Rapid locking device of carrying trolley

A handling trolley and quick-locking technology, applied in the directions of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problem of not being able to quickly connect or disengage the handling trolley and the transmission system, and achieve quick locking or opening, universal Strong and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

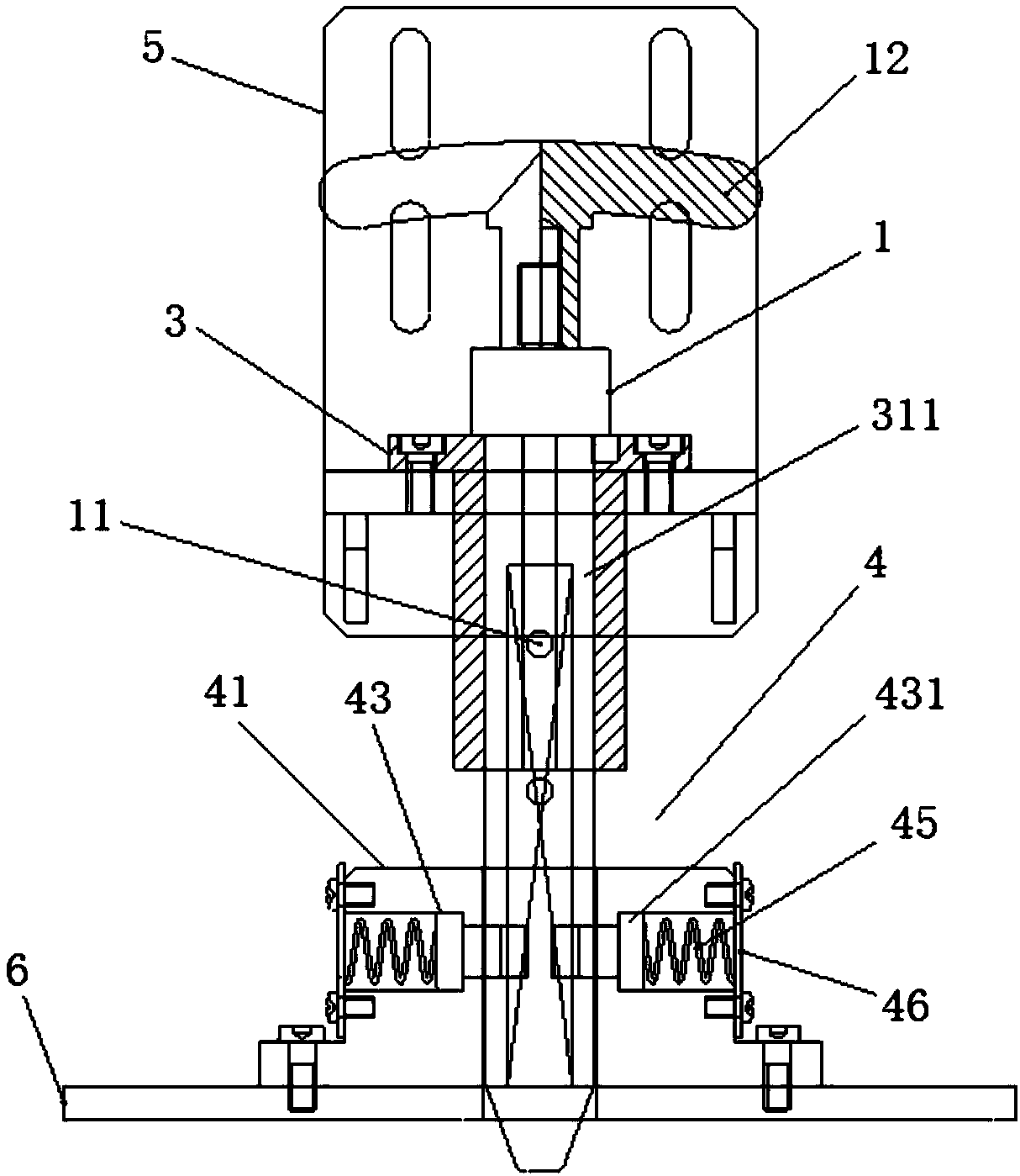

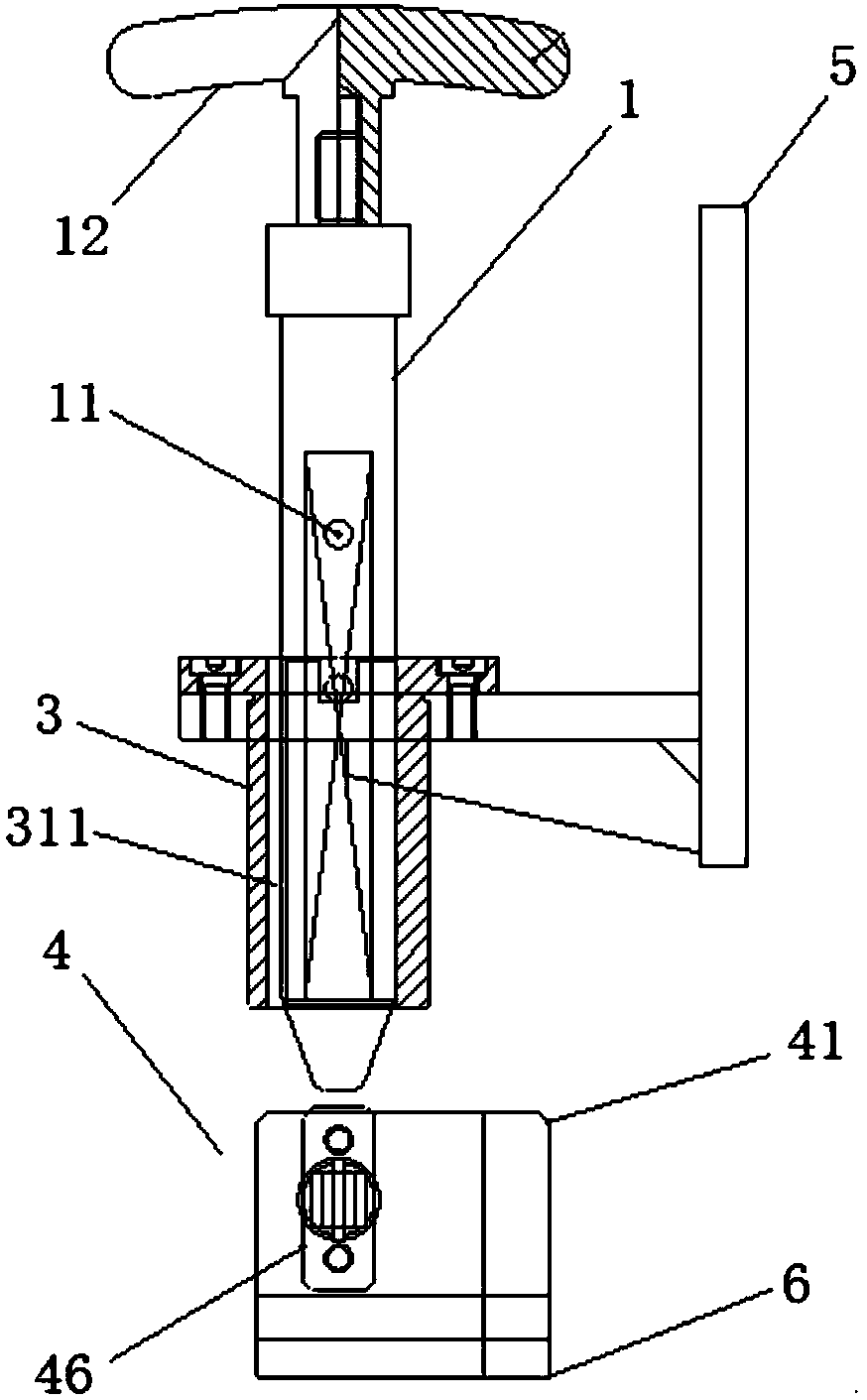

[0017] see Figures 1 to 5 According to an embodiment of the present invention, the quick lock device for a trolley on a robot assembly line includes a latch 1, a latch bracket 3 provided on the trolley 2, and a chain on the chain in the transmission system for driving the trolley 2. Several lock pin mechanisms 4.

[0018] The latch 1 is cylindrical and inserted in the latch bracket 3, and the upper end is threadedly connected with a handle 12, the upper half is provided with a flange, one side of the cylindrical surface is flattened and a positioning pin 11 is provided.

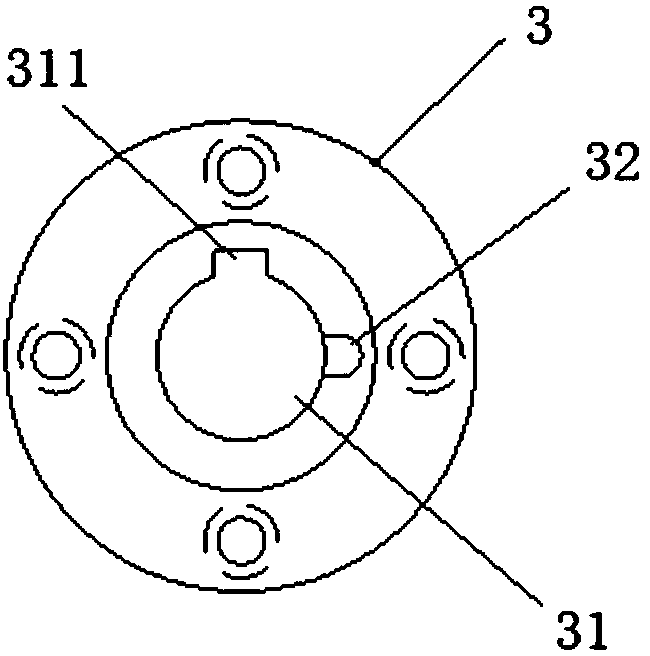

[0019] The bolt bracket 3 is fastened to the transport trolley 2 by means of a screw connection through the fixing frame 5, and is provided with a sleeve-shaped passage 31 that matches the shape of the bolt 1, and the bolt 1 can be inserted into the passage 31 and can face / backward to the locking mechanism 4 sports. Wherein, the diameter of the flange is larger than the inner diameter of the channel 31 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com