Production method of electronic-grade aqueous hydrogen peroxide solution

A technology of hydrogen peroxide and production methods, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, etc., can solve high cost and high energy consumption , inflexible production and other issues, to achieve the effect of reducing the amount of condensation, reducing the amount of cooling water, and reducing the workload of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

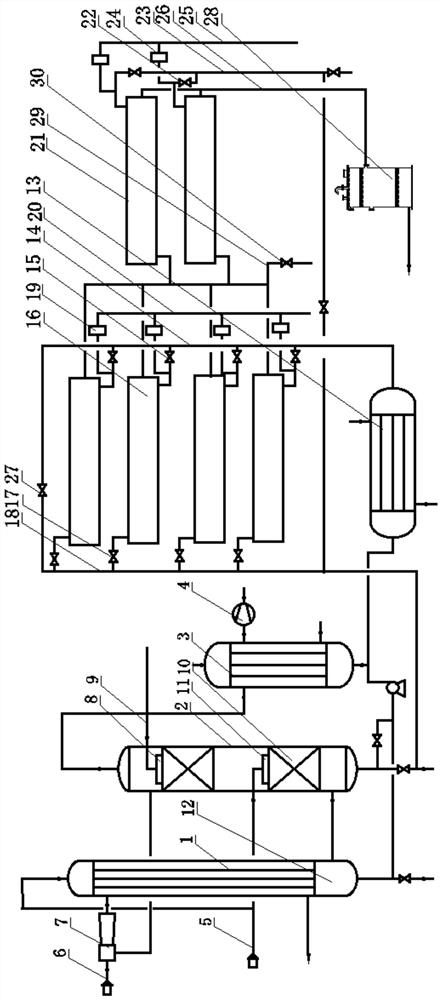

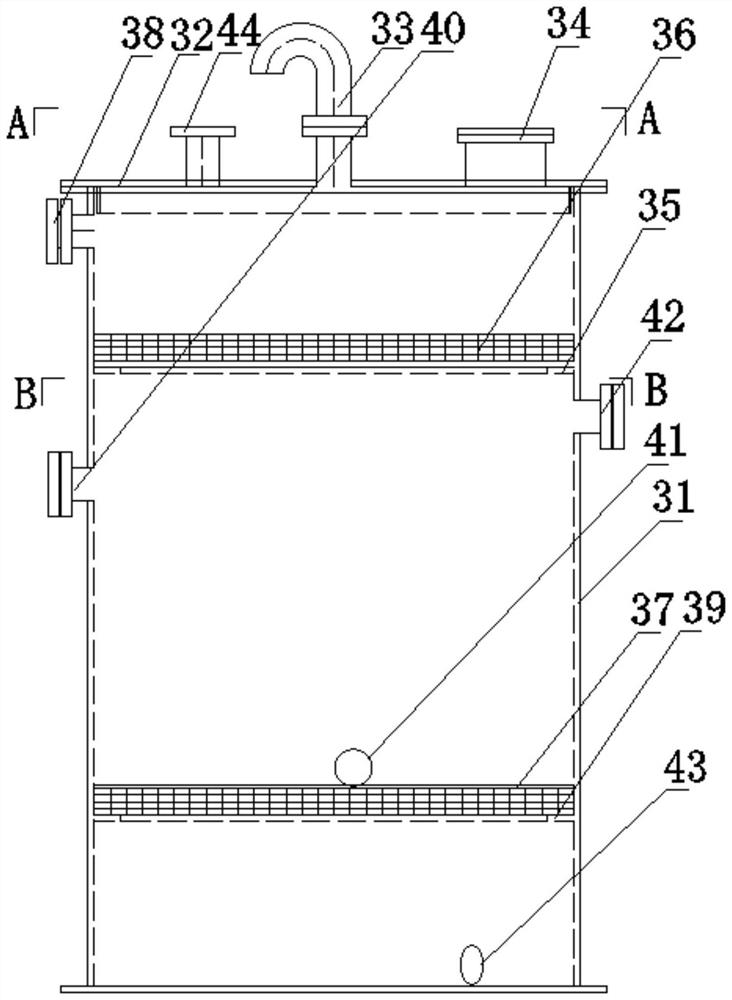

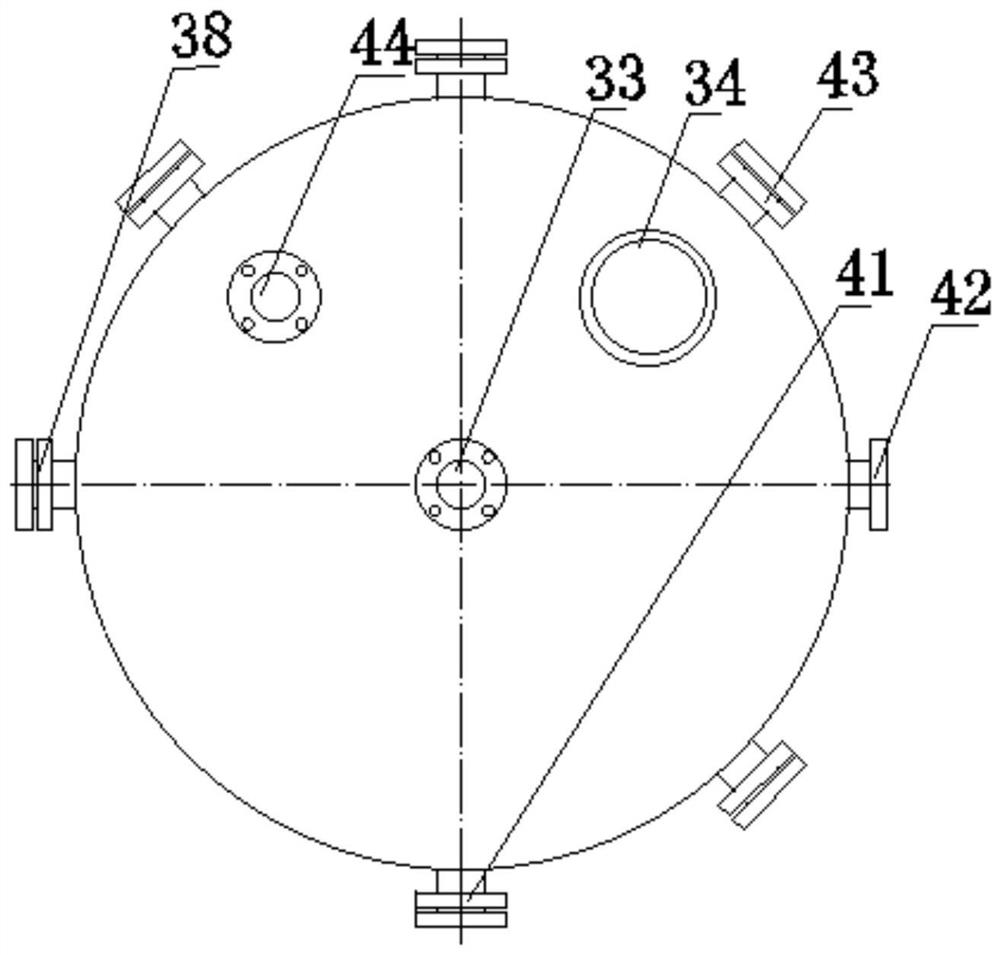

[0027] When producing electronic-grade hydrogen peroxide aqueous solution, the industrial-grade hydrogen peroxide aqueous solution is concentrated through a hydrogen oxide concentration device, cooled by a heat exchanger 13, reverse osmosis by a primary reverse osmosis device, a secondary reverse osmosis device, and ion exchange by an ion exchange device 28 be made of. Such as figure 1The shown hydrogen peroxide concentrating device comprises an evaporator 1, a rectifying tower 2, a condenser 3 communicated with the gas phase outlet of the rectifying tower 2, a vacuum pump 4 connected with the condenser 3, a concentrated liquid storage area 12 of the evaporator 1 and The first feed port of rectification tower 2 is communicated, and dilute hydrogen peroxide feed pipe 5 is communicated with the feed port of evaporator 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com