Circulating splash water cooling device of engraving machine

A water spray cooling and engraving machine technology, applied in engraving, decorative art, processing models, etc., can solve the problems of increased manufacturing costs, waste of water resources, large water consumption, etc., to achieve reduced production and manufacturing costs, small cooling water consumption, The effect of improving the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

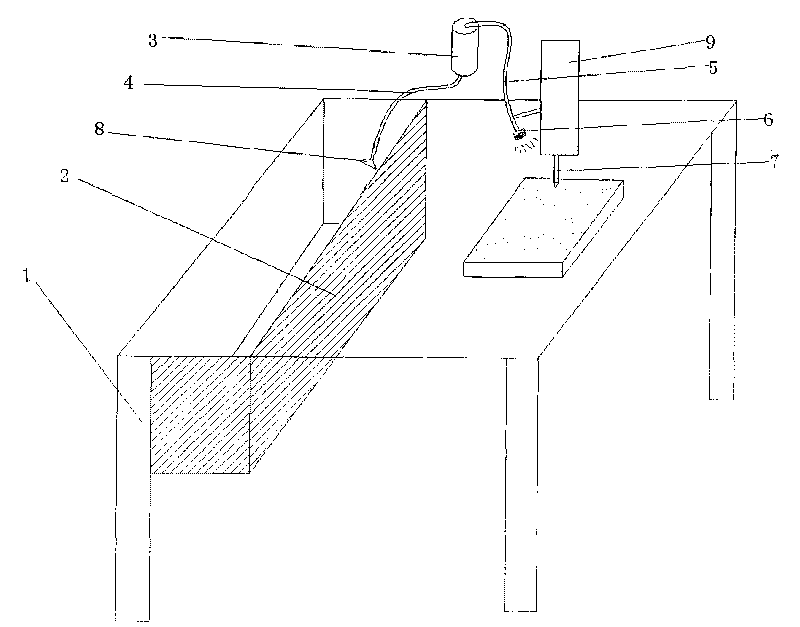

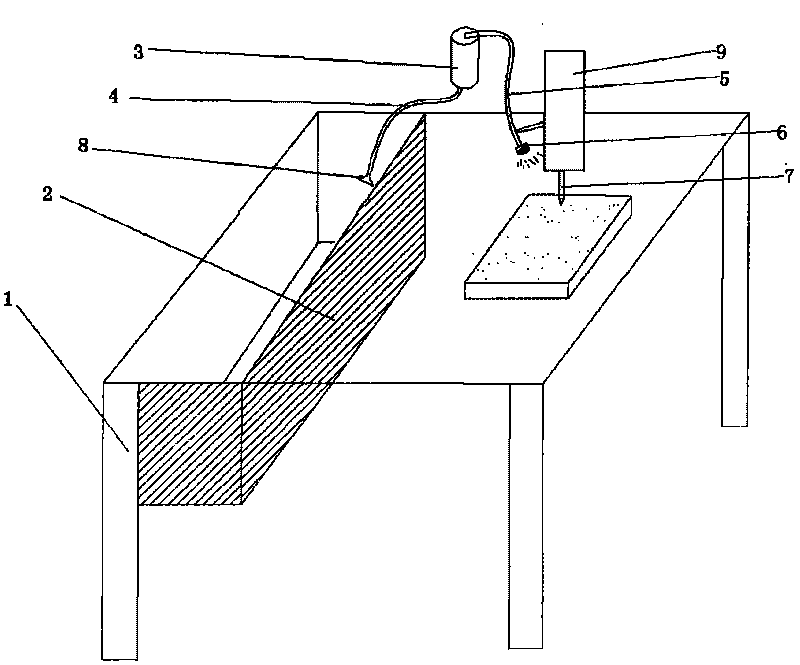

[0010] Referring to the accompanying drawings, the circulating water spray cooling device of the engraving machine includes a water storage tank 2 fixedly arranged in the frame 1, the water storage tank 2 is equipped with cooling water, a water pump 3 is provided, and the water inlet of the water pump 3 is connected with a water inlet pipe 4. The water outlet of the water pump is connected with a water outlet pipe 5, and the water inlet pipe 4 extends into the cooling water liquid surface in the water storage tank 2. The front end of the water outlet pipe 5 is equipped with a nozzle 6, and the nozzle 6 is facing the cutter 7 of the engraving machine. A filter screen 8 is installed on the nozzle end, and the shower head 6 is fixedly installed on the main cover 9 of the tool spindle, so as to realize the linkage between the shower head 6 and the tool 7 up and down, front and rear directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com