Step heating furnace beam and pole and its construction method

A kind of walking heating furnace, heating furnace technology, applied in the direction of lining repair, etc., can solve the problems of high temperature resistance, poor oxidation resistance, low service life, short only about three months, etc., to achieve high temperature resistance and resistance. The effect of increased oxidation and increased anchoring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

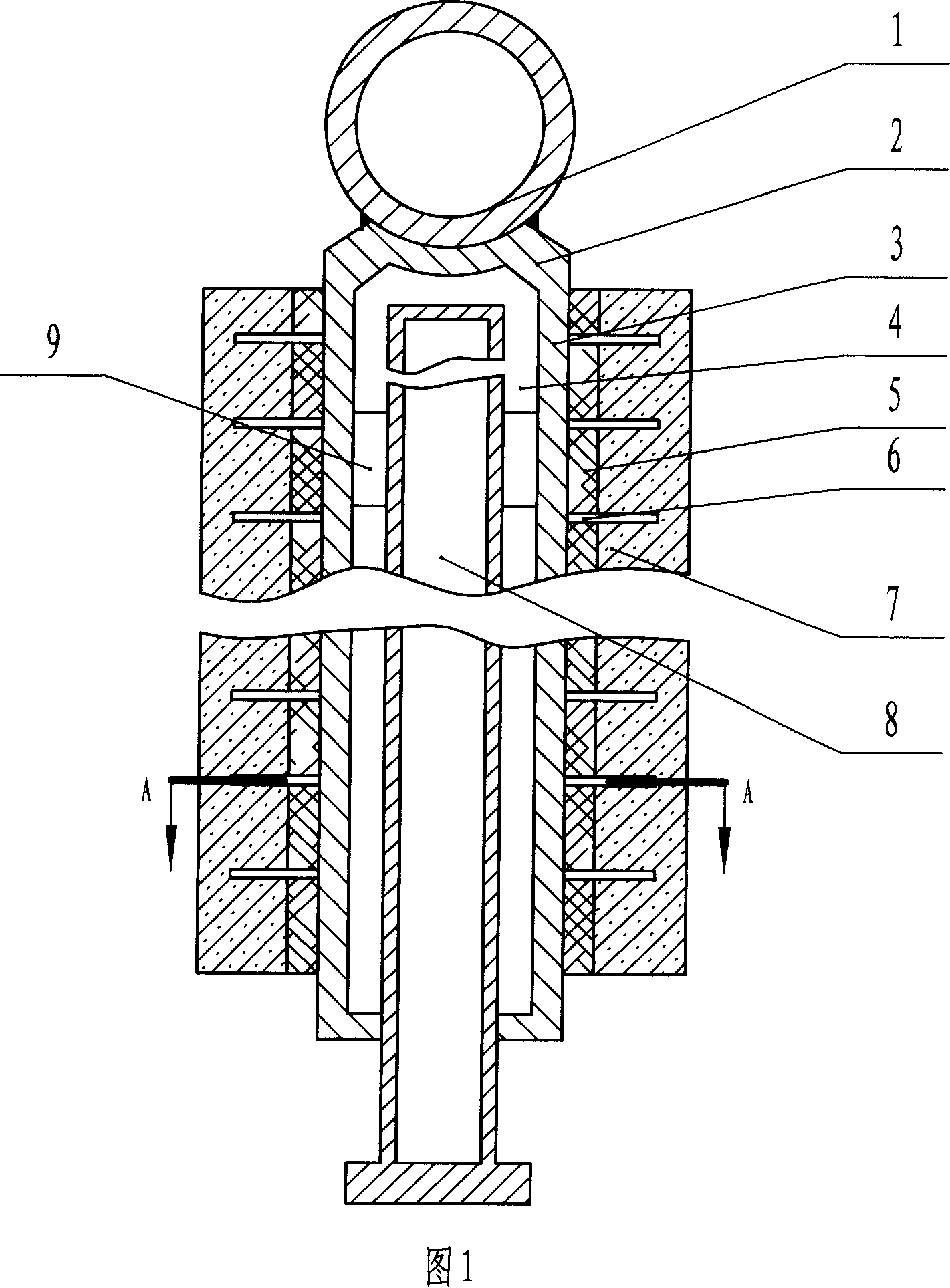

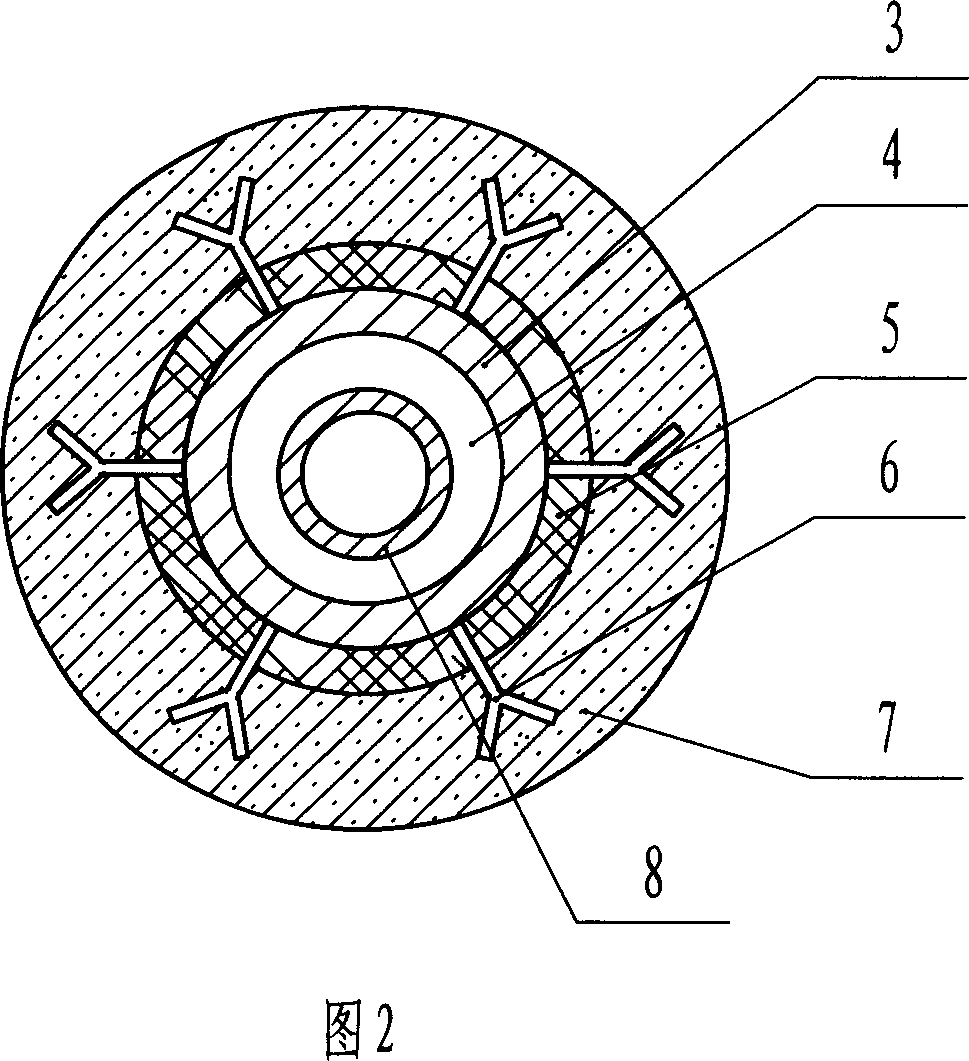

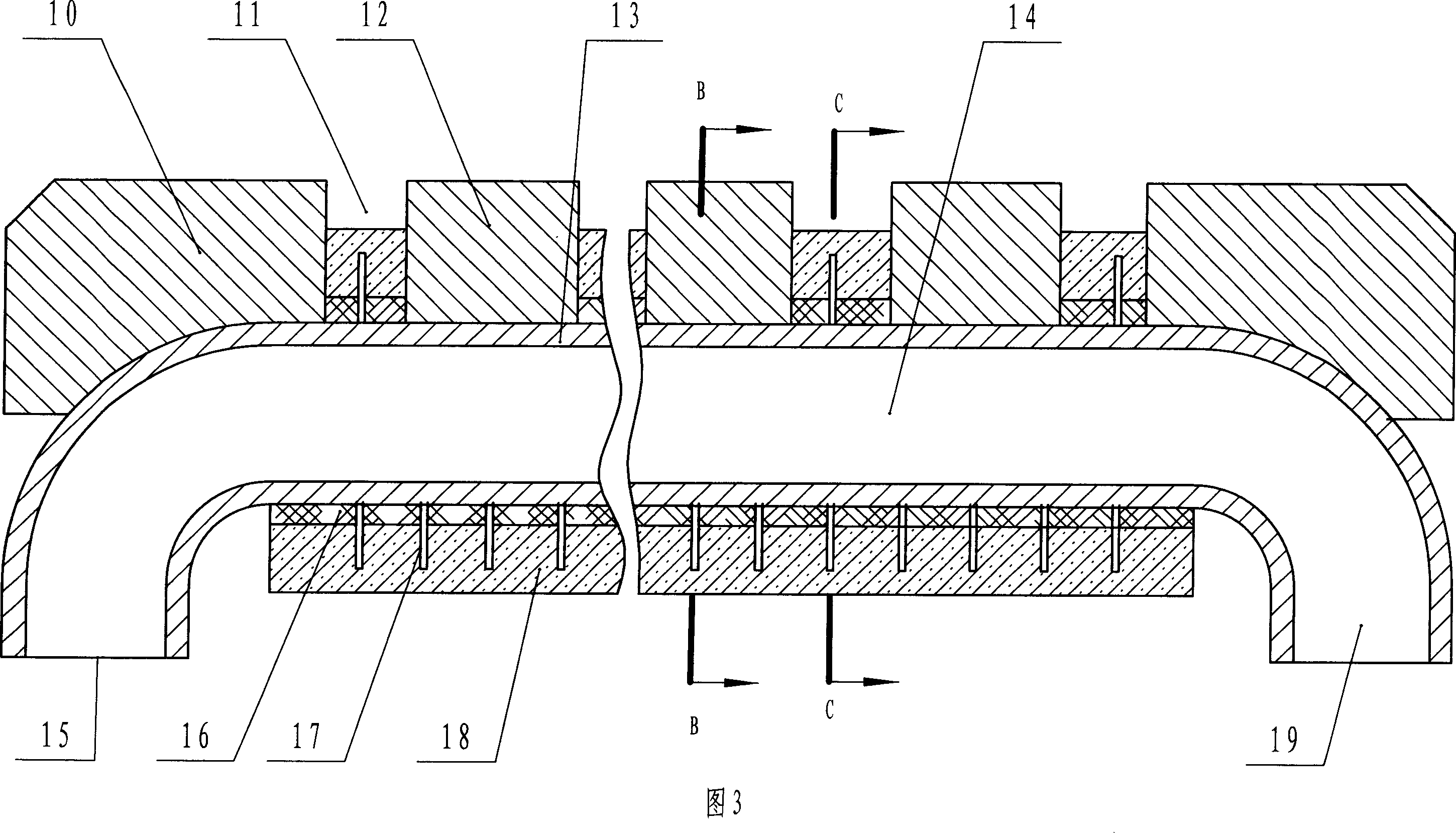

[0041] The specific implementations of the walking-type heating furnace beam and column and the construction method thereof of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings, but the specific implementations of the present invention are not limited to the following examples. Example of walking heating furnace column

[0042] The step-by-step heating furnace column described in FIGS. 1 and 2 includes a core tube 8 sealed at the upper end, a water tube 3, an anchor hook 6, a fiber blanket 5 and a castable layer 7, and the upper end of the core tube 8 is a saddle for installing the heating furnace beam 1 The seat 2, the core pipe 8 is worn in the water pipe 3, the anchoring hook 6 and the water pipe 3 are vertically fixed outside the water pipe 3, the fiber blanket 5 is wrapped outside the water pipe 3, the outer side of the castable layer 7 is cylindrical, and the castable layer 7 is fixed on the fiber. Out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com