Novel rectification method

A rectification, a new type of technology, applied in the direction of separation methods, chemical instruments and methods, fractionation, etc., can solve the problems of water quality environment impact, large latent heat of vaporization, increased energy consumption, etc., to reduce secondary pollution, reduce decomposition products, cool The effect of water consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

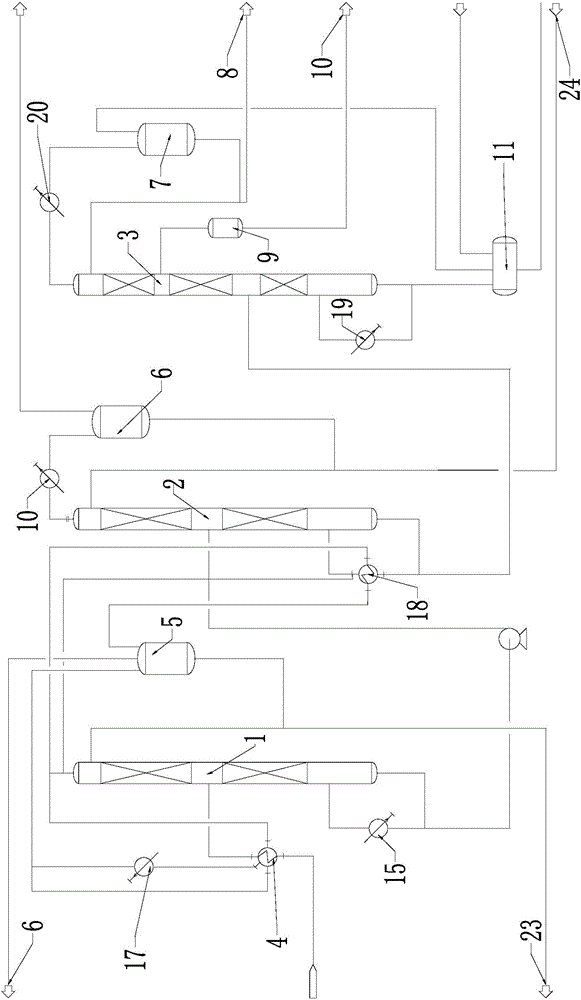

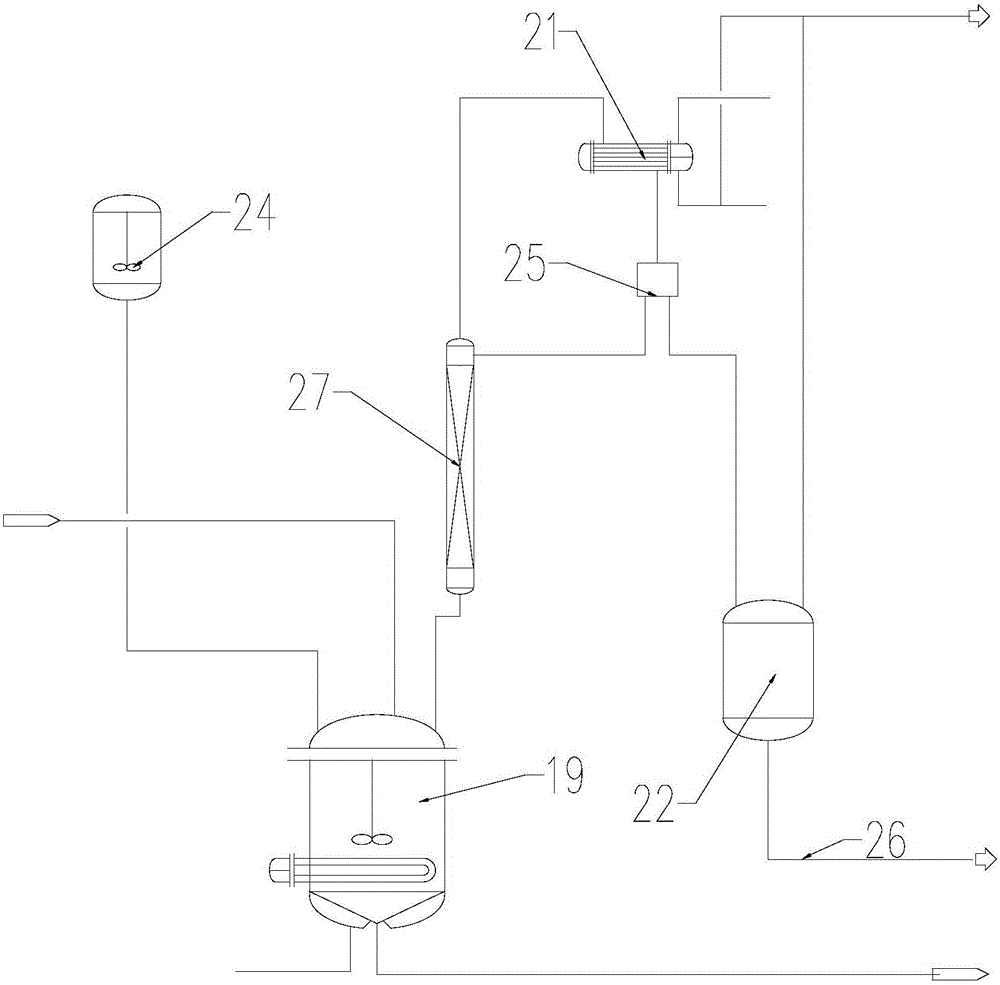

[0034] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0035] A new rectification method, the waste liquid containing low-concentration products enters the dehydration tower 1, the material in the bottom of the dehydration tower 1 enters the product tower 2, the material in the bottom of the product tower 2 enters the product refining tower 3, and condenses on the top of the product refining tower 3 Obtain qualified product, this method comprises the steps:

[0036] (1) The product waste liquid is pumped into the heat exchanger 4, preheated, and fed through the upper part of the dehydration tower 1;

[0037] (2) The material in the dehydration tower 1 is heated by the first reboiler 15 on the dehydration tower 1. After the material becomes steam, it rises to the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com