Patents

Literature

87results about How to "Resolve disengagement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

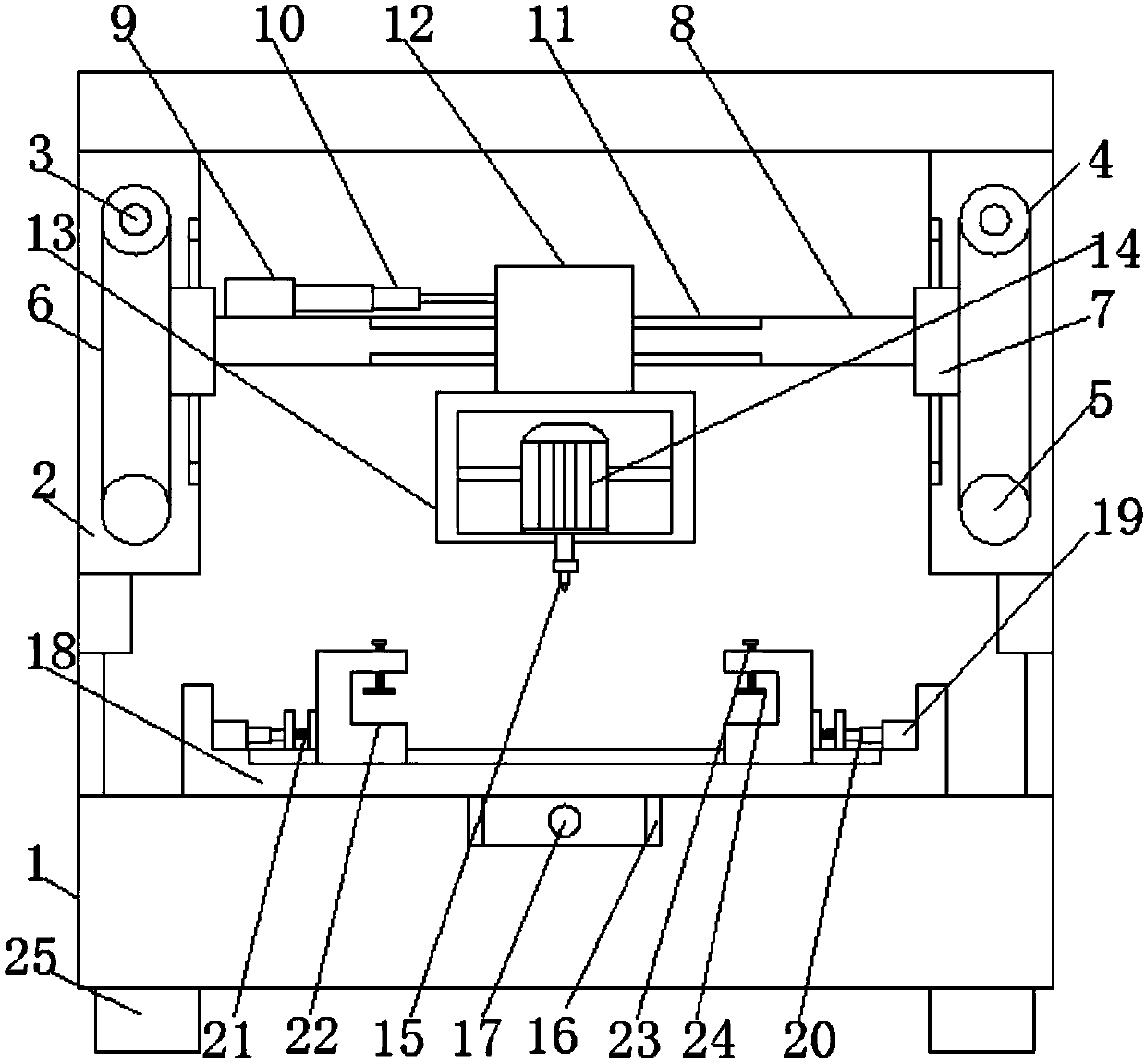

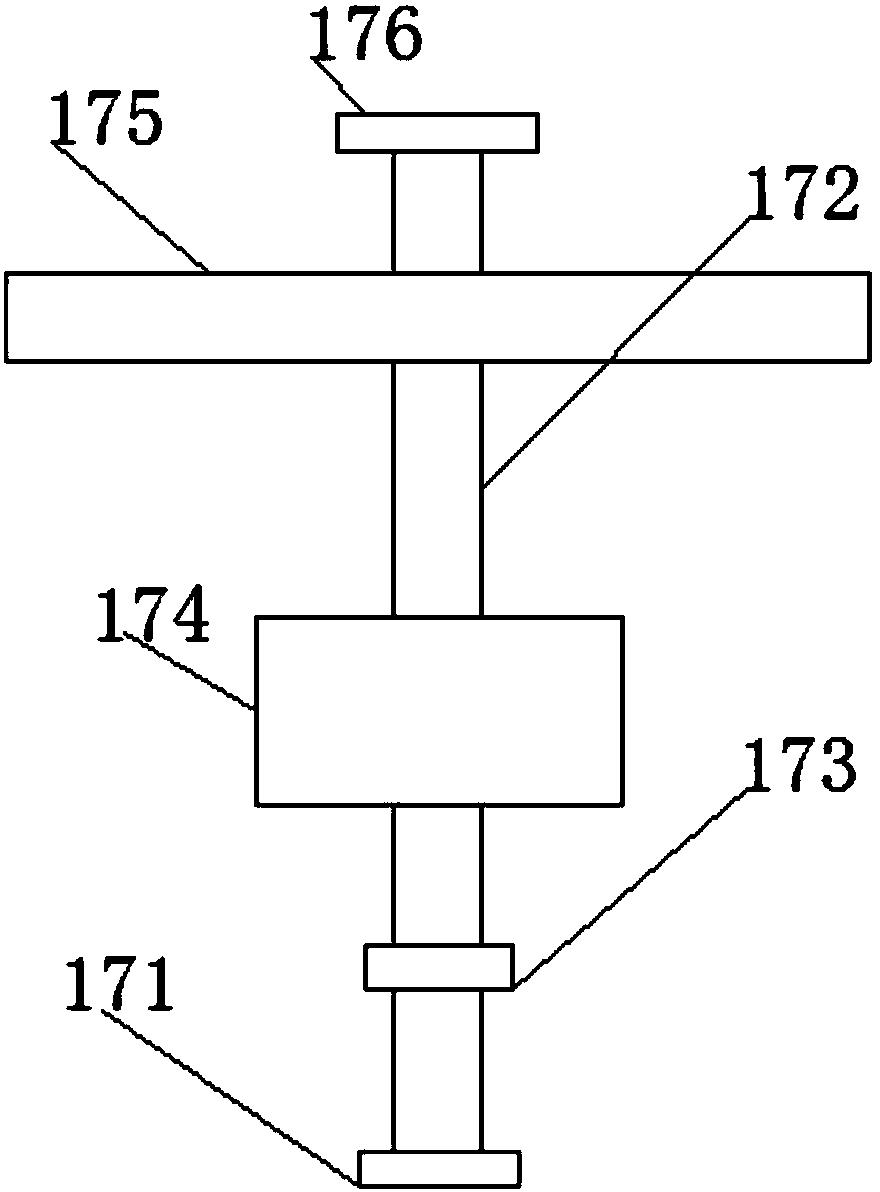

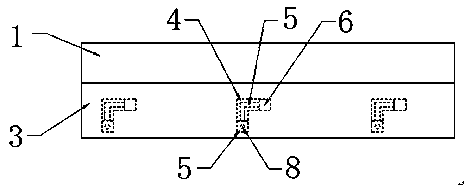

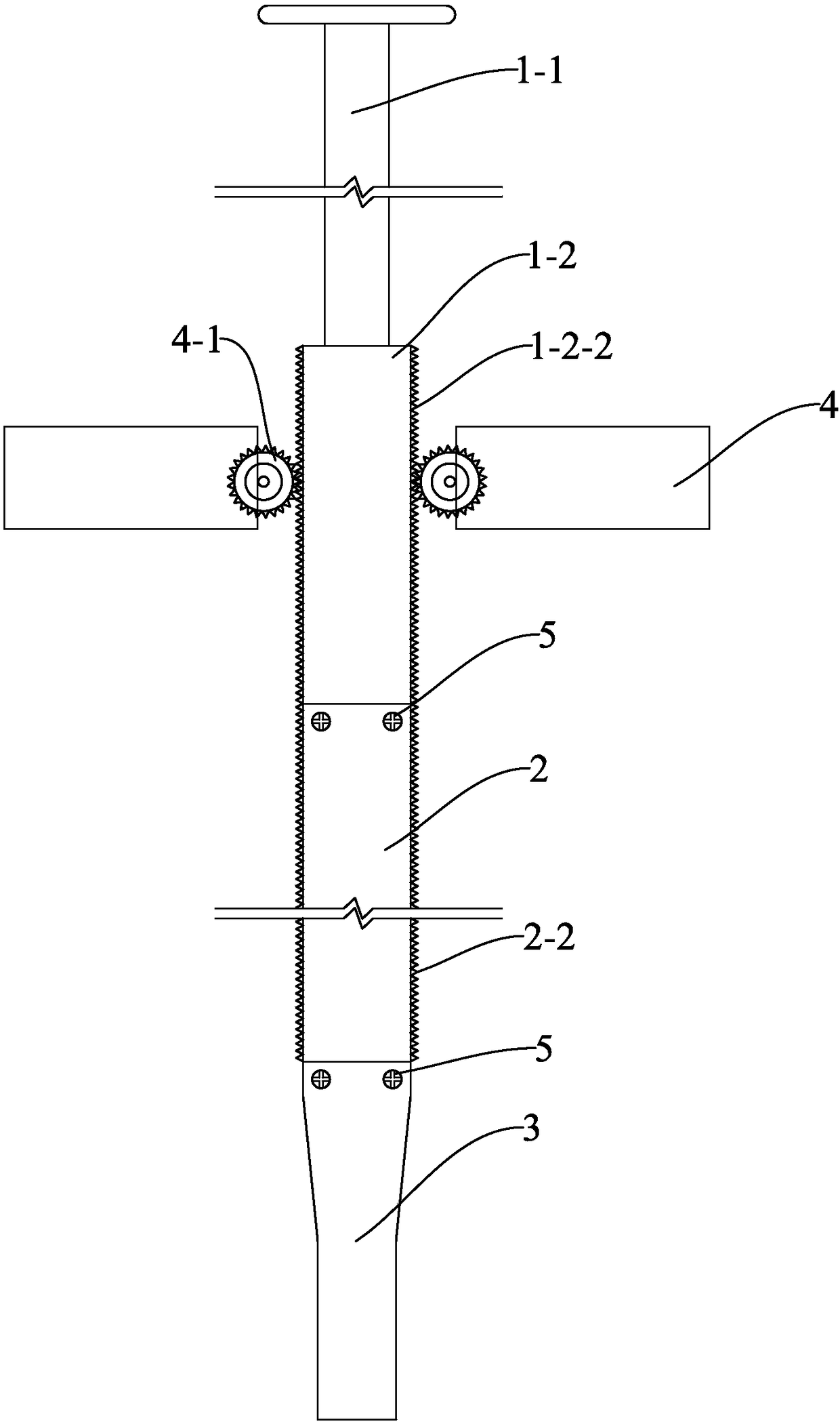

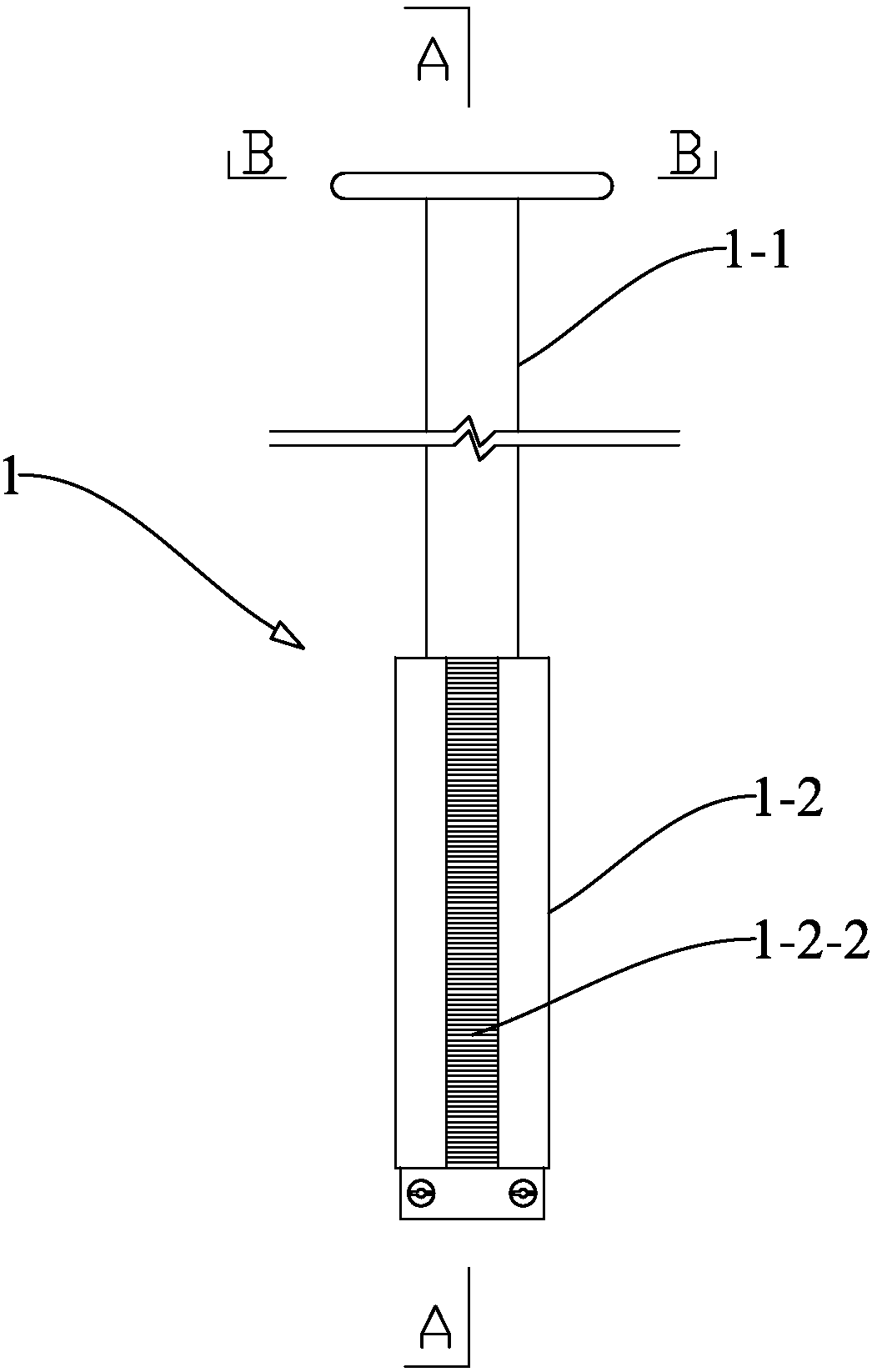

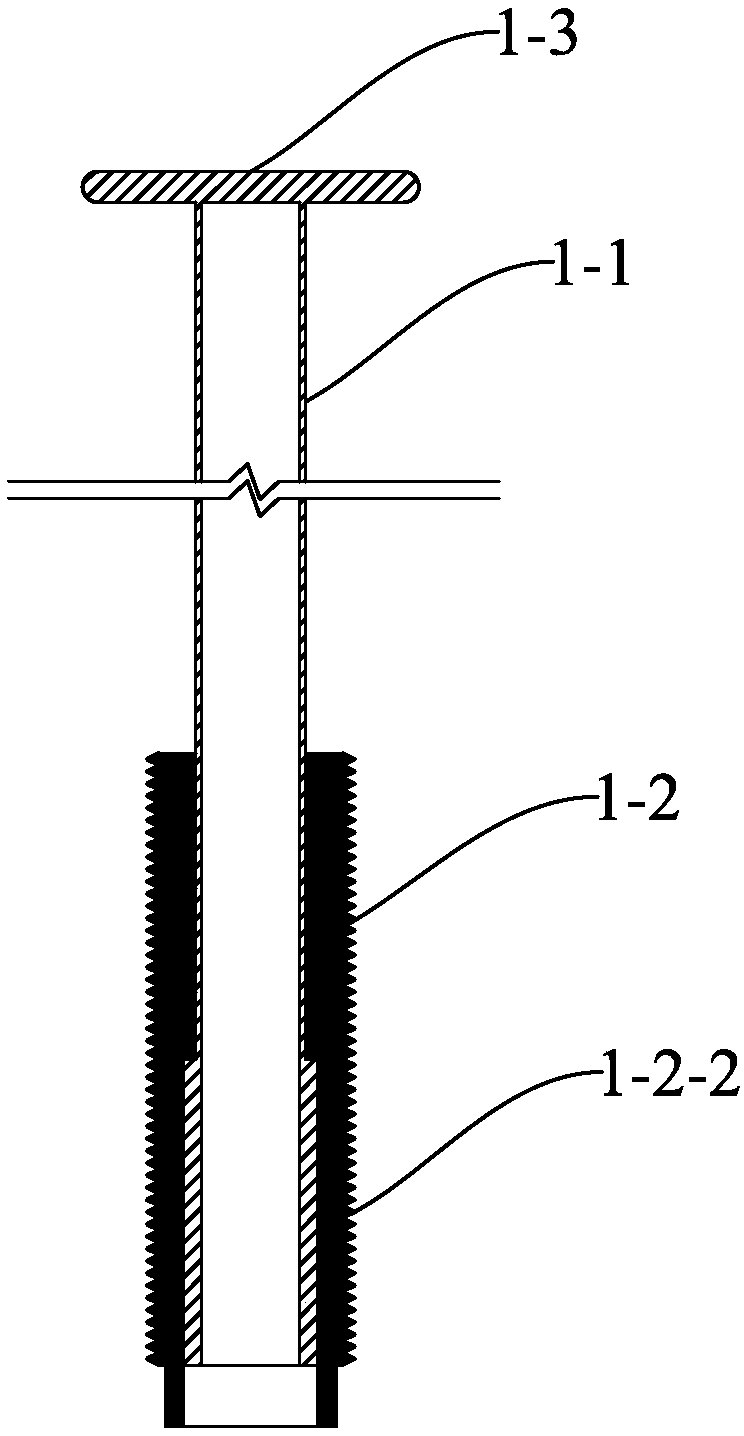

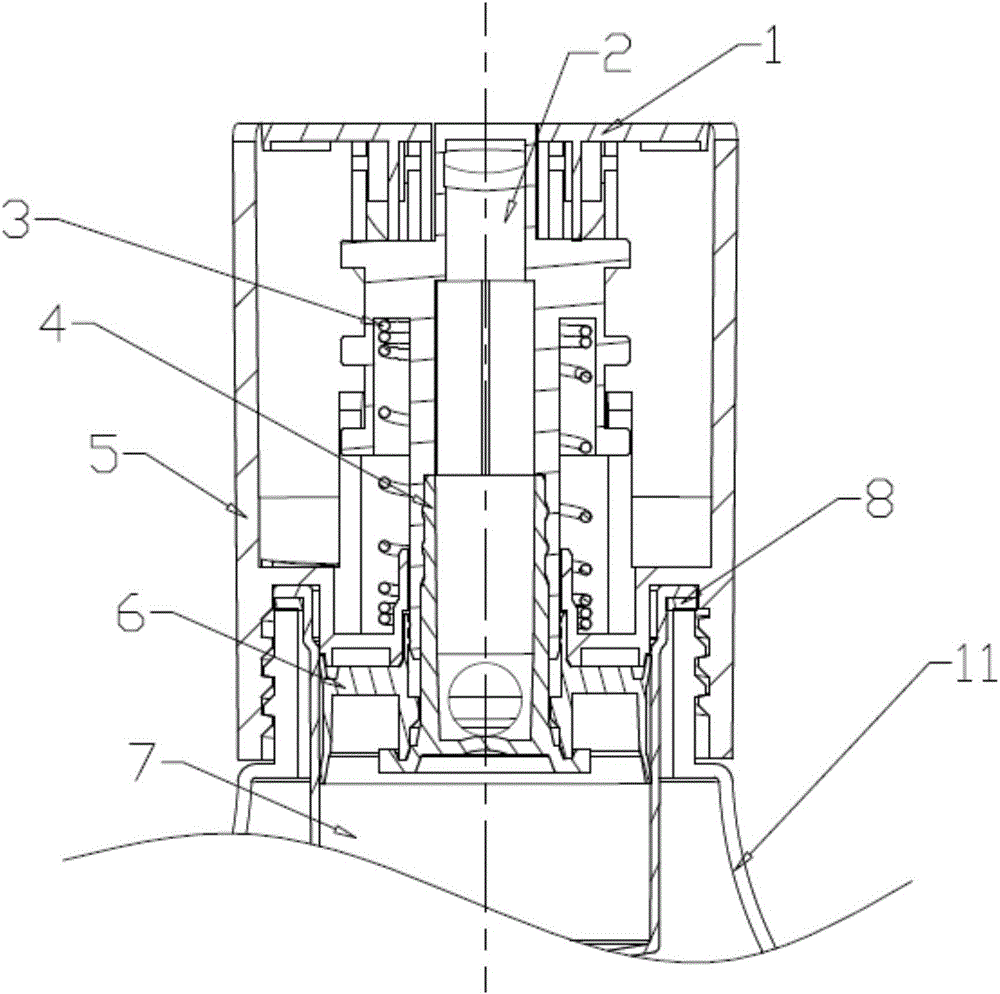

Steel structure drilling device

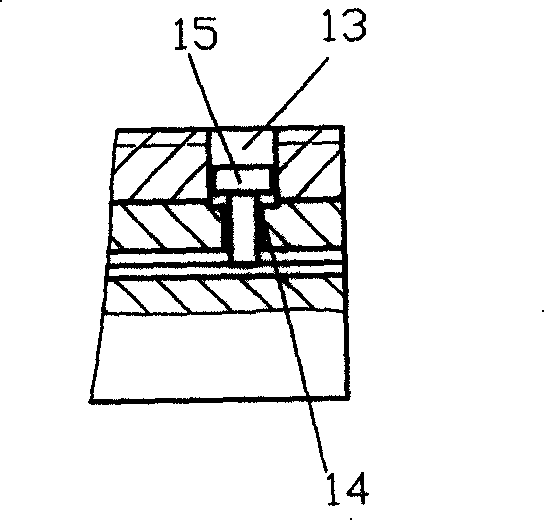

InactiveCN107824828AAvoid distortionAvoid stickingFeeding apparatusPositioning apparatusDrive wheelArchitectural engineering

The invention discloses a drilling device for a steel structure, which comprises a machine body. Both sides above the inner wall of the machine body are provided with organic casings. One motor, the output shafts of the two first motors are fixedly sleeved with driving wheels, the inner chambers of the two casings are provided with driven wheels, and belts are movably connected between the two driving wheels and the driven wheels, and the two belts Both of them are fixedly connected with fixed blocks, and the two fixed blocks are slidably connected to the inner wall of the through groove, and a support frame is fixedly connected between the two fixed blocks, and the left side of the top of the support frame is provided with a first cylinder. The invention solves the problem that the drill cannot be displaced laterally by adding a device for lateral movement to the drill, and achieves the purpose of the clamp device being able to move forward and backward by setting the turntable and the screw rod, and solves the problem that the existing steel structure drilling cannot be clamped at one time Problem with drilling multiple times.

Owner:余骆杨

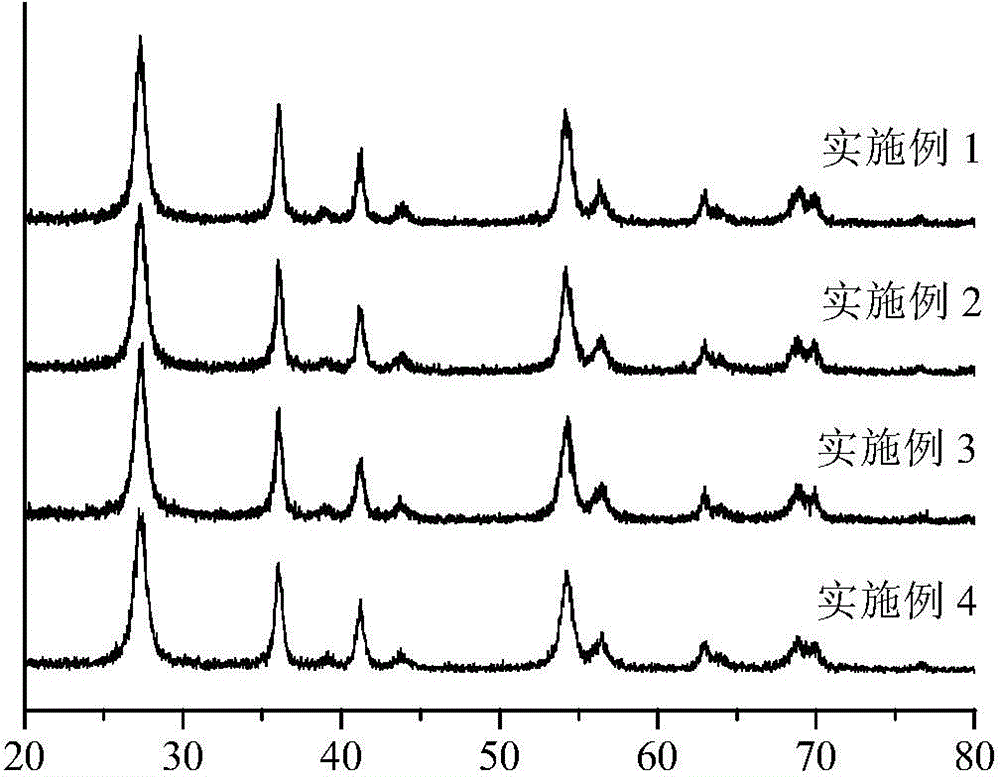

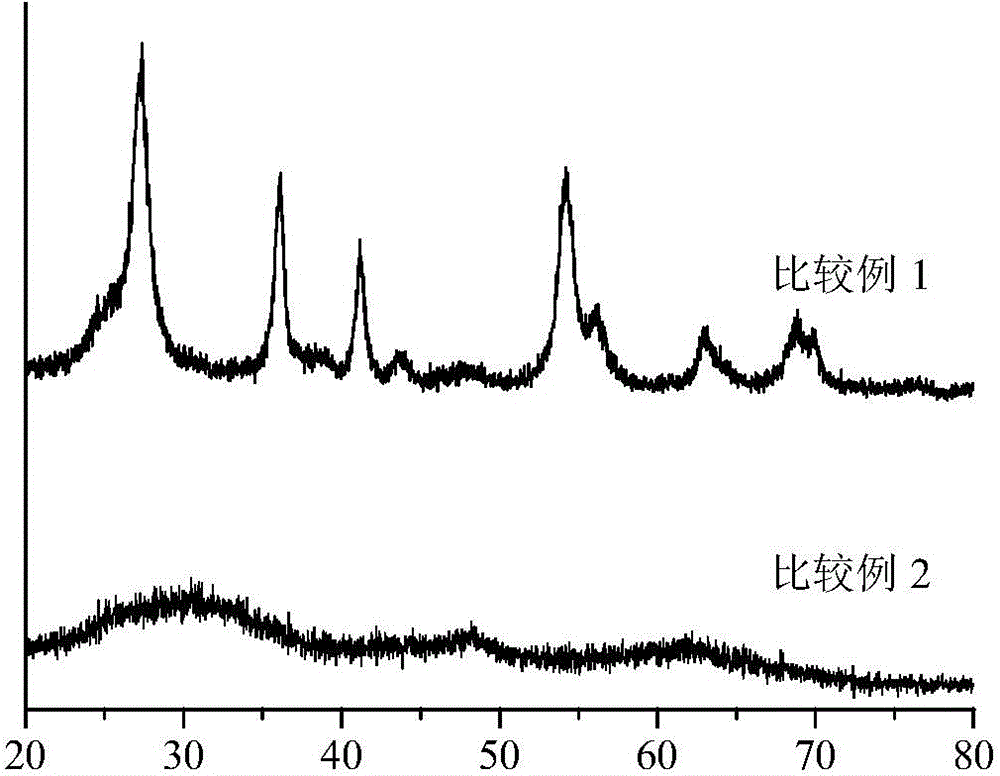

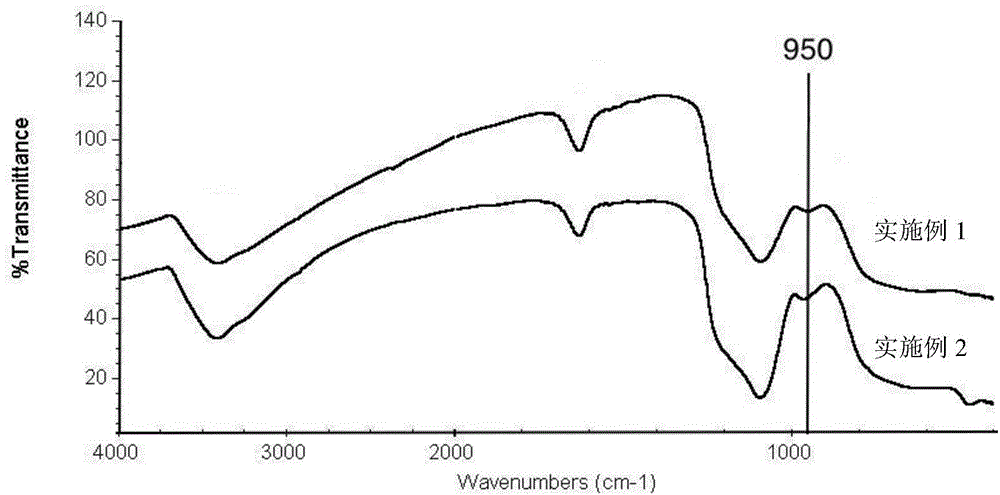

Preparation method of hollow sphere made of titanium dioxide composite

ActiveCN104671282AGood suspensionDoes not cause dissolutionMaterial nanotechnologyTitanium dioxideMetallic materialsAmorphous silicon

The invention belongs to the technical field of inorganic nonmetallic materials, particularly relates to a preparation method of a hollow sphere made of titanium dioxide composite, and specifically relates to a method for preparing a rutile type titanium dioxide hollow sphere with calcium carbonate serving as a template. The specific idea of the method is as follows: firstly, the surface of calcium carbonate is coated with amorphous silica, then, titanium dioxide nanocrystalline is deposited or grown on the surface of silica, meanwhile, calcium carbonate is removed, and the rutile type titanium dioxide hollow sphere is prepared.

Owner:常州纳欧新材料科技有限公司

Carbon-free ladle brick and preparation method thereof

ActiveCN102515794ASolve the problem of non-scouring resistance and aggregate powder separationGood structural flexibilityThermal expansionConstruction aggregate

The invention discloses a carbon-free ladle brick and a preparation method thereof. The carbon-free ladle brick is prepared by using bauxite chamotte, a corundum raw material, magnesium oxide and alumina micro powder as main raw materials, adding iron oxide, a magnesium chloride solution, sodium hexametaphosphate and canary dextrin, mixing the above-mentioned materials by using special procedures, storing an obtained mixed for 30 min, carrying out compression molding and drying the mixture at a temperature of 200 DEG C for 24 h. According to the invention, iron oxide and alumina micro powder are enabled to exist in gaps between aggregate and powder and form hercynite with a low thermal expansion coefficient at a medium-high temperature, and no excess iron oxide enters into a matrix, which enables the ladle brick to have good high temperature stability and anti-stripping performance; therefore, the problem that molten steel carburetting caused by high temperature melting loss of a refractory brick influences smelting quality is overcome, and the prepared carbon-free ladle brick has excellent performances of high strength, washing resistance, a long service life, etc.

Owner:山西高科耐火材料股份有限公司

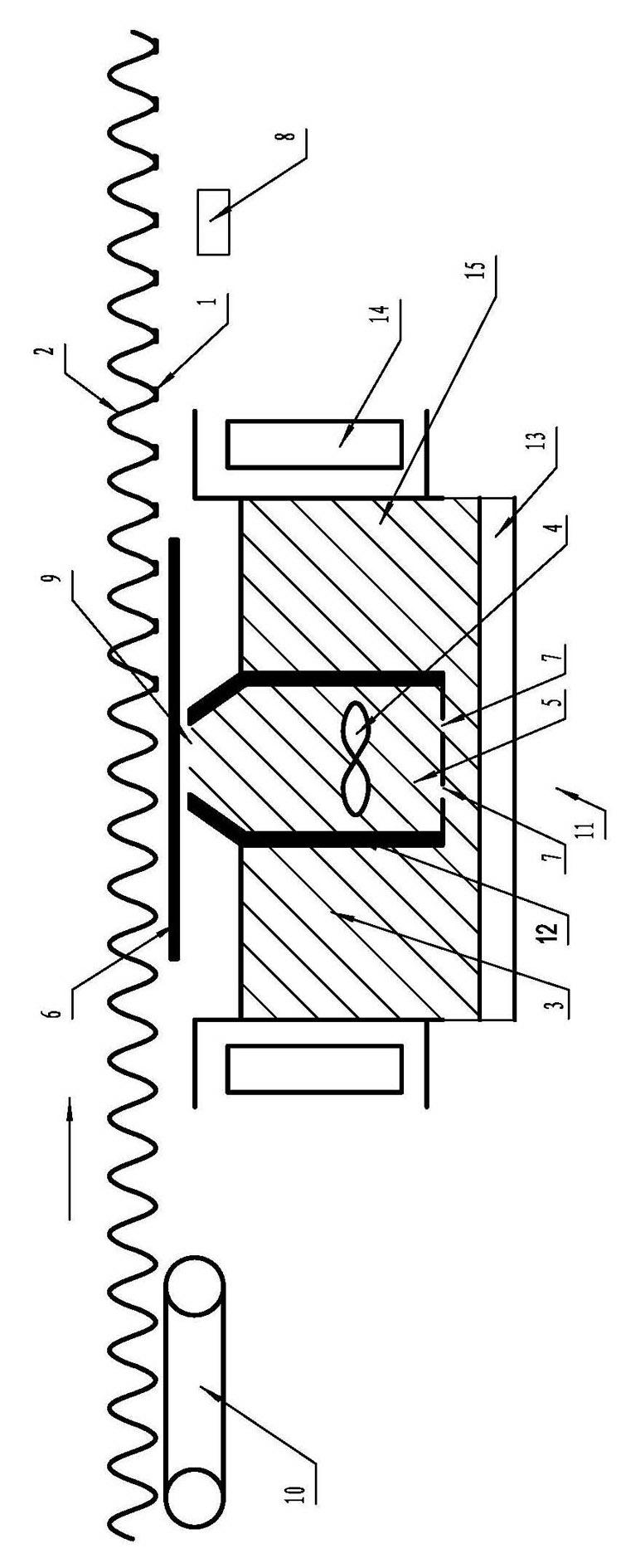

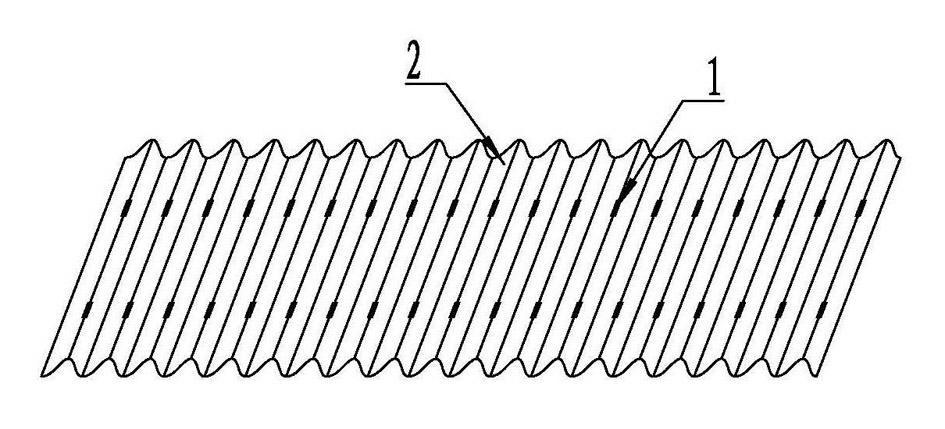

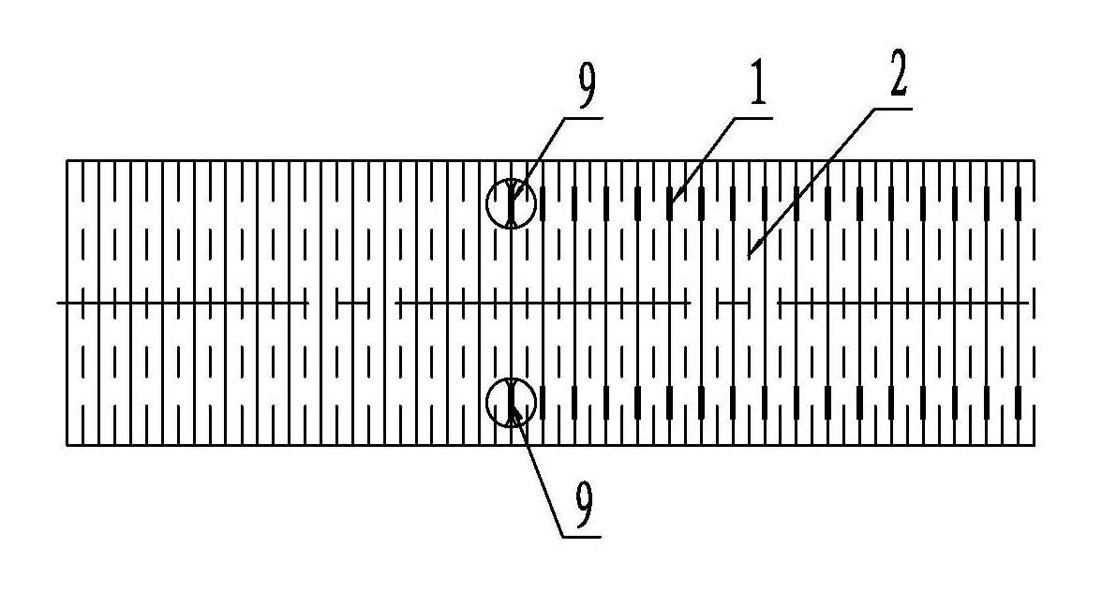

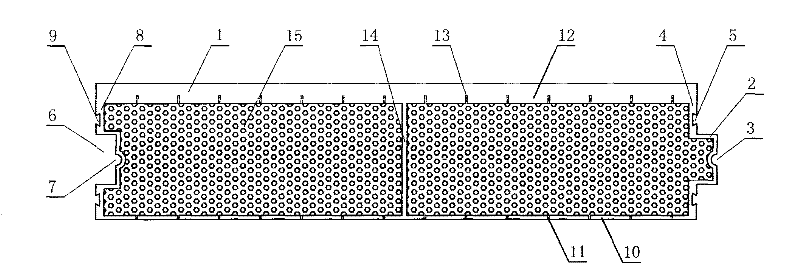

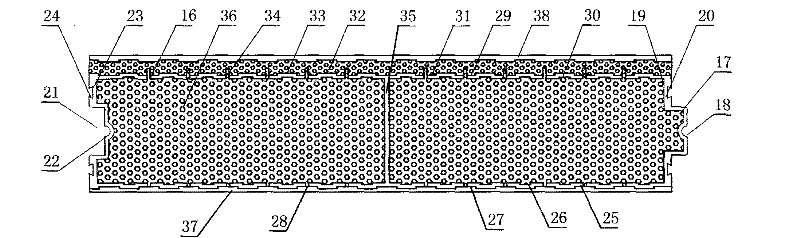

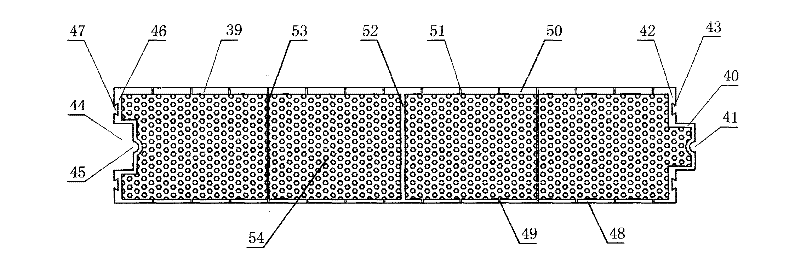

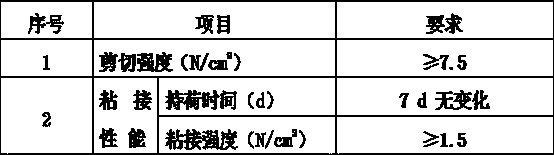

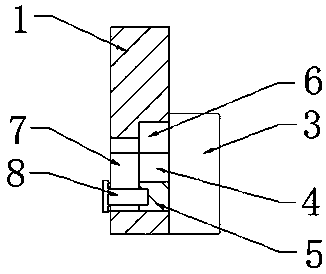

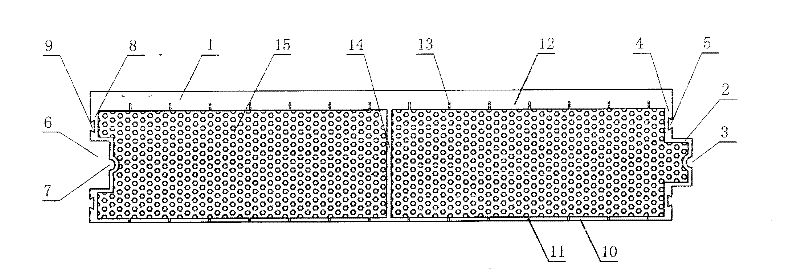

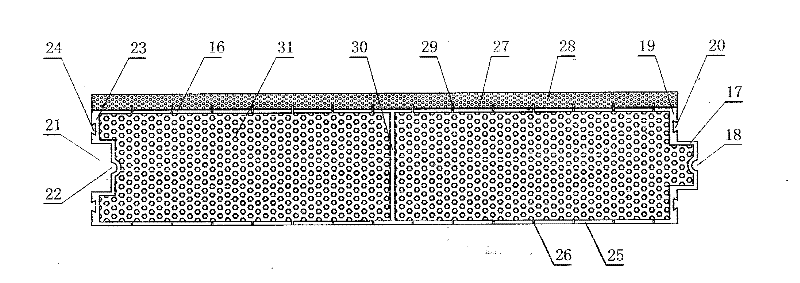

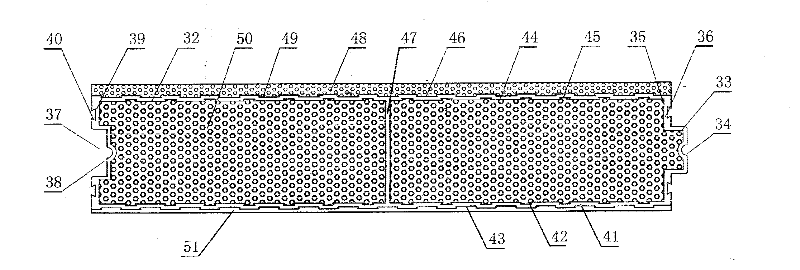

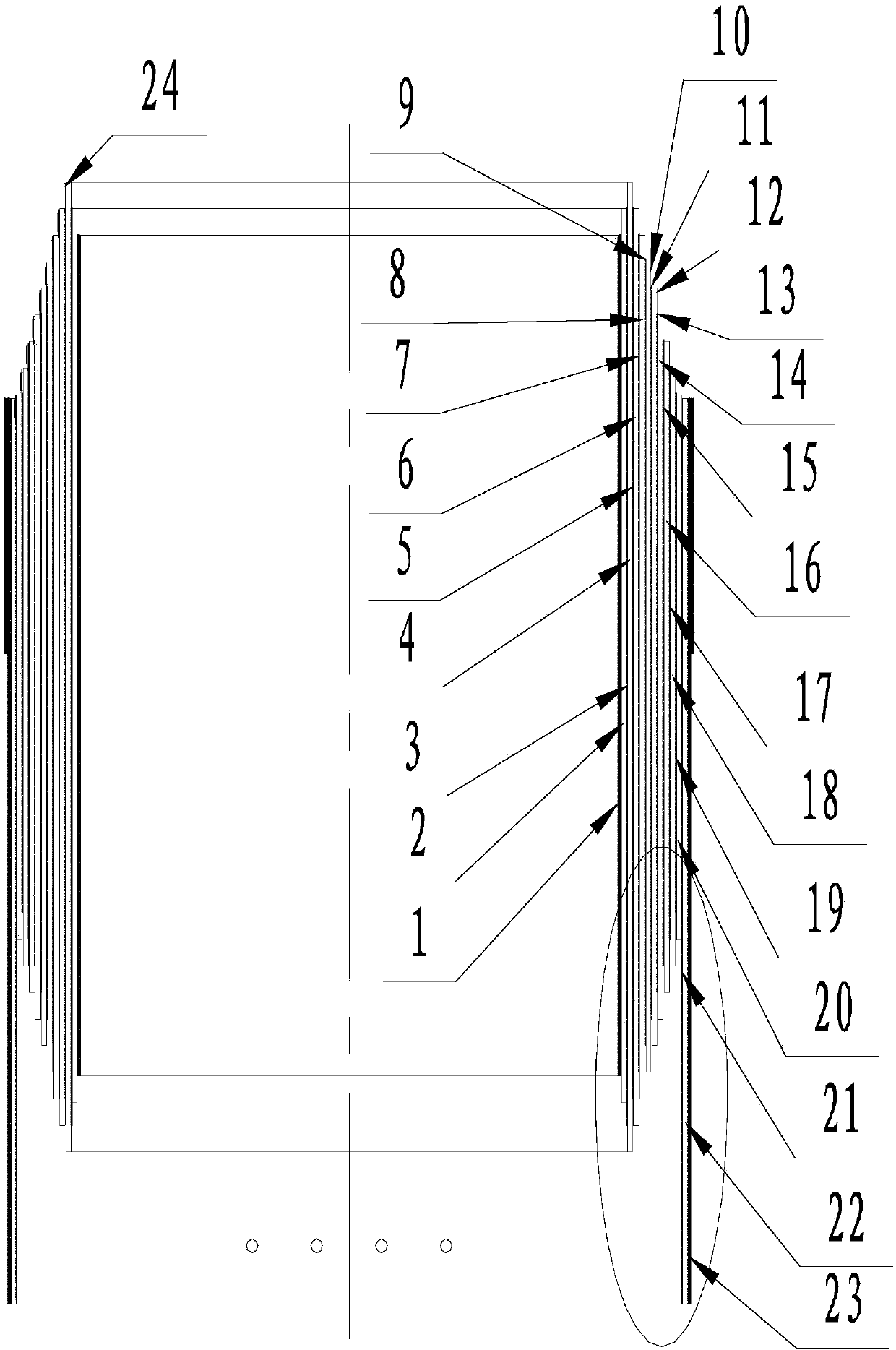

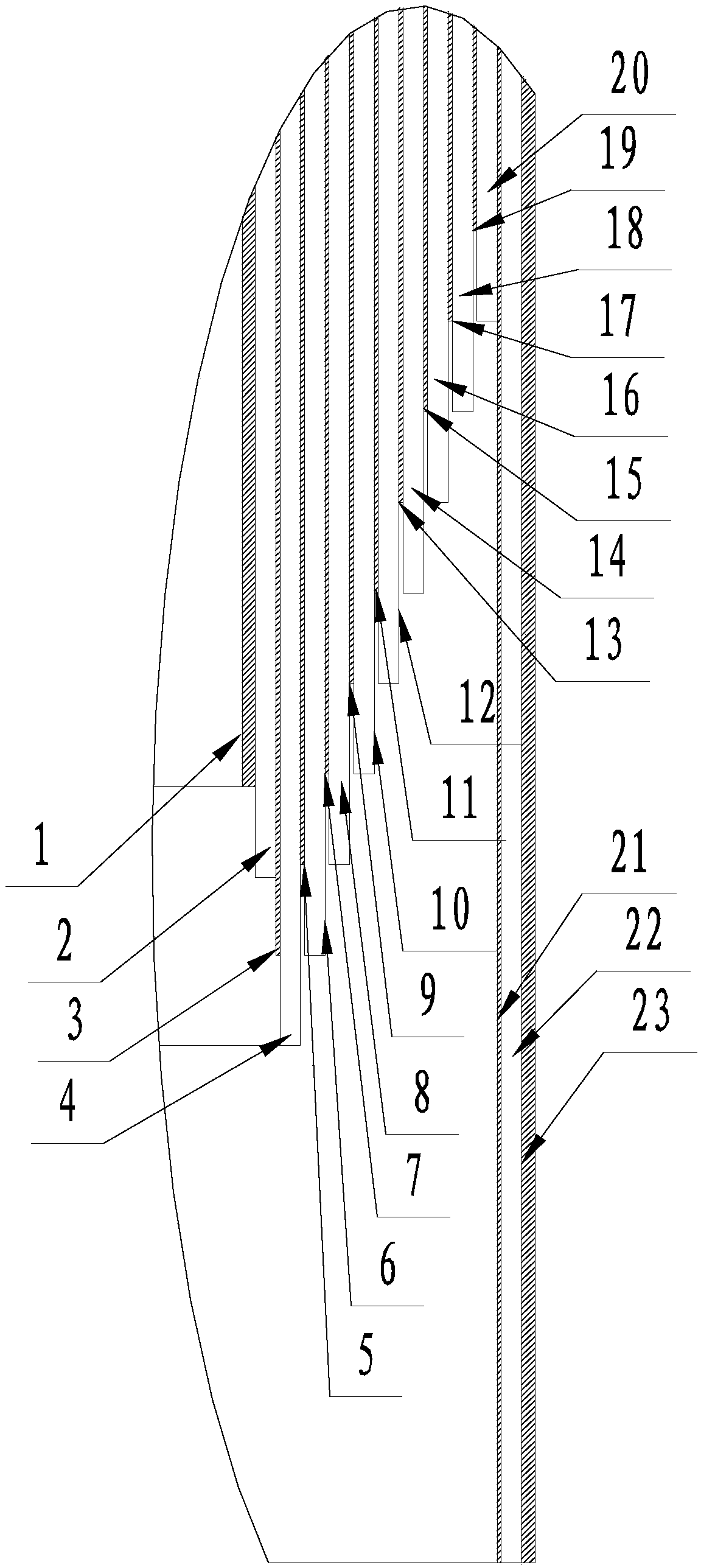

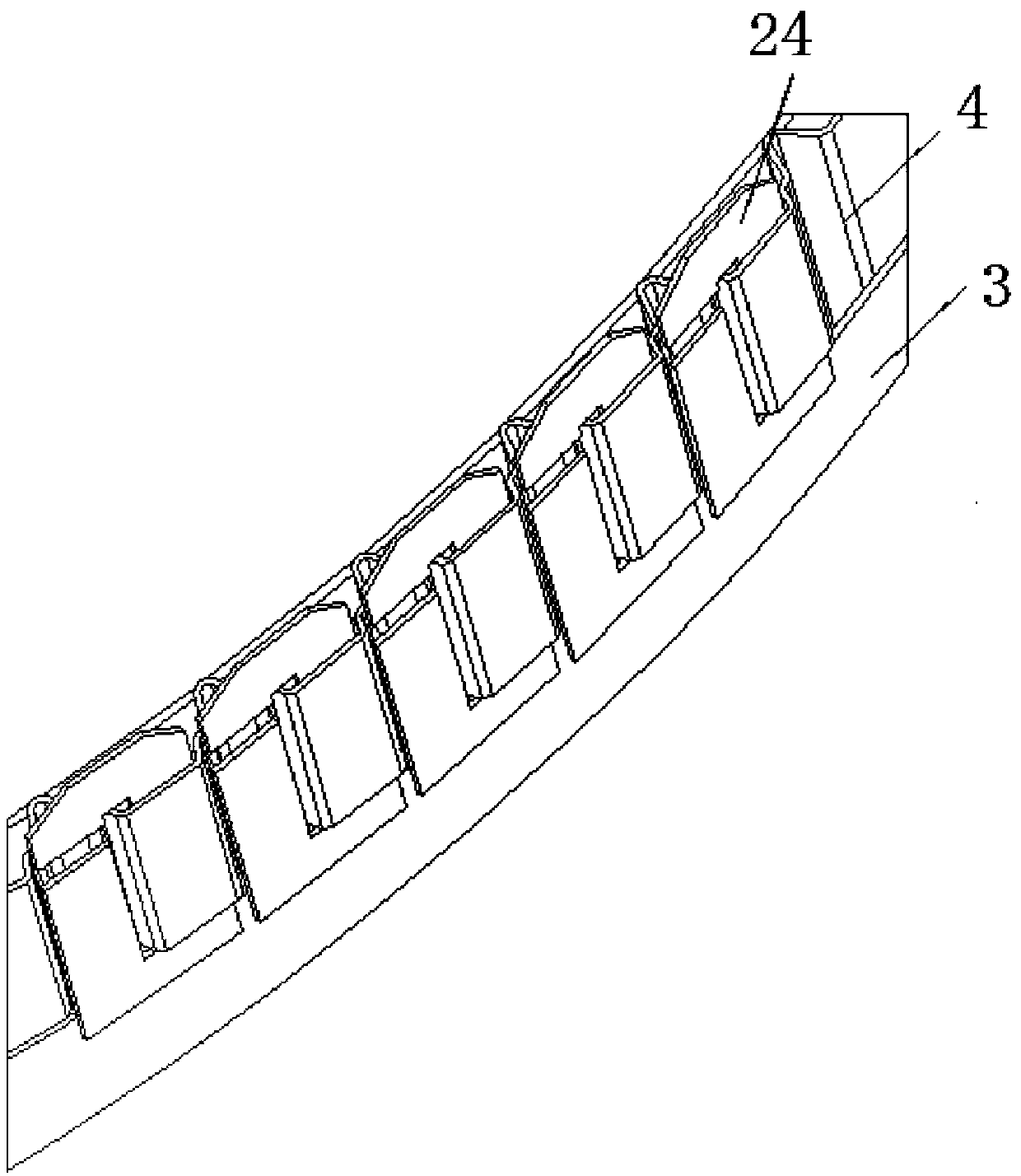

Method and device for soldering flux application

The invention belongs to the technical field of vehicle exhaust purification, and specifically relates to a method for applying soldering fluxes to metal corrugated ribbons and a device for implementing the method, wherein the metal corrugated ribbons to which the soldering fluxes are applied are preferably used for manufacturing metal honeycomb carriers for vehicle exhaust purifiers. The device for applying soldering fluxes to metal corrugated ribbons comprises a feeding device of metal corrugated ribbons, a soldering flux application unit for positioning the metal corrugated ribbons so as to carry out soldering flux application, and a gas cooling device or a heated-air drying device for solidifying the soldering fluxes. The method for applying soldering fluxes to metal corrugated ribbons is implemented mainly through the following step: applying soldering flux powder or a mixture consisting of the soldering flux powder and a binding agent to the metal corrugated ribbons by using the soldering flux application unit so as to form soldering fluxes solidified on or adhered to the wave crests or troughs of the metal corrugated ribbons. By using the method and device provided by the invention, the defects in the prior art, that the soldering fluxes are easy to fall off in the process of soldering flux application and the application strength of the prepared product is not enough, are overcome.

Owner:ZHEJIANG TIANZE ENVIRONMENTAL TECH

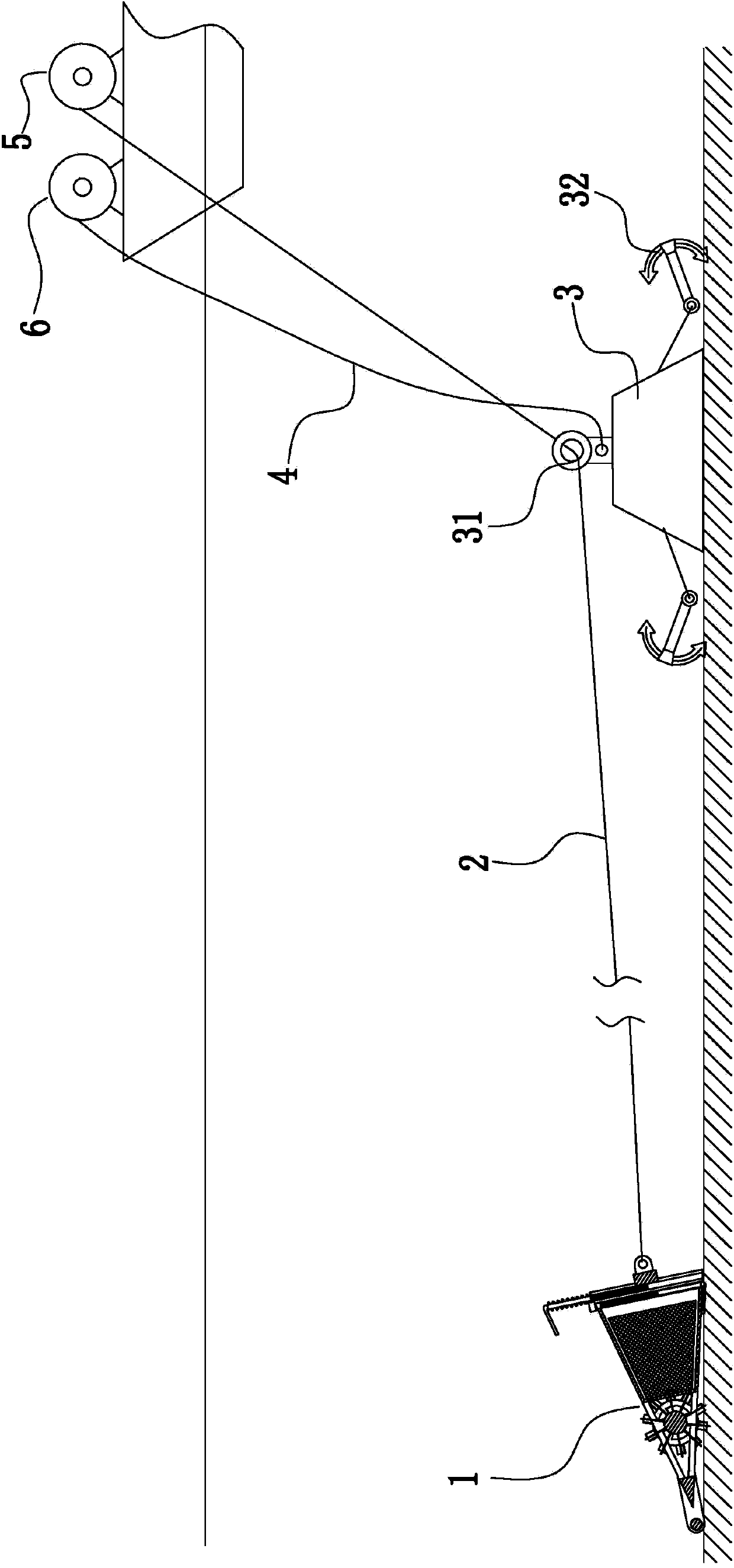

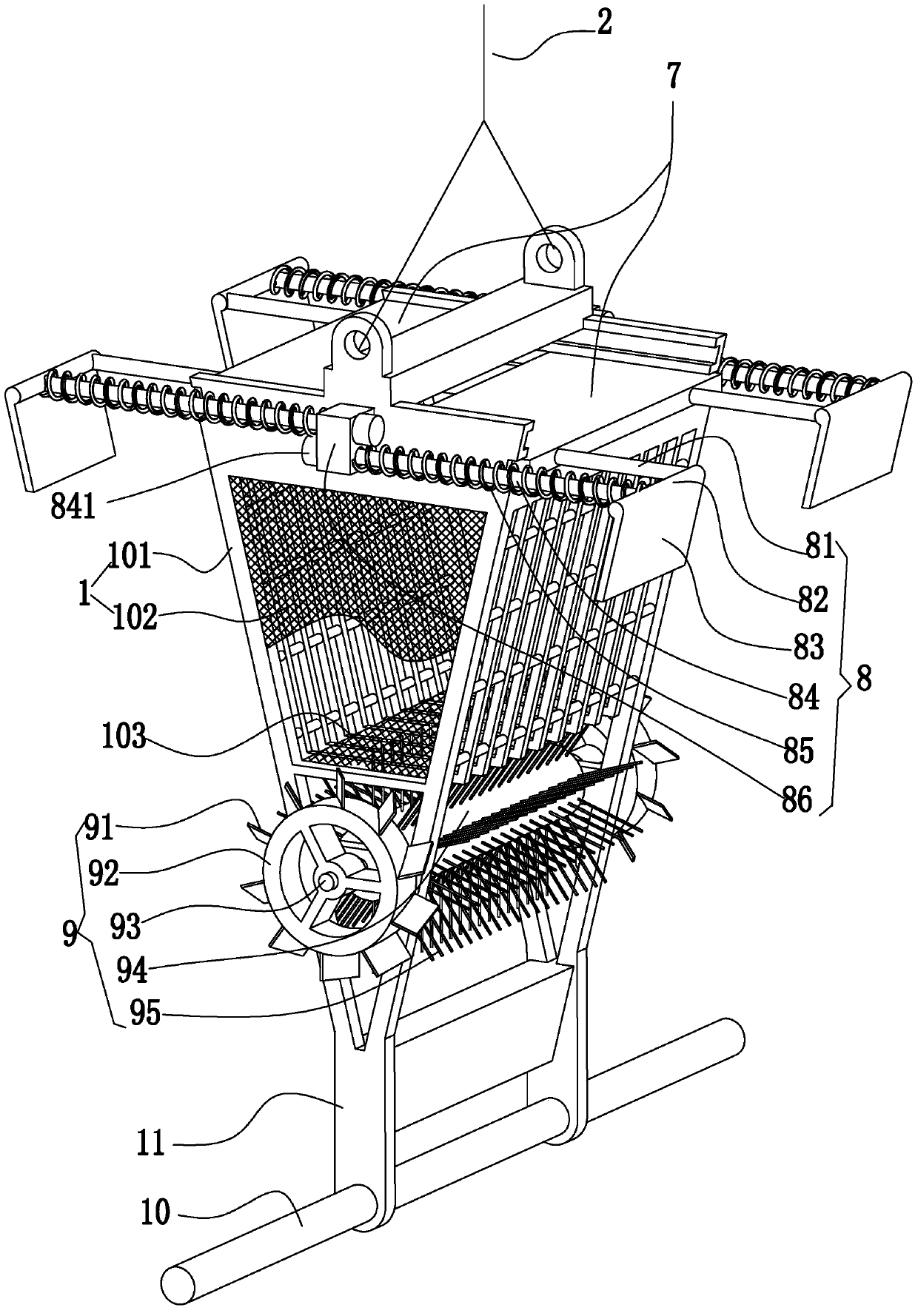

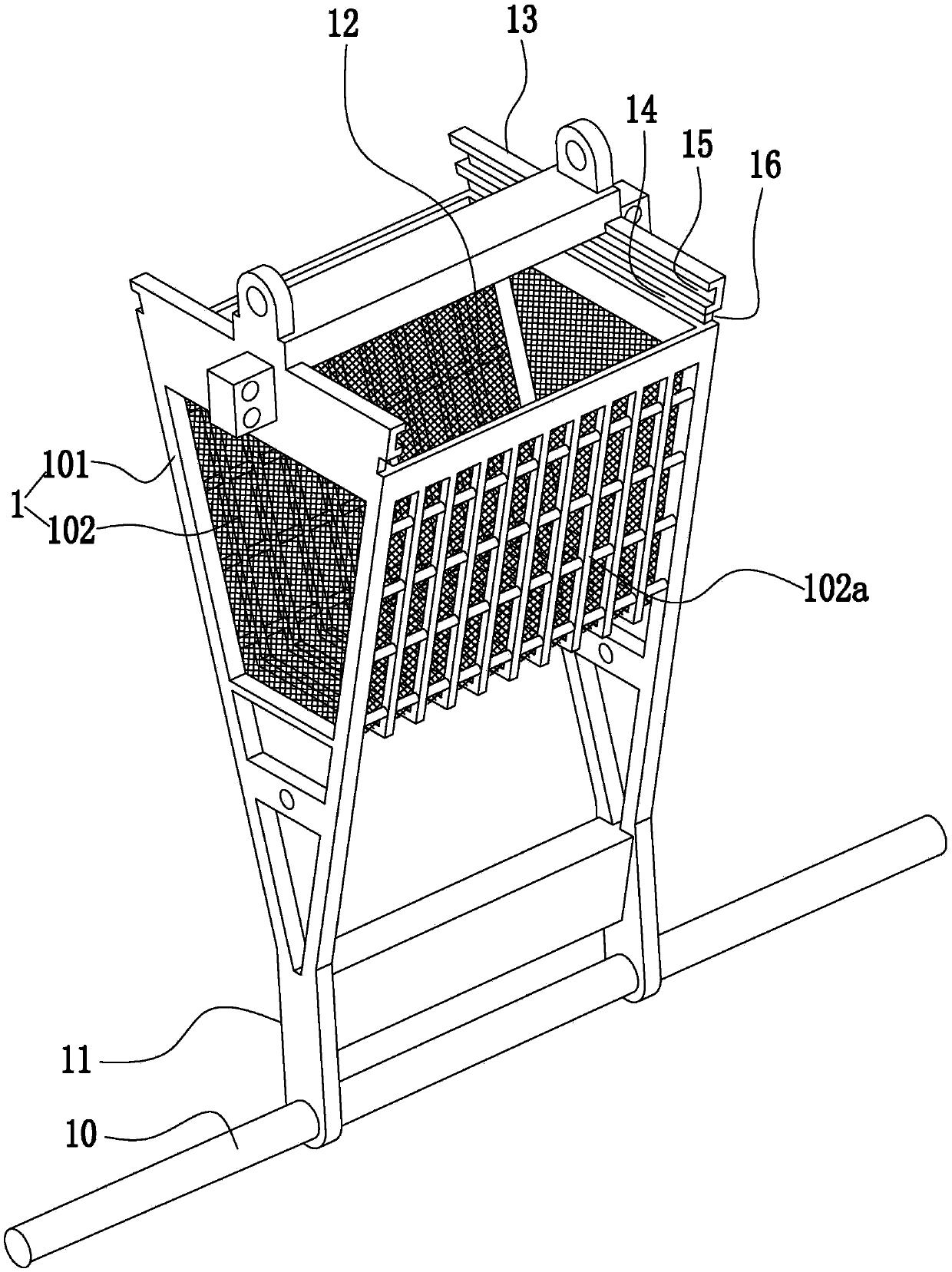

Marine bottom trawling trapper and trapping method thereof

The invention discloses a marine bottom trawling trapper and a trapping method thereof, and aims to provide the marine bottom trawling trapper which can effectively trap benthos perching on the surface of a seabed, and the trapping method thereof. The marine bottom trawling trapper comprises a trawl cage, a counterweight, at least one fixing anchor installed on the counterweight through a chain, a first reel rotatably arranged on a ship, a first rotating device for driving the first reel to rotate, a trawling rope reeled on the first reel, a second reel rotatably arranged on the ship, a second rotating device for driving the second reel to rotate, and a downwardly throwing rope reeled on the second reel, wherein the output shaft of the first rotating device is connected with the rotating shaft of the first reel through a first clutch; the output shaft of the second rotating device is connected with the rotating shaft of the second reel through a second clutch; the free end of the trawling rope is fixed on the trawl cage; the free end of the downwardly throwing rope is fixed on the counterweight; a guide ring is arranged on the counterweight; the trawling rope penetrates through the guide ring.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

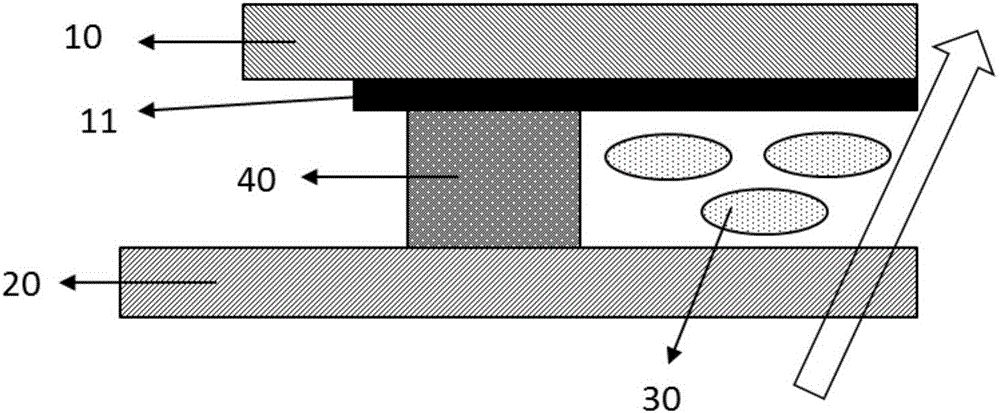

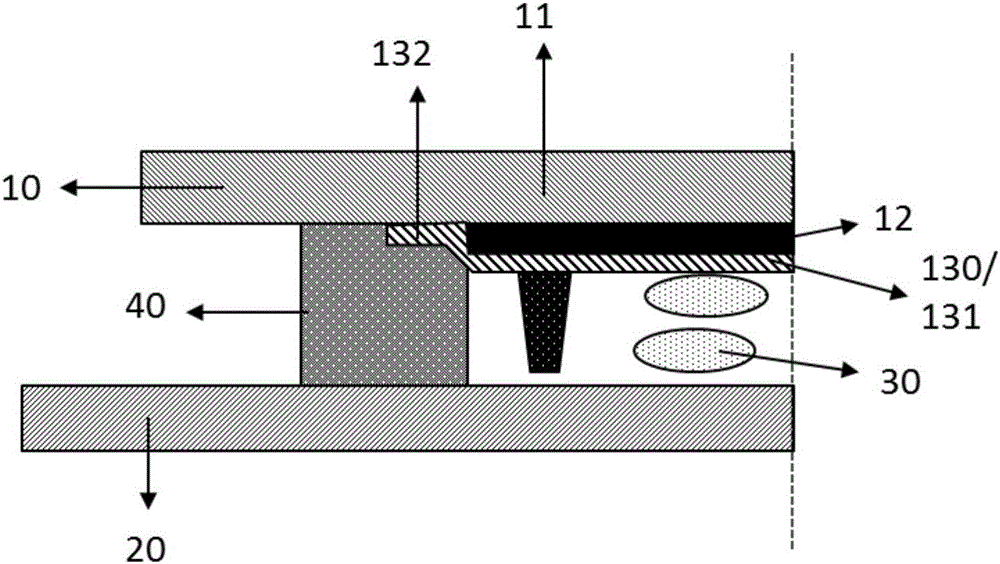

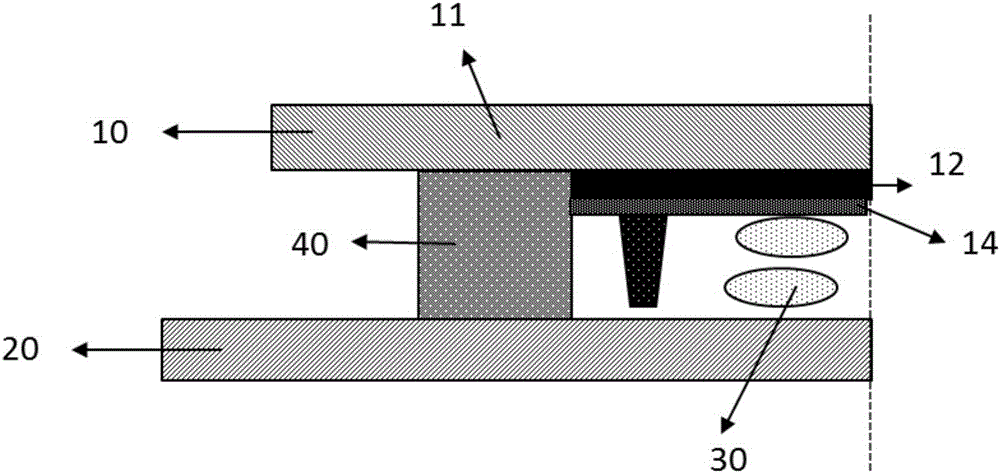

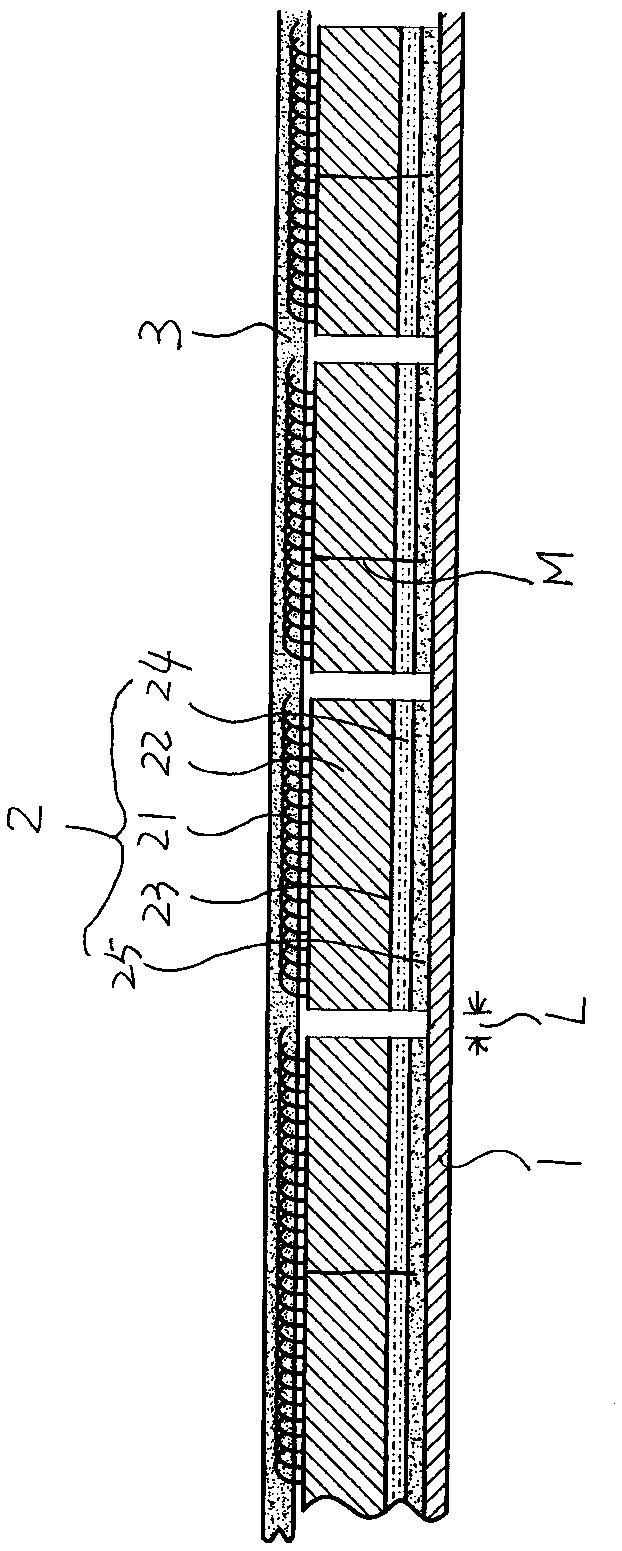

Liquid crystal display panel and manufacturing method thereof

InactiveCN106154638AImprove adhesionResolve disengagementNon-linear opticsLiquid-crystal displayLiquid crystal

The invention provides a liquid crystal display panel, which comprises a color film base plate, an array base plate, liquid crystals and black frame glue, wherein the color film base plate and the array base plate are in opposite arrangement; the liquid crystals are arranged between the color film base plate and the array base plate in a clamping way; the black frame glue is used for bonding the color film base plate and the array base plate; the color film base plate also comprises a glass base plate and a black matrix positioned on the glass base plate; at least partial black frame glue is in contact with the glass base plate. The liquid crystal display panel is applied to the periphery of the liquid crystal display panel; the black frame glue is directly applied on the glass base plate of the color film base plate; the bonding force between the color film base plate and the array base plate is enhanced; the problem of disengagement of the color film base plate and the array base plate of shadow hardening design in high-temperature and high-humidity environment can be effectively solved; the edge light leakage can be prevented by the black frame glue.

Owner:NANJING CEC PANDA LCD TECH

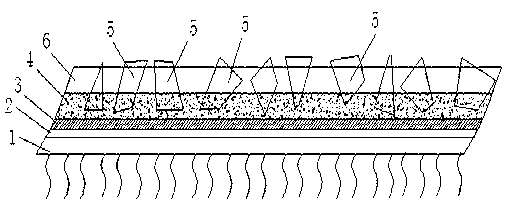

Fleece-based industrial abrasive cloth

The invention discloses fleece-based industrial abrasive cloth, and relates to fleece-based industrial abrasive cloth for polishing surfaces of metal and nonmetal materials. According to the technical scheme, the fleece-based industrial abrasive cloth comprises fleece, wherein a membrane is arranged on a non-piled surface of the fleece; a layer of base gel is coated on the membrane; an abrasive material is attached to the base gel through electrostatic sand planting; a layer of composite gel is coated on the base gel and the abrasive material; the thickness of the membrane is 10 to 20 micrometers, and the membrane is uniform and smooth; a layer of resin is coated on the membrane; and the base gel is coated on the resin. Compared with the conventional abrasive disc, the abrasive cloth has the advantages that abrasive paper gluing processes are reduced, the application of gluing resin is reduced, and the cost is greatly saved; and the problem that abrasive paper is separated from the fleece in the grinding and using process is radically solved.

Owner:谢泽

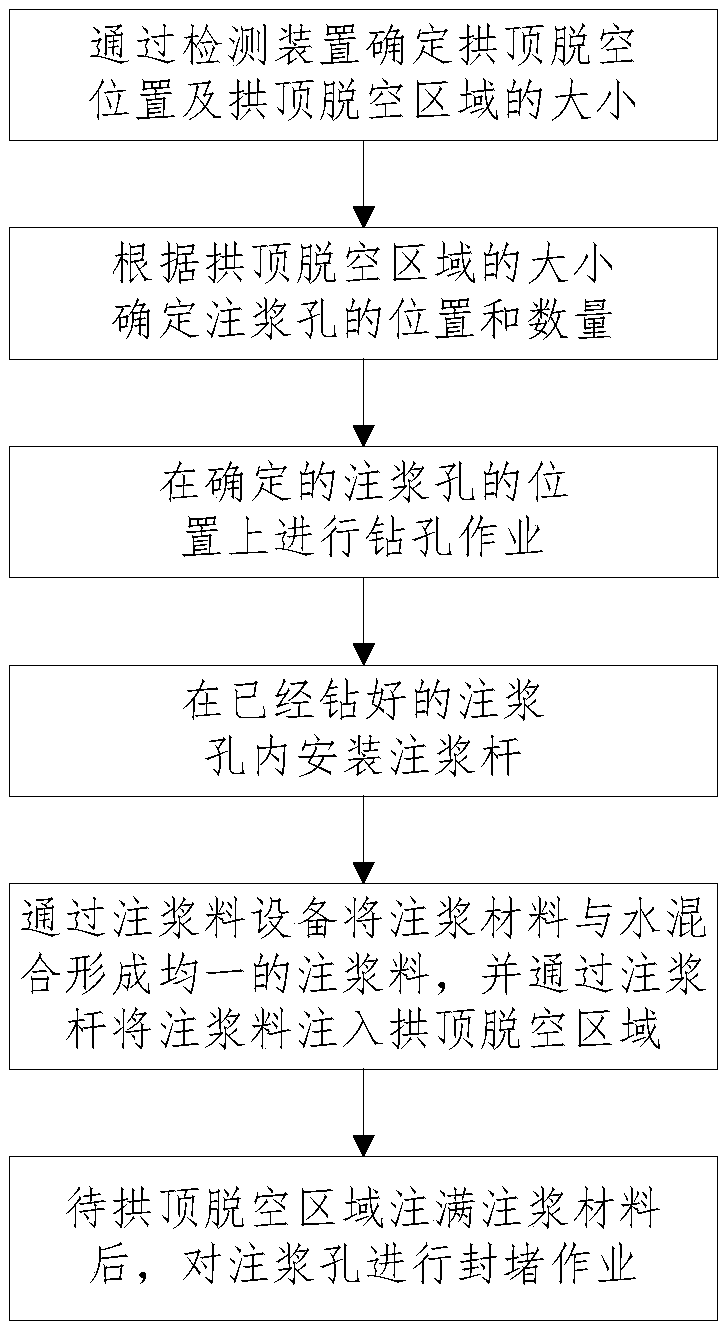

Technology for solving problem of tunnel lining vault disengaging

InactiveCN108625878AImprove construction efficiencyLow costUnderground chambersTunnel liningShrinkage rateUltimate tensile strength

The invention provides a technology for solving the problem of tunnel lining vault disengaging. The technology comprises the steps that the location and size of a disengaging area of a vault are determined by a detection device; the location and quantity of a grouting hole are determined according to the size of the disengaging area of the vault; the drilling operation is carried out at the location of the identified grouting hole; a grouting bar is installed in the drilled grouting hole; grouting materials are mixed with water to form uniform grouting materials through grouting equipment, andthe grouting materials are injected into the disengaging area of the vault through the grouting bar; and after the disengaging area of the vault is filled with the grouting materials, the grouting hole is subjected to plugging operation. A traditional grouting pipe is replaced by the grouting bar to improve the construction efficiency, and meanwhile, the grouting bar can be recycled for use to reduce the cost. The grouting materials adopt micro-expansion grouting materials, the micro-expansion grouting materials can be expanded to be fully combined with concrete in the moulding stage, the shrinkage rate is small after hardening, and the bond strength with concrete is high, and the problem of disengaging from concrete after hardening in the traditional process is solved.

Owner:BEIJING TIEKE SHOUGANG RAIL TECH CO LTD

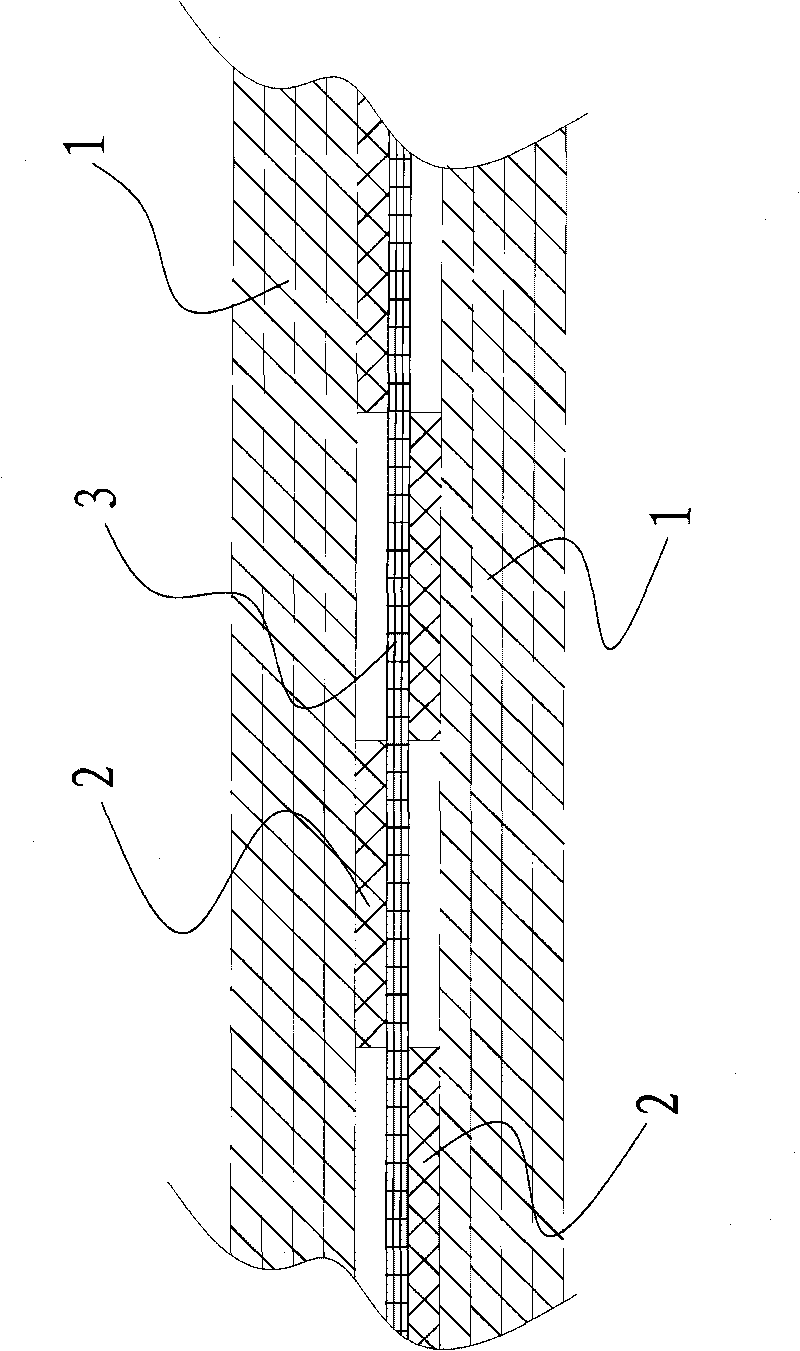

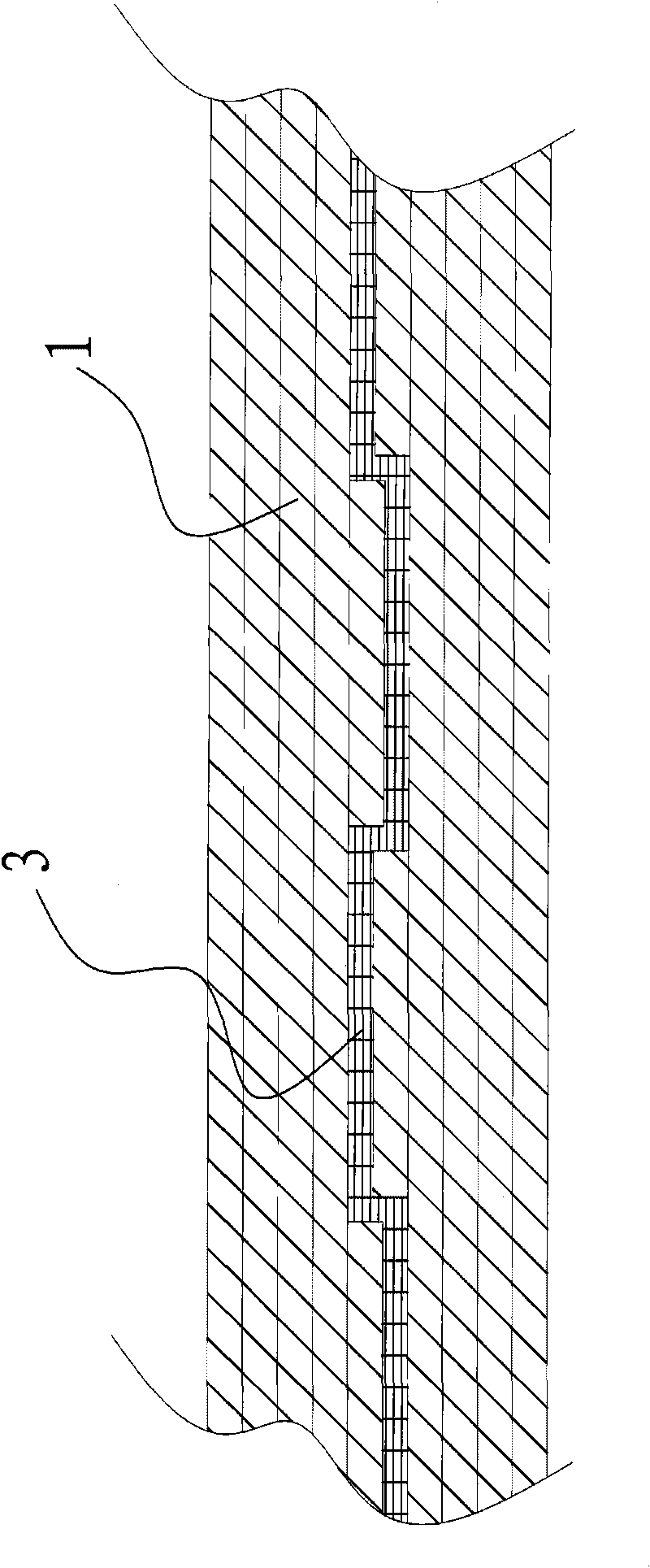

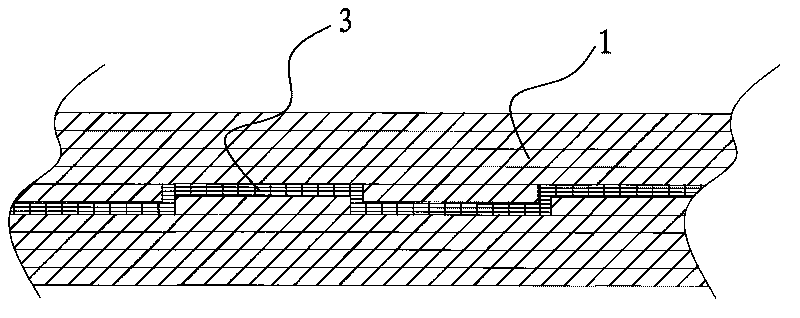

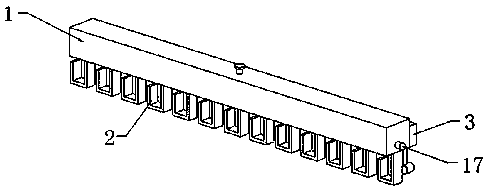

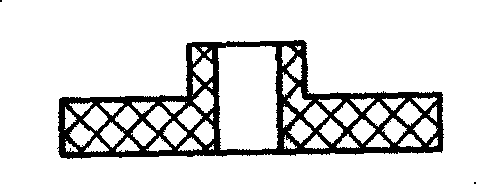

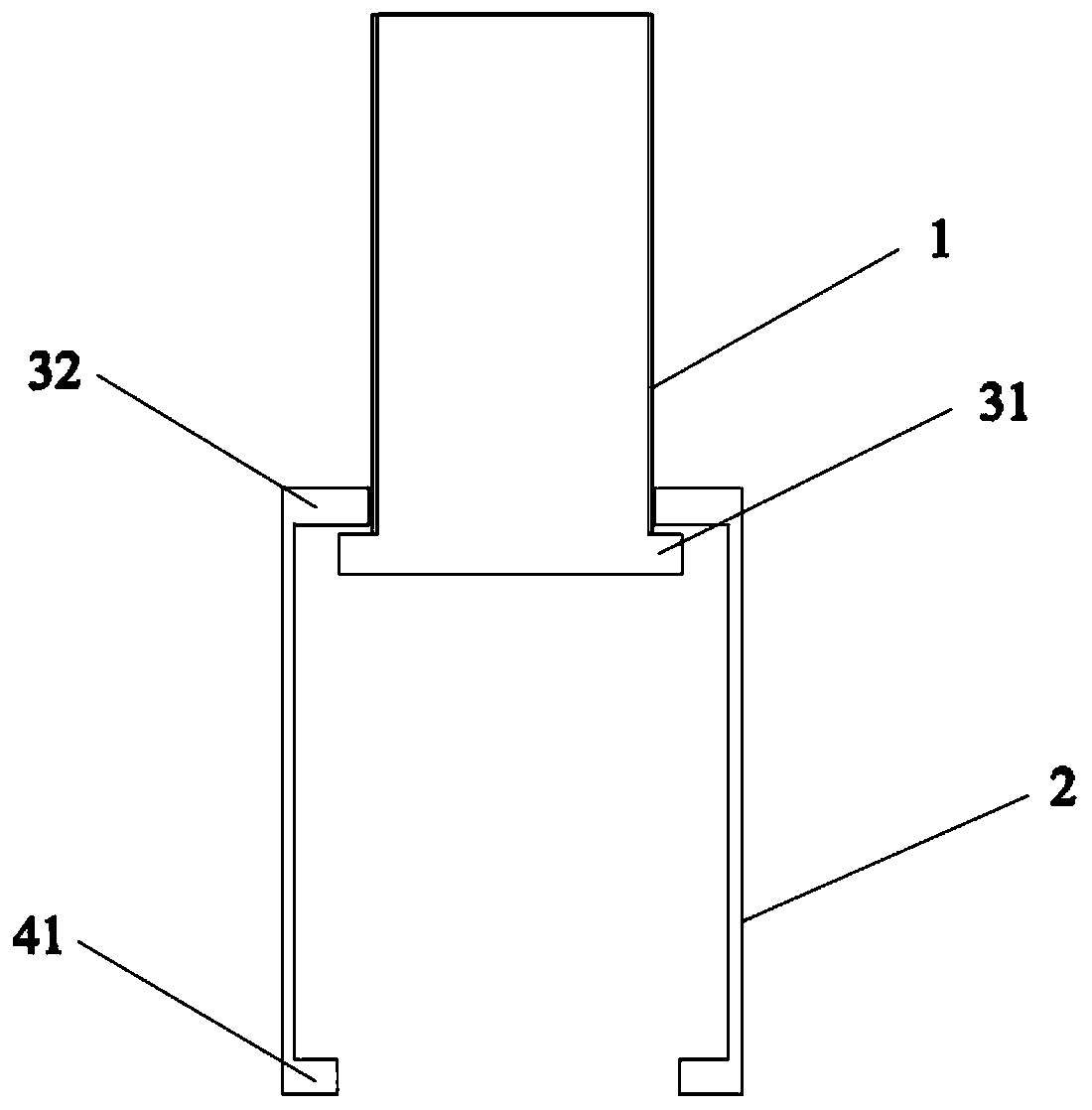

Hole wallboard internally filled with thermal insulation materials

InactiveCN102691356ASolve the temperature expansion detachment problemResolve disengagementCovering/liningsHeat proofingThermal insulationMaterials science

A hole wallboard internally filled with thermal insulation materials comprises wallboards and thermal insulation materials. Holes are arranged in wallboard planes; the thermal insulation materials are filled in a wallboard cavity; and the thermal insulation materials are inlaid in the wallboard plane holes.

Owner:王广武

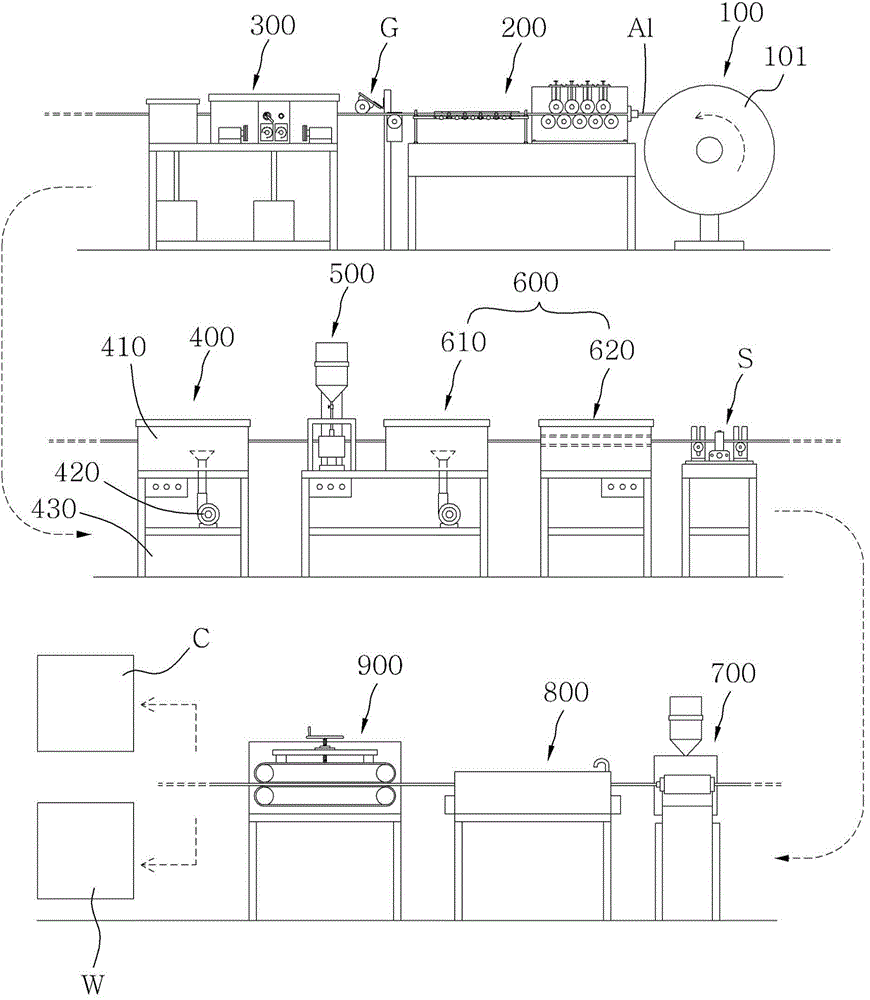

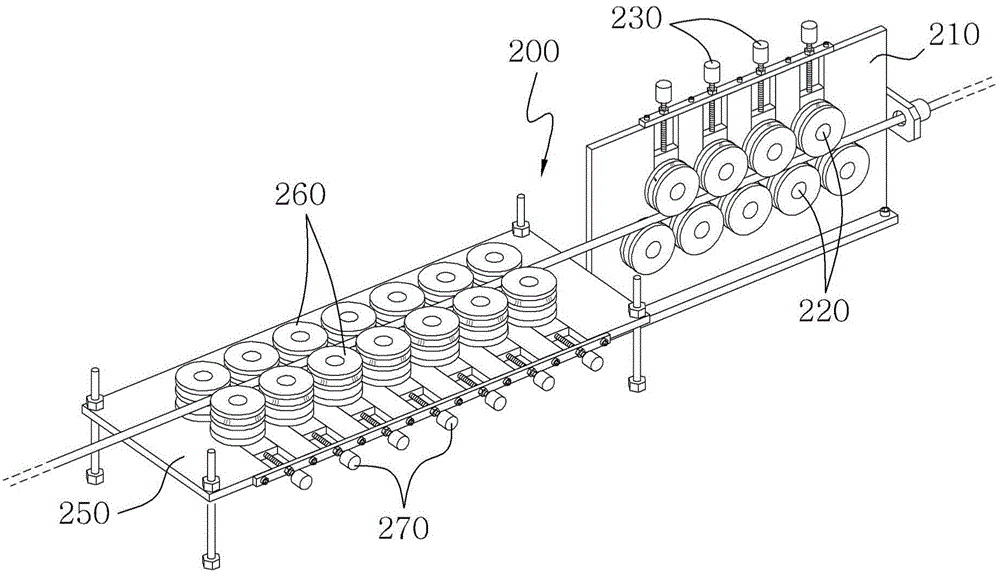

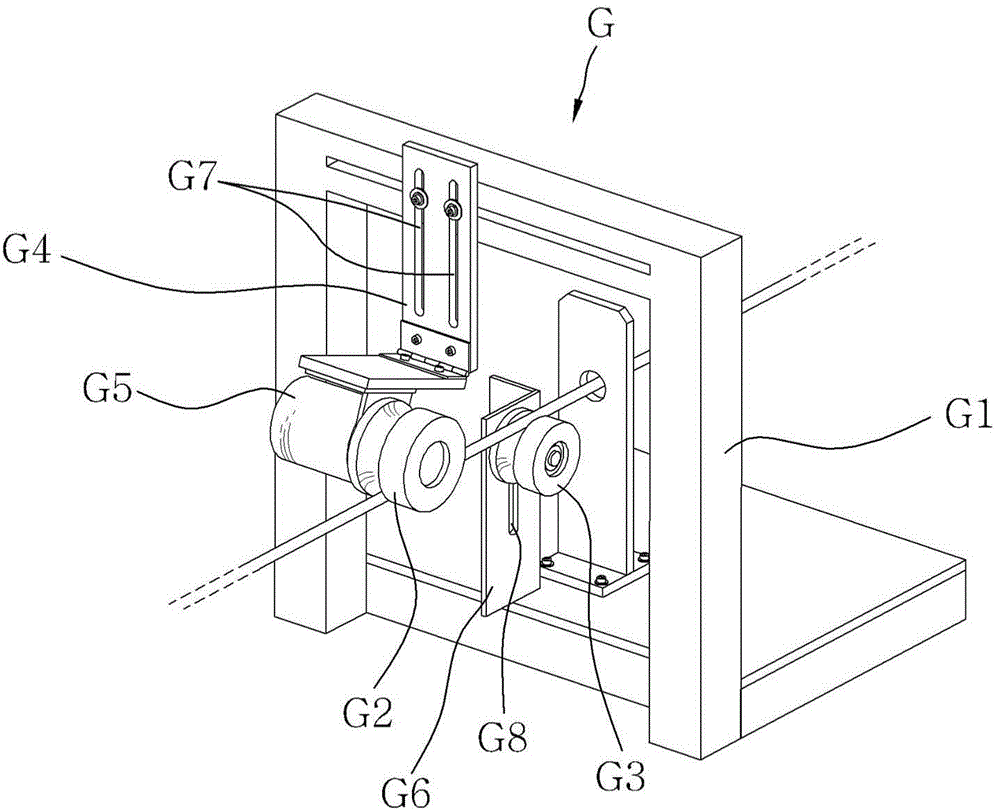

Aluminum pipe resin coating apparatus

ActiveCN105268616AResolve disengagementImprove qualityHollow article cleaningAdhesive processes with adhesive heatingAdhesiveResin coating

The present invention relates to an aluminum pipe resin coating apparatus which stably, solidly, and evenly coats resin on the outer surface of an aluminum pipe, an aluminum alloy pipe, and a copper (Cu) pipe (called aluminum pipe hereinafter) used for refrigerant pipes or hydraulic pipes, and other fuel lines, etc., the aluminum pipe resin coating apparatus comprising: a linearizing means (200) for linearizing an aluminum (Al) pipe supplied from an aluminum pipe supplying means (100); a washing means (300) for washing the surface of the linearized aluminum pipe and simultaneously generating fine scratches on the surface; a drying means (400) for drying the washed aluminum pipe; an adhesive applying means (500) for supplying and applying an adhesive on the dried aluminum pipe; a preheating means (600) for preheating the adhesive-applied aluminum pipe; a resin coating means (700) for coating a resin on the surface of the preheated aluminum pipe; a cooling means (800) for cooling the resin-coated aluminum pipe; and a drawing-out means (900) for drawing out the cooled aluminum pipe.

Owner:吴炯东

Waterproof plate, drainage plate and drainage-proof plate in tunnels and using method thereof

PendingCN108590714AOvercome self-respectGood adhesionUnderground chambersSynthetic resin layered productsEngineeringFastener

The invention belongs to the field of tunnel waterproof and drainage materials andparticularly relates to a waterproof plate, a drainage plate and a drainage-proof plate capable of being attached to aself-adhesive cloth of the tunnels and achieving adhesive type fixing and using method thereof. The waterproof plate, the drainage plate and the drainage-proof plate structurally comprise a waterproof plate body, and the waterproof plate body is provided with an attaching mechanism formed by a hook face, a foundation body, a back gum layer, a first attaching layer and a second attaching layer, wherein the hook face and the back gum layer are correspondingly arranged on the front and rear faces of the foundation body, the first attaching layer is attached on the back gum layer, and the secondattaching layer is combined on the first attaching layer. When in use, the hook face forming the tunnel waterproof plate, drainage plate and the drainage-proof plate is directly attached on the self-adhesive cloth layer which is fixed to the tunnel primary support by fasteners. The waterproof plate, drainage plate and the drainage-proof plate have the characteristics of being simple in structure and easy to fix.

Owner:河北省同创交通工程配套产品产业技术研究院 +2

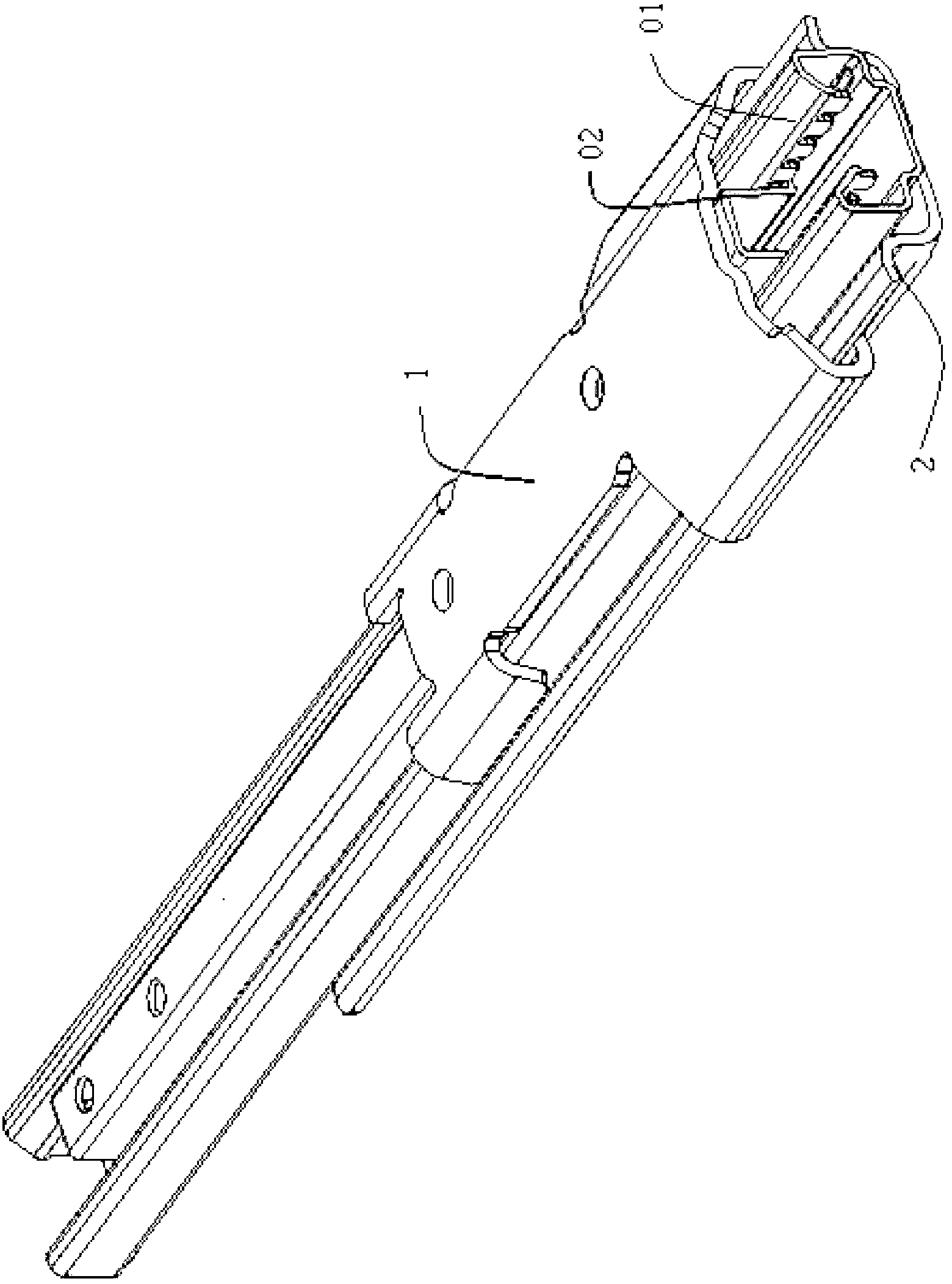

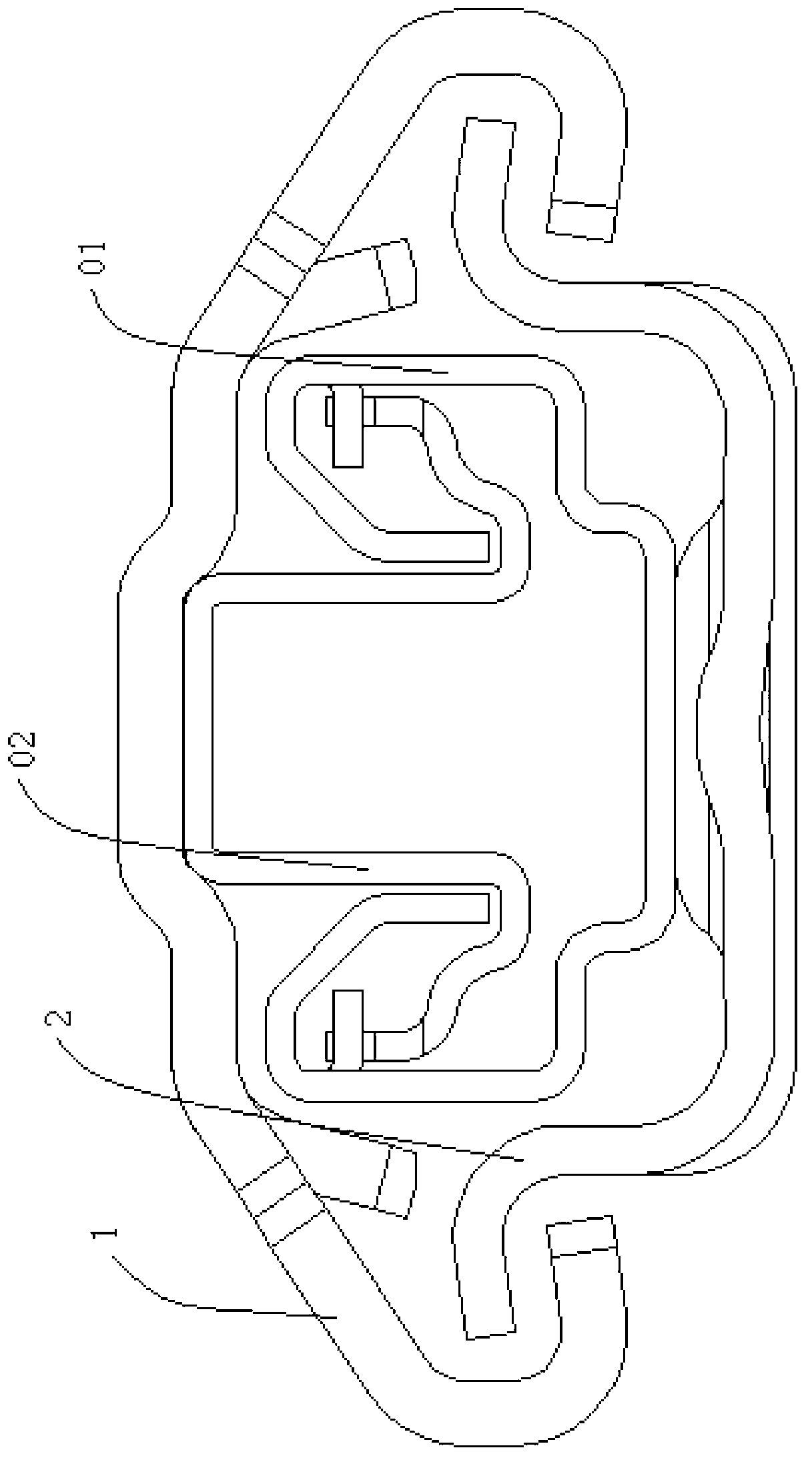

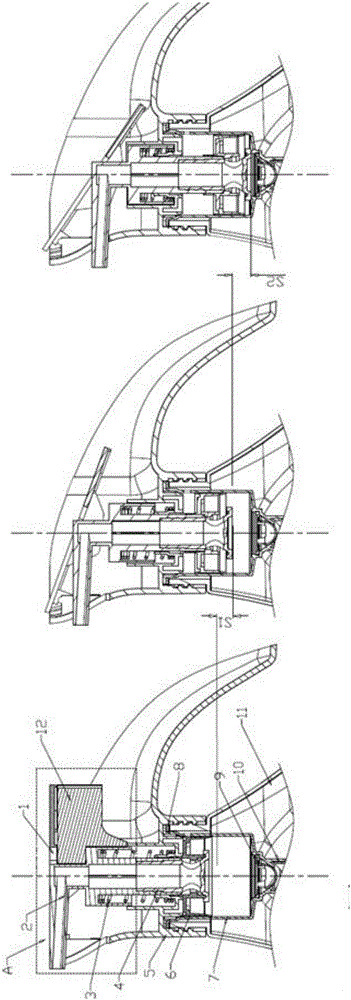

Automobile, automobile seat and siding rail mechanism of automobile seat

InactiveCN103253157AIncrease stiffnessNot easy to plastically deform or breakMovable seatsEngineeringFixed Slide

Owner:HUBEI AVIATION PRECISION MASCH TECH CO LTD

Electric heating mica plate and preparation method thereof

ActiveCN101730323AResolve disengagementGuaranteed powerHeating element materialsTime compressionResistor

The invention relates to an electric heating mica plate and a preparation method thereof. On one hand, a mode of one-time compression molding by laminating a plurality of layers of mica paper and a heating resistor sheet is adopted and is particularly suitable for the electric heating mica plate with the heating resistor sheet, and the combination between the heating resistor sheet and the mica paper adjacent to the heating resistor sheet is more tight and more complete without gaps; on the other hand, the prepared electric heating mica plate has a structure that the heating resistor sheet is in a continuous wave shape transversely and / or longitudinally; the expanding and shrinking range of the heating resistor sheet is moderate; and some forces separating the heating resistor sheet from the two sides which are generated due to expanding with heat, contracting with cold or wetting and other factors between an upper side and a lower side of the heating resistor sheet can be effectively cushioned. In a word, the phenomena of foaming and layering can be effectively avoided; and the power and service life of the heating resistor sheet are guaranteed. The electric heating mica plate is more environment-friendly and safer, and hardly to deform.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

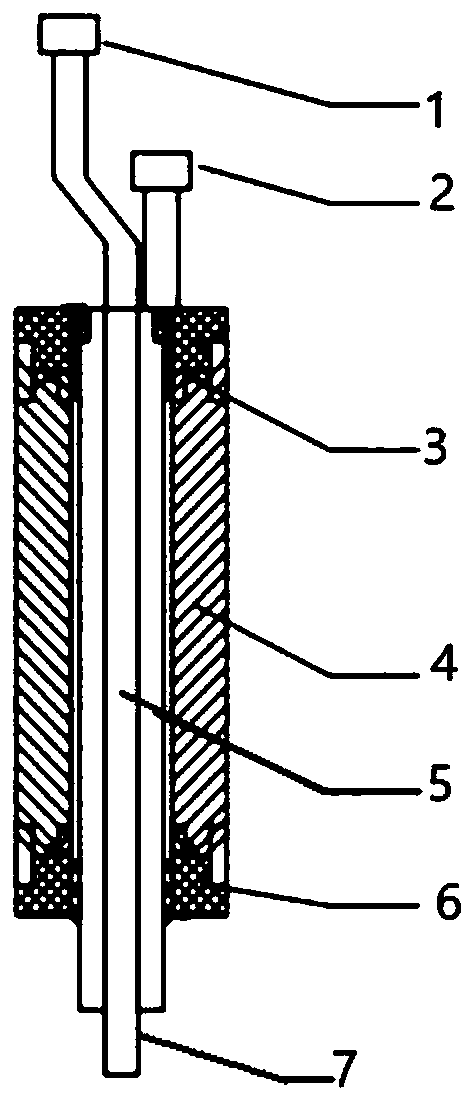

Harness wire take-off device of automatic drafting machine

Owner:江苏大邦智能科技有限公司

Anti-interference television system bidirectional user port capable of preventing creepage

ActiveCN101198001AAvoid threadingIncrease ratingsTelevision system detailsColor television detailsCapacitanceShielded cable

The invention discloses an anti-interference and creepage protective television system two-way user port which comprises an integral metallic shield casing, a circuit board, an input port and an output port arranged in the casing, wherein signal poles for connection with a coaxial signal cable and shaded poles for connection with a coaxial shield cable are arranged on both the input port and the output port, and the shaded poles of the input port respectively enter the casing through holes in the casing without communication with the casing and are isolated from the signal poles in a non-capacitance mode. The invention which not only meets the requirements of a digital TV but also is compatible with an analog TV has reliable and definite anti-interference and creepage protective functions which exist even in case of TV and set-top box circuit abnormality. In whatever cable TV networks of a digital TV system or an analog TV system, the invention can overcome the defects of the prior art and ensure the personnel safety of the user and excellent visual effect.

Owner:桂林市创琳电子科技发展有限公司

Balance toy car

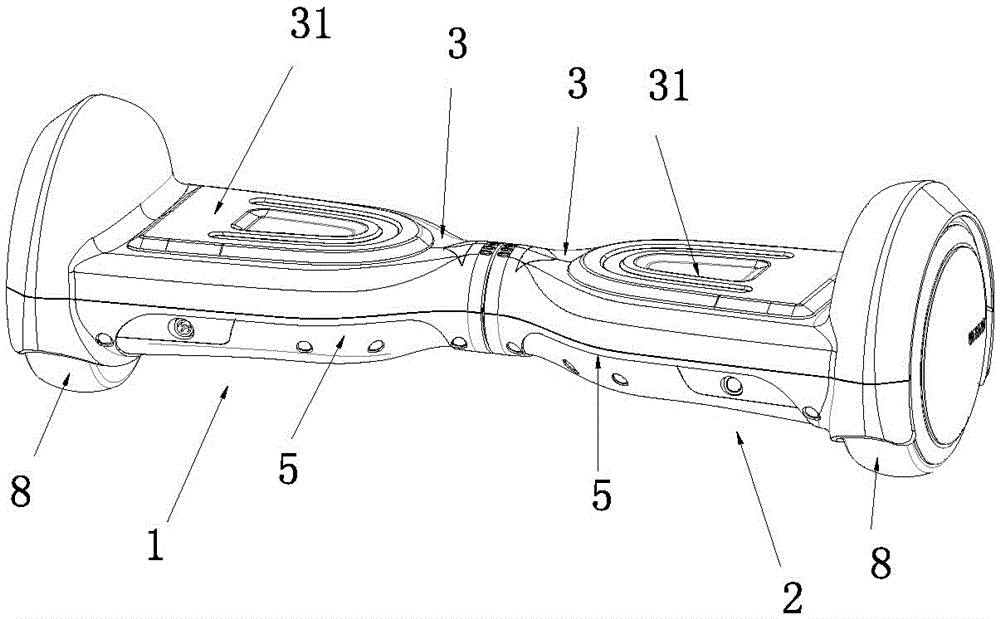

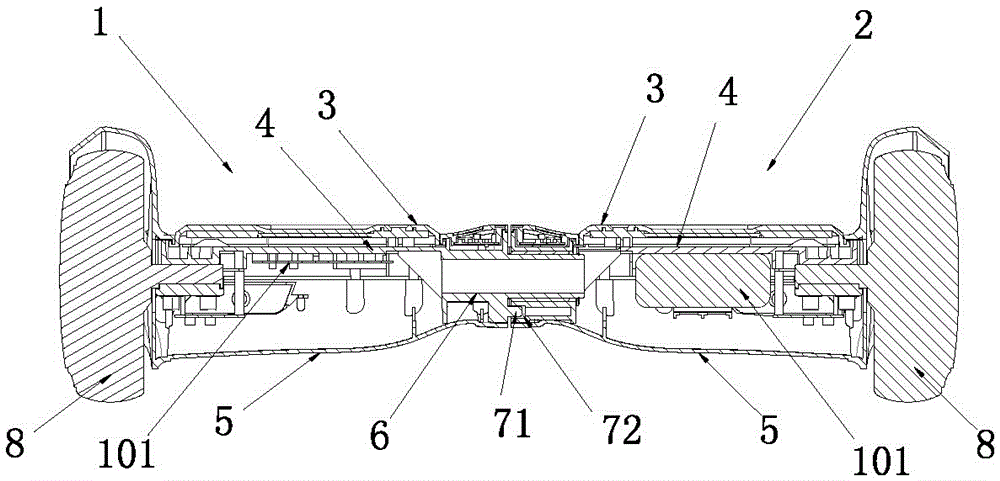

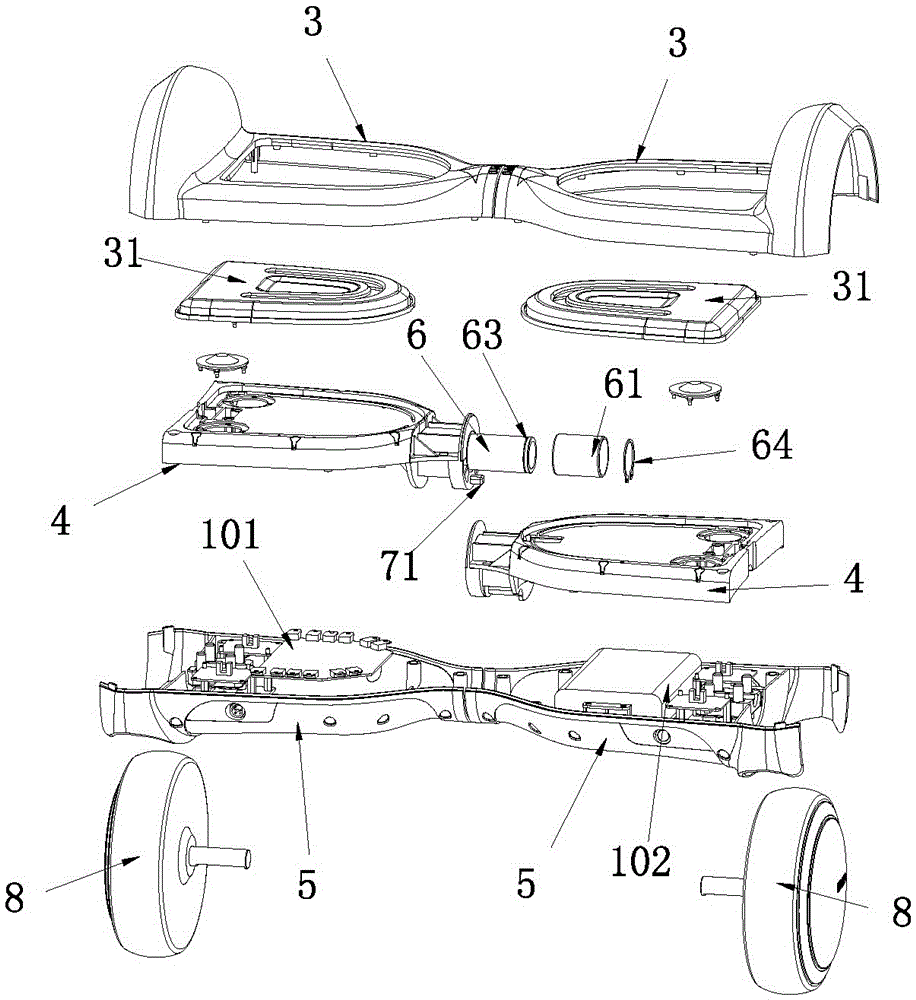

InactiveCN105882826AImprove securityGuaranteed smoothnessMotorcyclesBicyclesSupport planeAutomotive engineering

Owner:DONGGUAN CHEXIAOMI INTELLIGENT TECH CO LTD

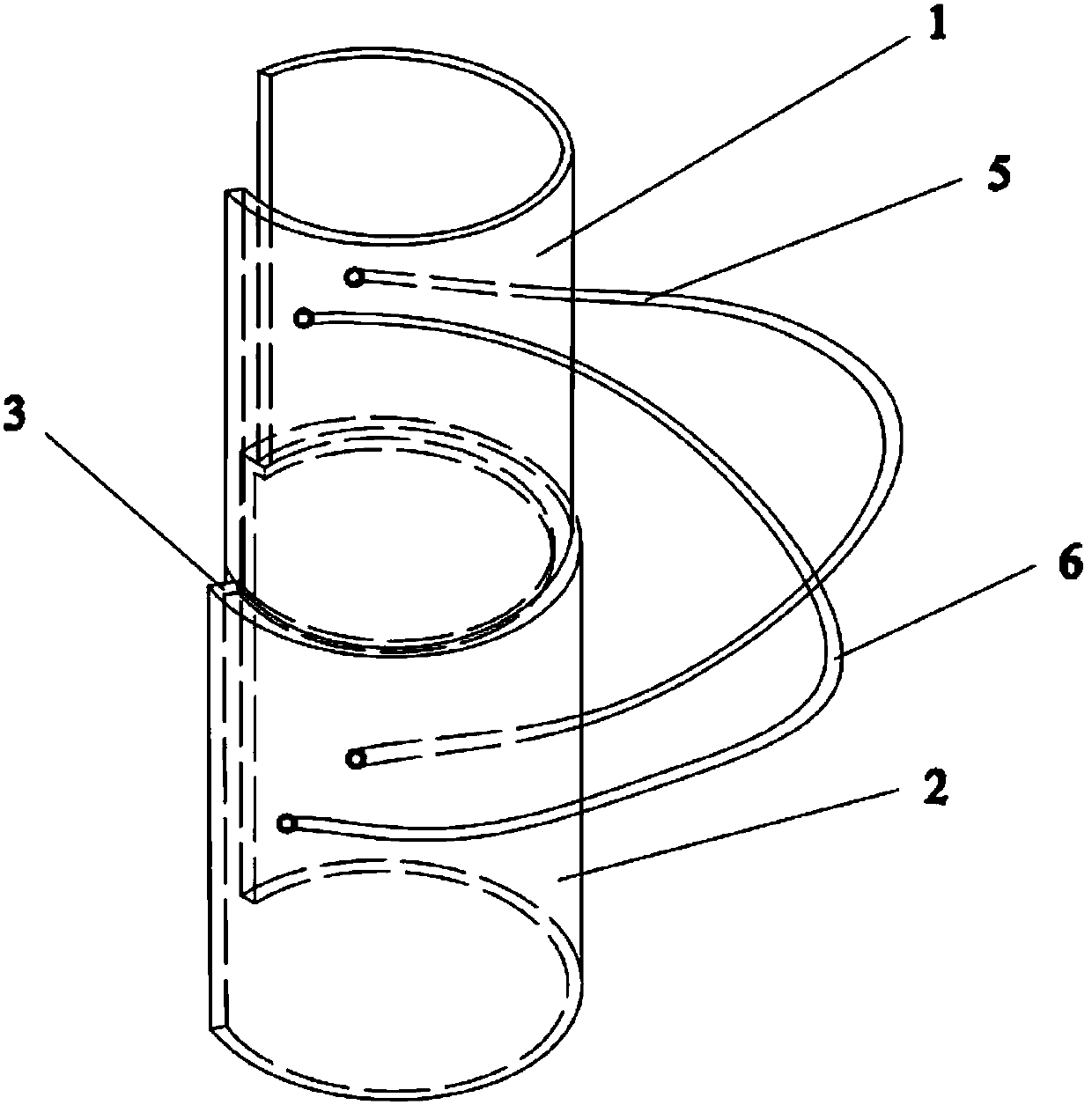

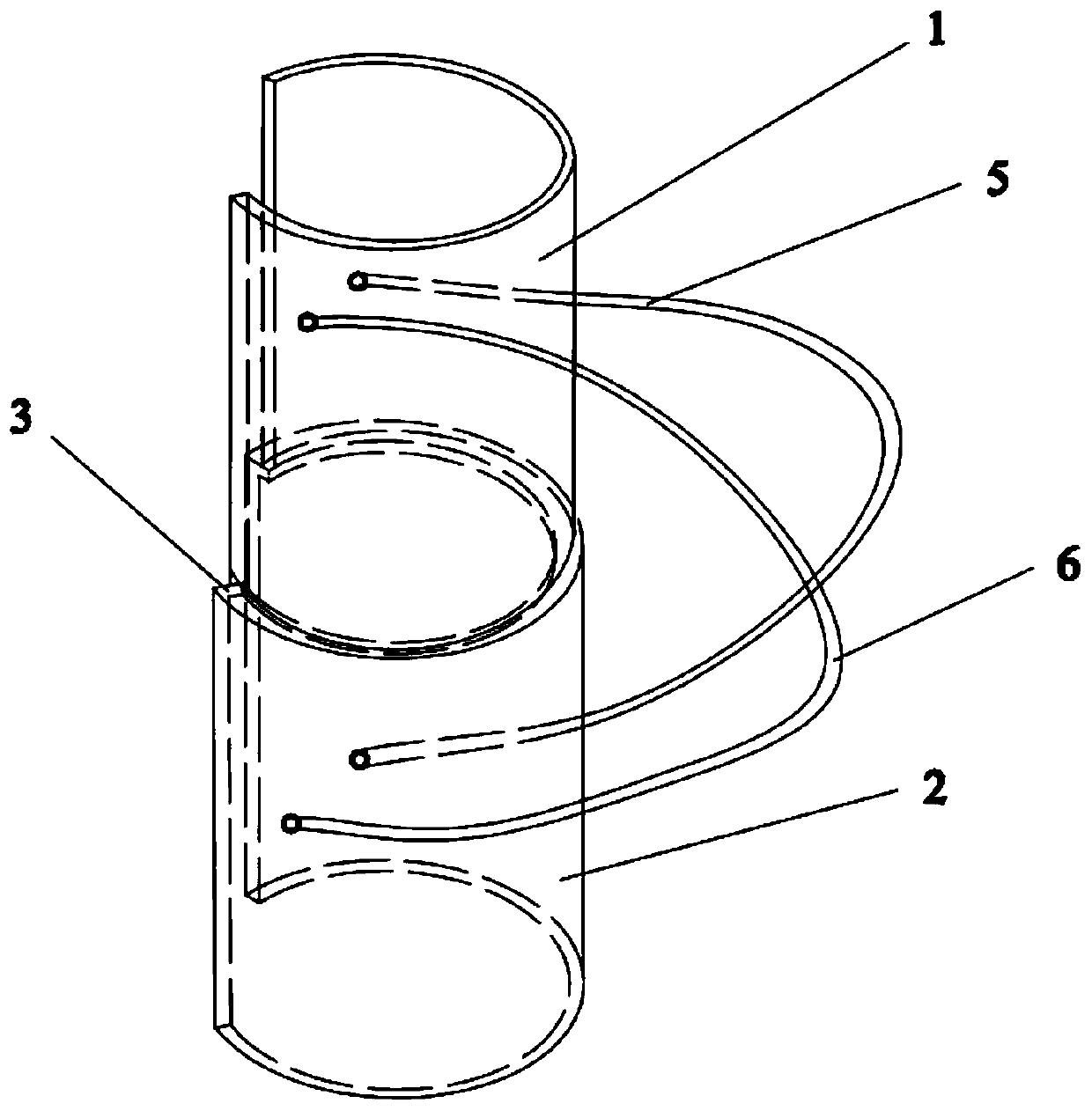

Electric pole shield

ActiveCN107834426AAdjustable lengthFixed lengthApparatus for overhead lines/cablesEngineeringFixed length

The invention discloses an electric pole shield. The electric pole shield comprises a shield body structure and a first anti-shedding structure, wherein the shield body structure at least comprises afirst shield body and a second shield body set outside the first shield body, the first shield body and the second shield body are tubular structures set on an electric pole in a foldable mode, the inner diameter of the first shield body is tightly matched with the outer diameter of the electric pole to make the first shield body be unable to move downwards relative to the electric pole under theaction of gravity, the inner diameter of the second shield body is greater than the outer diameter of the first shield body to make the second shield body freely fall relative to the first shield bodyunder the action of gravity, and the first anti-shedding structure is suitable for preventing the second shield body from being disengaged from the first shield body from a lower end of the first shield body when the shield body structure is set on the electric pole. The electric pole shield is advantaged in that the shield body structure is set to have the first shield body and the second shieldbody set outside the first shield body, adjustment on length of the electric pole shield can be realized through adjusting the overlapping portion between the first shield body and the second shieldbody, and a problem of fixed length of an electric pole shield in the prior art is solved.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Rapid locking device of carrying trolley

The invention discloses a rapid locking device of a carrying trolley. The rapid locking device comprises an inserted pin, an inserted pin support arranged on the carrying trolley and a plurality of pin locking mechanisms arranged on a chain in a transmission system for driving the carrying trolley; the inserted pin support is provided with a channnel which allows the inserted pin to move towards the pin locking mechanisms or moves away from the pin locking mechanisms, and the pin locking mechanisms can be matched with the inserted pin in use and used for locking the inserted pin. The rapid locking device is simple in structure, reasonable in design, capable of being quickly locked or opened, high in universality, high in efficiency and good in effect, and the problem that the carrying trolley cannot be quickly connected to or separated from the transmission system in the prior art is solved.

Owner:NANJING PANDA ELECTRONICS +1

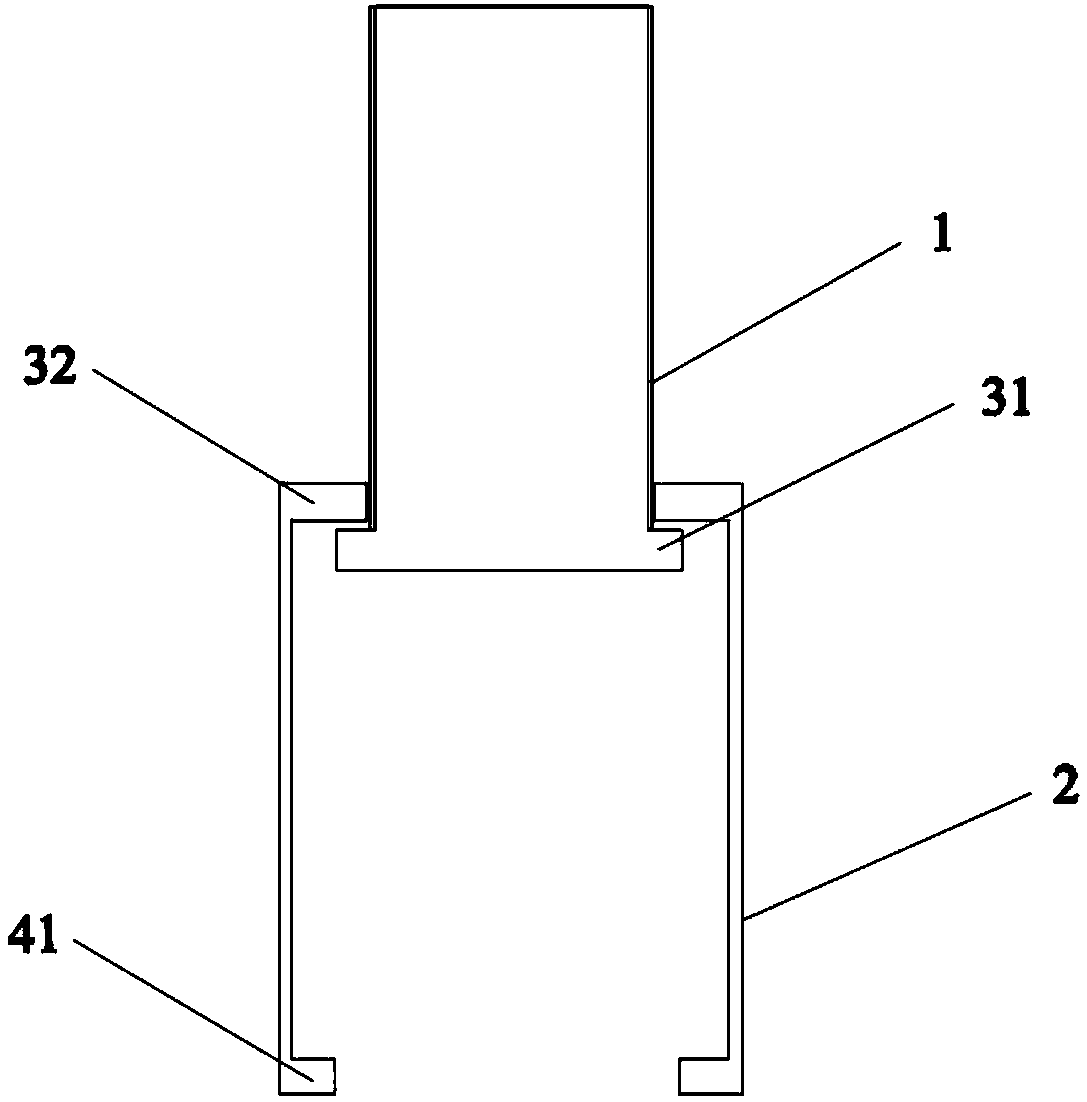

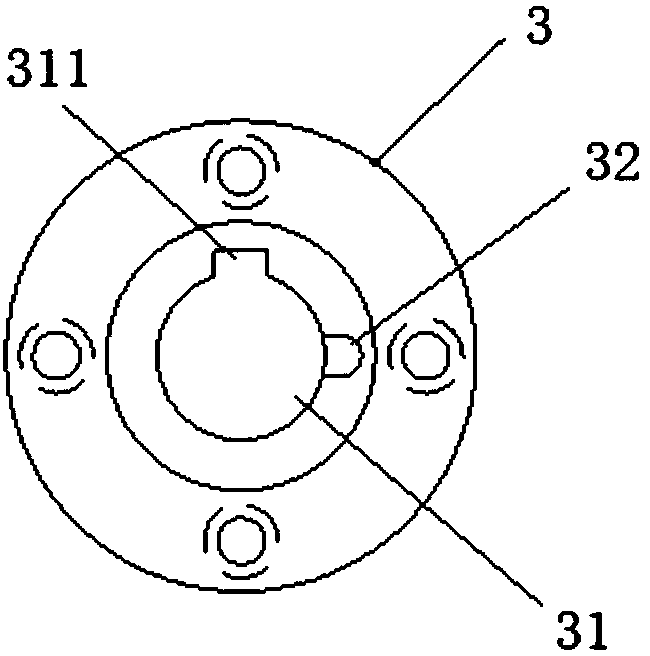

Drilling sleeve device suitable for offshore exploration ship and construction method thereof

PendingCN108343382AResolve disengagementEasy constructionDrilling rodsSealing/packingChinese charactersEngineering

Owner:ZHEJIANG HUADONG CONSTR ENG

Closed biological membrane type culture method for industrial production

InactiveCN107384801AHigh purityIncrease productionBioreactor/fermenter combinationsBiological substance pretreatmentsIsolation effectThin membrane

The invention relates to the technical field of microalgae culture methods and particularly relates to a closed biological membrane type culture method for industrial production. The culture method comprises the following step: with one surface of a microporous membrane as a microalgae cell inoculation surface as well as the other surface, opposite to the microalgae cell inoculation surface, of the microporous membrane as a feeding surface, inoculating microalgae cells to the microalgae cell inoculation surface. According to the closed biological membrane type culture method for the industrial production, microalgae biomass and a nutrient solution are separated through the microporous membrane, so that the problems of cell detachment and biological membrane falling are thoroughly solved; by virtue of a separation effect of the microporous membrane, pollutants such as infectious microbes in the nutrient solution cannot enter the microalgae biomass; by virtue of a coverage isolation effect of a transparent membrane, the pollution caused by pollutants such as external infectious microbes to the microalgae biomass is avoided, so that the impurity of the microalgae biomass is increased (reaching above 99%), and the quality of the microalgae biomass is improved.

Owner:李彤

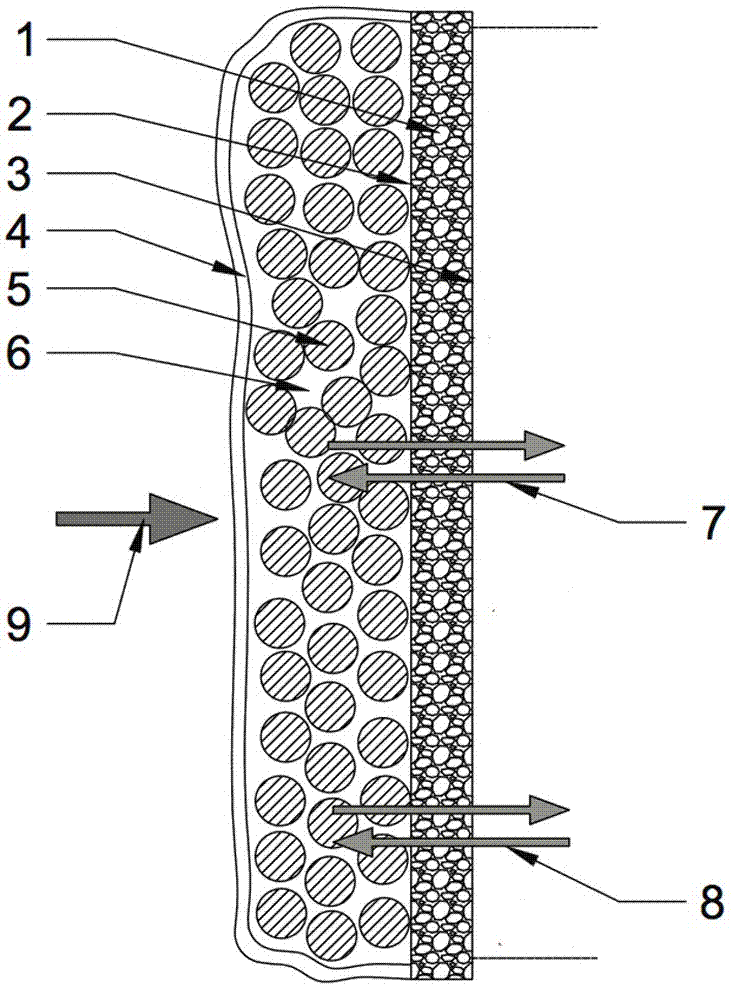

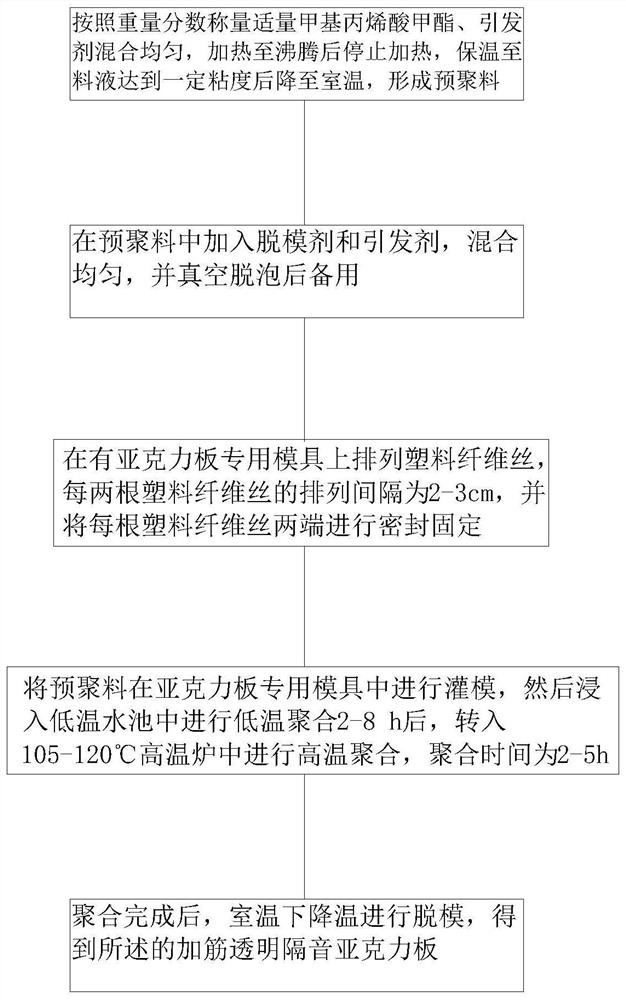

Reinforced transparent sound insulation acrylic plate and preparation method thereof

The invention relates to a reinforced transparent sound insulation acrylic plate, which comprises a transparent polymethyl methacrylate plate and plastic cellosilk uniformly embedded in the transparent polymethyl methacrylate plate, and a preparation method comprises the following steps: uniformly mixing a proper amount of methyl methacrylate and an initiator, heating until boiling, then stopping heating, keeping the temperature until a feed liquid reaches a certain viscosity, and then cooling to room temperature to form a pre-polymerized material; adding a release agent and an initiator into the pre-polymerized material, uniformly mixing, and carrying out vacuum defoaming for later use; arranging plastic fibers on a special mold with an acrylic plate, and sealing and fixing the two ends of each plastic fiber; performing mold filling on the pre-polymerized material in a special mold for the acrylic plate, wherein the polymerization time is 2-5 hours; after polymerization is completed, demolding, and the obtaining reinforced transparent sound insulation acrylic plate. The performance of the sound insulation acrylic plate is met, the problem that the base material is separated from the plastic fibers is solved on the premise that the plastic fibers do not need to be post-processed, and the preparation method is simple, low in cost and environmentally friendly.

Owner:ANHUI XINTAO OPTOELECTRONICS TECH CO LTD

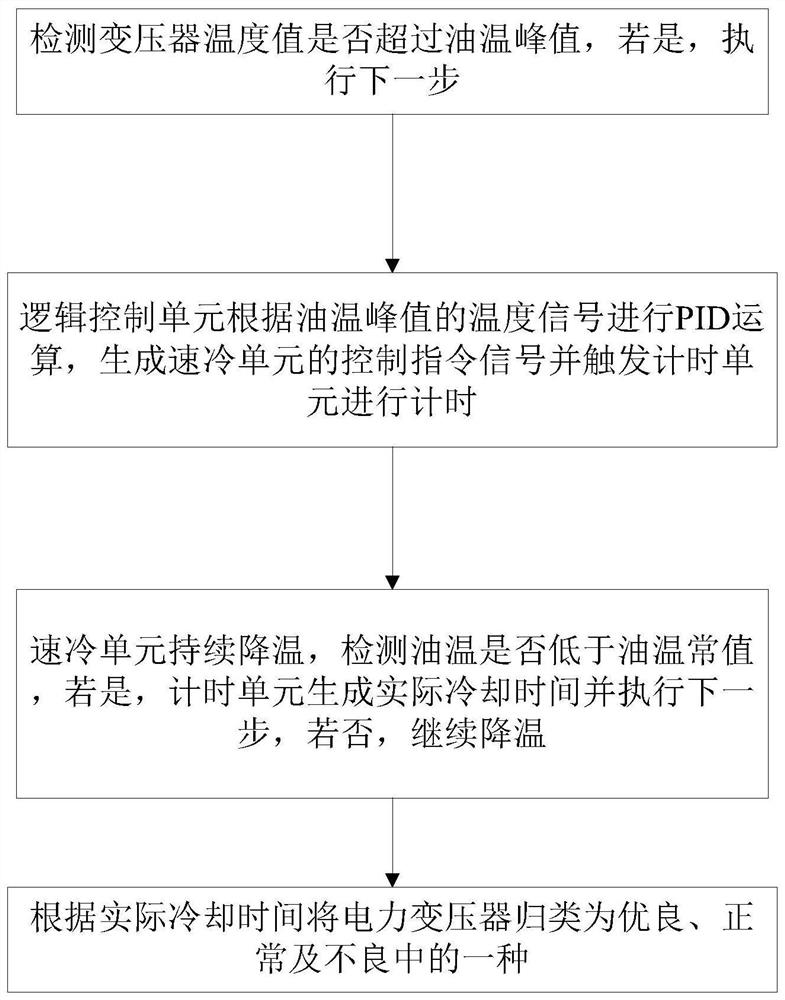

Power transformer cooling performance evaluation system and method

InactiveCN113484050ASolve the cooling effectResolve disengagementStructural/machines measurementTransformerElectric power

The invention discloses a power transformer cooling performance evaluation system, which comprises a temperature acquisition unit, a humidity acquisition unit, a timing unit, a cooling unit, a working information acquisition unit, a rapid cooling unit, a frequency converter unit, a logic control unit, a power supply unit, a simulation test vehicle and a control terminal, wherein the logic control unit sets an oil temperature peak value and an oil temperature constant value, the timing unit calculates the actual cooling time from the oil temperature peak value to the oil temperature constant value, and the control terminal adjusts the environment parameters of the simulation test vehicle according to the collected environment temperature information, environment humidity information and the working information of the transformer. According to the invention, the temperature acquisition unit, the humidity acquisition unit, the timing unit and the simulation test vehicle are matched to simulate the actual environment of the to-be-tested transformer, so that a comparison basis is provided for the evaluation of the to-be-tested transformer, and the problem that the cooling performance evaluation is separated from the reality is solved.

Owner:广州市一变电气设备有限公司

pole shield

ActiveCN107834426BAdjustable lengthFixed lengthApparatus for overhead lines/cablesEngineeringMechanical engineering

The invention discloses an electric pole shield. The electric pole shield comprises a shield body structure and a first anti-shedding structure, wherein the shield body structure at least comprises afirst shield body and a second shield body set outside the first shield body, the first shield body and the second shield body are tubular structures set on an electric pole in a foldable mode, the inner diameter of the first shield body is tightly matched with the outer diameter of the electric pole to make the first shield body be unable to move downwards relative to the electric pole under theaction of gravity, the inner diameter of the second shield body is greater than the outer diameter of the first shield body to make the second shield body freely fall relative to the first shield bodyunder the action of gravity, and the first anti-shedding structure is suitable for preventing the second shield body from being disengaged from the first shield body from a lower end of the first shield body when the shield body structure is set on the electric pole. The electric pole shield is advantaged in that the shield body structure is set to have the first shield body and the second shieldbody set outside the first shield body, adjustment on length of the electric pole shield can be realized through adjusting the overlapping portion between the first shield body and the second shieldbody, and a problem of fixed length of an electric pole shield in the prior art is solved.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

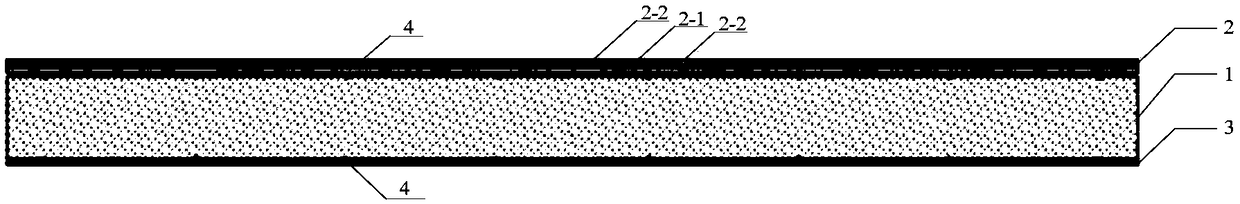

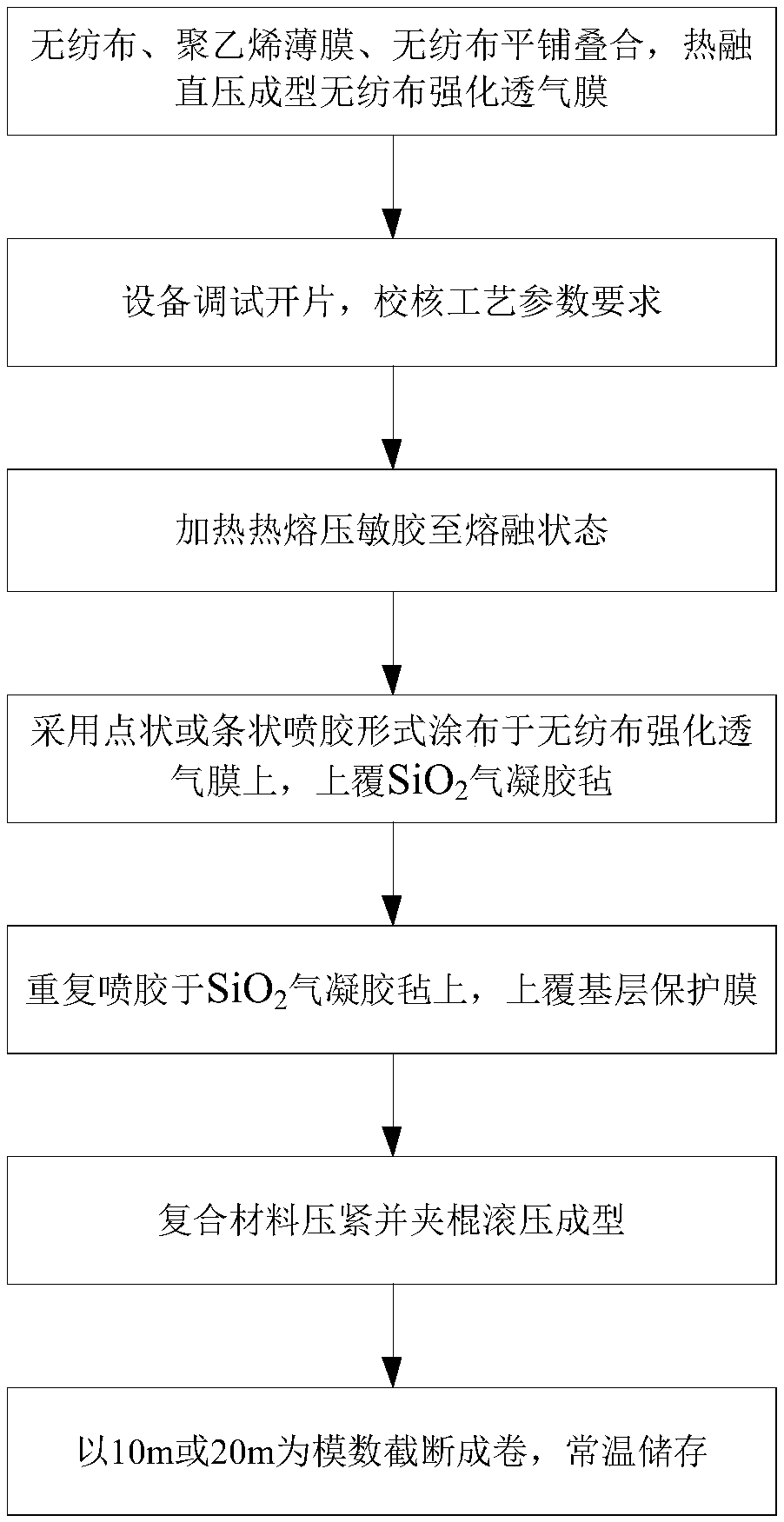

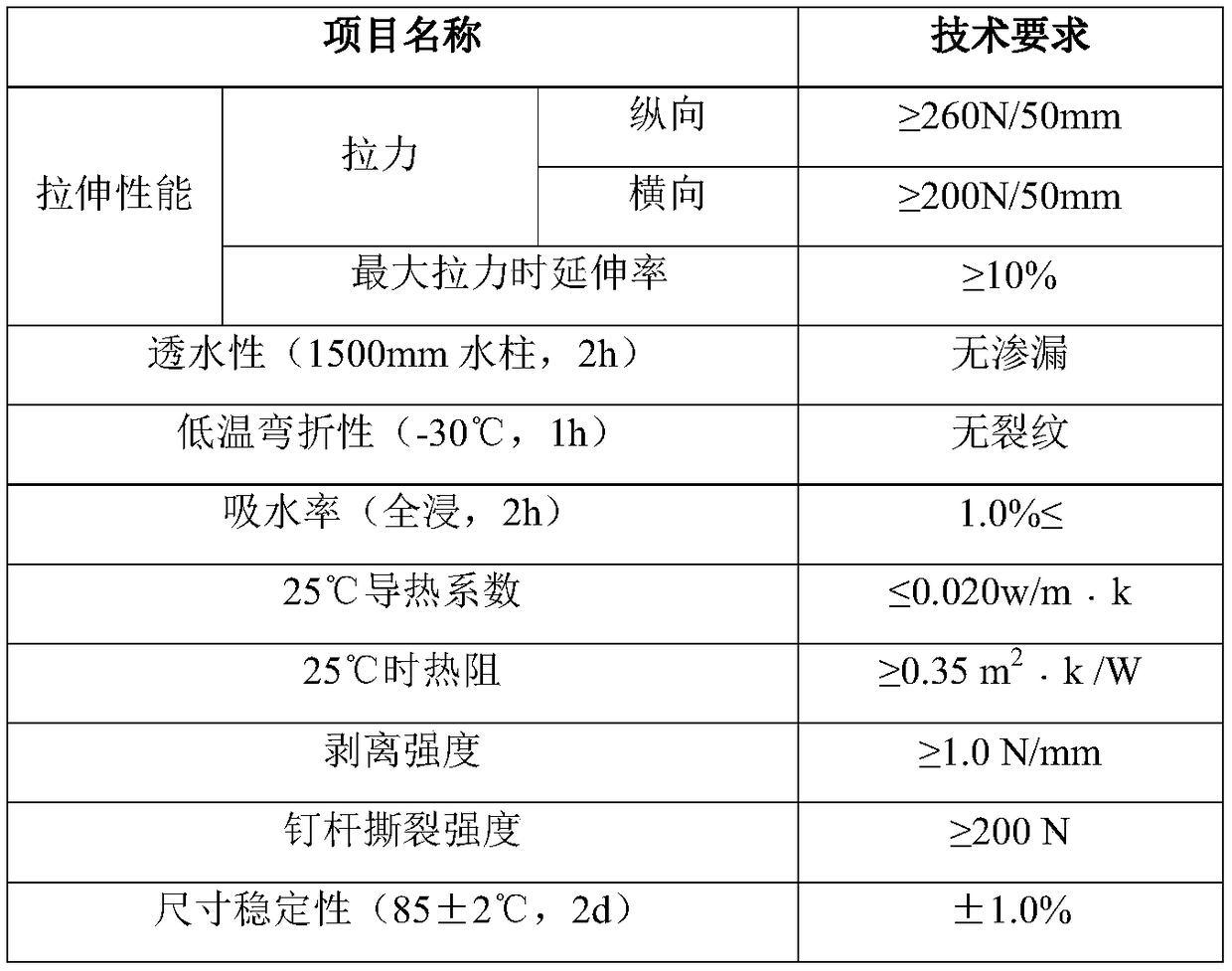

Heat preservation waterproof composite coiled material suitable for roof transformation and preparation method thereof

PendingCN108952205AReduce loadImprove insulation effectRoof covering using flexible materialsBuilding repairsTectorial membraneHot melt

The invention provides a heat preservation waterproof composite coiled material suitable for roof transformation and a preparation method thereof. The composite coiled material comprises a heat preservation and heat insulation core material, a non-woven fabric reinforced breathable film and a base layer protective film which are fused into a whole in a spot shape or a strip shape by using a hot-melt pressure-sensitive adhesive. The heat preservation and heat insulation core material is silica aerogel felt; the non-woven fabric reinforced breathable film is formed by stacking non-woven fabricson the upper and lower sides of a polyethylene film through hot-melting and direct-pressing; the base layer protective film is a steam-insulating film. The composite coiled material has the advantagesof achieving A grade fire prevention and being high in heat preservation and heat insulation property, high in air permeability and water resistance, light, flexible, high in deformation resistance and convenient to construct, the coiled material is especially suitable for existing house roof updating and transformation, the roof transformation and construction technology is simplified, the transformation and construction speed is increased, and the environment friendliness, energy conservation and use durability of a roof are greatly improved.

Owner:上海市房地产科学研究院 +1

External thick wall panel and internal thin wall panel hollow co-extrusion wallboard

Disclosed is an external thick panel and internal thin panel hollow co-extrusion wallboard. The invention is characterized in that the co-extrusion hollow wallboard adopts a thick wall panel outdoors and adopts a thin wall panel indoors. The thickness difference between the outdoor thick wall panel and the indoor thin wall panel is 2 mm or 3 mm or 4 mm or 5 mm or 6 mm or 7 mm or 8 mm or 9 mm or 10 mm or 11 mm or 12 mm or 13 mm or 14 mm or 15 mm or 16 mm or 17 mm or 18 mm or 19 mm or 20 mm or 21 mm or 22 mm or 23 mm or 24 mm or 25 mm.

Owner:王广武

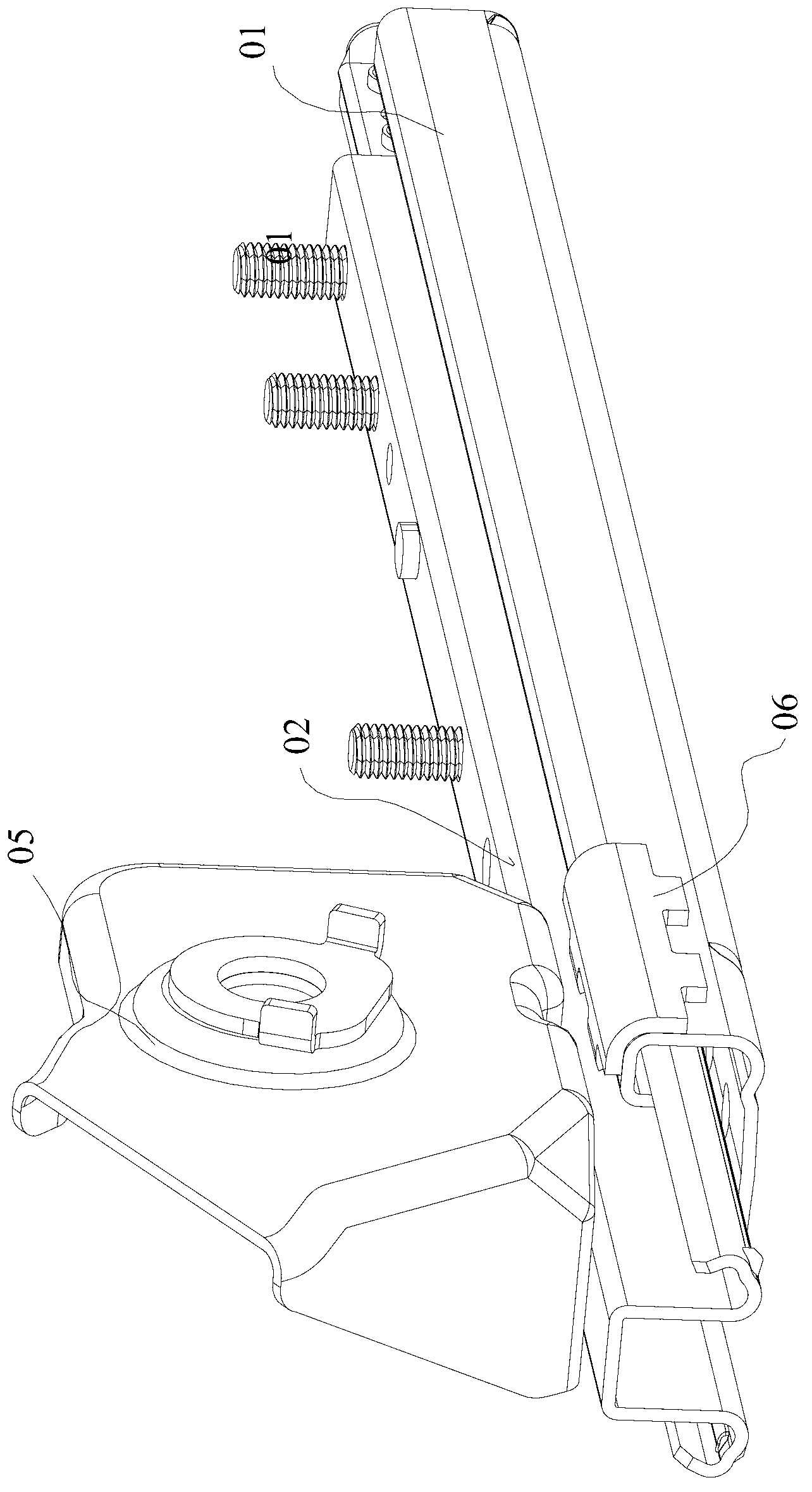

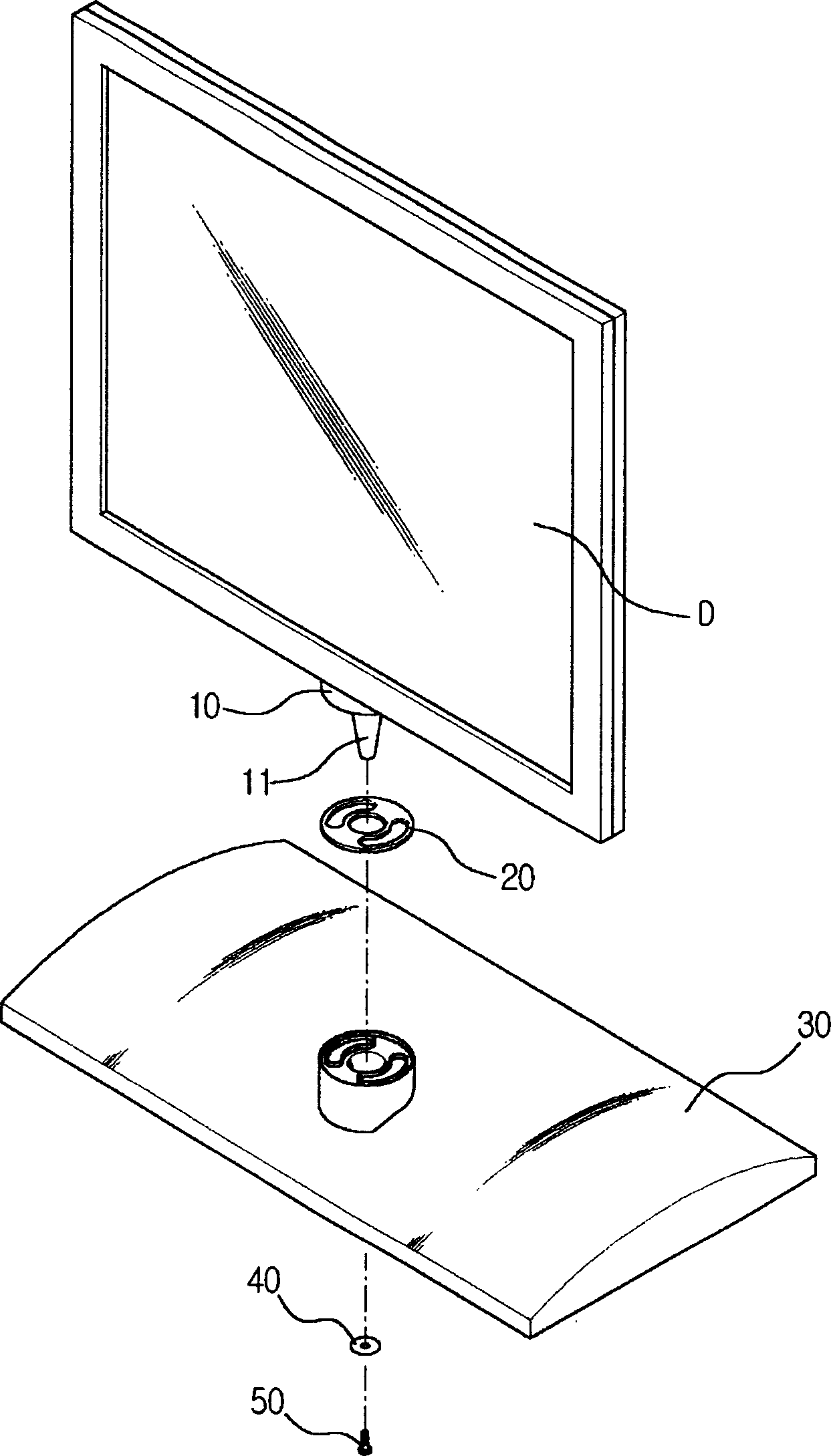

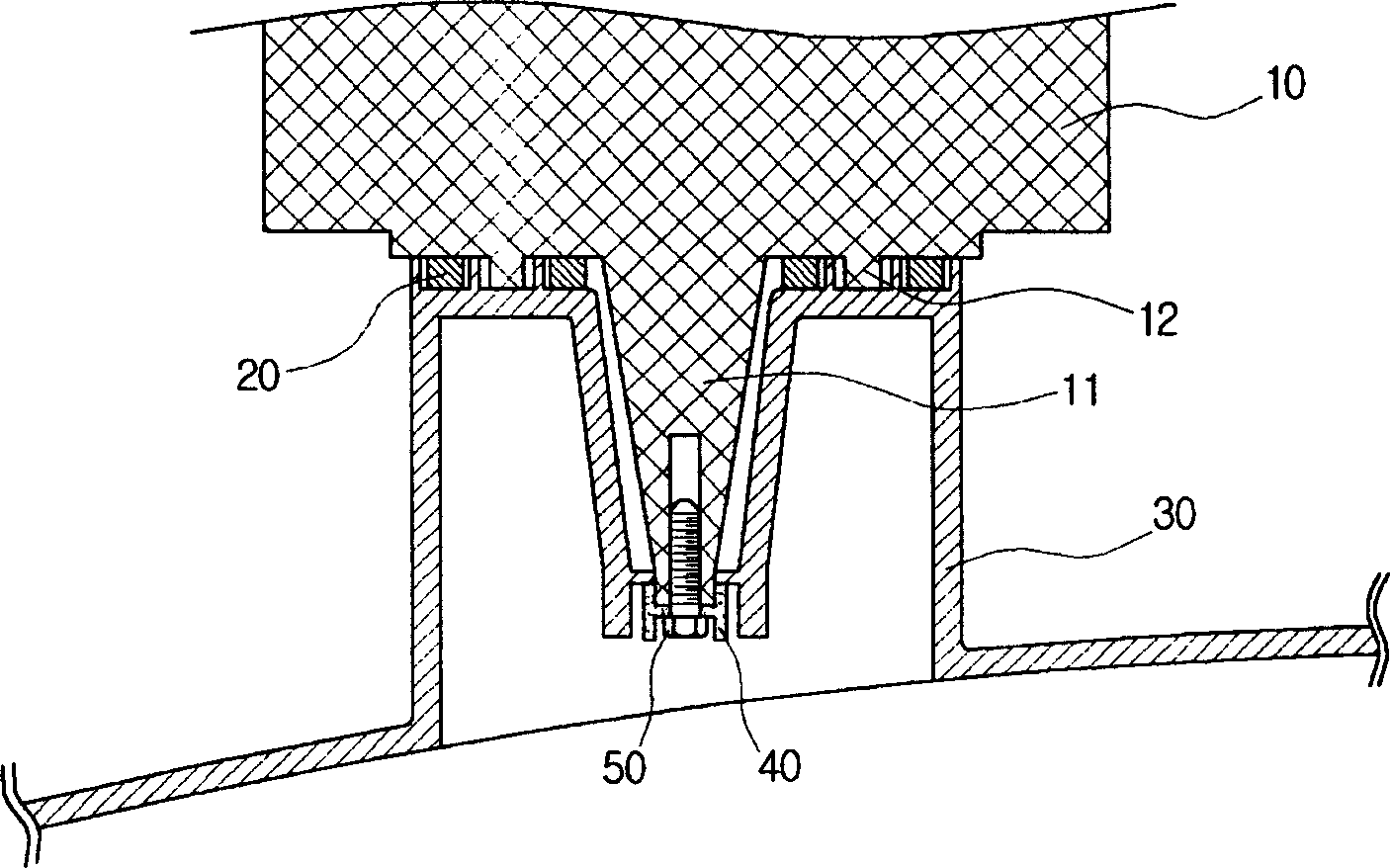

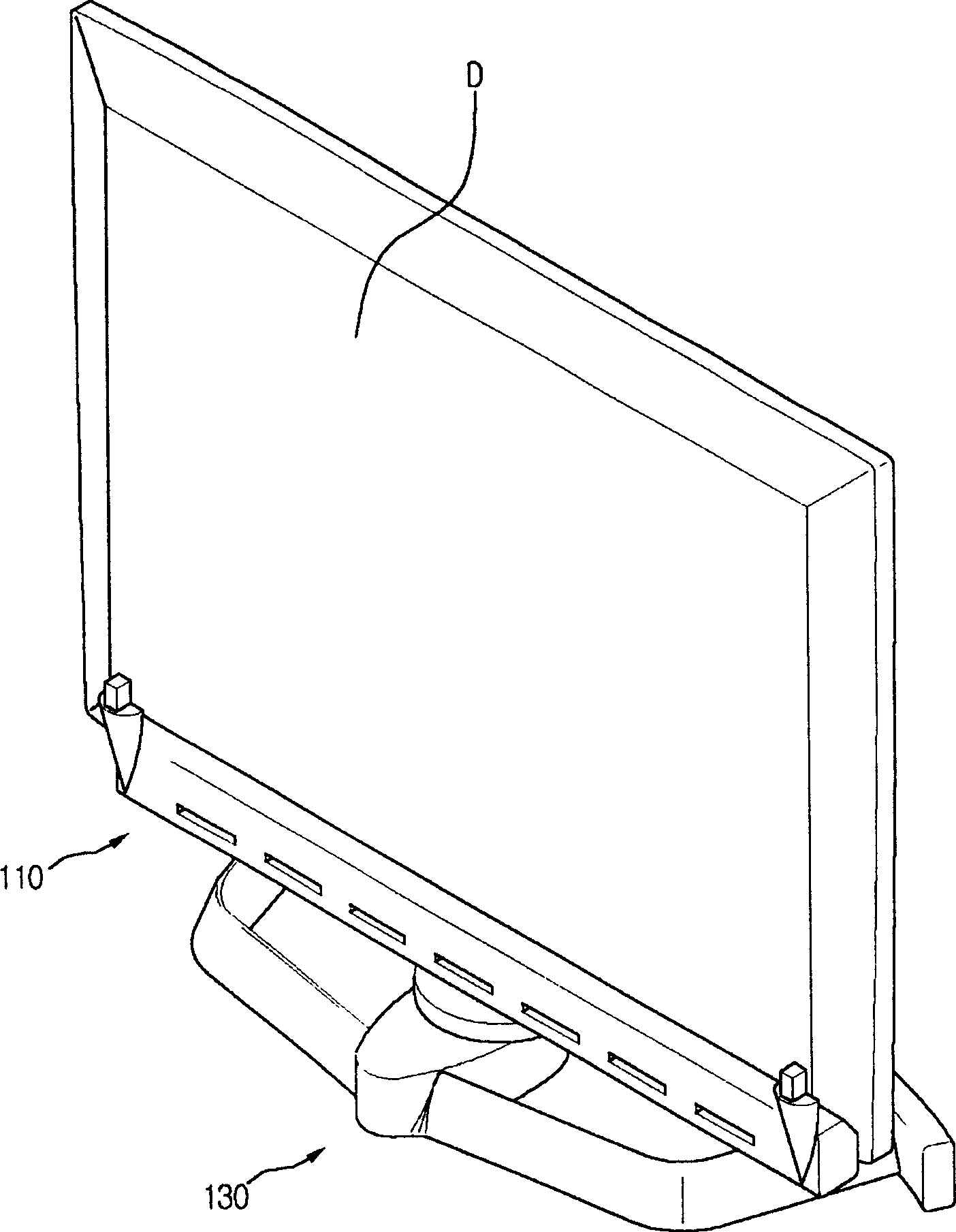

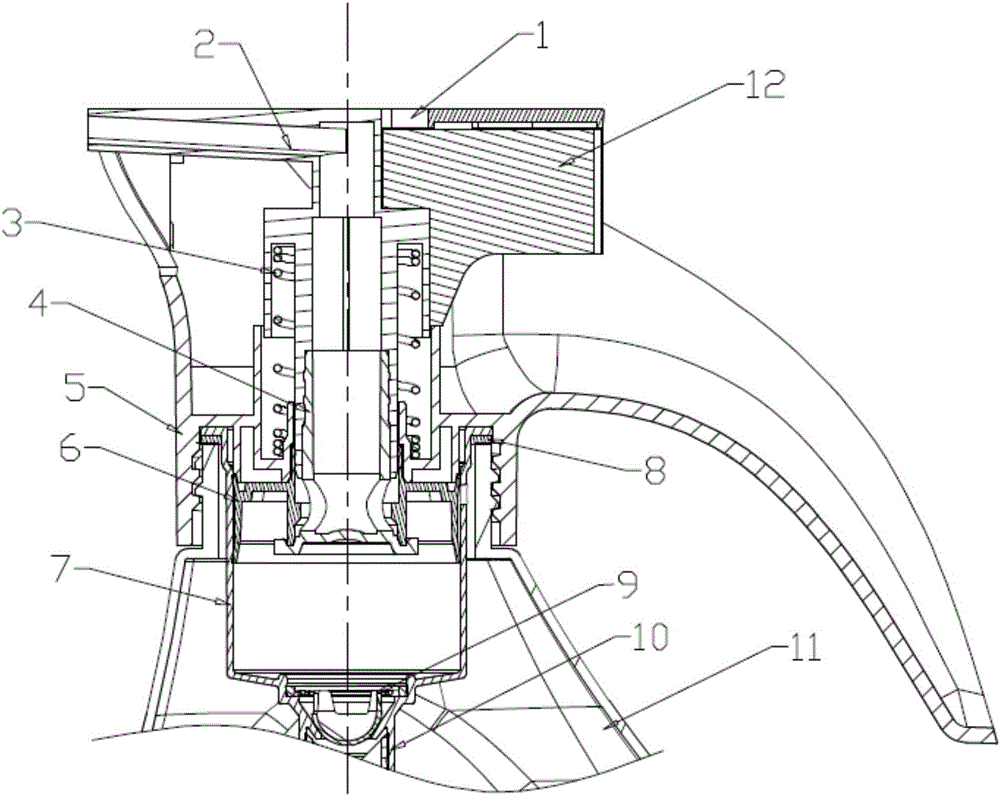

Supporting structure of image display device

InactiveCN1627135APrevent looseningResolve disengagementStatic indicating devicesRotation flapFixed frame

A support structure for an image display device includes a rotation frame with a display mounted on its lop, a fix frame connected to the rotation frame, an upper rotation component and a lower rotation component smoothly driving the rotation between the fixed frame and the rotation frame and a connecting component connecting them. A connection hole is formed at the shaft of the rotation frame and a joint project is formed above the lower rotation part corresponding to said hole, the rotation frame is connected with the lower rotation component to a connecting component.

Owner:NANJING LG TONGCHUANG COLOR DISPLAYS SYST CO LTD

Connecting structure of transformer wire outgoing device

ActiveCN111210979ASolve the problem of easy dischargeImprove reliabilityTransformers/inductances coils/windings/connectionsTransformerPaperboard

The invention discloses a connecting structure of a transformer wire outgoing device. According to the structure, a plurality of layers of paperboard cylinders divide oil gaps. Corrugated paperboard cylinders are inserted among the paperboard cylinders; a distance difference exists between the end parts of each layer of paperboard cylinder and adjacent corrugated paperboard cylinders; clamping sheets are assembled at the upper end and the lower end of each stage of corrugated paperboard cylinder; for the paperboard cylinders distributed from inside to outside, the height of the upper ends of the paperboard cylinders is gradually increased and gradually decreased in a transitional manner from two layers of paperboard cylinders to the other layers of paperboard cylinders; for the corrugatedpaperboard cylinders from inside to outside, the height of the upper ends of the corrugated paperboard cylinders is gradually increased, and gradually decreased in a transitional manner from two layers of corrugated paperboard cylinders to the other layers of corrugated paperboard cylinders; the height of the upper end of each layer of corrugated paperboard cylinder is higher than that of the corresponding layer of paperboard cylinder; as for the paperboard cylinders from inside to outside, the length of the lower ends of the paperboard cylinders is gradually increased, and then is gradually decreased in a transitional manner from the two innermost layers of paperboard cylinders to the other layers of the paperboard cylinders, and the length of the lower ends of the two outermost layers ofthe paperboard cylinders are increased; and as for the corrugated paperboard cylinders from inside to outside, the length of the lower ends of the corrugated paperboard cylinders is gradually increased, and then is gradually decreased in a transitional manner from the innermost two layers of corrugated paperboard cylinders, and the outermost layer of corrugated paperboard cylinder is lengthened.According to the connecting structure of the invention, the clamping sheets are adopted for limiting connection, so that the problem that an insulating screw is prone to discharging, and the problem acushion block falls off or the problem that a corrugated board moves are solved, and the reliability of the wire outgoing device is improved.

Owner:TBEA SHENYANG TRANSFORMER GRP CO LTD +1

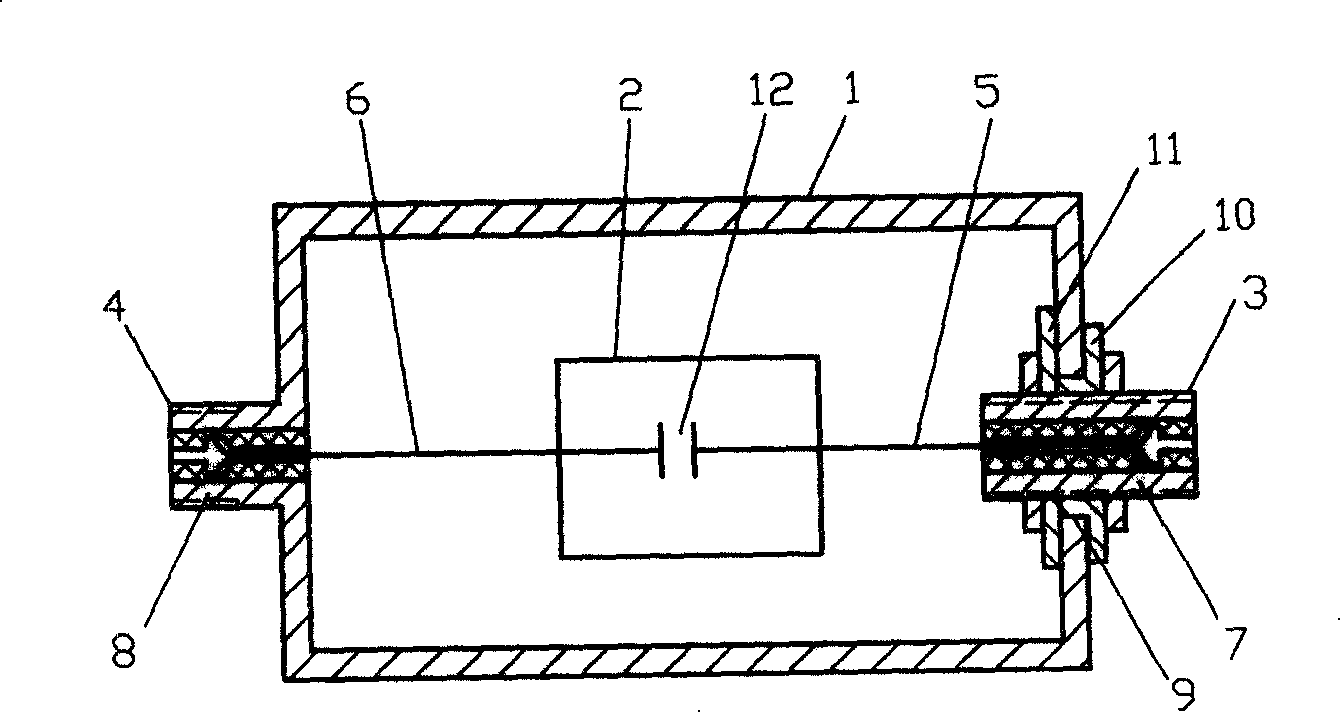

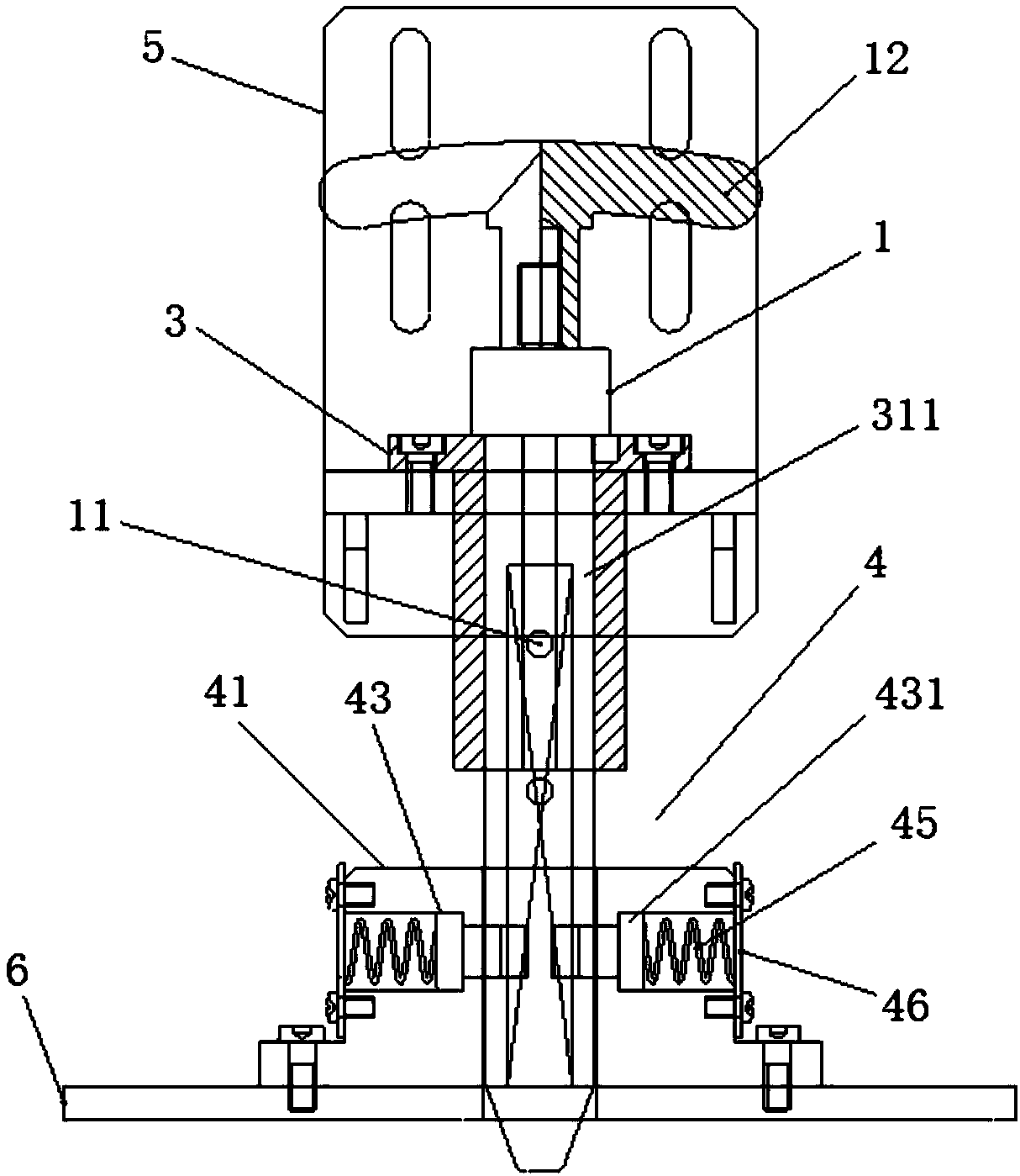

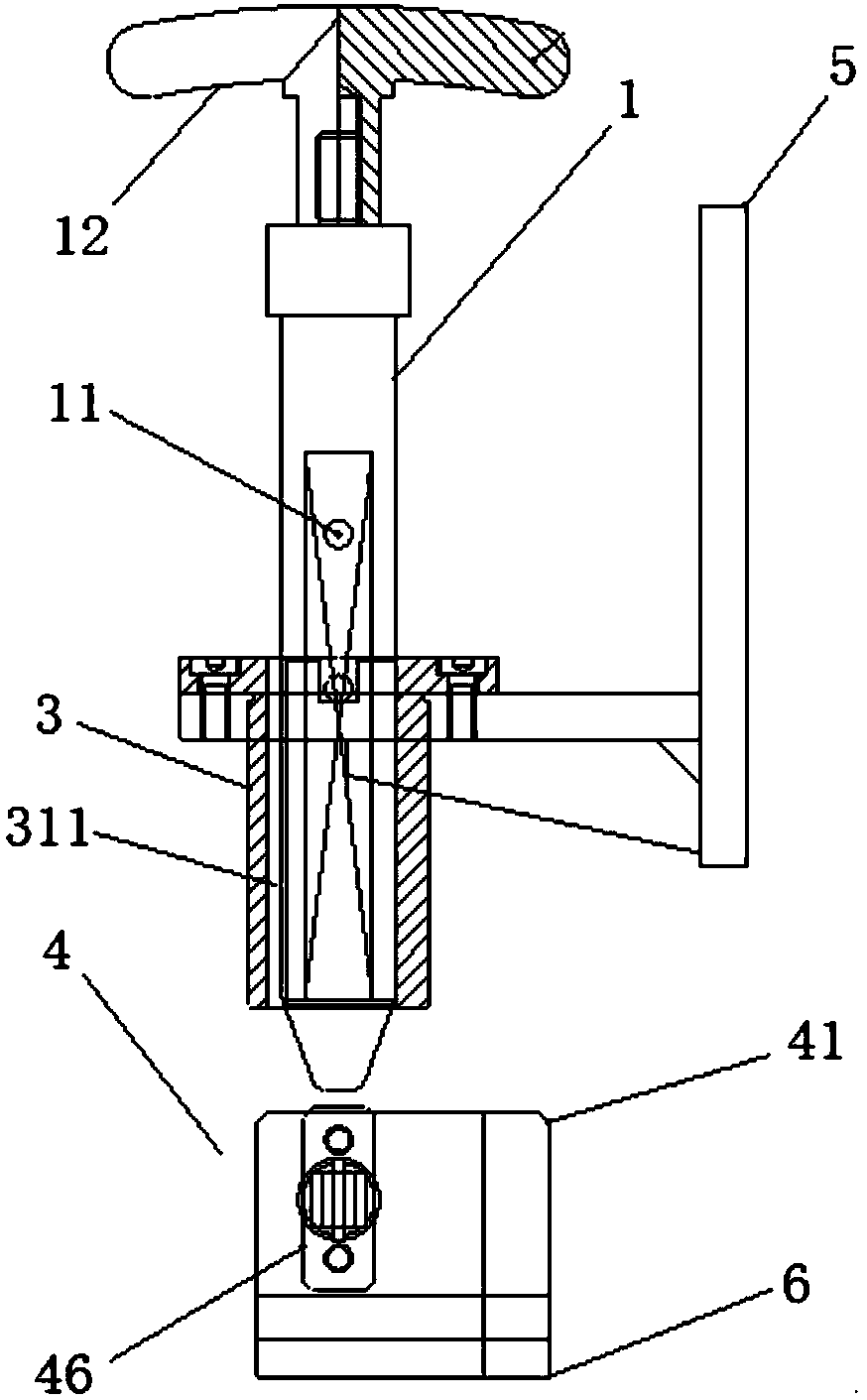

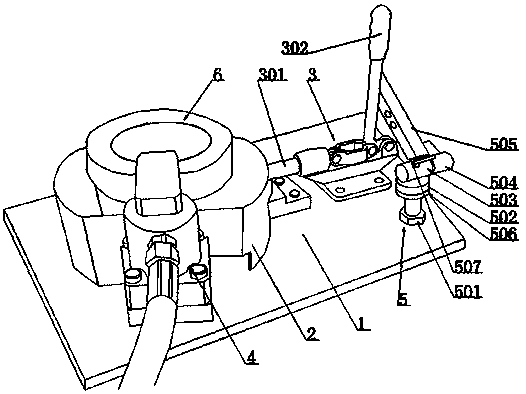

Positioning pin lock for piston valve pit tool

InactiveCN108942325AResolve disengagementSimple structurePositioning apparatusMetal-working holdersAxial displacementEngineering

The invention relates to a positioning pin lock for a piston valve pit tool. The positioning pin lock comprises a tool bottom plate, wherein a piston stopper tire seat, a clamp, a compressing cylinderand a positioning pin lock body are arranged on the tool bottom plate, and a piston is positioned on the piston stopper tire seat; a positioning pin at the front end of the clamp extends into a piston pin hole to radially position the piston, and the compressing cylinder can axially compress the piston; the positioning pin lock body can lock a handle of the clamp; the positioning pin lock body iscomposed of a supporting column, a rotating shaft seat, a long shaft, a short shaft and a lock rod; an internal threaded hole is formed in one end of the long shaft, an external thread is arranged onthe outer circumference surface of one end of the short shaft, and an internal thread of the long shaft meshes with the external thread of the short shaft to form a movable shaft; and the short shaftcan drive the rotation and axial displacement of the lock rod, and the lock rod converts the pre-tightening force of the short shaft into the pressing force required for the positioning pin, and thatis to say, the problem of separation of the positioning pin and a workpiece is solved.

Owner:DONGFENG PISTON & BEARING

Quantitative pressing spray nozzle and container with quantitative pressing spray nozzle

InactiveCN105880074AEasy to useSolve the one-handed extraction problemClosuresSingle-unit apparatusSpray nozzleHand held

The present invention provides a quantitative pressing spray head, comprising: a pressure plate, a pressure head and a portable screw cap for connecting with a container; On the pressure head; one end of the pressure plate is a fixed end connected with the portable screw cap, and the other end is a pressing end. The pressure plate uses the fixed end as a lever fulcrum to link with the pressure head. The end and the fixed end form a first force arm, the indenter and the fixed end form a second force arm, and the first force arm is greater than the second force arm. The present invention adopts the principle of levers, and under the condition of equal reaction moments, the longer the force arm, the smaller the required force. The present invention uses the fixed end of the pressing plate and the portable screw cap as the fulcrum and the pressing plate as the lever, and reduces the force required to press the pressing head by increasing the distance between the pressing end and the fixed end.

Owner:DERJIN (JIANGSU) PLASTIC PACKAGING CO LTD

Mobile phone antenna surface metallization process

ActiveCN113355663AIncrease productivityImprove hydrophilicityLiquid/solution decomposition chemical coatingChemical platingInjection moulding

The invention relates to the field of mobile phone antenna preparation, in particular to a mobile phone antenna surface metallization process. The mobile phone antenna surface metallization process comprises the following steps of: S1, injection molding of a middle frame; S2, performing laser etching treatment on a preset laser etching area on the surface of the middle frame; S3, ultrasonically cleaning and drying the laser-etched middle frame S4, performing roughening treatment, neutralizing treatment, water washing and drying on the middle frame; S5, activating, reducing, washing and drying the middle frame; S6, carrying out chemical cobalt plating treatment on the middle frame to form a first cobalt plating layer; S7, performing copper plating treatment on the middle frame to form a copper plating layer on the surface of the first cobalt plating layer; S8, carrying out chemical cobalt plating treatment on the middle frame to form a second cobalt plating layer on the surface of the copper plating layer; and S9, ultrasonically cleaning and drying the middle frame. The mobile phone antenna surface metallization process has the advantages that the process is simple, the production efficiency of the middle frame is improved, the product quality is improved, the production cost of an enterprise is reduced, the bonding performance of the prepared chemical plating layer and the middle frame is good, and a cobalt plating layer is originally adopted to replace an existing nickel plating layer.

Owner:DONGGUAN ZHENGWEI PRECISION PLASTIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com