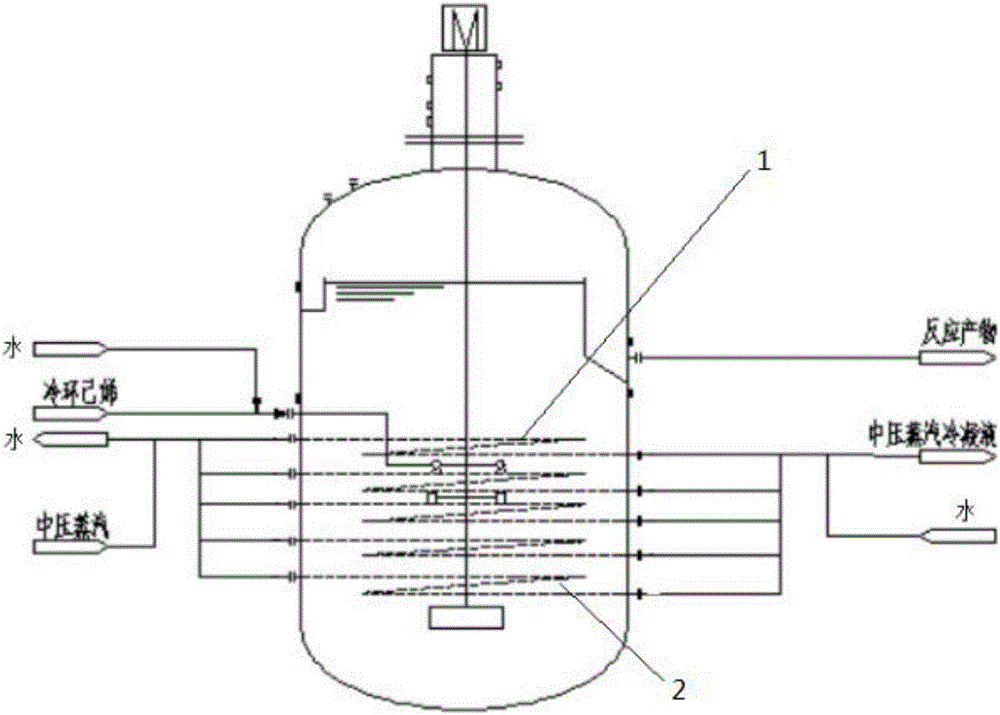

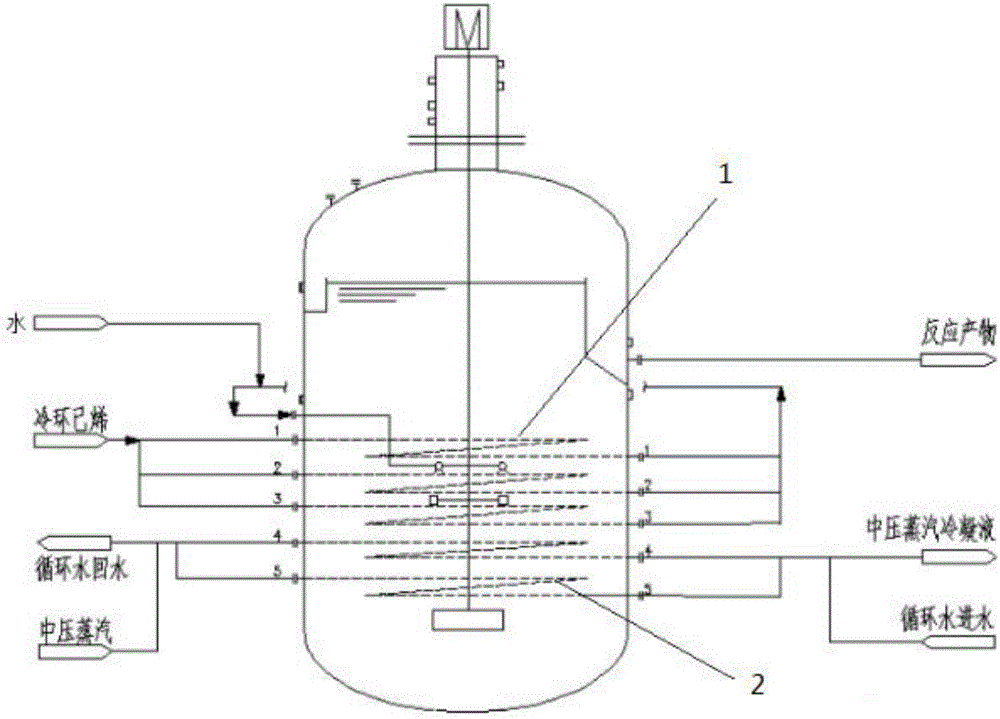

Heat energy synergy method of hydration reactor

A hydration reactor and hydration reaction technology, applied in chemical instruments and methods, hydroxyl addition preparation, organic chemistry, etc., can solve the problems of heat waste of cooling water, large consumption of steam and cooling water, and increased coal consumption, etc., to achieve Reduce cooling water consumption and save water vapor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Load feed: 130t / h, temperature: 70.9°C, hydration reactor temperature: 118°C, hydration reactor pressure: 0.52MPaG, heat transfer area: 150m 2 , outlet temperature: 80.9°C, obtained heat energy: 236.6×10 4 KJ / h, saving 8.047t / h of cooling desalted water.

Embodiment 2

[0036] Load feed: 140t / h, temperature: 71.3°C, hydration reactor temperature: 118°C, hydration reactor pressure: 0.52MPaG, heat transfer area: 150m 2 , outlet temperature: 83.5°C, obtained heat energy: 310.8×10 4 KJ / h, saving 9.487t / h of cooling desalted water.

Embodiment 3

[0038] Load feed: 150t / h, temperature: 71.1°C, hydration reactor temperature: 118°C, hydration reactor pressure: 0.52MPaG, heat transfer area: 150m2, outlet temperature: 83.3°C, obtained heat energy: 333.1×104KJ / h, saving 9.791t / h of cooling desalted water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com