Rapid flotation device

A flotation device, fast technology, applied in flotation, solid separation, etc., can solve the problem of long beneficiation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The core of the present invention is to provide a fast flotation device, which can quickly separate concentrate from raw ore pulp.

[0022] In order to enable those skilled in the art to better understand the technical solution of the present invention, the fast flotation device of the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

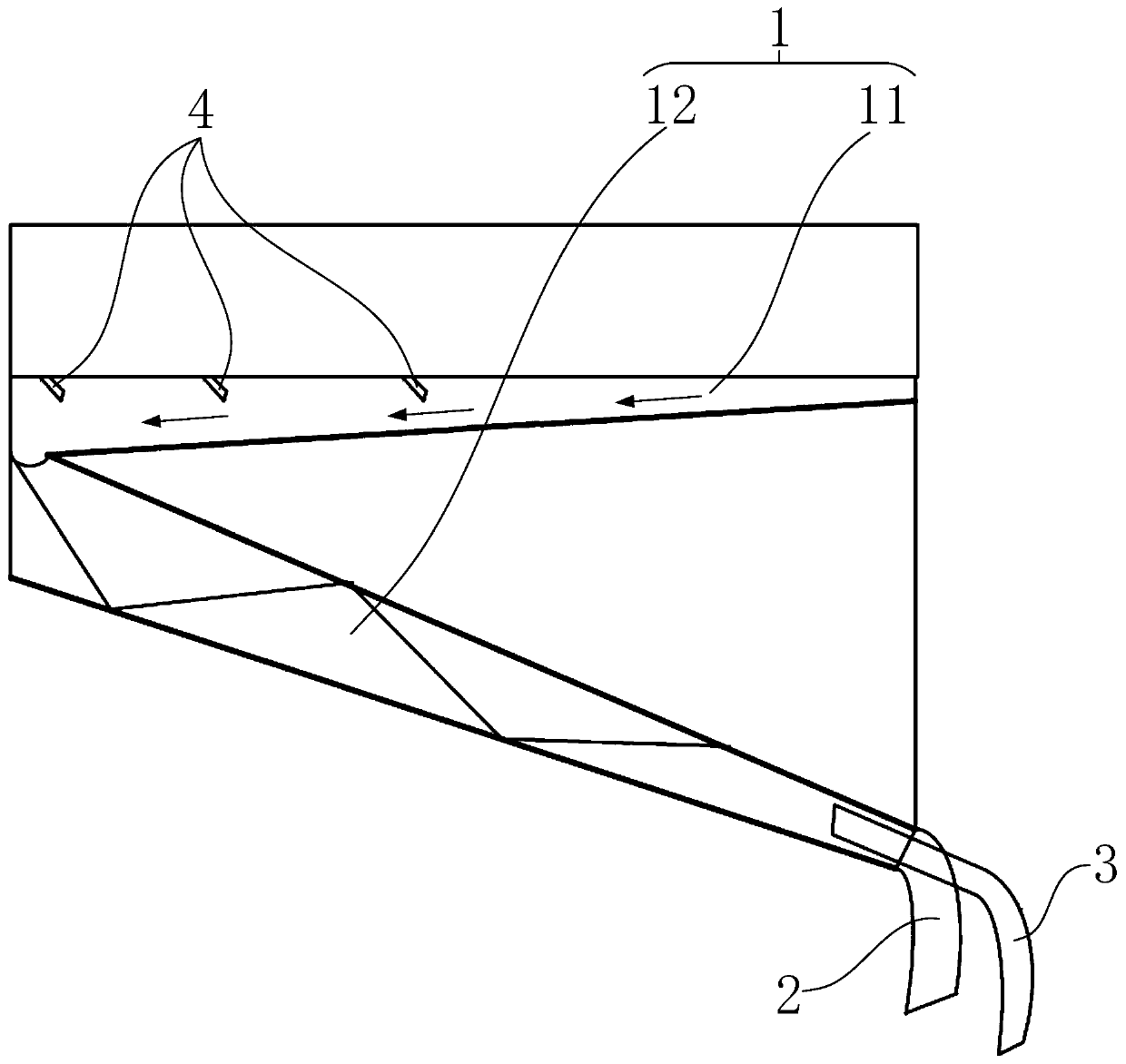

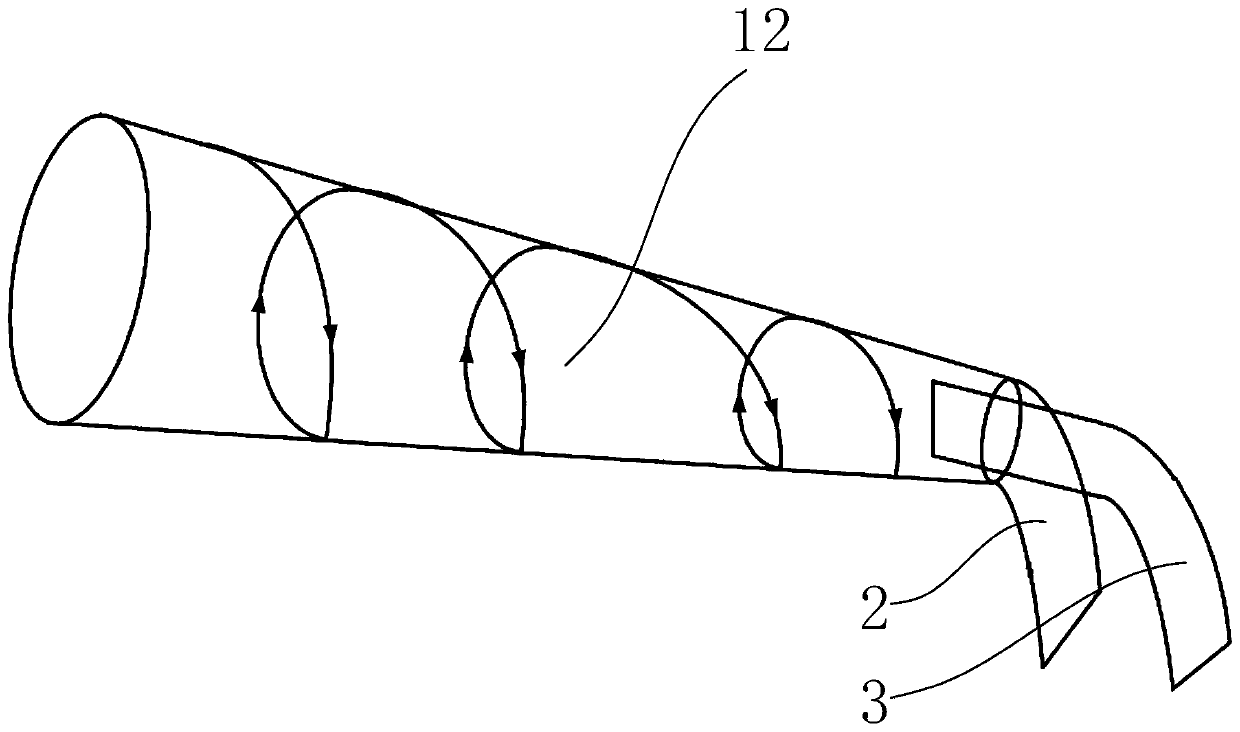

[0023] Such as figure 1 Shown is a structural schematic diagram of a specific embodiment of the fast flotation device provided by the present invention; the device includes a flotation chute 1 docked with a bubble scraper, and the flotation chute 1 plays the role of diverting pulp, and the flotation chute 1 is inclined. The top entrance of the flotation chute 1 is used to receive the foam-containing pulp scraped by the bubble scraping machine and guide the pulp to flow downward. The pulp flows downward in the flotation chute 1 under the action of gravity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com