Ethylbenzene/styrene energy-saving separation method

A technology of ethylbenzene styrene and separation method, applied in distillation purification/separation, organic chemistry and other directions, can solve the problem of high energy consumption, and achieve the effects of reducing separation energy consumption, less investment, and large design temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

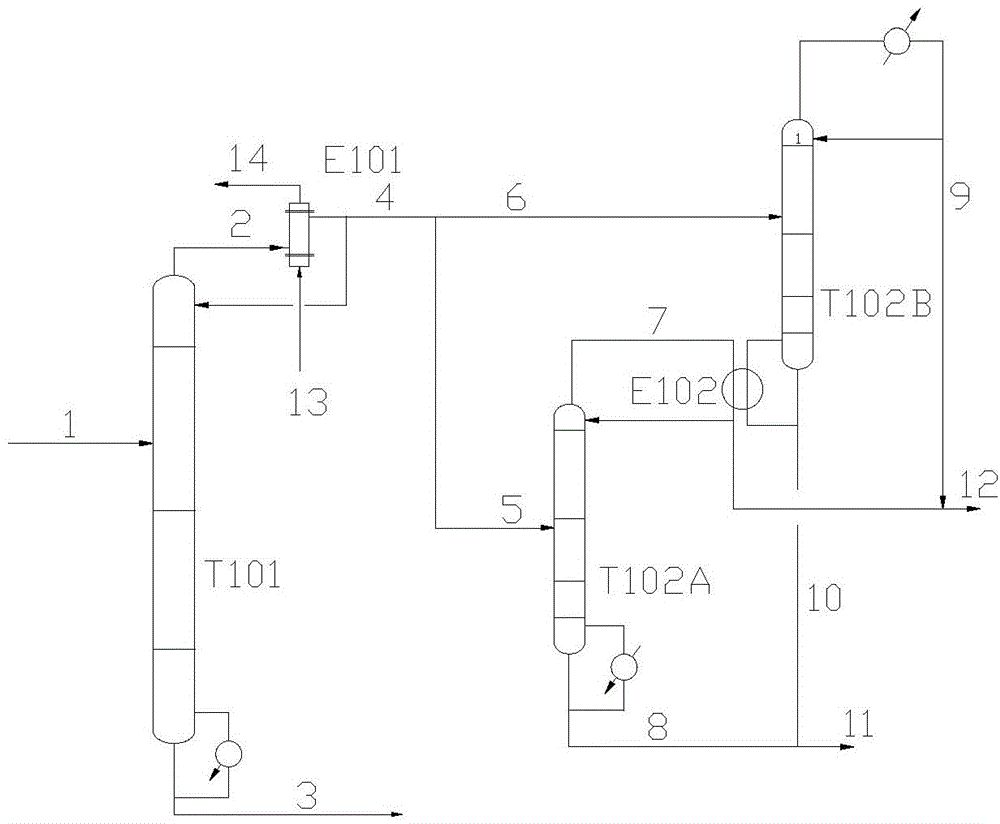

[0022] A 100,000 tons / year styrene plant (annual operating hours 8000 hours), its styrene separation system adopts figure 1 technology, the ethylbenzene / styrene separation tower feed flow rate is 21.5 tons / hour, and the percentage by weight is composed of: benzene 0.4%, toluene 1.4%, ethylbenzene 36%, styrene 60%, heavy component 2.2%, ethylbenzene / The molar composition of water mixture (stream 13) is: ethylbenzene 25%, water 75%, main operation condition and consumption see Table 1:

[0023] Table 1

[0024] Ethylbenzene / styrene tower T101 top pressure kPaA

[0025] Low-pressure ethylbenzene separation tower reboiler E102 structure type

Embodiment 2

[0027] A 100,000 tons / year styrene plant (annual operating hours 8000 hours), its styrene separation system adopts figure 1 technology, the ethylbenzene / styrene separation tower feed flow rate is 21.5 tons / hour, and the percentage by weight is composed of: benzene 0.3%, toluene 1.0%, ethylbenzene 35%, styrene 61%, heavy component 1.8%, ethylbenzene / The molar composition of water mixture (stream 13) is: ethylbenzene 22%, water 78%, main operation condition and consumption are shown in Table 2:

[0028] Table 2

[0029] Ethylbenzene / styrene tower T101 top pressure kPaA

Embodiment 3

[0032] A 100,000 tons / year styrene plant (annual operating hours 8000 hours), its styrene separation system adopts figure 1 technology, the ethylbenzene / styrene separation tower feed flow rate is 21.5 tons / hour, and the percentage by weight is composed of: benzene 0.5%, toluene 1.5%, ethylbenzene 37%, styrene 59%, heavy component 2.0%, ethylbenzene / The molar composition of water mixture (stream 13) is: ethylbenzene 20%, water 80%, main operation condition and consumption are shown in Table 3:

[0033] table 3

[0034] Ethylbenzene / styrene tower T101 top pressure kPaA

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com