Nitride ceramic ammonia gas tail gas treatment system and treatment method thereof

A technology of nitride ceramics and tail gas treatment, which is applied in combustion methods, waste heat treatment, incinerators, etc., can solve the problems of incomplete removal of waste gas flammable gases, failure to meet environmental protection requirements, unsatisfactory treatment effects, etc., and achieve simple manufacturing process , small equipment investment, good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

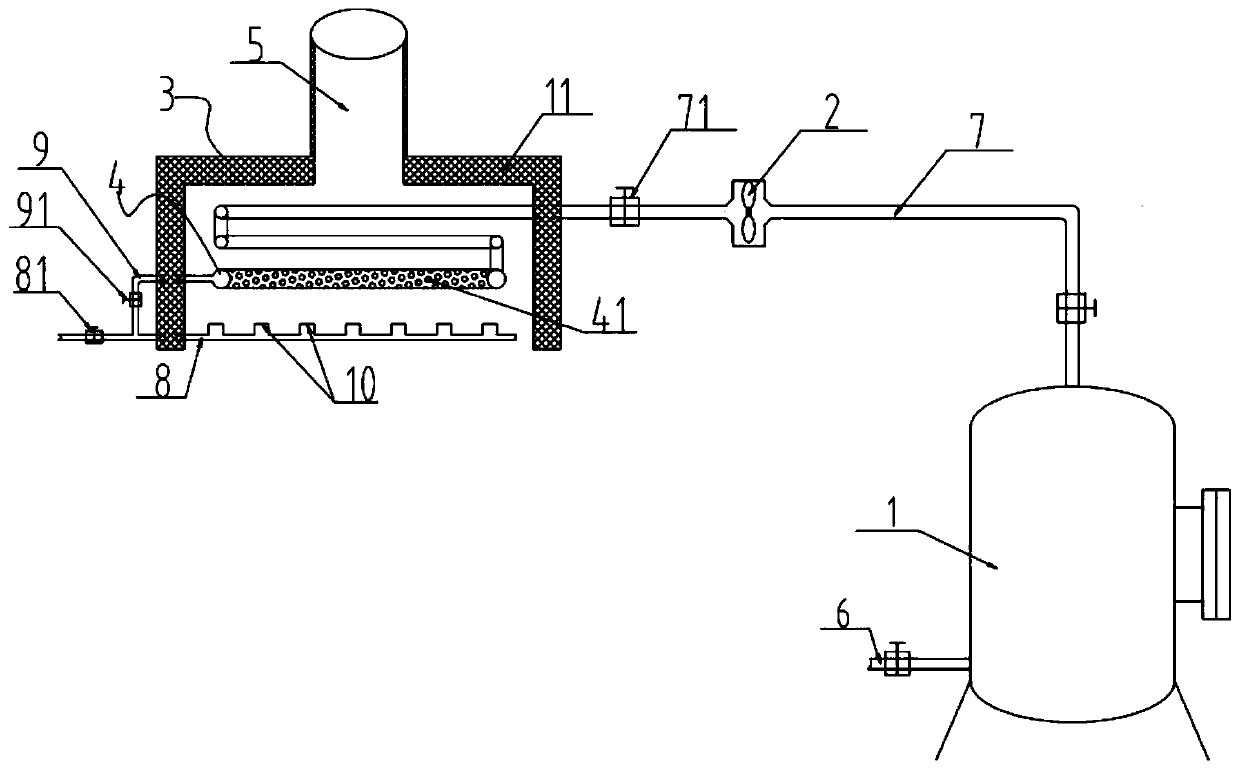

[0024] refer to figure 1 , a nitride ceramic ammonia tail gas treatment system, its structure includes a nitriding furnace 1, a pipe fan 2, a furnace 3, an ammonia preheating pipe 4 and an exhaust pipe 5, and the lower left end of the nitriding furnace 1 is provided with an inlet The top of the nitriding furnace 1 is provided with a gas outlet, the gas inlet of the nitriding furnace 1 is connected with an ammonia gas pipeline 6, and the gas outlet of the nitriding furnace 1 is connected with a connecting pipeline 7, which is close to the furnace chamber 3 There is a first valve 71 connected to the end face, the pipe fan 2 is arranged on the middle part of the connecting pipe 7, the other end of the connecting pipe 7 extends into the furnace 3, and communicates with the ammonia gas preheating pipe 4 located in the furnace 3 , the ammonia preheating pipeline 4 has a built-in catalyst 41, the other end of the ammonia preheating pipeline 4 is connected with a nitrogen-hydrogen mix...

Embodiment 2

[0026] refer to figure 1 , a treatment method for a nitride ceramic ammonia tail gas treatment system. First, open the natural gas valve, and the natural gas will flow from the natural gas source into the combustion pipeline. At this time, the natural gas will preheat the furnace. When the temperature in the furnace reaches the ammonia gas At the cracking temperature (800°C), open the first valve, and then gradually close the natural gas valve, and the exhaust gas from the gas outlet of the nitriding furnace enters the ammonia preheating pipeline through the connecting pipeline. Under the action of the nickel catalyst, the ammonia The gas will be cracked, and the nitrogen-hydrogen mixture and tail gas produced by ammonia cracking will flow into the combustion pipe together, and the combustion port on the combustion pipe will burn hydrogen and other combustible gases together. expelled from the trachea.

[0027] It should be noted that the electrical components presented in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com