Technology for solving problem of tunnel lining vault disengaging

A vaulting and voiding technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., to achieve the effects of small shrinkage, cost reduction, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

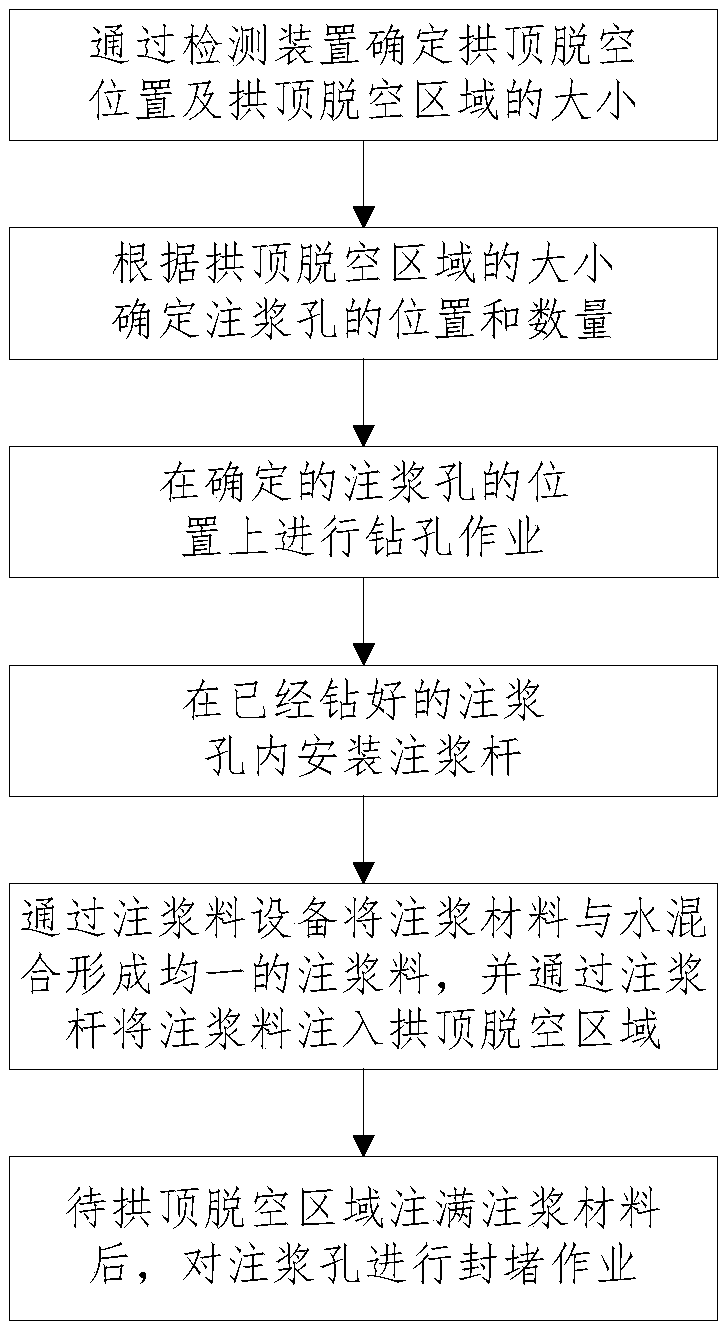

[0038] Such as figure 1 As shown, the present invention provides a kind of technology that solves the tunnel lining arch void problem, and concrete process is as follows:

[0039] S01: Determine the position of the void area of the vault and the size of the void area of the vault through the detection device;

[0040] In this embodiment, the detection device is a radar scanning device, which scans the tunnel to determine the position and specification of the void area.

[0041] S02: Determine the location and number of grouting holes according to the size of the void area of the vault;

[0042] According to the specifications of the void area of the vault determined by the radar scanning device, the number and location of the grouting holes are specifically determined. The distance between the grout holes is 1m-1.5m. Such a distance setting is beneficial to ensure the flow radius of the grouting material. The specific distance value should be determined according to ...

Embodiment 2

[0058] The micro-expansion grouting material in this embodiment has the following characteristics:

[0059] A. The micro-expansion grouting material has high fluidity. The basic fluidity of the traditional grouting material is about 320mm, while the initial fluidity of the grouting material in this embodiment is 390mm. Under the grouting pressure, the fillable radius of the micro-expansion grouting material is greatly increased, and the fillable radius is less than 2mm. Gaps, filling effect is good.

[0060] B. The volume expands slightly after mixing with water. The grouting material has an expansion rate of 0.7% in the plastic stage, which can actively and effectively fill the void area.

[0061] C. The coagulation time is fast. This means that the plugging can be carried out within 1 to 2 hours after the grouting is completed, which improves the construction efficiency.

[0062] D. High bonding strength with concrete. The micro-expansion grouting material has good tens...

Embodiment 3

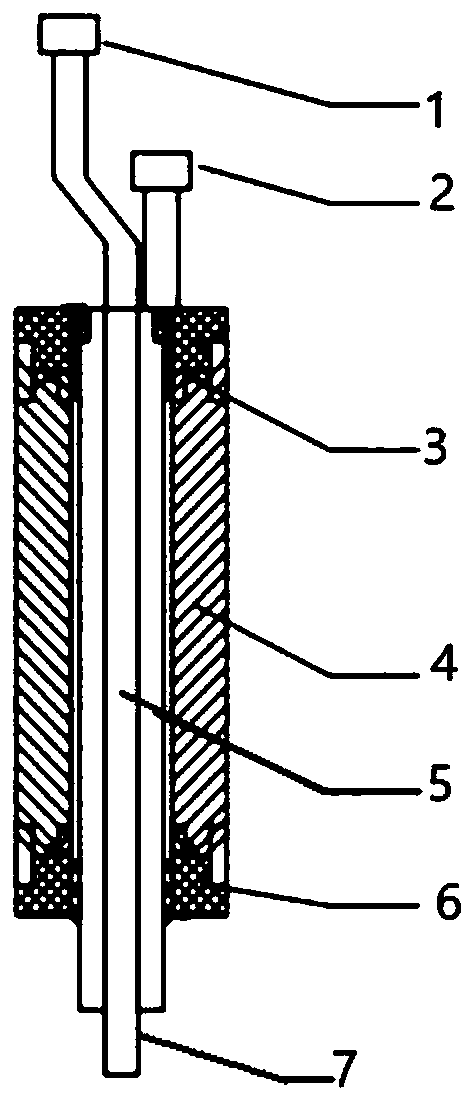

[0066] Such as figure 2 Shown is a schematic diagram of a grouting rod for a process to solve the problem of hollowing out of a tunnel lining vault according to an embodiment of the present invention. 2. Locking hoop 3, rubber bladder 4, grouting pipe 5 and movable hoop 6; one end of grouting pipe 5 is connected to grouting port 1, and the other end is connected to grouting port 7; water injection port 2 and rubber bladder 4 The rubber bag 4 is set on the grouting pipe 5, and the two ends of the grouting pipe 5 are exposed, and one end of the rubber bag 4 is fixed on the grouting pipe 5 through the locking hoop 3, and the locking hoop 3 Near the side of the grouting port 1, the movable collar 6 used to limit the displacement direction of the rubber bladder 4 during the expansion process is located at the other end of the rubber bladder 4, and the front end of the rubber bladder 4 can slide on the grouting pipe 5; at the same time, close to the movable collar 6 The exposed se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com