Method for preparing hydraulic cementing material by utilizing sulfur fixation ash

A technology of hydraulic gelling and cementitious materials, which is applied in the direction of cement production, etc., can solve the problems of poor practicability, high cost, and high production cost, and achieve the effects of increasing strength, eliminating expansibility, and reducing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

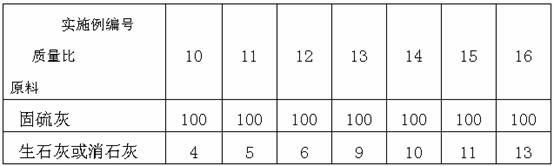

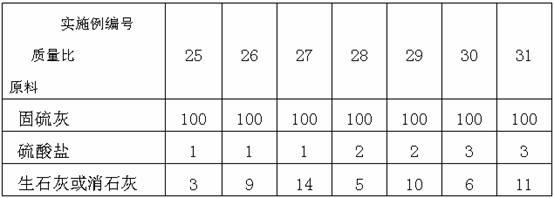

Examples

Embodiment 1

[0034] A kind of method utilizing sulfur-fixed ash to prepare hydraulic cementitious material, comprises the following steps:

[0035] (1) Raw material grinding: Grinding raw materials such as sulfur-fixed ash (that is, circulating fluidized bed coal-fired sulfur-fixed ash, the same below), quicklime, etc., so that the fineness of sulfur-fixed ash is d 50 =14μm, lime fineness 80μm standard sieve residue is 10%;

[0036] Under laboratory conditions, the raw materials are all ground in the SM-500 ball mill, and the ratio of material to ball is 1:20, the same as the following;

[0037] The main chemical composition and mass percentage of the sulfur-fixing ash used are: SiO 2 37%, Al 2 o 3 14%, Fe 2 o 3 12%, CaO19%, SO 3 14%, f-CaO4%, the same below;

[0038] The effective calcium oxide mass percentage content of quicklime is 84.2%, and the sieve residue of 80 μm standard sieve is 10%;

[0039] (2) Ingredients: take fineness d 50 14 μm sulfur-fixed ash, according to the m...

Embodiment 2

[0044] A kind of method utilizing sulfur-fixed ash to prepare hydraulic cementitious material, comprises the following steps:

[0045] (1) Raw material grinding: Grinding the coal-fired sulfur-fixed ash in a circulating fluidized bed so that the fineness of the sulfur-fixed ash is d 50 =14μm;

[0046] (2) Ingredients: take fineness d 50 14μm sulfur-fixed ash, according to sulfur-fixed ash: CaSO 4 · 2H 2 O is a mass ratio of 100:2, and the raw materials are sulfur-fixed ash and CaSO 4 · 2H 2 O;

[0047] (3) Mixing of raw materials: the sulfur-fixed ash and CaSO 4 · 2H 2 O mixing and stirring to make it fully mixed evenly to obtain a gelled material. Under laboratory conditions, due to CaSO 4 · 2H 2 The amount of O is small, first divide the sulfur-fixing ash into 5 equal parts, and then mix with CaSO 4 · 2H 2 After O mixing, then slowly dry the mixture in a mortar mixer for 3 minutes;

[0048] (4) Storage: Seal and store the mixed materials in a dry environment. T...

Embodiment 3

[0051] A kind of method utilizing sulfur-fixed ash to prepare hydraulic cementitious material, comprises the following steps:

[0052] (1) Raw material grinding: Grinding the coal-fired sulfur-fixed ash in a circulating fluidized bed so that the fineness of the sulfur-fixed ash is d 50 =14μm;

[0053] (2) Ingredients: take fineness d 50 14μm sulfur-fixing ash, according to sulfur-fixing ash: Na 2 SO 4 The mass ratio is 100:1.5, and the raw materials sulfur-fixing ash and Na 2 SO 4 ;

[0054] (3) Raw material packaging: due to Na 2 SO 4 The particles are crystalline, so the sulfur-fixed ash and Na 2 SO 4 Packaged separately, during use, Na 2 SO 4 Dissolve in water first, and then mix with sulfur-fixing ash for use. The prepared slurry is a hydraulic cementitious material;

[0055] (4) Storage: Store the packaged materials tightly in a dry environment.

[0056] The physical properties of the cementitious material were tested according to the method of cement physica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com