Novel high-temperature reaction process and device for producing epoxidized soybean oil

A technology of epoxidized soybean oil and high-temperature reaction, which is applied in the direction of organic chemistry, can solve the problems of product quality not meeting high requirements, long reaction time, side reactions, etc., achieves shortened dropping time, simple process, and improved reaction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

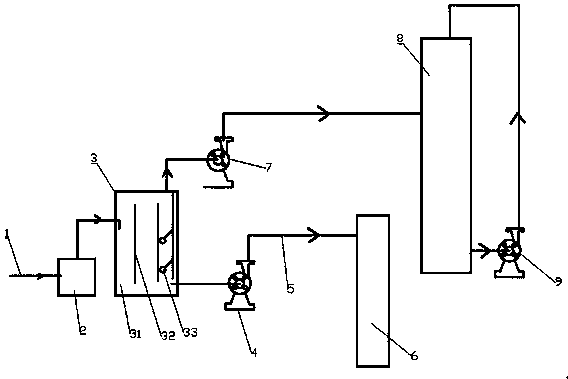

Method used

Image

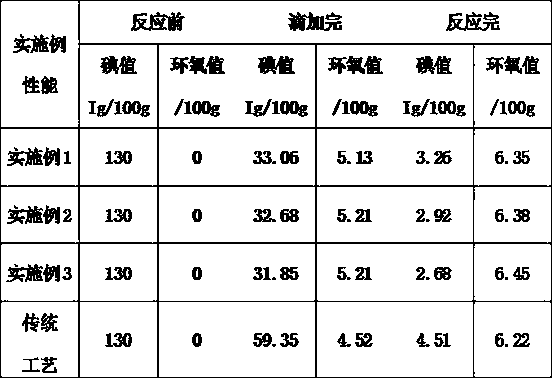

Examples

Embodiment 1

[0022] A novel high-temperature reaction process for producing epoxidized soybean oil is characterized in that: successively through the dripping stage and the continuing reaction stage, the concrete steps are as follows:

[0023] 1) Dropping stage: first fully mix formic acid and soybean oil, and then add hydrogen peroxide dropwise, the dropping temperature is 70-76°C, and the dropping time is 7 hours;

[0024] 2) Continue the reaction stage: firstly heat to 70°C, react for 5 hours, then continue to heat to 78°C, and react for 3 hours.

Embodiment 2

[0026] A novel high-temperature reaction process for producing epoxidized soybean oil is characterized in that: successively through the dripping stage and the continuing reaction stage, the concrete steps are as follows:

[0027] 1) Dropping stage: first fully mix formic acid and soybean oil, and then add hydrogen peroxide dropwise, the dropping temperature is 70-76°C, and the dropping time is 7 hours;

[0028] 2) Continue the reaction stage: firstly heat to 74°C, react for 5 hours, then continue to heat to 80°C, and react for 3 hours.

Embodiment 3

[0030] A novel high-temperature reaction process for producing epoxidized soybean oil is characterized in that: successively through the dripping stage and the continuing reaction stage, the concrete steps are as follows:

[0031] 1) Dropping stage: first fully mix formic acid and soybean oil, and then add hydrogen peroxide dropwise, the dropping temperature is 70-76°C, and the dropping time is 7 hours;

[0032] 2) Continue the reaction stage: firstly heat to 78°C, react for 5 hours, then continue to heat to 82°C, and react for 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com