Positioning pin lock for piston valve pit tool

A valve pit and positioning pin technology, which is applied in the field of fixtures and fixtures, can solve the problems of positioning pins and workpieces being separated, and achieve the effects of ensuring production tasks, stabilizing product quality, and simple structural methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

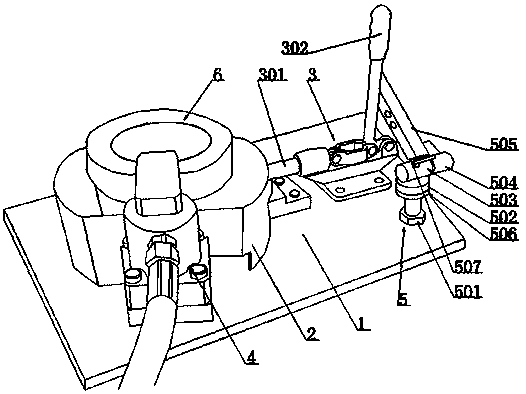

[0010] like figure 1 As shown, a positioning pin lock for piston valve pit tooling, including a tooling base plate 1, a piston stop seat 2, a clamp 3, a compression cylinder 4, a positioning pin lock 5, and a piston 6 is positioned on the piston stop seat 2, the piston pin hole is arranged on the peripheral surface of the piston stop seat 2, and the positioning pin at the front end of the clamp 3 extends into the piston pin hole to radially position the piston 6, press The tightening cylinder 4 can axially compress the piston 6, and the positioning pin lock 5 can lock the handle of the clamp 3; , short shaft 504, lock bar 505, the upright supporting column 501 can be fixed on the tooling base plate 1, the upper end of the rotating shaft seat 502 is connected with the supporting column 51; that is, the supporting column is a bolt, the rotating shaft seat is a cap nut, and the head end of the bolt Fixed on the bottom plate of the tooling fixture, the cap nut is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com