Beneficiation process for copper sulphide ore

A copper sulfide ore and process technology, applied in flotation, solid separation, etc., can solve problems such as poor flotation effect of sulfide ore and oxide ore, great harm to the environment and operators, strong corrosion of flotation equipment, etc., to achieve The effect of shortening the flotation time, reducing the flotation time, and stabilizing the bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

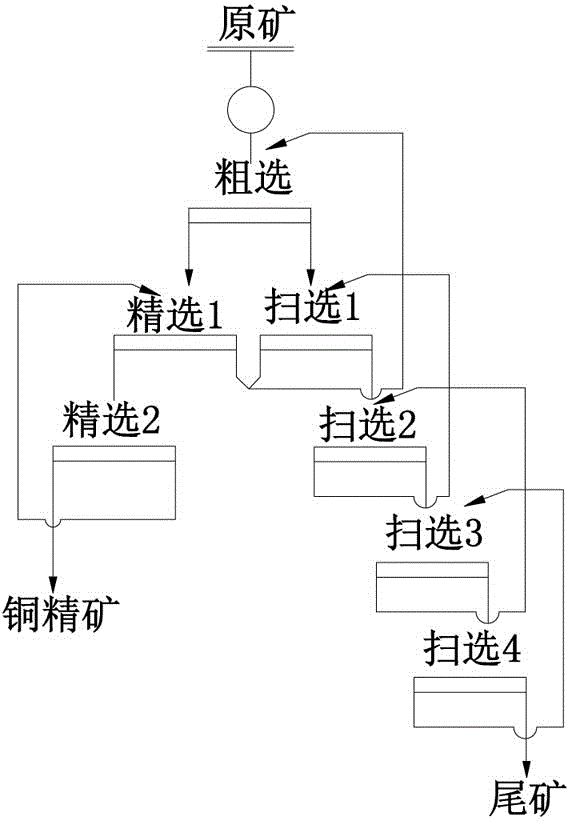

[0021] see figure 1 , a kind of copper sulfide ore beneficiation process of the present embodiment, raw ore obtains ore pulp after ball mill grinding, adds 1300g lime, 120g lotus leaf and taro leaf juice, 110g lotus leaf and taro leaf residue, 60g pine oil in every ton of raw ore, The pH of the pulp is adjusted to 8, and the pulp is subjected to roughing, second-stage beneficiation and fourth-stage sweeping to obtain copper concentrate with a copper content higher than 20% and tailings with a copper content lower than 0.039%.

[0022] The mineral particle size of the pulp described in this embodiment is less than 200 mesh, accounting for 57%.

[0023] The ratio of lotus leaf and taro leaf in the present invention is 4:1 by weight, and the lotus leaf and taro leaf residue are dried or dried and crushed into more than 400 meshes, and the lotus leaf and taro leaf juice are dripped join in.

Embodiment 2

[0025] see figure 1 , a kind of copper sulfide ore beneficiation process of the present embodiment, raw ore obtains ore slurry after ball mill grinding, adds 1200g lime, 100g lotus leaf and taro leaf juice, 120g lotus leaf and taro leaf residue, 50g pine oil in every ton of raw ore, The pH of the pulp is adjusted to 8, and the pulp is subjected to roughing, second-stage beneficiation and fourth-stage sweeping to obtain copper concentrate with a copper content higher than 20% and tailings with a copper content lower than 0.039%.

[0026] The mineral particle size of the pulp described in this embodiment is less than 200 mesh, accounting for 55%.

[0027] The ratio of lotus leaf and taro leaf in the present invention is 4:1 by weight, and the lotus leaf and taro leaf residue are dried or dried and crushed into more than 400 meshes, and the lotus leaf and taro leaf juice are dripped join in.

Embodiment 3

[0029] see figure 1 , a kind of copper sulfide ore beneficiation process of the present embodiment, raw ore obtains ore pulp after ball mill grinding, adds 1500g lime, 150g lotus leaf and taro leaf juice, 100g lotus leaf and taro leaf residue, 70g pine oil in every ton of raw ore, The pH of the pulp is adjusted to 8, and the pulp is subjected to roughing, second-stage beneficiation and fourth-stage sweeping to obtain copper concentrate with a copper content higher than 20% and tailings with a copper content lower than 0.039%.

[0030] The mineral particle size of the pulp described in this embodiment is less than 200 mesh, accounting for 60%.

[0031] The ratio of lotus leaf and taro leaf in the present invention is 4:1 by weight, and the lotus leaf and taro leaf residue are dried or dried and crushed into more than 400 meshes, and the lotus leaf and taro leaf juice are dripped join in.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com