Method and device for soldering flux application

A solder and equipment technology, applied in the field of motor vehicle exhaust gas purification, can solve the problems of insufficient strength and easy falling off of solder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

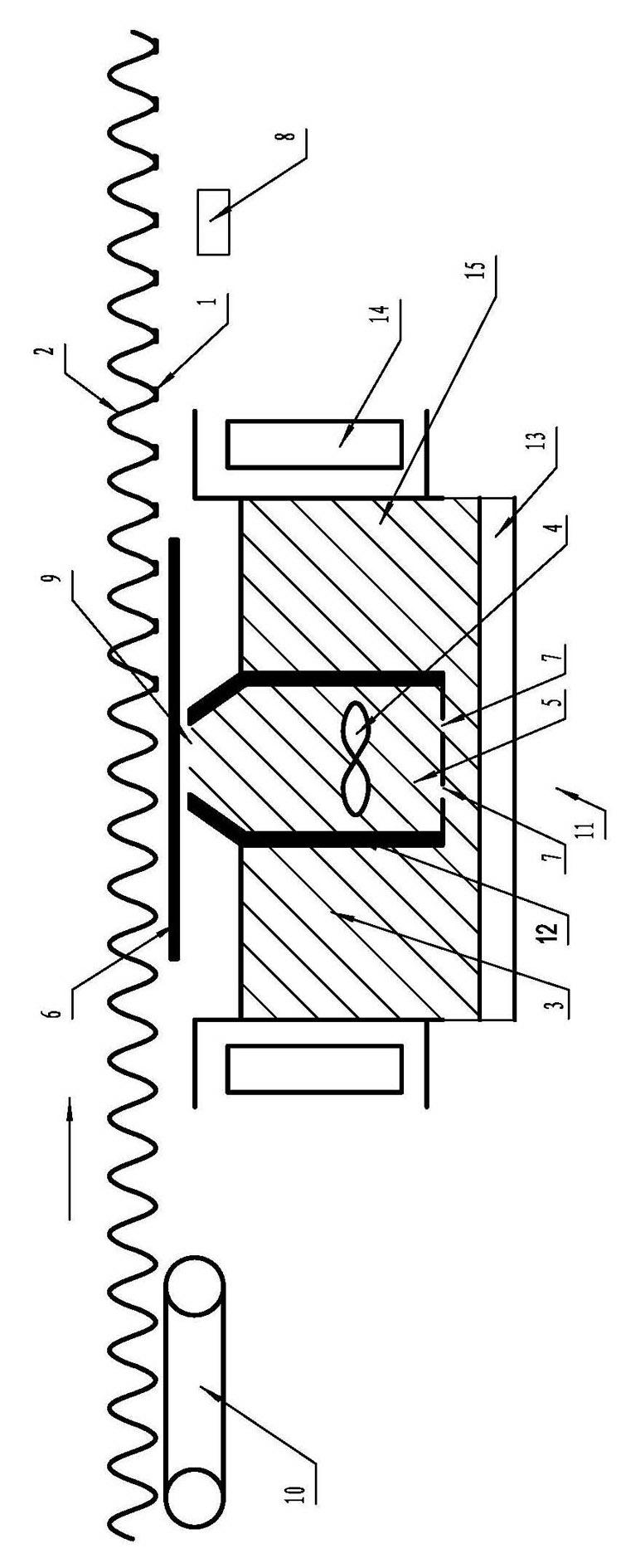

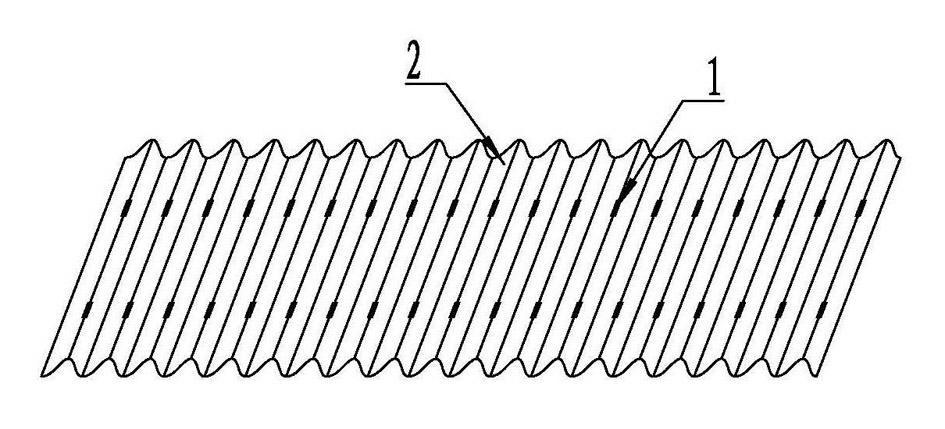

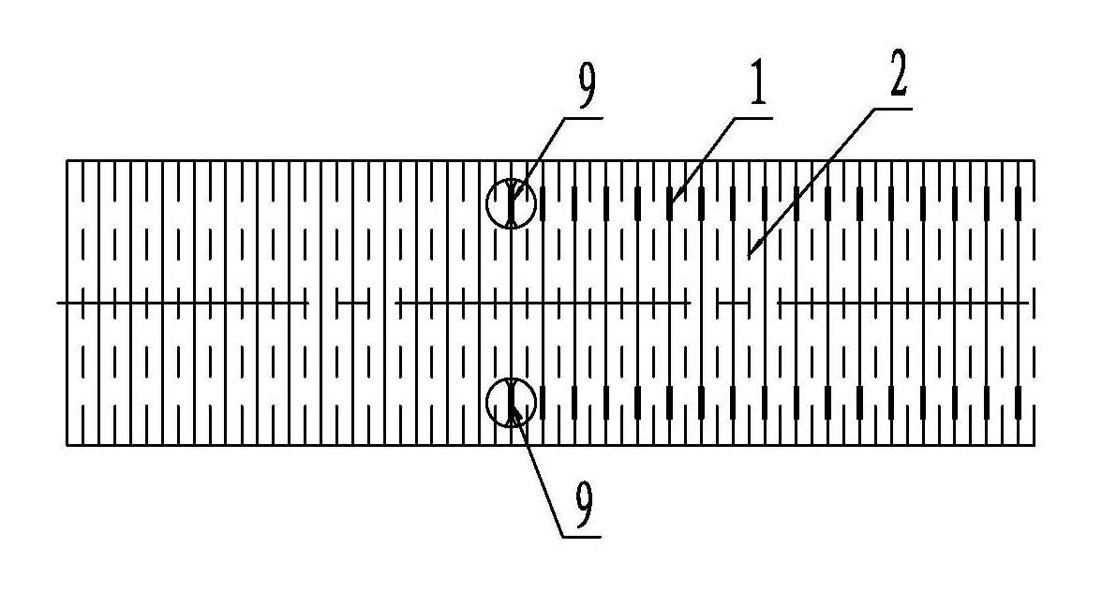

[0034] Such as figure 1 , 2 A kind of equipment for applying solder 1 on metal corrugated belt 2 shown in and 3, this equipment comprises: be used for the feeding device 10 of metal corrugated belt 2, be used for the solder of metal corrugated belt 2 positioning application solder 1 An application unit 11, and a gas cooling device 8 for solidifying the solder. The solder applying unit 11 includes a material chamber 15 for containing solder powder or a mixture of solder powder and a binder, and a material feeding chamber 12 communicating with the material chamber 15 . A rotating blade 4 is fixed in the feeding chamber 12, and the rotating blade 4 is connected with a motor for controlling its rotation. The bottom of the feeding chamber 12 is provided with an opening 7 for entering liquid solder, and the opening 7 is located below the rotating blade, so that the liquid solder 3 in the feeding chamber 15 can flow into the feeding chamber 12 under the agitation of the rotating bl...

Embodiment 2

[0040] The specific scheme is the same as in Example 1, the difference is that the gas cooling device 8 used to solidify the solder is changed to a hot air drying device, and the hot air drying device is used to provide hot air at 50°C to 100°C for solder powder and normal temperature adhesive mixture is dried. The hot air drying device in this embodiment is a hot air blower, and since the hot air blower is not the focus of the improvement of the present invention, it will not be described in detail.

Embodiment 3

[0042] Adopt the equipment of embodiment 1, select the wide solder nozzle 9 of 10mm for use, and as image 3 The way in which is arranged in the solder applying unit 11, so that the solder is fixed at a predetermined position. Add 1000 g of pure solder powder into the material chamber 15, and the whole process of applying solder is carried out under the protection of argon gas. Turn on the power supply of the heating device 14, set the temperature of the heating device to 1150° C. and start heating. After the solder powder melts into a molten state, turn on the motor connected to the rotating blade 4 to make the rotating blade 4 start to rotate, observe the solder outflow situation in the solder nozzle 9, and adjust the rotational speed of the rotating blade 4 so that the solder flow in the solder nozzle meets the process requirements. Start the feeding device 10 of the metal corrugated belt, make the metal corrugated belt pass smoothly above the solder application unit 11 at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com