A thread automatic rotary mold ejector

An automatic rotation and thread technology, applied in the direction of threaded products, household appliances, other household appliances, etc., can solve the problems of reducing processing efficiency, product end fracture, affecting processing, etc., to ensure product efficiency, improve product quality, Good quality product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

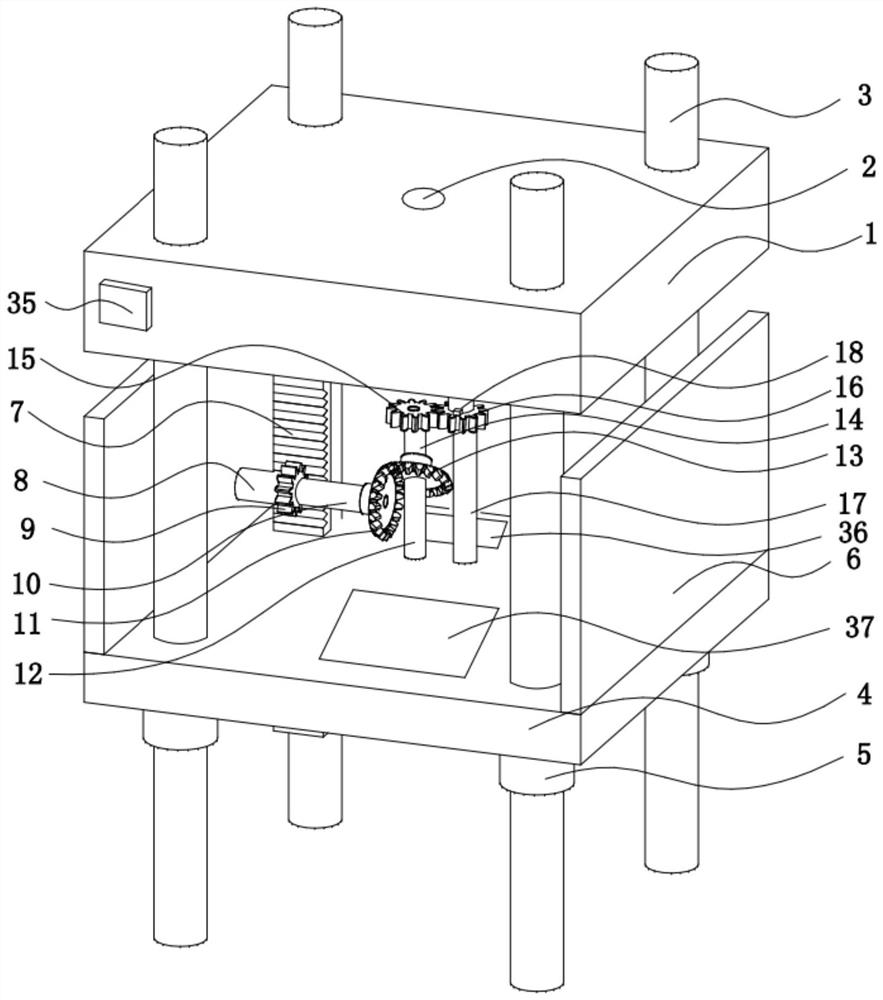

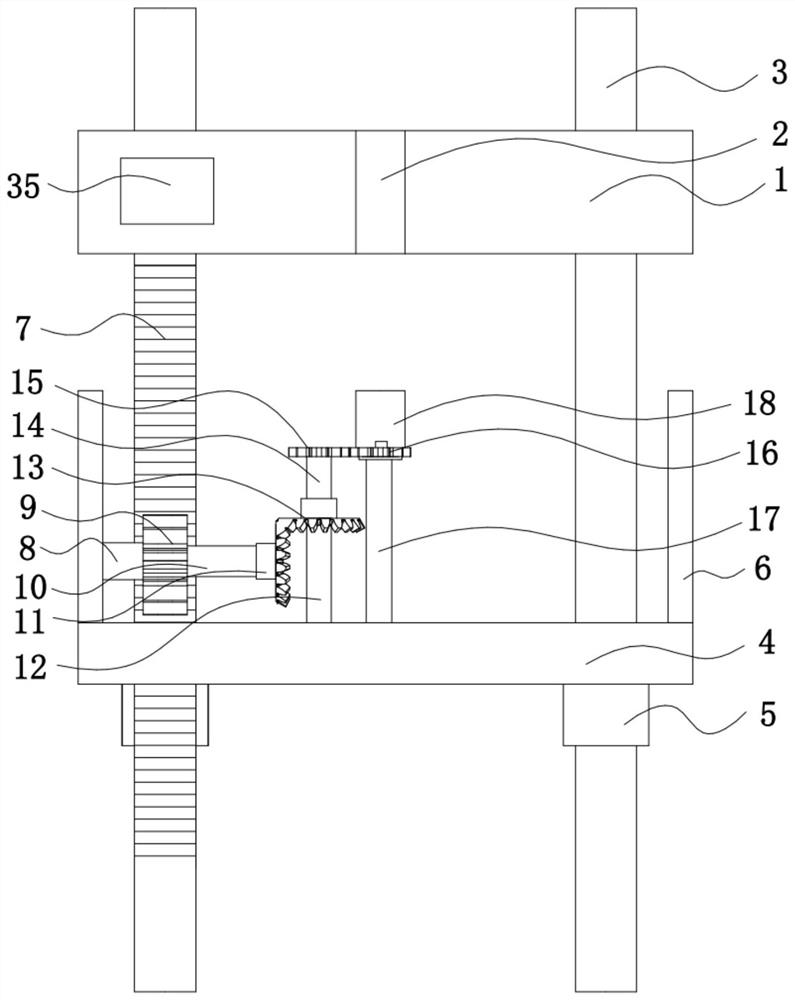

[0031] Such as Figure 1-3, a screw thread automatic rotary molding machine, including a static template 1, the static template 1 will not be displaced during the production process, and is in a static state, the static template 1 is opened with a glue injection port 2 inside, and the top of the glue injection port 2 is set There is a glue injection device, which directly injects glue into the glue injection port 2 to make the required external thread product. The inside of the glue injection device is equipped with a top glue needle. After the glue injection process is completed, the top glue The needle can eject the external thread product from the injection port 2, thereby facilitating unloading and improving processing efficiency. A controller 35 is provided on one side of the static template 1, and the controller 35 electrically controls each electrical component.

[0032] The bottom of the static template 1 is slidably connected with the movable template 4 through a slid...

no. 2 example

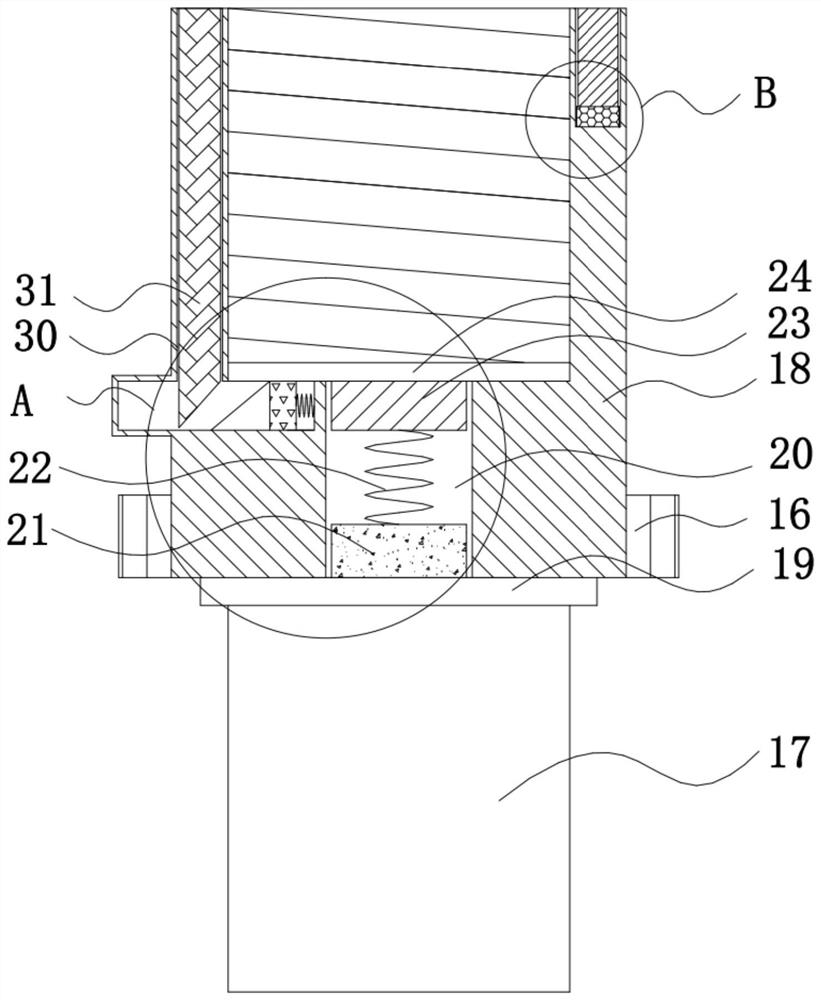

[0044] Such as Figure 3-7 , based on a screw thread automatic rotary mold ejector provided in the first embodiment, at the initial stage of mold ejection, since the rubber material adheres to the internal thread 29 inside the cavity 18, the cavity 18 is easy to drive the outer thread when the mold is ejected by rotation. The threaded product rotates synchronously with the rotation of the cavity 18, thereby causing inconvenience in mold release, and what is more, damage to the external thread product; at the same time, if the external thread product breaks during the injection process or when the mold is released, the waste product will remain It cannot be withdrawn inside the cavity 18, which will affect the subsequent glue injection production; and if the finished products and waste products are uniformly recycled after the mold is released, the products still need to be sorted manually, thereby reducing production efficiency. This problem ensures the stability of the device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com