Reinforced transparent sound insulation acrylic plate and preparation method thereof

An acrylic board and transparent technology, applied in the field of acrylic board, can solve the problems of hitting the sound insulation board, the vehicle rushing out of the channel edge, and the processing time is long, and achieves the effect of improving impact resistance, increasing structural strength, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Production of plastic fiber yarn: The plastic fiber yarn used for reinforced transparent sound-proof acrylic board contains 75 parts of polyamide, 17 parts of talcum powder, 5 parts of lubricant and 3 parts of antioxidant, and is produced by melt extrusion process.

[0029] Production of transparent polymethyl methacrylate board: The transparent polymethyl methacrylate board used for reinforced transparent sound-proof acrylic board contains 85 parts of methyl methacrylate, 0.001 part of initiator, and 0.1 part of release agent

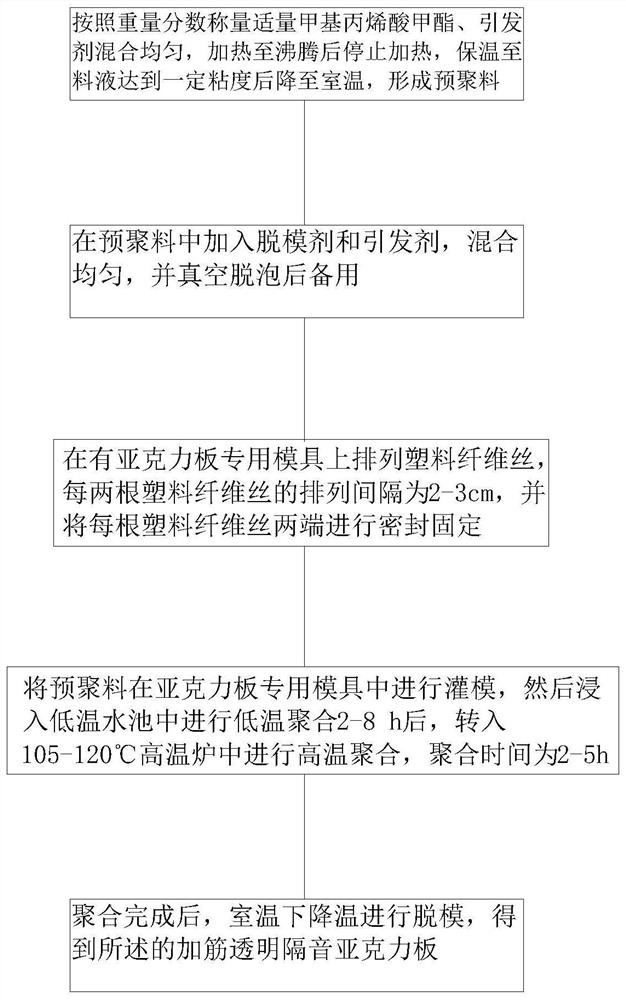

[0030] The preparation method of the reinforced transparent soundproof acrylic board is as follows:

[0031] (1) Weigh the raw material methyl methacrylate and the initiator according to the weight fraction, mix evenly, stop heating after heating to boiling, and keep warm until the material liquid reaches a certain viscosity and drops to room temperature.

[0032] (2) Add a release agent and an initiator to the prepolymer, mix well, and vacuum d...

Embodiment 2

[0037] Production of plastic fiber yarn: The plastic fiber yarn used for reinforced transparent sound-proof acrylic board contains 75 parts of polyamide, 17 parts of talcum powder, 5 parts of lubricant and 3 parts of antioxidant, and is produced by melt extrusion process.

[0038] Production of transparent polymethyl methacrylate board: The transparent polymethyl methacrylate board used for reinforced transparent soundproof acrylic board contains 90 parts of methyl methacrylate, 0.002 parts of initiator and 1 part of release agent

[0039] The preparation method of the reinforced transparent soundproof acrylic board is as follows:

[0040] (1) Weigh the raw material methyl methacrylate and the initiator according to the weight fraction, mix evenly, stop heating after heating to boiling, and keep warm until the material liquid reaches a certain viscosity and drops to room temperature.

[0041] (2) Add a release agent and an initiator to the prepolymer, mix well, and vacuum defo...

Embodiment 3

[0046] Production of plastic fiber yarn: The plastic fiber yarn used for reinforced transparent sound-proof acrylic board contains 75 parts of polyamide, 17 parts of talcum powder, 5 parts of lubricant and 3 parts of antioxidant, and is produced by melt extrusion process.

[0047] Production of transparent polymethyl methacrylate board: The transparent polymethyl methacrylate board used for reinforced transparent soundproof acrylic board contains 100 parts of methyl methacrylate, 0.005 parts of initiator and 2 parts of release agent

[0048] The preparation method of the reinforced transparent soundproof acrylic board is as follows:

[0049] (1) Weigh the raw material methyl methacrylate and the initiator according to the weight fraction, mix evenly, stop heating after heating to boiling, and keep warm until the material liquid reaches a certain viscosity and drops to room temperature.

[0050] (2) Add a release agent and an initiator to the prepolymer, mix well, and vacuum de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com