Method for increasing temperature of semi-hardness aluminum-zinc-plating strip steel entering zinc pot

A kind of galvanized, semi-rigid technology, applied in the direction of hot-dip galvanizing process, coating, furnace type, etc., can solve the problems that the surface quality of galvanized products cannot be guaranteed, the bonding force between the coating and the substrate, and the temperature requirements cannot be met. , to achieve the effect of saving cooling water consumption, stabilizing temperature and reducing temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific embodiment:

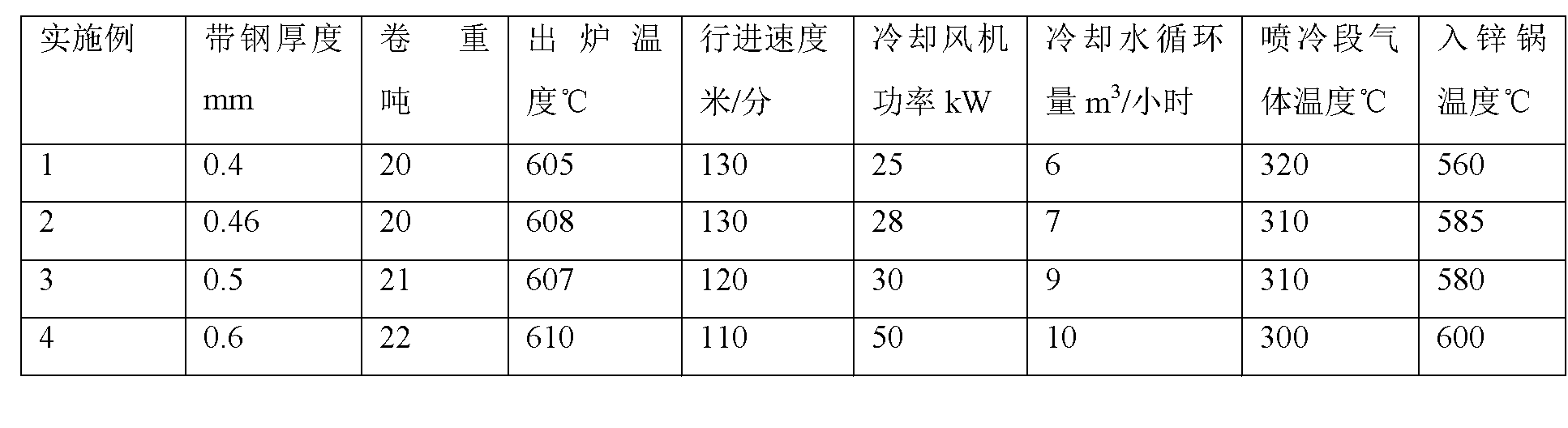

[0019] The invention is a method for increasing the temperature of the semi-hard aluminum-galvanized strip steel entering the zinc pot, aiming at controlling the cooling capacity of the cooling system in the spray cooling section for the thin strip steel of 0.4-0.6 mm, so that the protective gas is in contact with the strip steel The intermediate strip is gradually heated to increase the temperature of the protective gas in the spray cooling section. The specific control steps are as follows:

[0020] 1) Control the temperature of the strip steel out of the annealing furnace at 605-610°C, the weight of the strip steel coil is 20-22 tons, and control the traveling speed of the strip steel in the 80-85 meter heat preservation and slow cooling section and spray cooling section to 110- 130m / min, controlling coil weight and traveling speed is conducive to process control and stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com