Fleece-based industrial abrasive cloth

A flannelette and industrial technology, which is applied in the field of industrial abrasive cloth, can solve the problems of difficulty in laminating fleece cloth and sandpaper, poor flatness, poor adhesion and heat resistance, etc., to solve the problem of separation between sandpaper and fleece cloth, reduce application, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

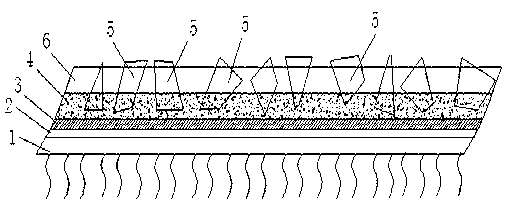

[0018] Such as figure 1 A kind of industrial emery cloth based on fleece cloth as shown, comprises fleece cloth, and the non-velvet surface of described fleece cloth forms a layer of film by processing, and the thickness of film is generally 10--20 micron, in order to prevent resin from soaking, Make the surface of the film smooth, pre-coat a layer of resin directly on the film, and then start applying primer, of course, you can also directly apply primer on the film without pre-coating resin; then electrostatic sanding implants abrasives, and then apply glue , that is, coat a layer of compound glue on the primer and abrasive, and make its structure firm after curing. The invention directly forms a layer of film on the fleece cloth, and directly produces fleece cloth emery cloth by electrostatic sanding on the film, saving materials and processes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com