Quantitative pressing spray nozzle and container with quantitative pressing spray nozzle

A spray head and pressure head technology, which is applied to spray devices, single handheld devices, closing and other directions, can solve the problems of inconvenient use, reduce the air tightness of the pressure head cylinder, and support the pressure head spring with large elastic force, so as to achieve convenient and efficient use. Effort-saving, easy to operate with one hand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in terms of specific embodiments in conjunction with the accompanying drawings. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It is to be noted that other embodiments may be utilized or structural and functional modifications may be made to the embodiments set forth herein without departing from the scope and spirit of the invention.

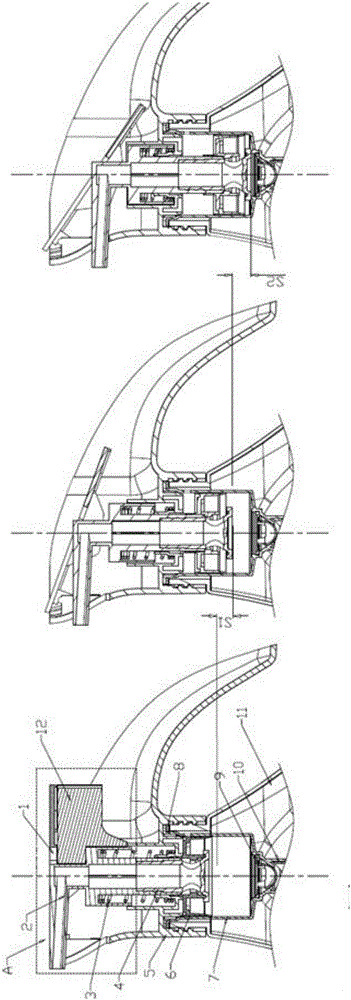

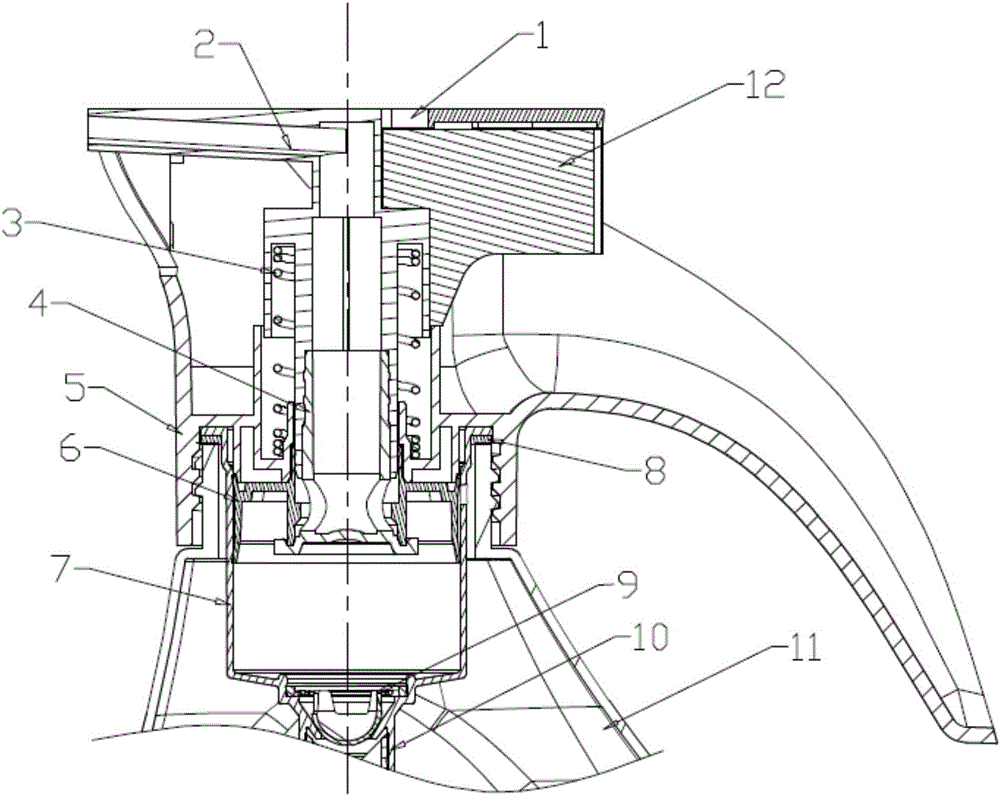

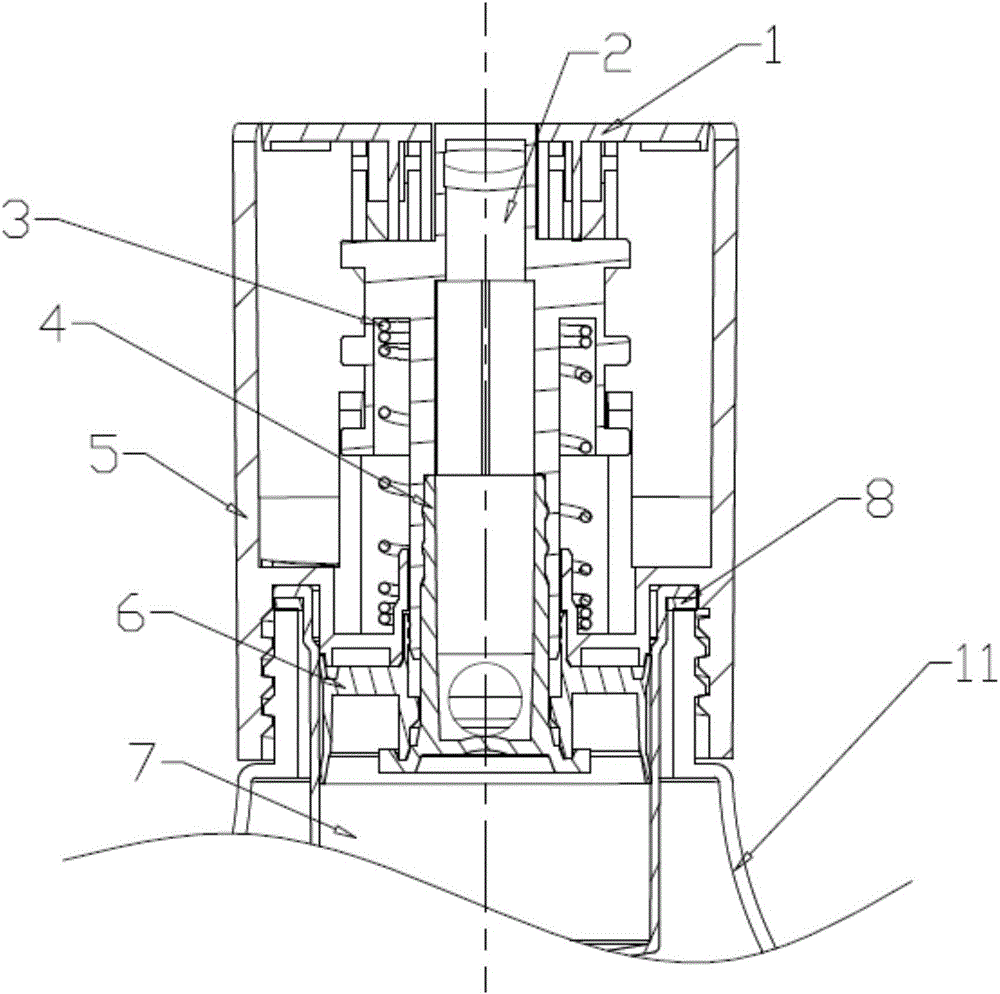

[0038] In the embodiment of a quantitative pressing nozzle provided by the present invention, such as Figure 1-4 As shown, it includes: a pressure plate 1, a pressure head 2 and a portable screw cap 5 for connecting with the container 11; the pressure head 2 is penetrated in the portable screw cap 5, and the pressure plate 1 is set against the On the pressure head 2;

[0039] One end of the pressing plate 1 is a fixed end connected to the portable screw cap 5, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com