Balance toy car

A twisting and balancing technology, applied in the field of balancing twisting vehicles, can solve problems such as affecting the rotating performance of twisting vehicles, endangering the life safety of users, and detaching the bearing from the shaft, so as to simplify the structure, increase the safety, and improve the rotation. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further described in conjunction with the following examples.

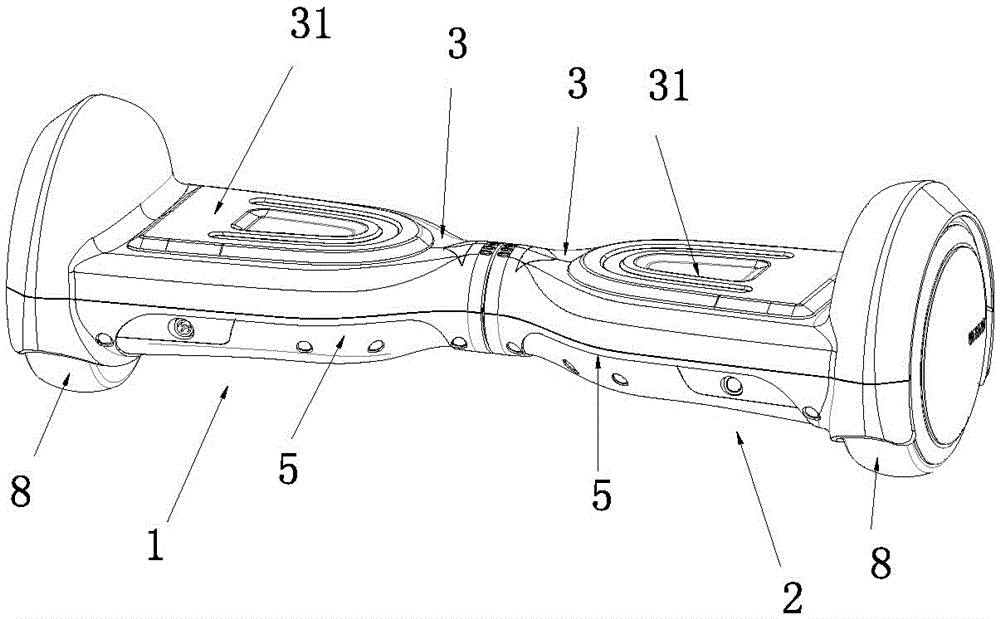

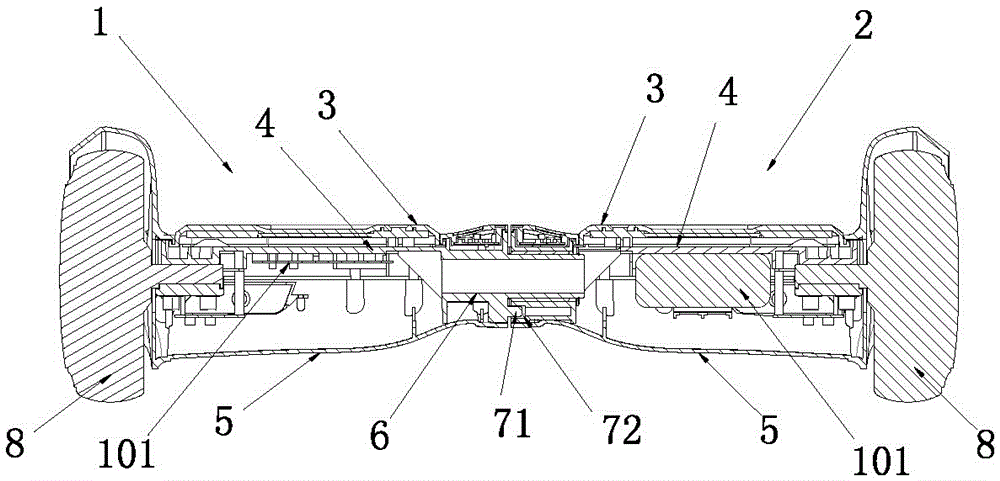

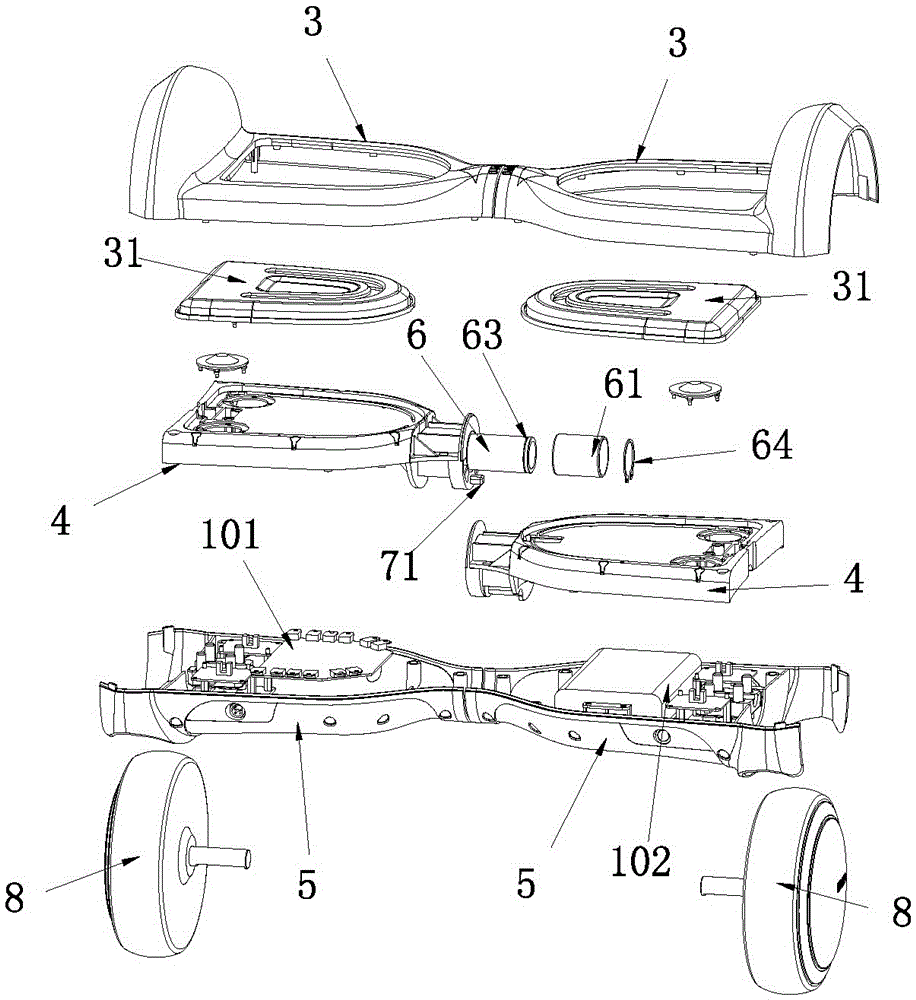

[0033] A specific embodiment of a balanced twist car of the present invention, such as figure 1 and Figure 4 As shown, its structure includes a first torsion body 1 and a second torsion body 2, and both the first torsion body 1 and the second torsion body 2 include an upper cover, an inner cover 4 and a bottom cover 5 sequentially connected from top to bottom. A support frame and a second support frame correspond to the inner cover 4 in the first torsion body 1 and the second torsion body 2, and the shaft 6 is formed on the inner cover 4 in the first torsion body 1, specifically, the shaft 6 The material and the material of the inner cover 4 are different kinds of metal materials, wherein the material of the inner cover 4 is made of aluminum material that is lighter than the material of the shaft rod 6, so that the overall weight of the twisting car is reduced, and it is more conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com