Brown coal pre-drying-air preheating-waste heat utilization composite coal-fired power generation system

A technology for preheating air and power generation systems, applied in the direction of preheating, combustion methods, steam applications, etc., can solve the problems of ineffective and full utilization of power generation resources, complicated power generation processes, energy waste, etc., and achieve energy density improvement and reduction Effects of smoke exhaust loss and equipment investment reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

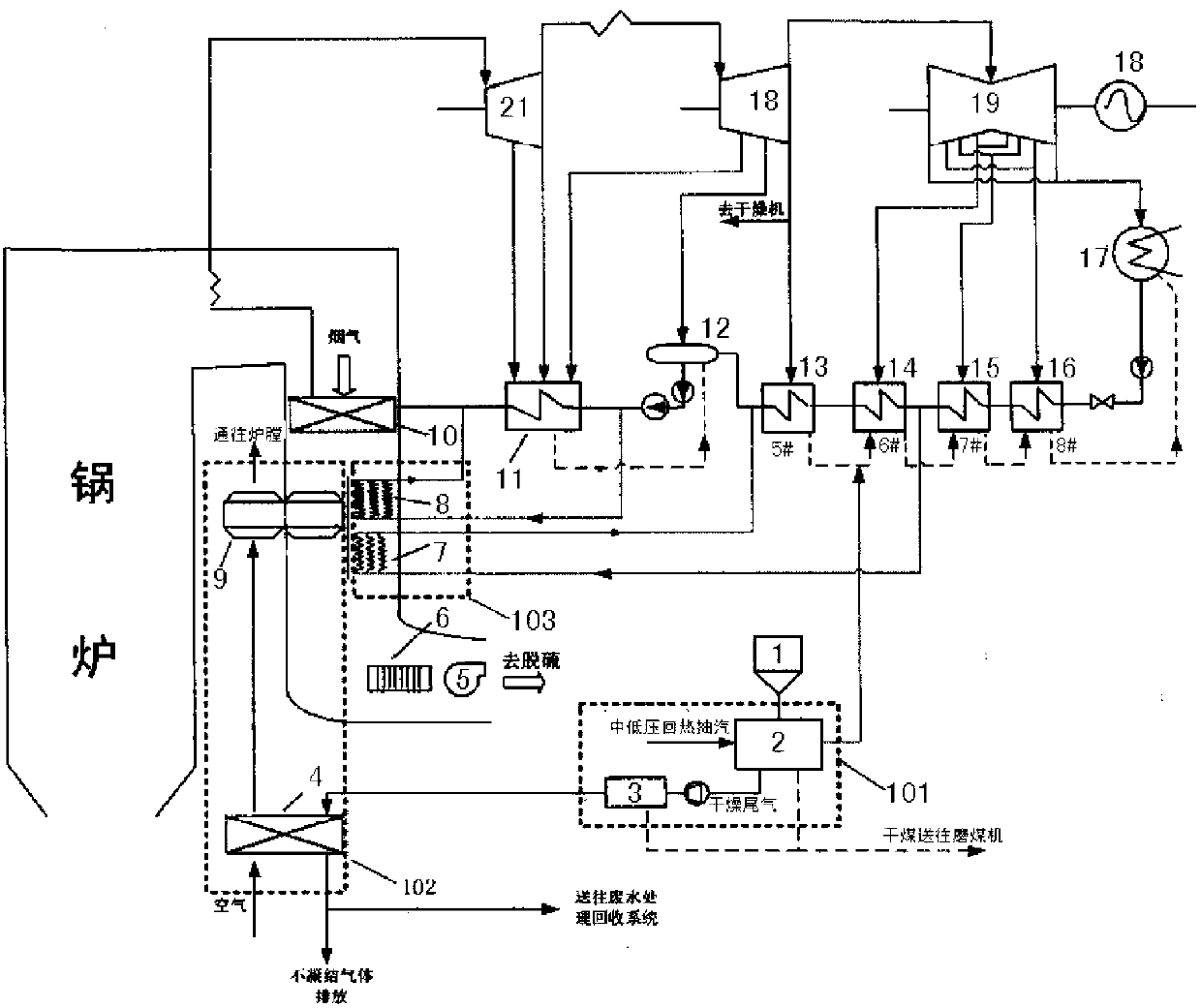

[0017] The present invention provides a lignite pre-drying-preheating air-waste heat utilization composite coal-fired power generation system, which will be further described below in conjunction with the accompanying drawings and specific implementation methods.

[0018] figure 1 Shown is a schematic diagram of the structure of the composite coal-fired power generation system. The system is mainly composed of lignite drying system 101 connected with steam turbine recuperation system and air preheating system 102, flue gas heating condensate system 103 connected with steam turbine recuperation system and air preheating system 102, steam turbine reheating system and steam turbine power generation device Connected structure, so that the dried lignite can be directly burned to generate electricity.

[0019] The lignite drying system 101 is composed of the dryer 2 connected to the separator 3 through the dry tail gas pipeline, the coal feeder 1 is fixed on the upper part of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com