Closed biological membrane type culture method for industrial production

A cultivation method and biofilm technology, which is applied in the field of closed biofilm culture for industrial production of microalgae, can solve problems such as microalgae biomass pollution, achieve cell detachment and biofilm shedding, reduce dehydration costs, and reduce usage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

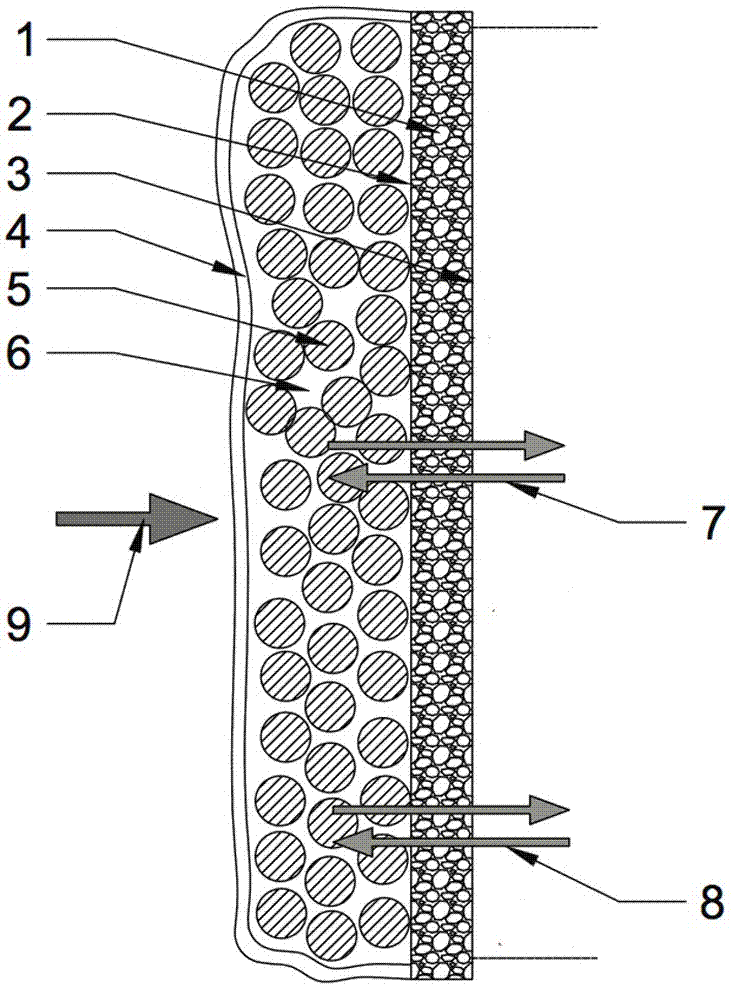

[0023] Embodiment 1: as attached figure 1 As shown, the closed biofilm culture method for industrialized production of microalgae is carried out as follows: one surface of the microporous film 1 is used as the microalgae cell inoculation surface 2, and the microalgae cell inoculation surface 2 is opposite to the microalgae cell inoculation surface. The other surface of the porous film 1 is used as the supply surface 3, and the microalgae cells 5 are inoculated on the microalgae cell inoculation surface 2. The microalgae cells 5 cannot pass through the micropores of the microporous film 1 to reach the supply surface 3. After inoculation, the microalgae cells The algae cell inoculation surface 2 is covered with a transparent film 4, and the gaseous phase and culture solution containing carbon dioxide are supplied to the microalgae cells 5 from the supply surface 3, and the carbon dioxide and the culture solution can pass through the micropores of the microporous film 1 to reach ...

Embodiment 2

[0028] Embodiment 2: as the optimization of above-mentioned embodiment, microporous film 1 is the filter material that aperture is less than microalgae cell 5, and filter material is filter paper or filter membrane or fiber fabric; And / or, transparent film 4 is transparent nontoxic film Material, the transparent film 4 is a semi-permeable film or a non-porous transparent film, and the aperture of the semi-permeable film is less than or equal to the aperture of the microporous film 1.

[0029] The filter material can adopt the existing cheap material, thereby reducing the production cost.

Embodiment 3

[0030] Embodiment 3: As an optimization of the above embodiments, the surfaces of the microporous film 1 and the transparent film 4 are flat or curved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com