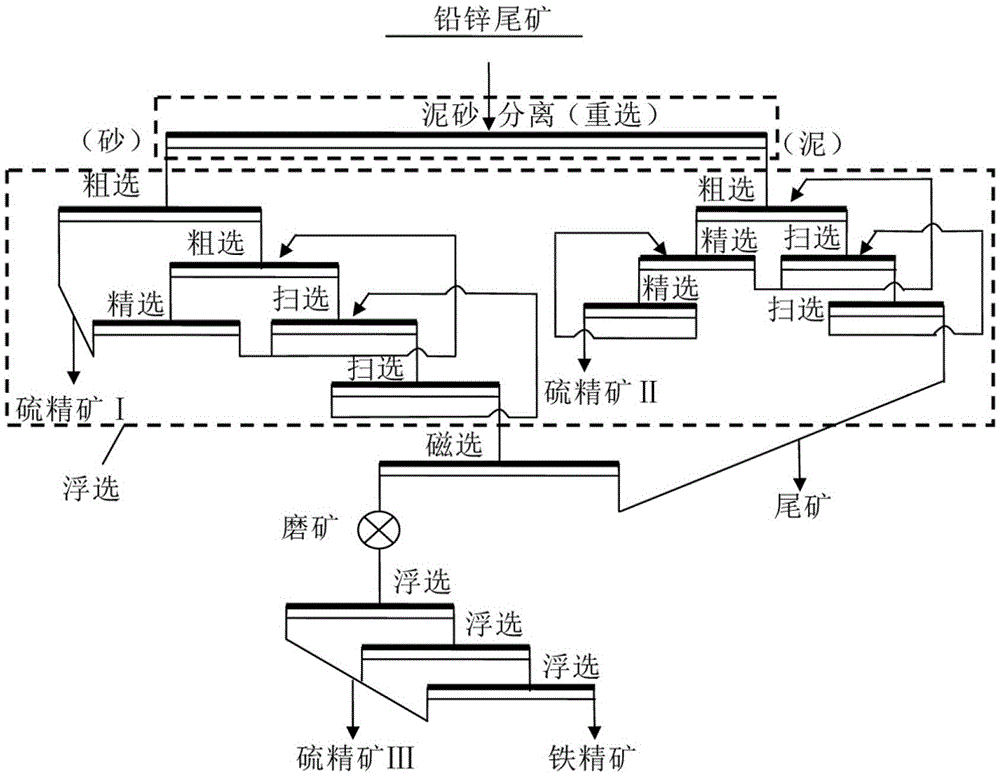

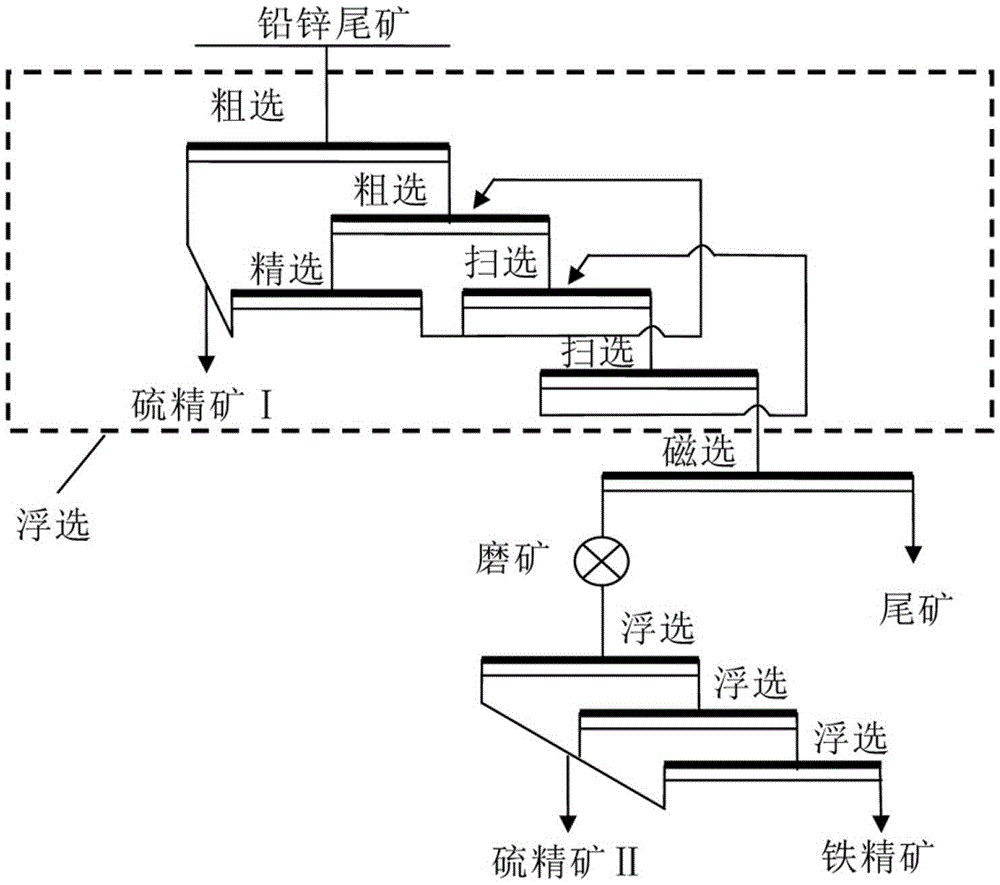

A combination process for recovering pyrite from lead-zinc tailings

A combined process and sulfur recovery technology, which is applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of unqualified iron ore concentrate, environmental threats, resource waste, etc., and achieve stable and good product indicators. Economic benefits, the effect of reducing the amount of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

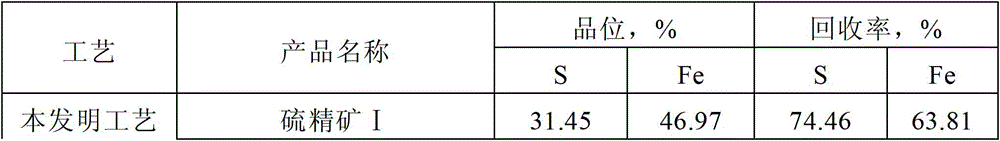

Embodiment 1

[0031] For a lead-zinc tailings mine, the sulfur content in the ore is 15.87%, and the iron content is 27.93%. The metal minerals in the ore are mainly pyrrhotite and pyrite. Pyrrhotite accounts for 21.84% of the total mineral content, pyrite accounts for 9.62% of the mineral content, and magnetite mineral content is 2.16%. In addition to these useful minerals composed of beneficial elements, there are also a large number of veins in the ore. Stone minerals feldspar, pyroxene, diopside, garnet, quartz and other silicate rocks, and also contain a small amount of other gangue minerals such as calcite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com