Aluminum pipe resin coating apparatus

A technology for coating devices and aluminum tubes, which is applied in the direction of surface coating liquid devices, coatings, cleaning hollow objects, etc., which can solve problems such as coating layer peeling, cracks and cracks, and imperfect cleaning of the surface of aluminum tubes. , to achieve high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

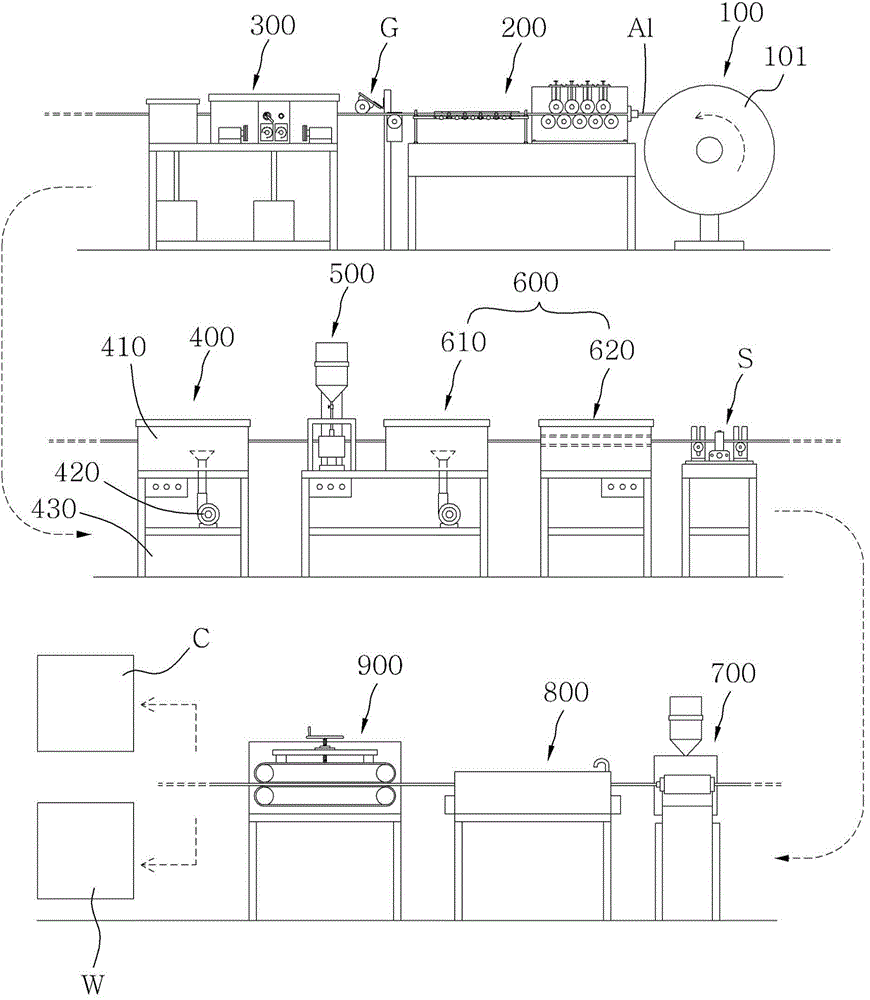

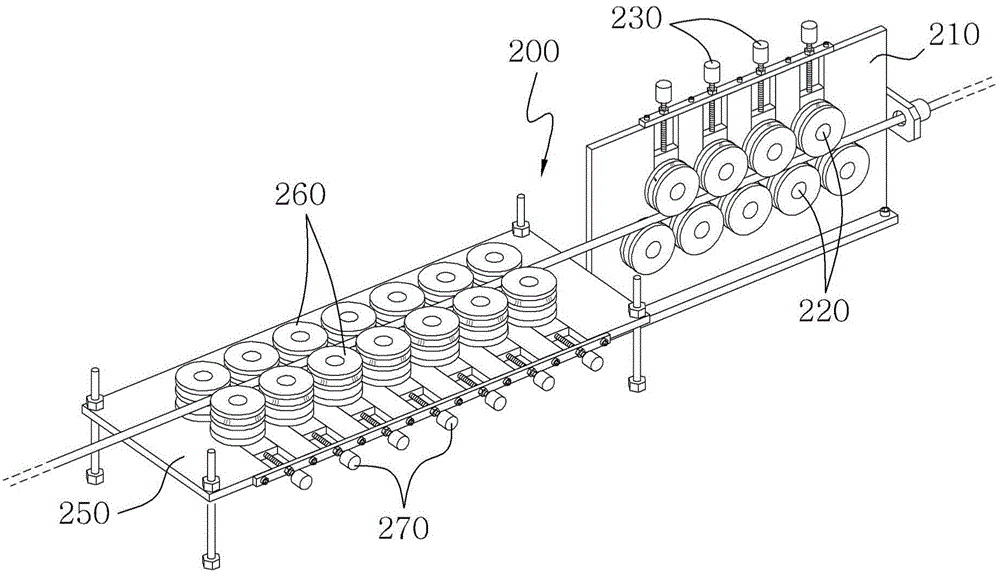

[0037] The aluminum tube resin coating device of the present invention includes: a linearization unit 200, which linearizes the aluminum tube Al supplied by the aluminum tube supply unit 100; a cleaning unit 300, which cleans the surface of the aluminum tube linearized by the linearization unit. Generating fine scratches; drying unit 400, drying the aluminum tube cleaned by the cleaning unit; adhesive coating unit 500, supplying adhesive to the aluminum tube dried by the drying unit and coating; preheating unit 600, Preheat the aluminum pipe coated with adhesive through the adhesive coating unit; the resin coating unit 700 applies resin to the surface of the aluminum pipe preheated through the preheating unit; the cooling unit 800 applies the resin The coating unit cools the aluminum pipe coated with resin; the drawing unit 900 draws out the aluminum pipe cooled by the cooling unit.

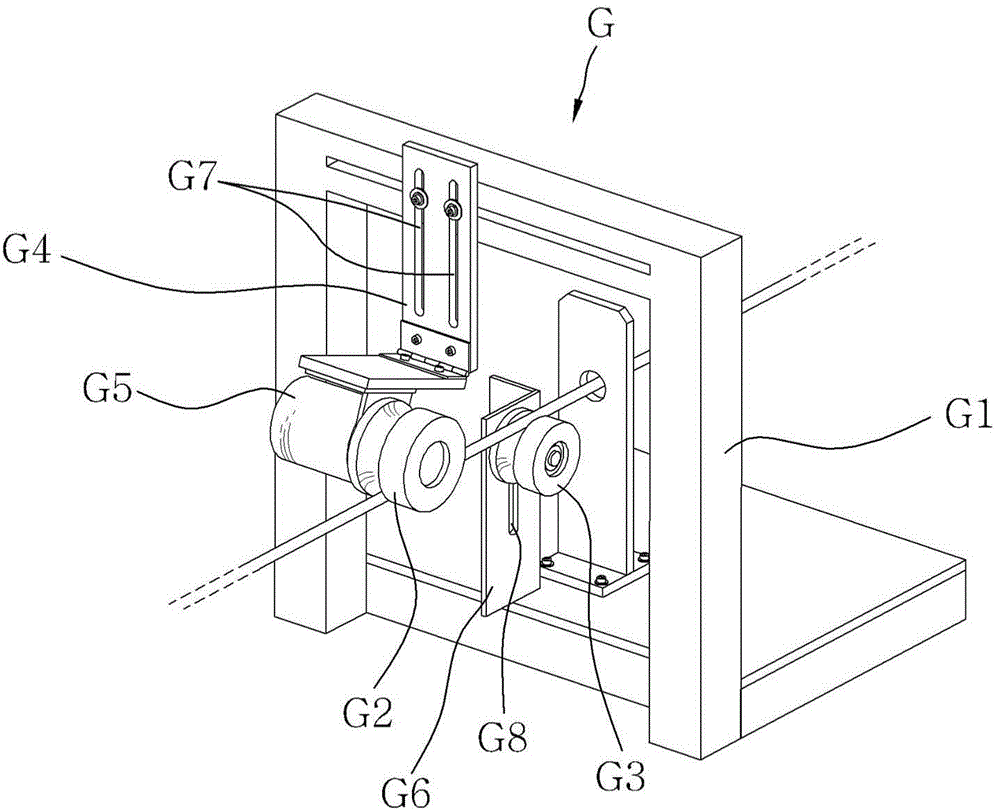

[0038] Moreover, a guide unit G is installed between the linearization unit 200 and the clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com