Automobile, automobile seat and siding rail mechanism of automobile seat

A technology for car seats and slide rails, which is applied in the field of automobiles and car seats, can solve the problems of separation of moving slide rails from fixed slide rails, increase the production cost of slide rail mechanisms, and complex structure of anti-separation mechanisms, so as to ensure safety, Simple structure and enhanced rigidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The core of the present invention is to provide a slide rail mechanism for car seats. On the basis of controlling the manufacturing cost of the slide rail mechanism, it is not easy for the moving slide rail to move from the fixed slide rail under the alternating load or impact load of the safety belt. The purpose of detachment, so as to ensure the safety of the car during driving. On this basis, the present invention also provides a car seat including the above-mentioned slide rail mechanism, and a car including the above-mentioned car seat.

[0030] Without loss of generality, this embodiment will now be described in detail in conjunction with the accompanying drawings.

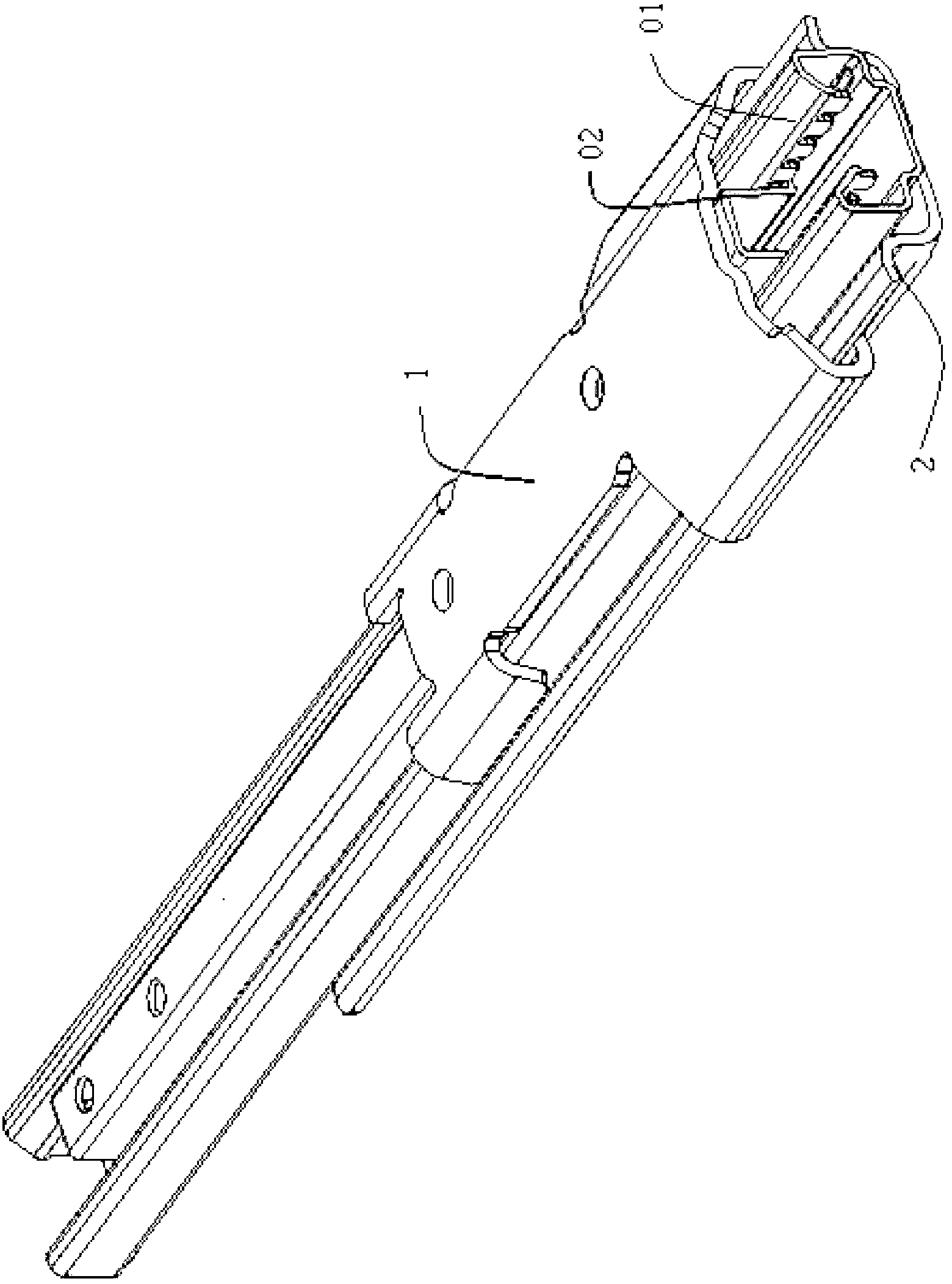

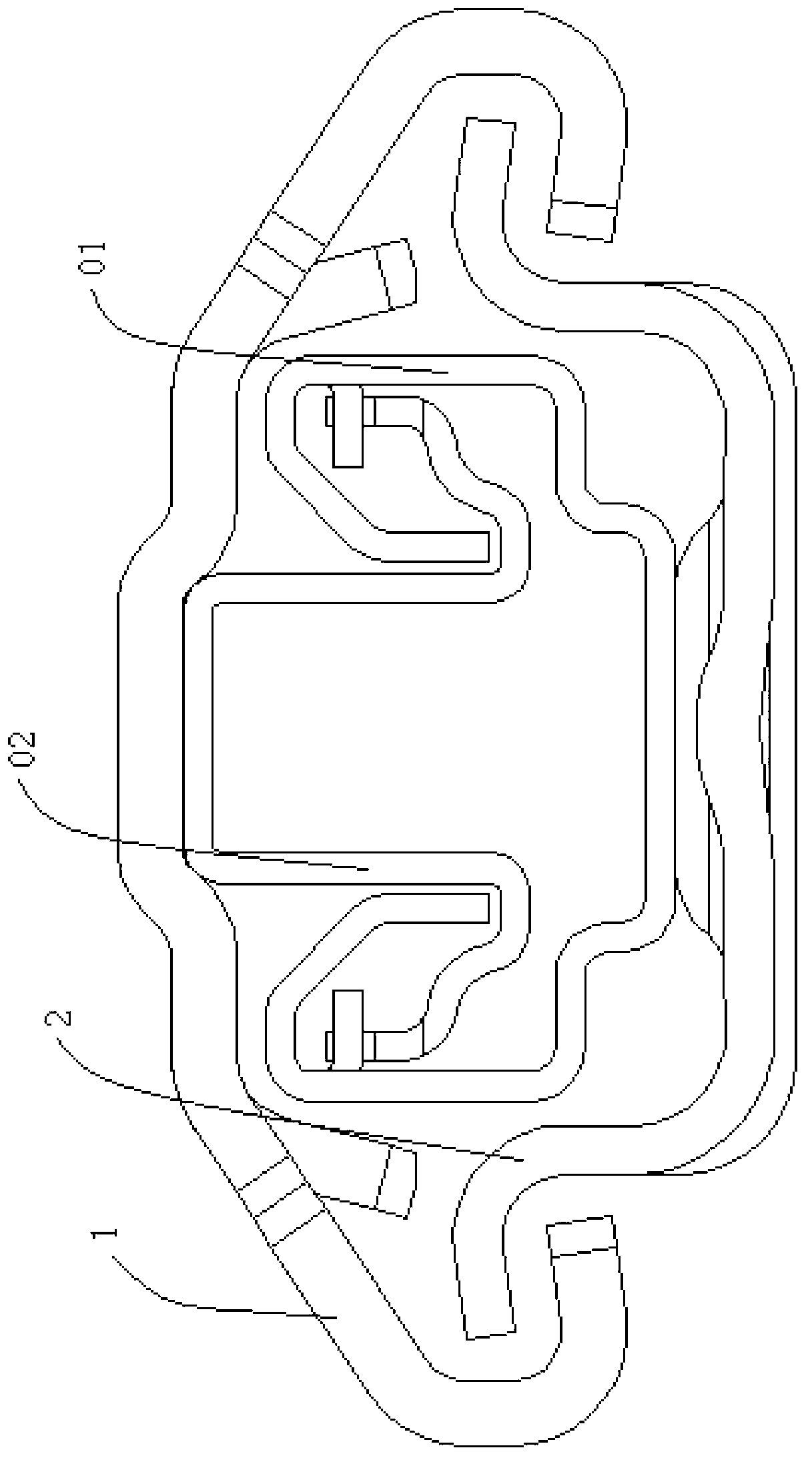

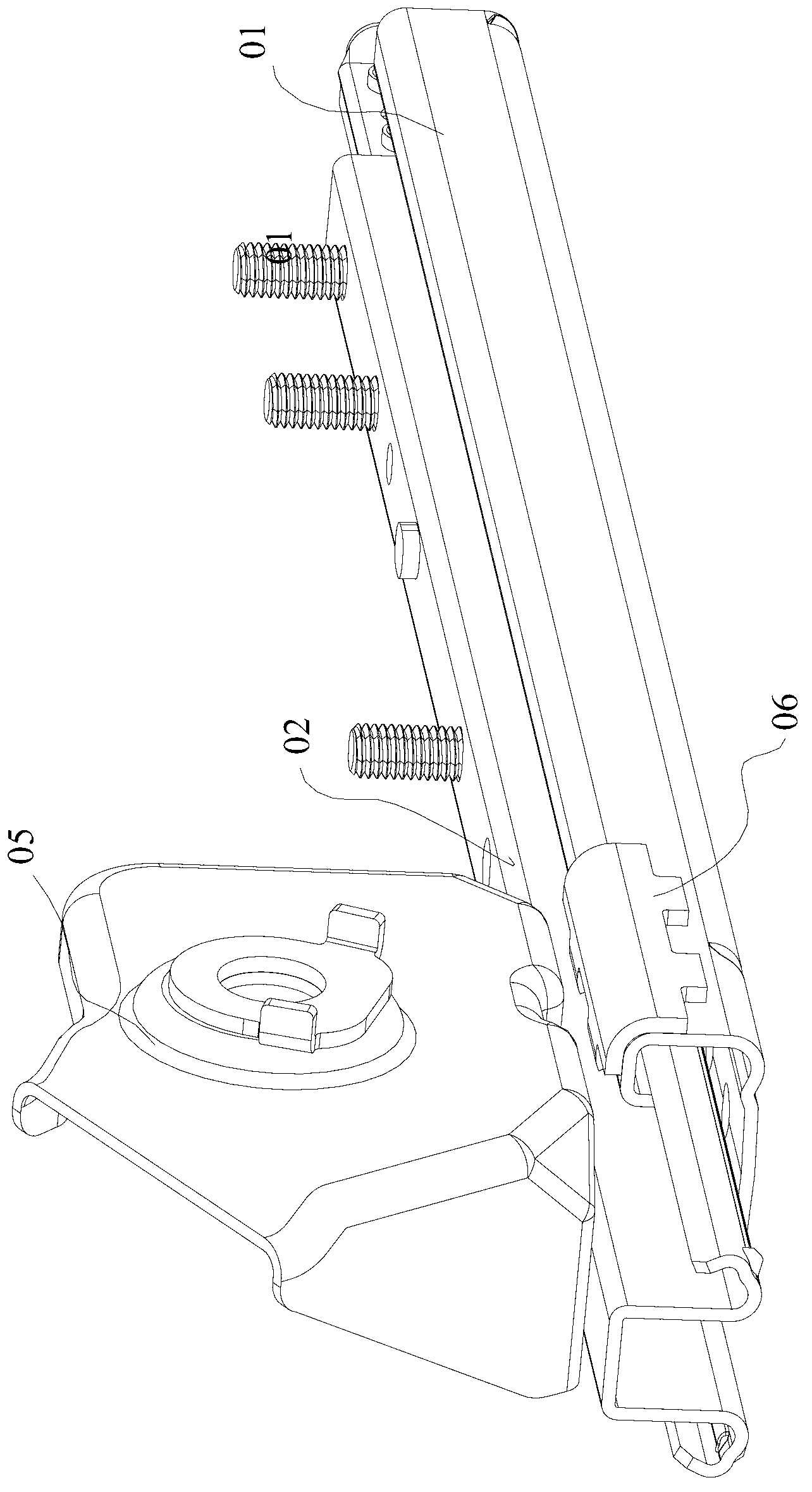

[0031] See Figure 4 , Figure 5 and Figure 6 ,in, Figure 4 It is an axonometric view of the first embodiment of the slide rail mechanism in the present invention, Figure 5 for Figure 4 Schematic diagram of the front view of the middle slide rail mechanism, Figure 6 for Figure 4 Schemati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com