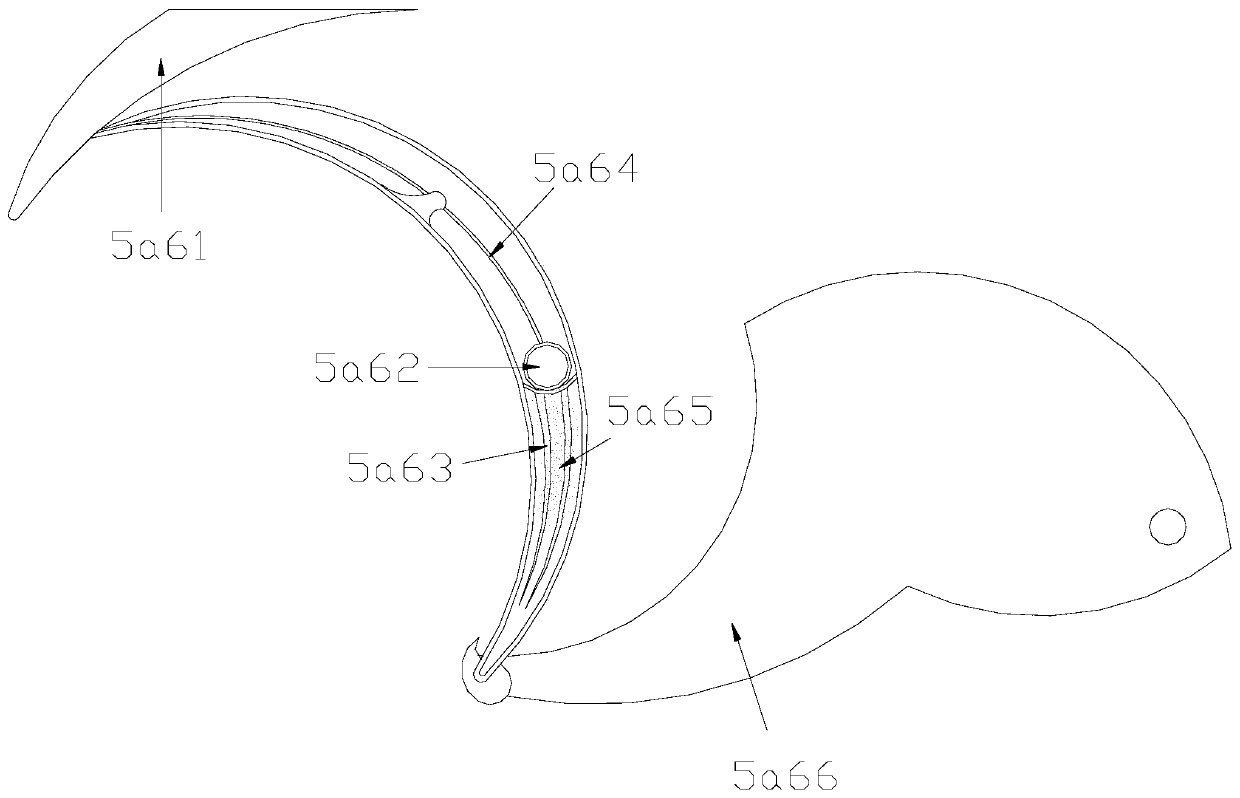

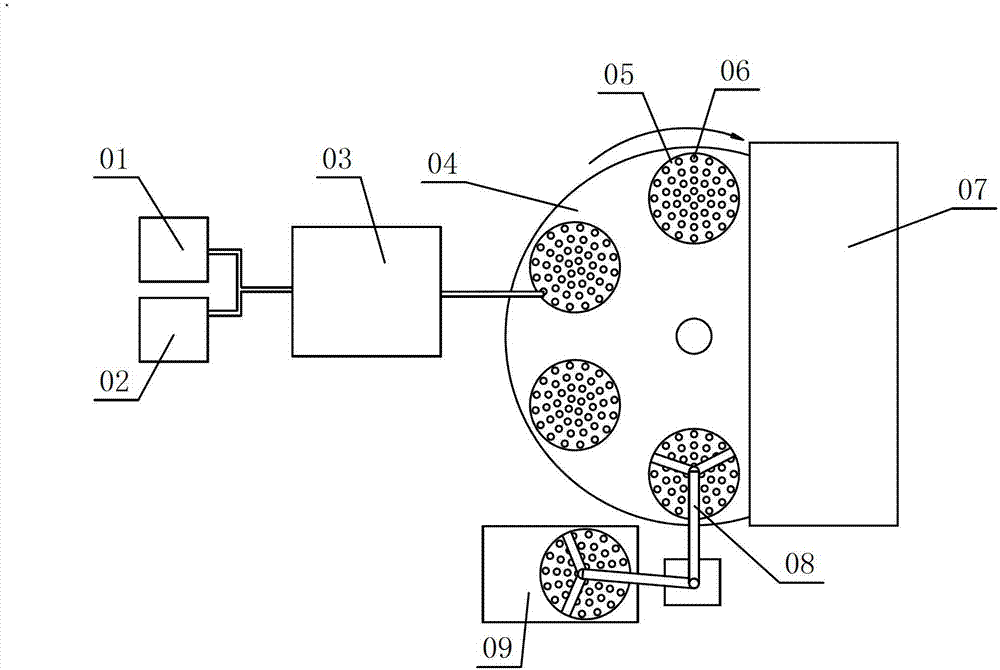

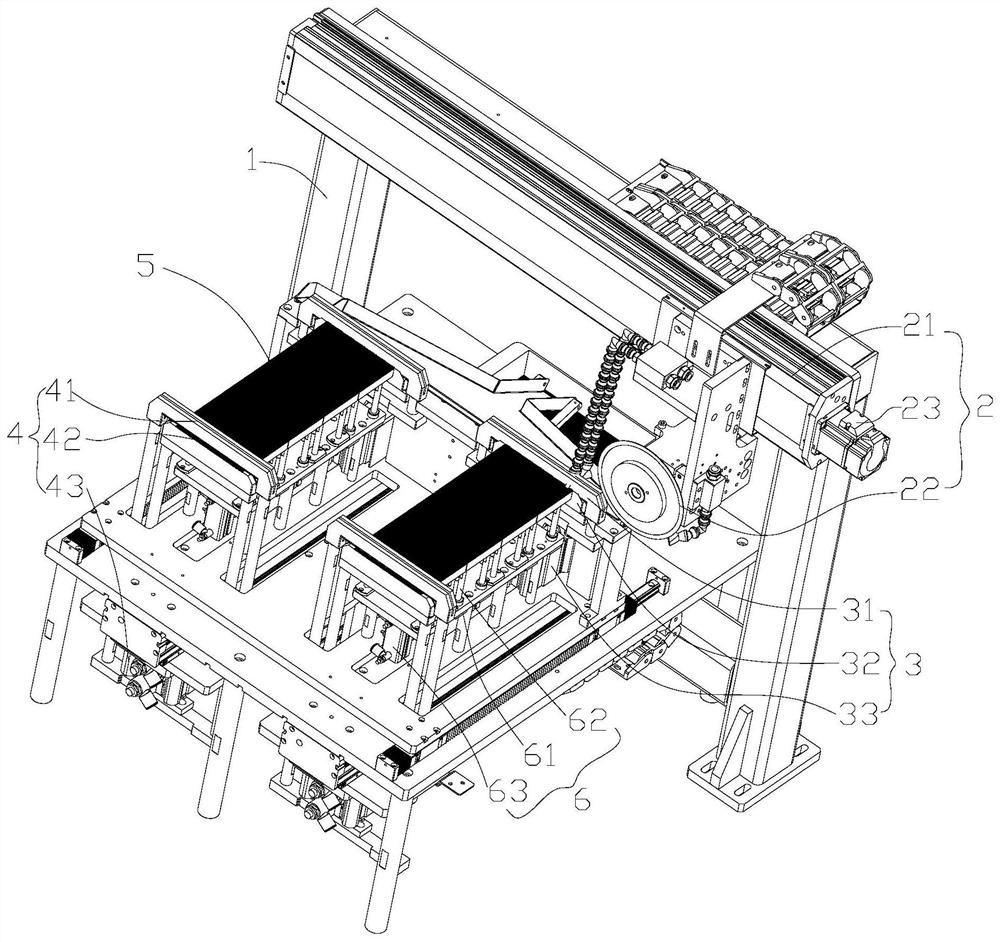

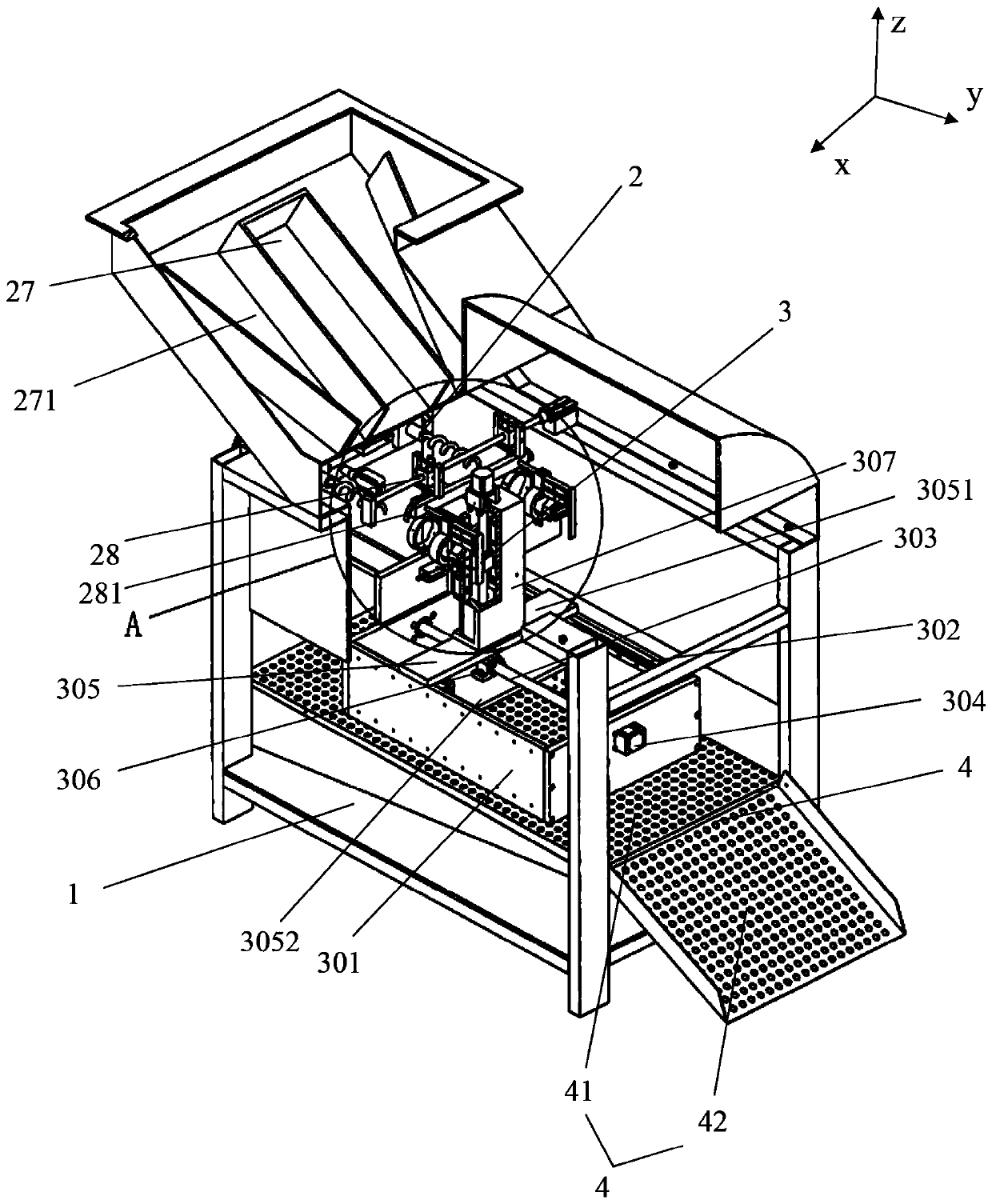

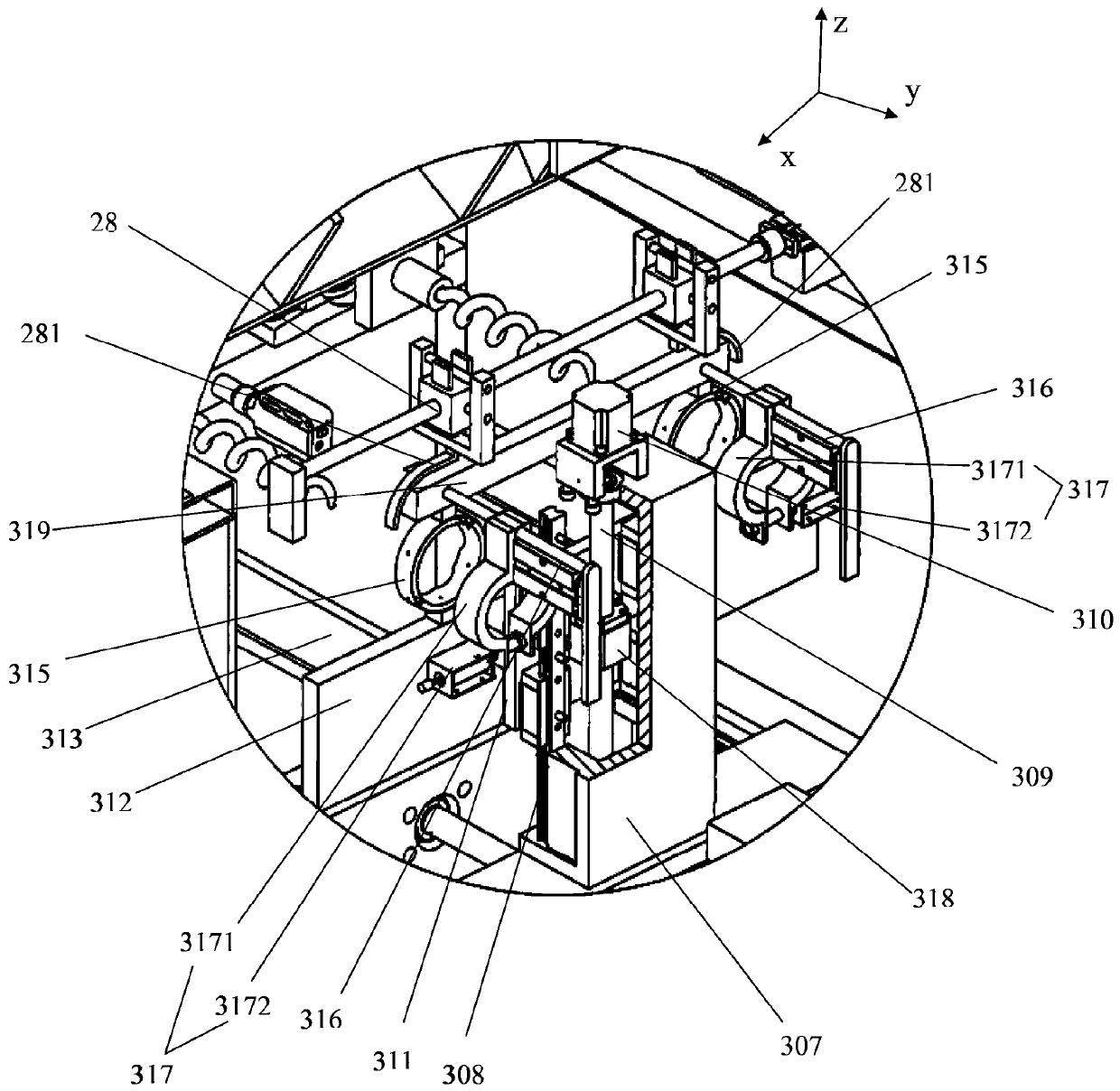

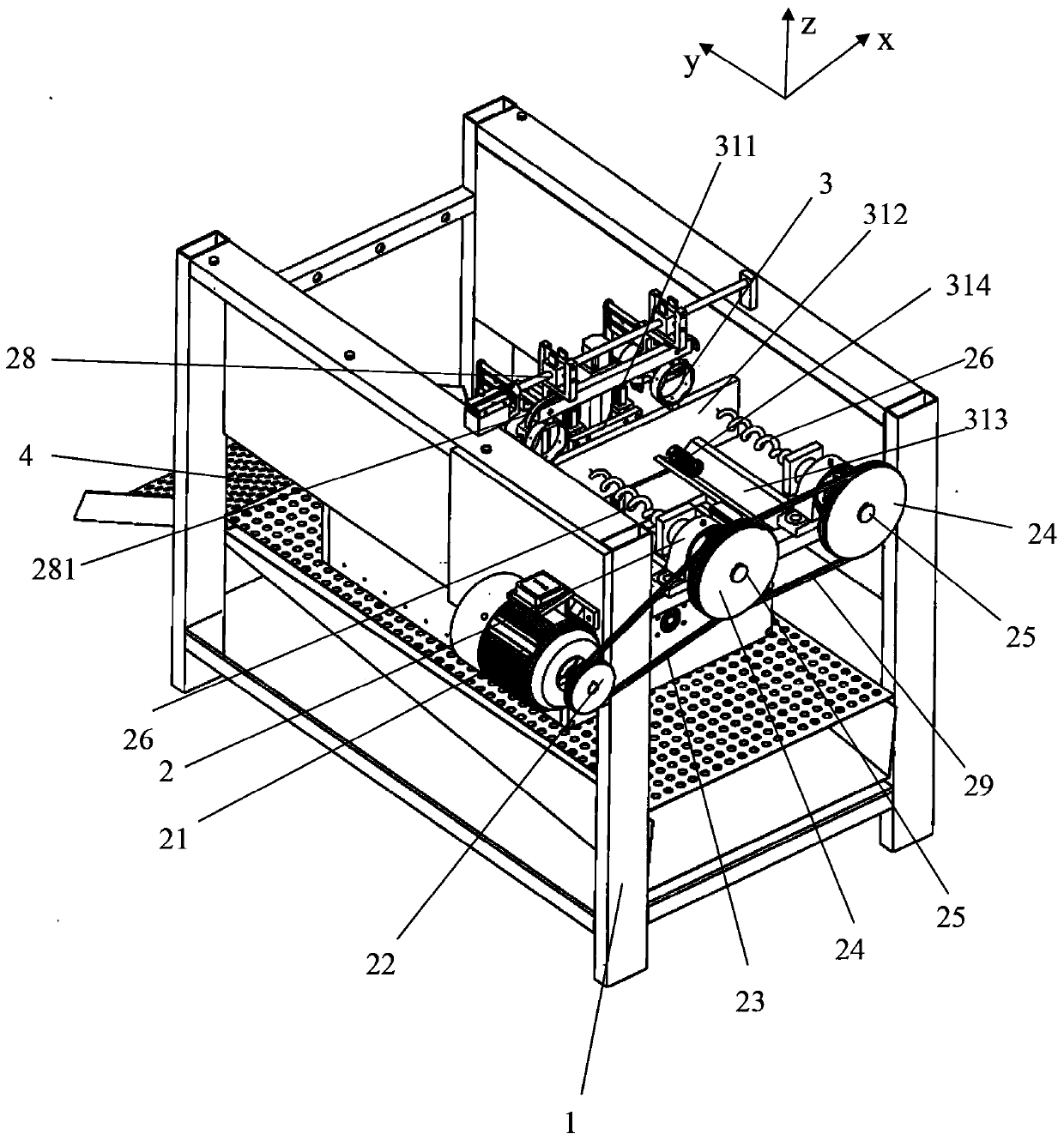

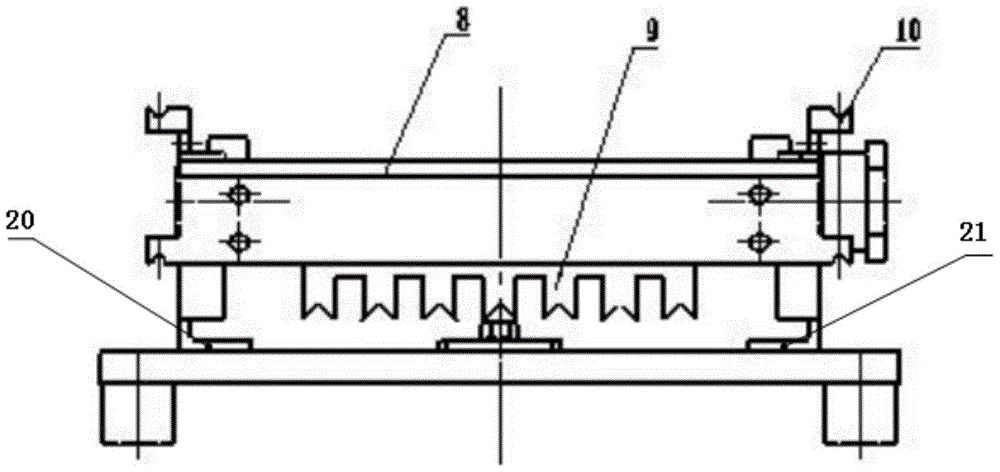

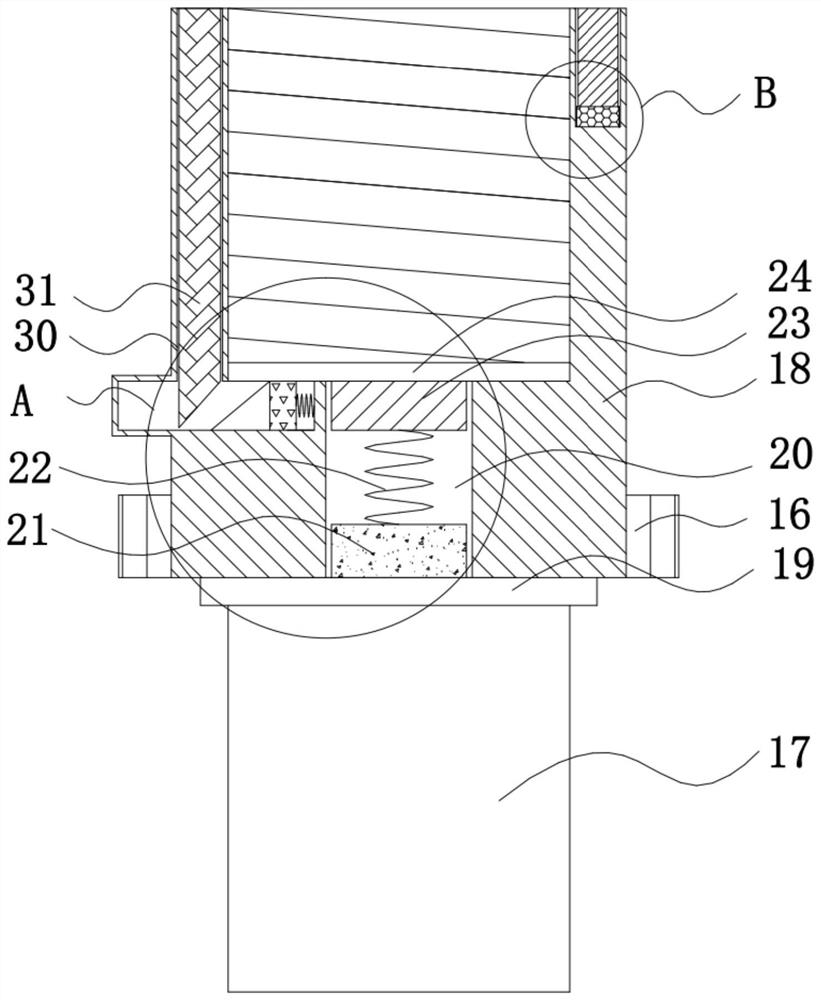

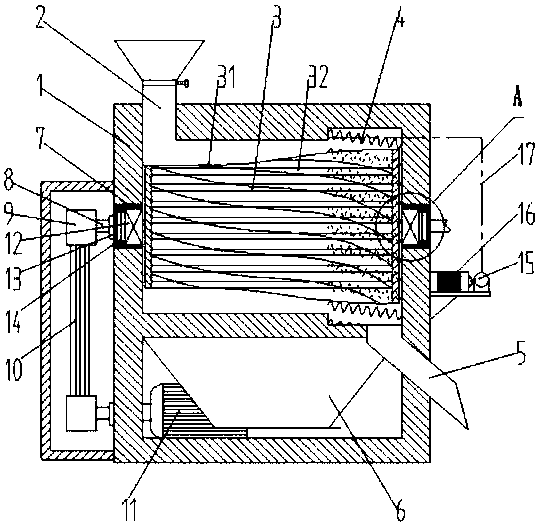

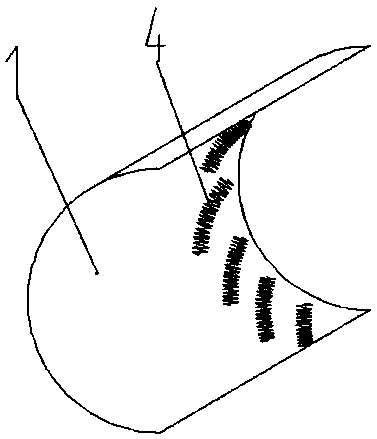

A kind of corn thresher

A corn thresher comprises a controller, a rack, a corn holding assembly, a threshing assembly and a screening assembly. The corn thresher is characterized in that the corn holding assembly comprises amotor, the motor drives a V belt pulley II through an output V belt, and the V belt pulley II sleeves a transmission shaft which is connected with a screw; the threshing assembly comprises a base provided with two guide rails I and a lead screw I, the lead screw I is connected with a stepping motor I, a frame is arranged on the two guide rails I slidably, a lead screw nut I matched with the leadscrew I is arranged on the lower portion of the frame, a tool holder mount is mounted above the frame and provided with two guide rails II and a lead screw II, the lead screw II is connected with a stepping motor II, a mounting board is arranged on the two guide rails II slidably and is fixedly connected with a guard board, a V-shaped groove extends out of the guard board, a toothed cutter is arranged above the guard board, a guide rod extends above the the toothed cutter and is provided with an electromagnetic clamping mechanism, and the mounting board is provided with a lead screw nut II matched with the lead screw II. The corn thresher has the advantages of improving corn threshing quality and efficiency.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Walnut peeling device

The invention discloses a walnut peeling device. The walnut peeling device comprises a housing, a peeling roller group and a driving mechanism, wherein a feed opening and a discharge opening are formed in the housing; the peeling roller group is located in the housing; the peeling roller group is connected with the driving mechanism; the peeling roller group comprises a coarse shell peeling rollerand a fine shell peeling roller; the coarse shell peeling roller and the fine shell peeling roller are arranged along the same rotation axis and rotate synchronously under the action of the driving mechanism; the feed opening is formed in a position above a coarse shell peeling roller end; the discharge opening is formed in a position below a fine shell peeling roller end; and the slope of the generatrix of the coarse shell peeling roller is not equal to zero. Through reasonable arrangement of relevant mechanical peeling parts, walnuts in different sizes can be peeled at the same time, the screening process of the walnuts is omitted, and the problems that an existing walnut peeling machine is poor in peeling effects, is low in peeling efficiency of walnut green husks and is high in laborcosts are solved.

Owner:周鑫

A device for rapid preparation of explosive stability test samples

ActiveCN104330295BNot easy to produceReduce risk of development explosionPreparing sample for investigationShear stressEngineering

Owner:XIAN MODERN CHEM RES INST

A thread automatic rotary mold ejector

The invention belongs to the technical field of screw thread ejection, in particular to a screw thread automatic rotary ejection machine, which includes a static template, which has a glue injection port inside, and a controller is provided on one side of the static template; The bottom of the static formwork is slidably connected with the movable formwork through a sliding device, and the bottom of the static formwork and the top of the movable formwork are provided with a cavity through a transmission part, and internal threads are provided inside the cavity; the top of the movable formwork is provided with A fixed column, the other end of the fixed column passes through the central axis of the cavity and is rotatably connected with the cavity through a support bearing, the top of the fixed column is dug with a first chute, and the inner bottom of the first chute Equipped with the first electromagnet, this device can not only realize single-cavity mold ejection, avoid parting line, improve the aesthetics of external thread products, but also eject the broken external thread products in the cavity to avoid its damage. It will affect the next injection, and can self-adaptively screen the external thread products to improve the efficiency of mold release.

Owner:ZHENGZHOU XINJIEYE AUTOMOTIVE ELECTRONICS

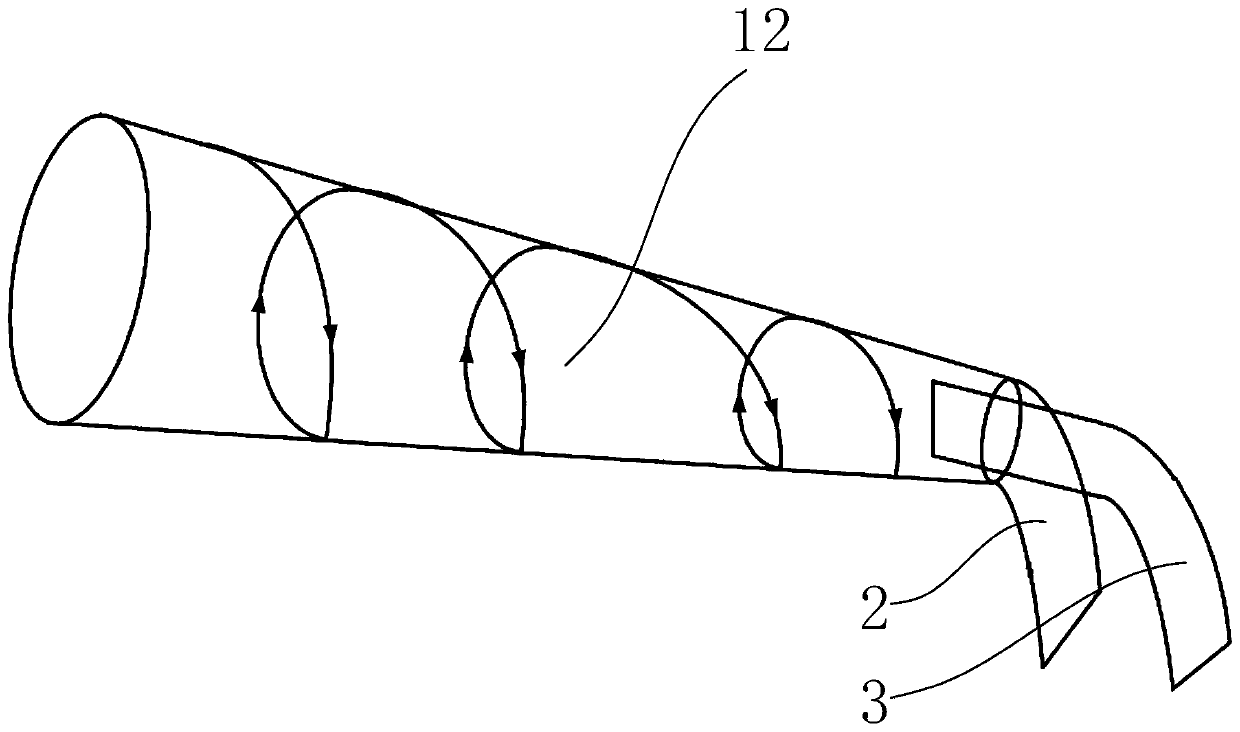

Method for efficiently manufacturing ferrite rubber and plastic magnetic powder

ActiveCN111370215AImprove performanceReduce screening processIron compoundsMagnetic core manufactureFilter pressBall mill

The invention relates to the technical field of ferrite rubber and plastic magnetic powder preparation. Aiming at the problems of complex process, long production period and high cost of the existingferrite rubber and plastic magnetic powder manufacturing method, the invention discloses an efficient method for manufacturing ferrite rubber and plastic magnetic powder, wherein the method comprisesthe following steps of: directly putting a pre-sintered ball material with a particle size of less than or equal to 10 mm into a ball mill, carrying out wet fine grinding, spraying into a drying and annealing integrated kiln, and carrying out annealing calcining; and dispersing through a 60-100-mesh sieve mesh to obtain the ferrite rubber and plastic magnetic powder. According to the invention, adrying and annealing integrated kiln and slurry spraying combined drying and annealing mode is adopted, so that drying and annealing integration is achieved on the basis that the performance of ferrite rubber and plastic magnetic powder is kept, the procedures of dry grinding, deep filter pressing dehydration and screening after drying are omitted, the production period is shortened, and the costis reduced; and the slurry is sprayed and dried, and the wet fine grinding process is optimized, so that more than 65% of the granularity of the fine grinding material is intensively distributed nearthe average granularity, and the performance of the annealed rubber and plastic magnetic powder is improved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Peeling machine of walnut green husks

InactiveCN107625147AFully shelledGuaranteed movement trackCleaning using gasesHuskingWalnut NutHobbing

The invention discloses a peeling machine of walnut green husks. The peeling machine comprises a machine box, a peeling roller and a slag shell cleaning mechanism, wherein the peeling roller is rotatably connected in the machine box; the slag shell cleaning mechanism is also arranged on the machine box; the peeling roller comprises one or more layers of annular peeling surfaces consisting of a plurality of hobbing cutters; every two adjacent hobbing cutters are mounted in a manner of forming a certain gap; the generatrix of each peeling surface is an inclined straight line or a curve; two endsof the peeling roller are respectively a small end and a big end; a feeding box and a discharging box are connected to the machine box; a discharging end of the feeding box is arranged in a manner ofleading to the small end of the peeling roller; the discharging box is arranged below the big end of the peeling roller; and the slag shell cleaning mechanism is arranged on the outer side of the annular peeling surface of the big end of the peeling roller. Through reasonable arrangement of relevant mechanical parts for removing shells, the shells of walnuts in different sizes can be removed at the same time, the screening process of the walnuts is omitted, and the problems that an existing peeling machine of walnut green husks is poor in shell removing effects, is low in peeling efficiency of the walnut green husks and is high in labor costs are solved.

Owner:周鑫

Rapid flotation device

The invention discloses a rapid flotation device which comprises a flotation chute which is in butt joint with a foam scraping machine, and is obliquely arranged and used for guiding ore pulp from topto bottom; a top end inlet of the flotation chute is used for receiving foam-containing ore pulp scraped by the foam scraping machine, and the ore pulp flows under the flow guide of the flotation chute; a bottom outlet of the flotation chute is in butt joint with a concentrate pipe and a coarse ore pipe; the density of metal concentrate in the ore pulp and the density of ore in the ore pulp are different, so that ore pulp is layered in the flowing process in the flotation chute, the concentrate pipe is used for receiving the concentrate separated out from the flotation chute, the coarse ore pipe is used for receiving the coarse ore separated out from the flotation chute, the concentrate is separated out from the ore pulp, the concentrate can be directly used, the raw ore screening processis shortened, and the concentrate can be rapidly separated out from the raw ore pulp.

Owner:TIBET HUATAILONG MINING DEV

Equipment for multistage peeling of walnuts

The invention discloses a device for multi-stage peeling of walnuts, which comprises a casing, a peeling roller group and a driving mechanism; Mechanism connection, the peeling roller group includes coarse shell peeling rollers and fine shell peeling rollers, the coarse shell peeling rollers and fine shell peeling rollers are arranged along the same rotation axis; there is a feed inlet above the end of the coarse shell peeling rollers, There is a discharge port below the end of the fine shell peeling roller; the coarse shell peeling roller includes the first hob unit and the second hob unit, and the first hob unit and the second hob unit are arranged in a gap from outside to inside; the gap is used for walnut Through and within it for peeling; the feed port is set opposite to the feed end of the gap; through reasonable setting of peeling related mechanical parts, walnuts with uneven sizes can be peeled at the same time, reducing the screening process of walnuts and solving the problem The problems of poor peeling effect, low peeling efficiency and high labor cost of the existing equipment for walnut multi-stage peeling are solved.

Owner:周鑫

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com