A kind of corn thresher

A technology for thresher and corn, applied in the direction of threshing equipment, agricultural machinery and implements, agriculture, etc., can solve the problems of unfavorable storage, high labor intensity, many manual participation links, etc., to improve quality and efficiency, high degree of automation, The effect of reducing the screening process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

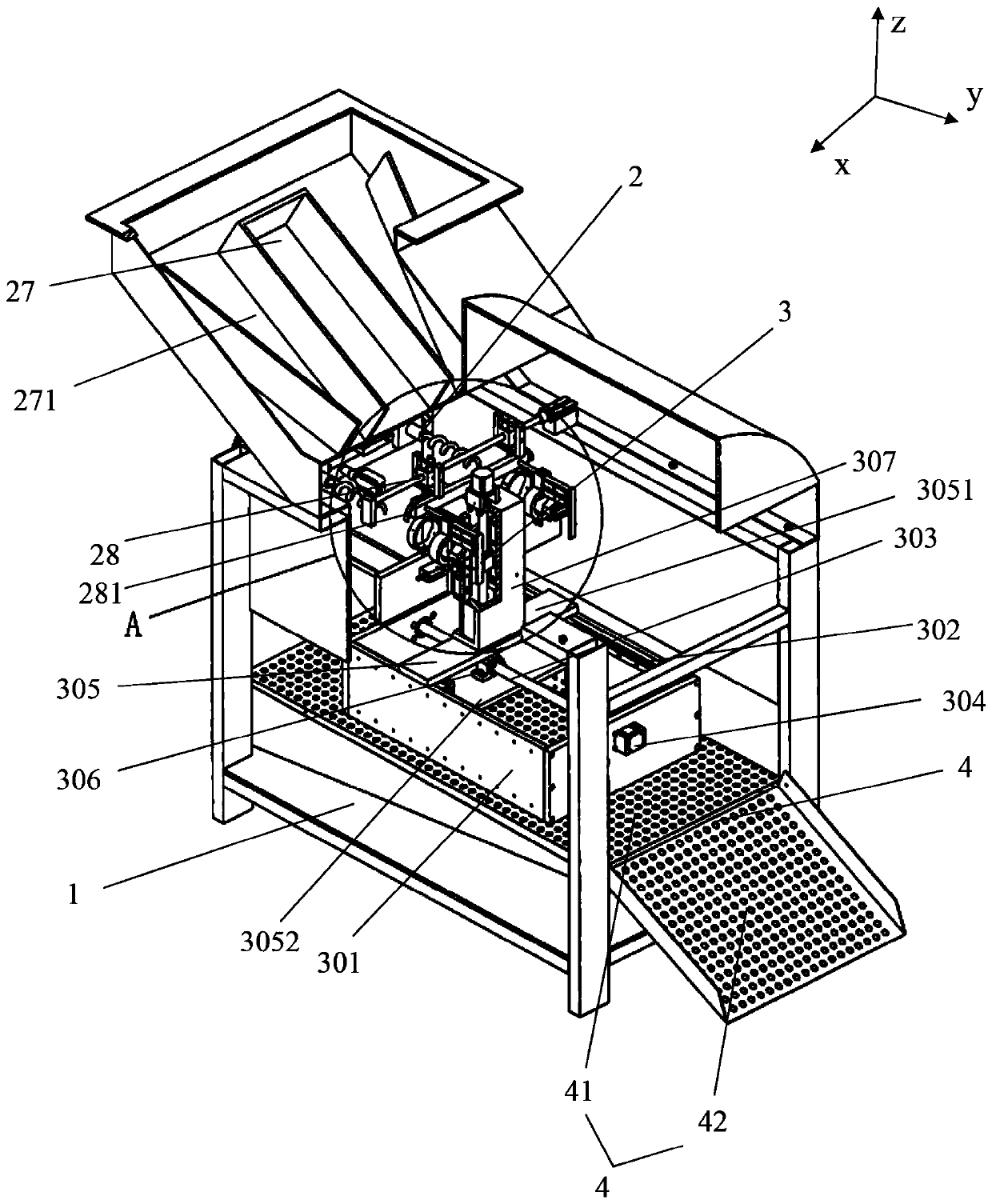

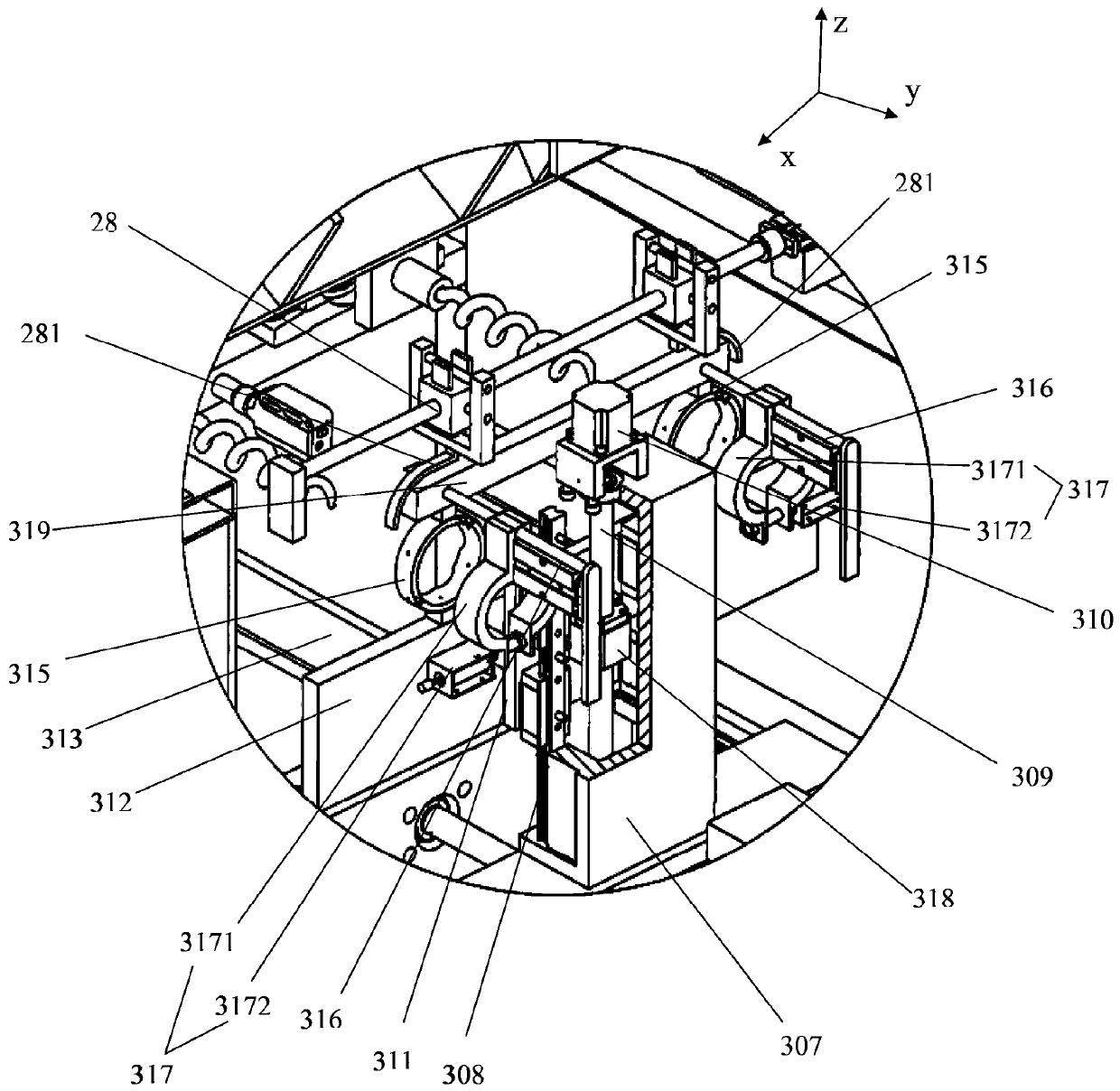

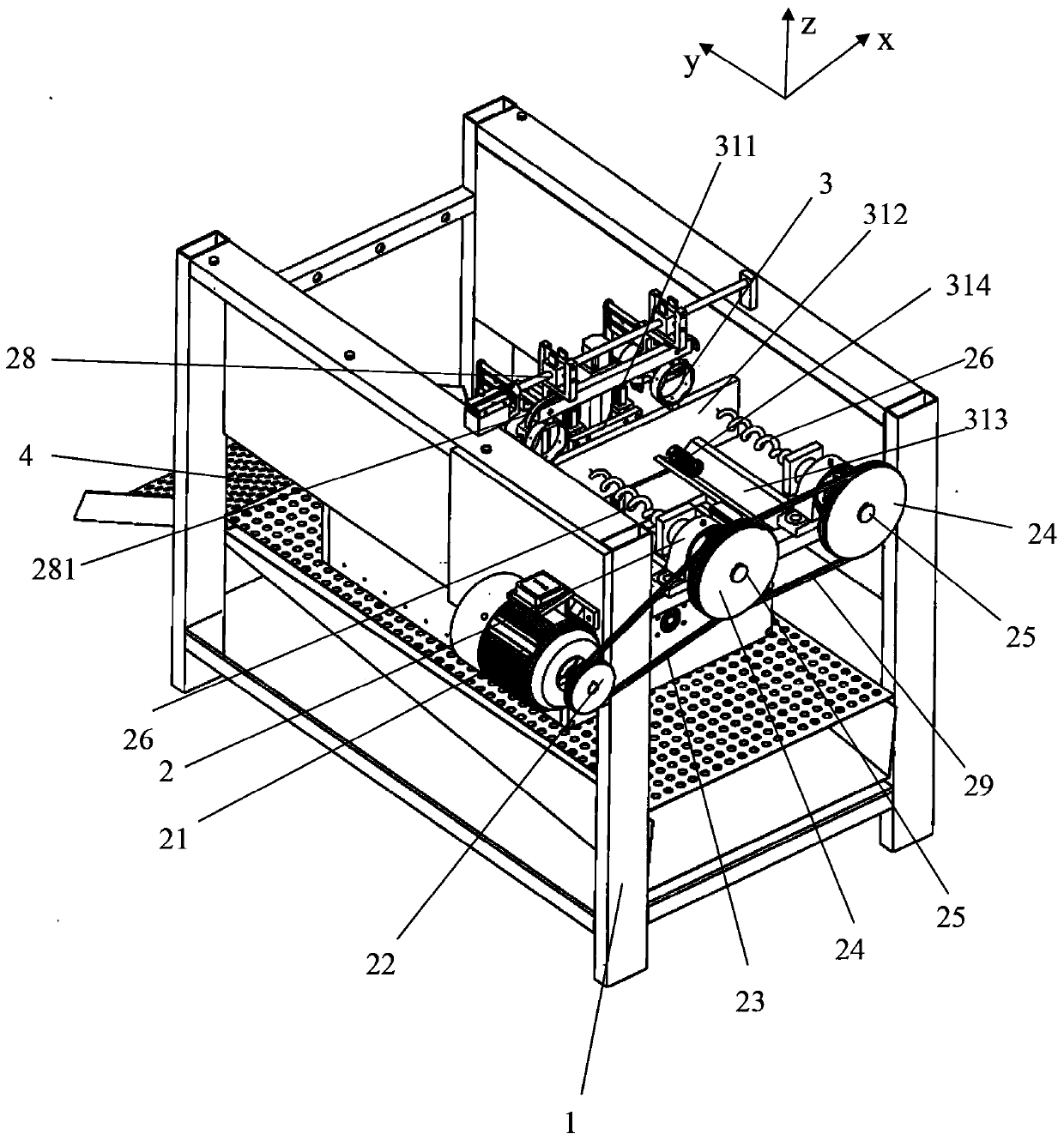

[0020] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but the applicant's description of the embodiments is not a limitation to the technical solution, and any changes based on the concept of the present invention in form but not in essence should be regarded as the protection scope of the present invention.

[0021] First of all, what the applicant needs to explain is: in the following description, all the concepts related to orientation, such as left and right, up and down, are for the position state shown in the figure, so it cannot be understood as a reference to the present invention. Restriction of the scheme; In addition, in this embodiment, the height direction is defined as the z-axis direction, and the two directions perpendicular to the z-axis and mutually perpendicular are respectively set as the x-axis and the y-axis, and the x-axis and the y-axis and z-axis directions are shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com