Hole wallboard internally filled with thermal insulation materials

A technology for thermal insulation materials and wall panels, which is applied in thermal insulation, building components, covering/lining, etc., and can solve problems such as separation of wall panels and thermal insulation materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

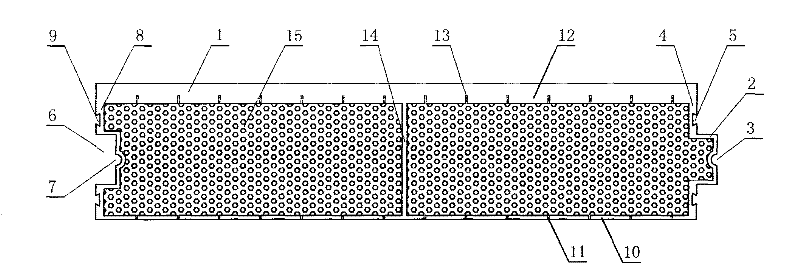

Embodiment 1

[0016] The end face of a thermal insulation wallboard with inner penetrating holes and outer blind holes is shown in Fig. figure 1 As shown, among them: 1 is the wood-plastic wallboard, 2 is the wallboard with a cavity connecting tenon, 3 is the tenon sealing groove, 4 is the sealing platform, 5 is the dovetail groove of the sealing platform, 6 is the wallboard connecting groove, 7 is the groove sealing Groove, 8 is the side boss of the wall panel with cavity connection groove, 9 is the dovetail groove of the side boss, 10 is the inner thin-wall panel of the wood-plastic wall panel, 11 is the through hole of the inner thin-wall panel of the wood-plastic wall panel, and 12 is the wood-plastic The outer thick-walled panel of the wallboard, 13 is the blind hole of the outer thick-walled panel of the wood-plastic wallboard, 14 is the support rib of the wood-plastic wallboard, and 15 is a self-hardening resin insulation material.

[0017] The self-hardening resin insulation materia...

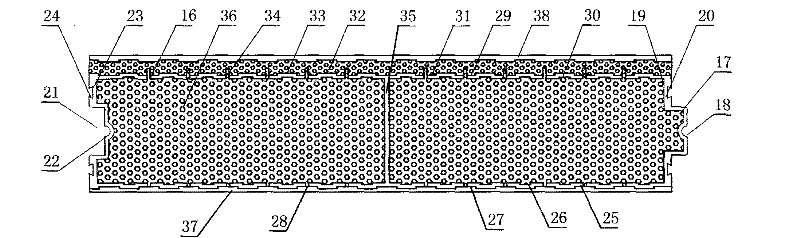

Embodiment 2

[0019] The end face of a thermal insulation wallboard with inner penetrating holes and outer blind holes is shown in Fig. figure 2 As shown, among them: 16 is the wood-plastic wallboard, 17 is the wallboard with cavity connection tenon, 18 is the tenon sealing groove, 19 is the sealing platform, 20 is the dovetail groove of the sealing platform, 21 is the wallboard connecting groove, 22 is the groove sealing Groove, 23 is the side boss of the wall panel with cavity connection groove, 24 is the dovetail groove of the side boss, 25 is the inner wall panel of the wood-plastic wall panel, 26 is the inner groove of the inner wall panel of the wood-plastic wall panel, and 27 is the inner wall of the wood-plastic wall panel The outer groove of the panel, 28 is the through hole of the inner wall panel of the wood-plastic wallboard, 29 is the outer wall panel of the wood-plastic wallboard, 30 is the inner groove of the outer wall panel of the wood-plastic wallboard, 31 is the outer gro...

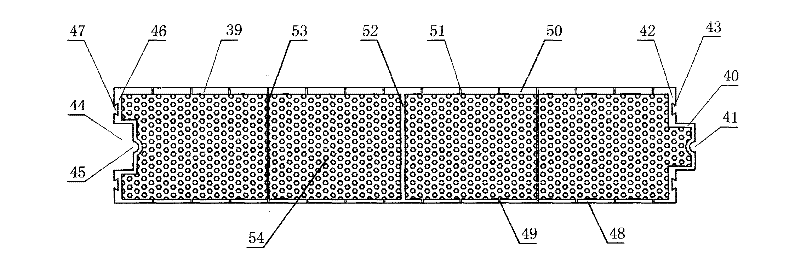

Embodiment 3

[0022] The end face of a wall panel with inlaid transverse columns and thermal insulation material with internal and external perforations is shown in the figure image 3 As shown, among them: 39 is the wood-plastic wallboard, 40 is the wallboard with cavity connecting tenon, 41 is the tenon sealing groove, 42 is the sealing platform, 43 is the dovetail groove of the sealing platform, 44 is the wallboard connecting groove, 45 is the groove sealing Groove, 46 is the side boss of the wall panel with cavity connection groove, 47 is the dovetail groove of the side boss, 48 is the inner panel of the wood-plastic wall panel, 49 is the through hole of the inner panel of the wood-plastic wall panel, and 50 is the outer panel of the wood-plastic wall panel , 51 is the through hole of the outer panel of the wood-plastic wallboard, 52 is the support rib of the wood-plastic wallboard, 53 is the horizontal column, and 54 is the thermal insulation material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com