Electric heating mica plate and preparation method thereof

A mica board, electric heating technology, applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of affecting heating power and life, detachment of heating resistors, unsafe, etc., to ensure power and life, not easy to deform , to prevent foaming" effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

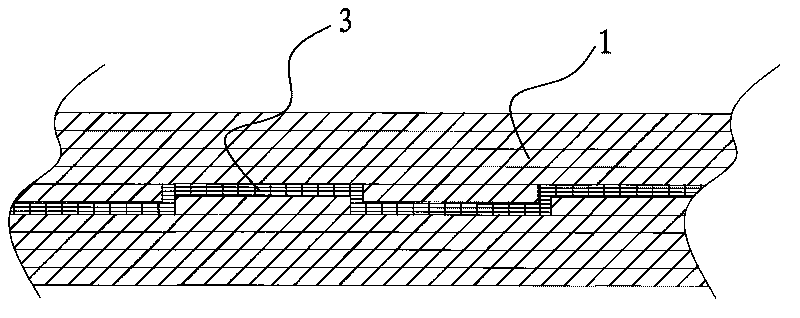

[0025] Preparation of electric heating mica board (length 394mm; width 513mm; thickness 0.7mm):

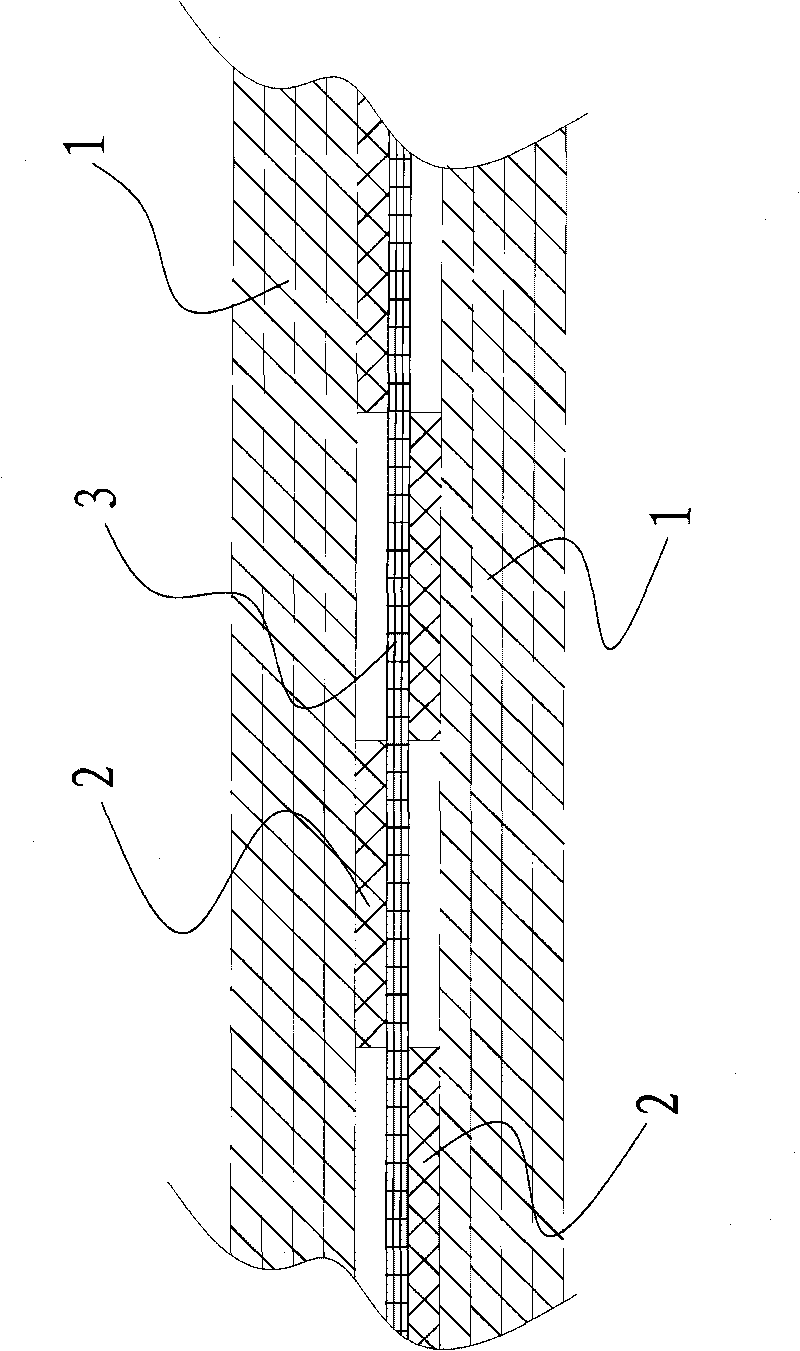

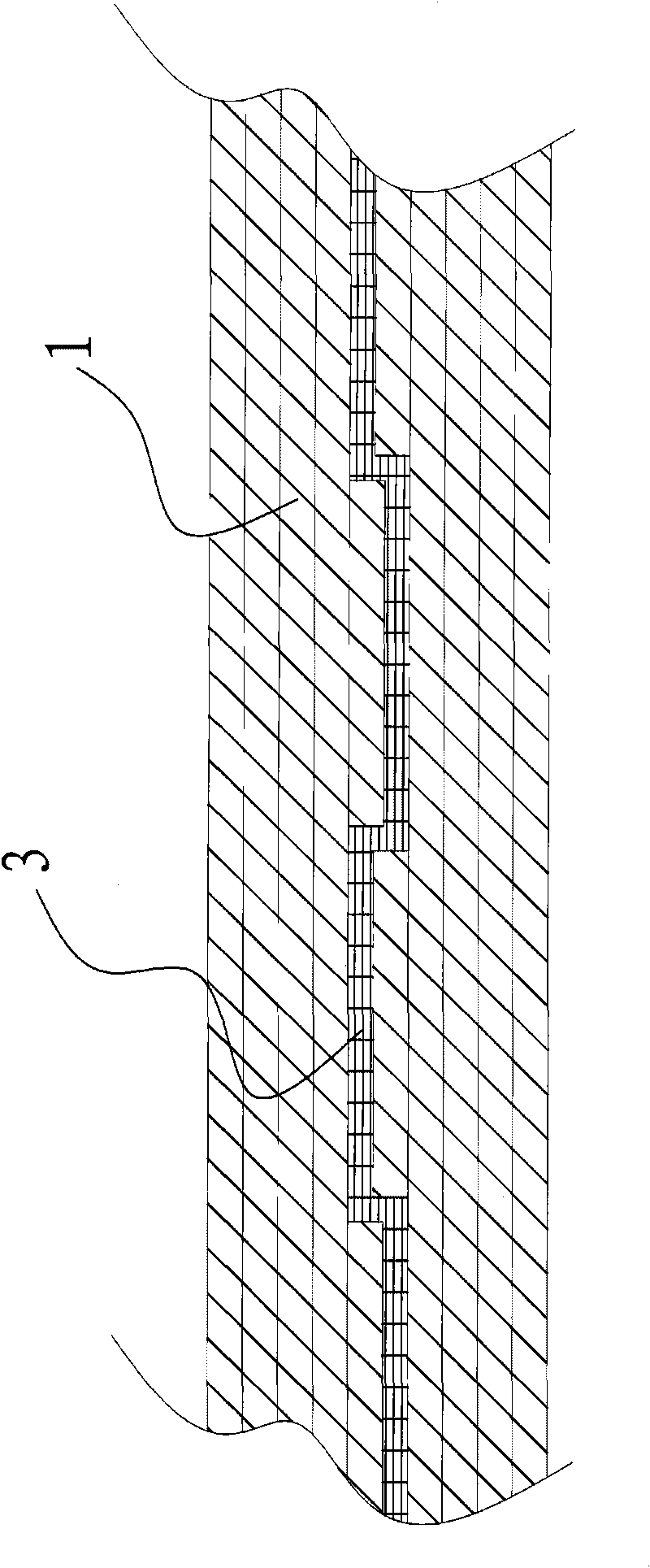

[0026] 1. Making resistance sheet 3 (EDM): Cut about 100 sheets of 0.05mm thick 304 stainless steel heating resistor sheets (length 420mm, width 530mm) that have passed the inspection, stack them neatly and fix them on the EDM wire cutting machine. On the wire cutting guide rail of the machine tool DK7763B; check the computer program and input it to the wire cutting controller, check the molybdenum wire and other parts of the wire cutting machine tool, and start the machine tool for EDM after everything is normal (continuous inspection during the cutting process); the cutting is completed Soak the resistance sheet in the cleaning solvent for about 15 minutes, take it out and drain it; bake it in an oven (270℃~280℃) for 2 hours and take it out;

[0027] 2. Production of mica paper: Prepare the sheet-shaped non-calcined powder mica paper 1 arranged on the outer layer (4 sheets each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com