a tio 2 Magnetic porous composite material and preparation method thereof

A porous composite material and composite material technology, applied in the field of TiO2-based magnetic porous composite materials and its preparation, can solve the problems of difficult control of the shape and size of hollow catalytic materials, high recombination efficiency of electrons and holes, and loss of active components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

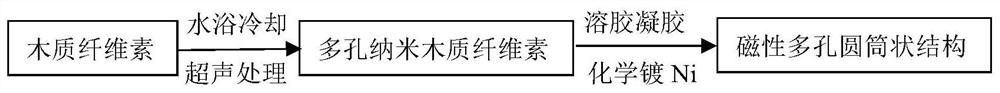

[0028] A kind of TiO 2 A method for preparing a magnetic-based porous composite material, comprising:

[0029] Step 1, weighing lignocellulose, dissolving in deionized water, stirring evenly until a uniform suspension is formed;

[0030] Step 2, using an ultrasonic signal generator to disperse lignocellulose; the dispersion time is 180 minutes, the power is 960W, the temperature of the ultrasonic water bath is 30-40°C, and the climate environment affects its temperature setting.

[0031] Step 3, prepare activating solution A liquid, activating solution B liquid, chemical plating solution C liquid, described activating solution A liquid is the mixed solution of concentrated hydrochloric acid and nickel sulfate, and its concentration is 0.7-0.9mL / g; Said activating solution Liquid B is a mixed solution of sodium hydroxide and sodium borohydride, and its mass ratio is 0.7-0.9:0.9-1.1; Liquid C is a mixed plating solution of nickel sulfate, sodium citrate, sodium hypophosphite an...

Embodiment 1

[0042] Example 1: TiO 2 The preparation method of base magnetic porous composite material, see figure 1 ,Specific steps are as follows:

[0043] (1) Weigh 0.6 g of lignocellulose with an electronic balance, measure 300 mL of distilled water with a 500 mL beaker and dissolve the weighed lignocellulose in it, and stir evenly with a glass rod until a uniform suspension is formed in the beaker.

[0044] (2) Using the SM-1200D ultrasonic signal generator to disperse lignocellulose, the adjustment of the horn should pay attention to three points: 1. The horn is placed at half the height of the solution, 2. The horn is located at the center of the solution circle, 3. The horn must not be close to the temperature control sensor; the dispersion time is 180 minutes, the power is 960W, put the beaker with dissolved lignocellulose in the device with ice cubes, and change the ice cubes continuously during the period The frequency is different according to the season. The ice is changed e...

Embodiment 2

[0048] Example 2: TiO 2 The preparation method of base magnetic porous composite material, concrete steps are as follows:

[0049] (1) Weigh 0.6 g of lignocellulose with an electronic balance, measure 300 mL of distilled water with a 500 mL beaker and dissolve the weighed lignocellulose in it, and stir evenly with a glass rod until a uniform suspension is formed in the beaker.

[0050] (2) Using the SM-1200D ultrasonic signal generator to disperse lignocellulose, the adjustment of the horn should pay attention to three points: 1. The horn is placed at half the height of the solution, 2. The horn is located at the center of the solution circle, 3. The horn must not be close to the temperature control sensor; the dispersion time is 180 minutes, the power is 960W, put the beaker with dissolved lignocellulose in the device with ice cubes, and change the ice cubes continuously during the period The frequency is different according to the seasons. The ice is changed every 15 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com