Dam core wall gravel-doped stone preparation system and method

A stone and gravel technology, applied in the field of dam core wall mixed gravel material preparation system, can solve the problems of high operating cost and complicated process, and achieve the effect of reducing the crushing and screening process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

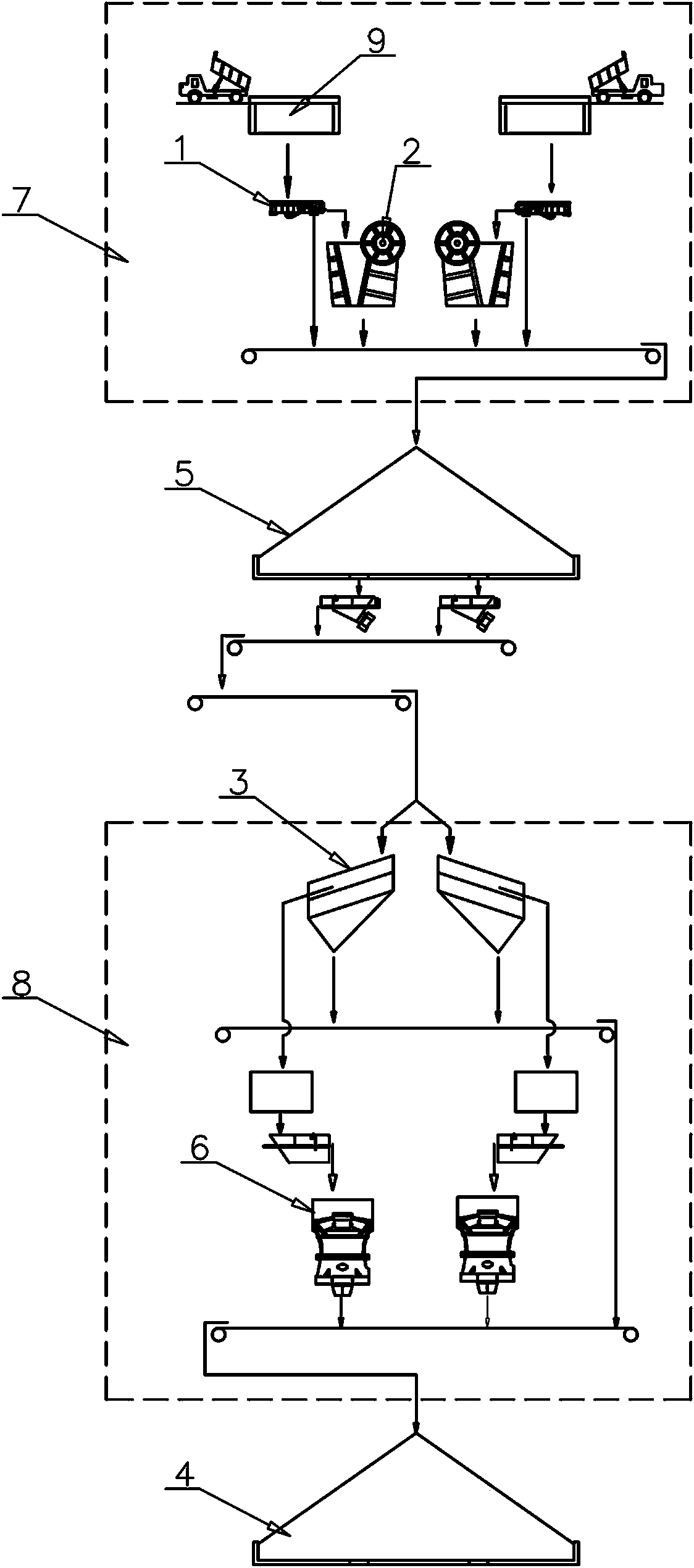

[0024] Such as figure 1 Among them, a gravel material preparation system for the dam core wall, a rod feeder 1 is provided under the receiving bin 9, and the screen of the rod feeder 1 is connected with the jaw crusher 2, and the rod feeder 1 is connected to the jaw crusher 2, and the rod feeder 1 The under-sieve of the feeder 1 and the discharge port of the jaw crusher 2 are connected to the semi-finished gravel material storage yard 5 through a belt conveyor;

[0025] The gravel semi-finished product storage yard 5 is connected with the screening machine 3 through the belt conveyor, the underscreen of the screening machine 3 is connected with the gravel material finished storage yard 4 through the belt conveyor, and the upper screen of the screening machine 3 is connected with the cone crusher 6, and the cone crushing The outlet of machine 6 is connected with gravel material finished product stockyard 4 by belt conveyor.

[0026] The rod spacing of the rod feeder 1 is 150mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com