Method for efficiently preheating coke oven gas

A high-efficiency technology of coke oven gas, which is applied in the fields of metallurgy and chemical industry, can solve the problems affecting the continuous and stable operation of the system, the inability to use coke oven gas to preheat, and the high calorific value of coke oven gas, so as to prevent potential hidden dangers of explosion and poisoning, Continuous and stable industrial production, the effect of high preheating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

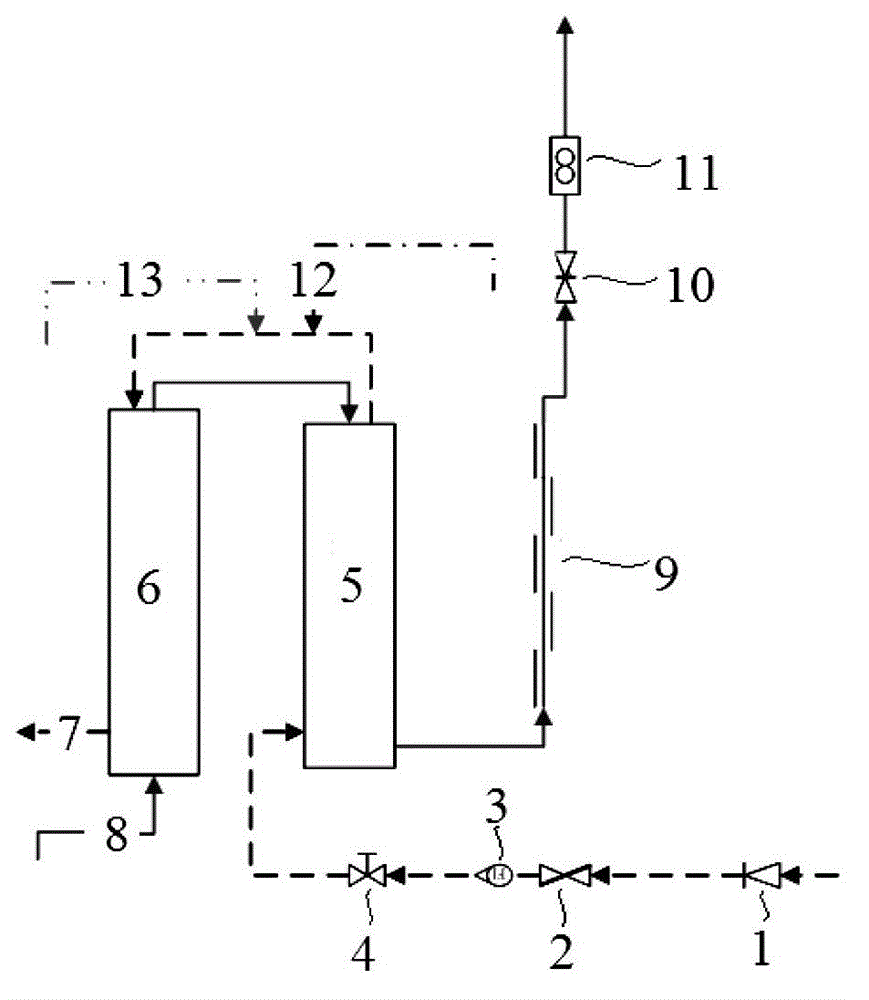

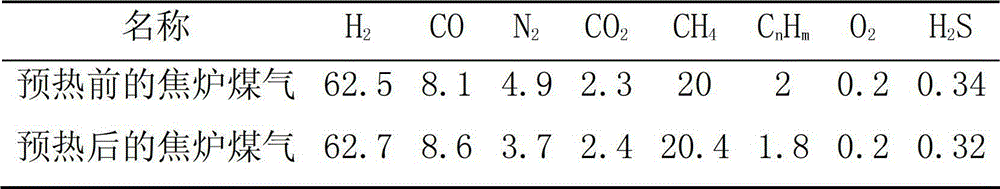

[0044] Such as figure 1 As shown, open the coke oven gas check valve, quick shut-off valve, and coke oven gas regulating valve in sequence, adjust the amount of coke oven gas to be preheated by controlling the opening of the coke oven gas regulating valve, and adjust the opening of the coke oven gas regulating valve Controlled at 60%, the amount of coke oven gas is 120±10Nm 3 / h; use the high-temperature exhaust gas produced by the combustion chamber to preheat the coke oven gas. The temperature of the high-temperature exhaust gas is 1230±10°C. Control at 30%, and the exhaust gas flow is controlled at 350±50Nm 3 / h. Before entering the preheating device, the temperature of the coke oven gas is detected to be 35°C, and the chemical composition is shown in Table 1. After the coke oven gas passes through the convection preheating chamber for heat exchange, the temperature rises to 565~600°C, and then 3~3.5Kg / h of steam is added to the coke oven gas, and the coke oven gas conti...

example 2

[0049] Such as figure 1 As shown, open the coke oven gas check valve, quick shut-off valve, and coke oven gas regulating valve in sequence, adjust the amount of coke oven gas to be preheated by controlling the opening of the coke oven gas regulating valve, and adjust the opening of the coke oven gas regulating valve Controlled at 70%, coke oven gas feed rate is 150±10Nm 3 / h; use the high-temperature exhaust gas produced by the combustion chamber to preheat the coke oven gas. The temperature of the high-temperature exhaust gas is 1250±10°C. Control at 45%, and control the exhaust gas flow at 550±50Nm 3 / h. Before entering the preheating device, the temperature of the coke oven gas is detected to be 35°C, and the chemical composition is shown in Table 2. After the coke oven gas passes through the convection preheating chamber for heat exchange, the temperature rises to 575-610°C, and then 3-4.5Kg / h of steam is added to the coke oven gas, and the coke oven gas continues to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com