Composite beneficiation reagent for extracting vanadium from stone coal

A beneficiation agent, stone coal technology, applied in flotation, solid separation and other directions, can solve the problems of not improving the comprehensive utilization value of stone coal resources, reducing the economic benefits of stone coal resource utilization, not considering the utilization of carbon resources, etc. Concentrate grade and recovery of vanadium, the effect of shortening flotation time and reducing dosing points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

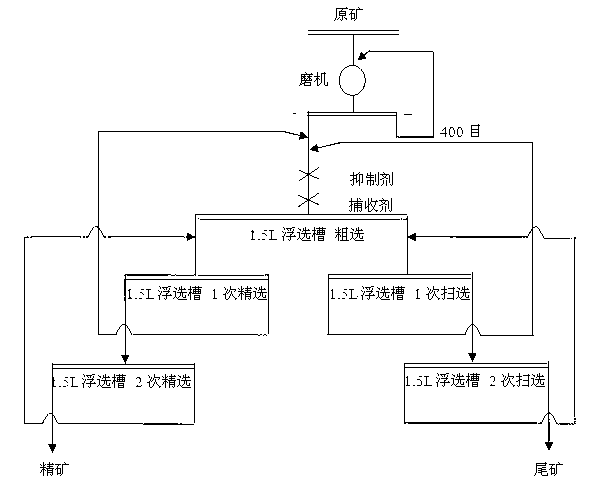

Method used

Image

Examples

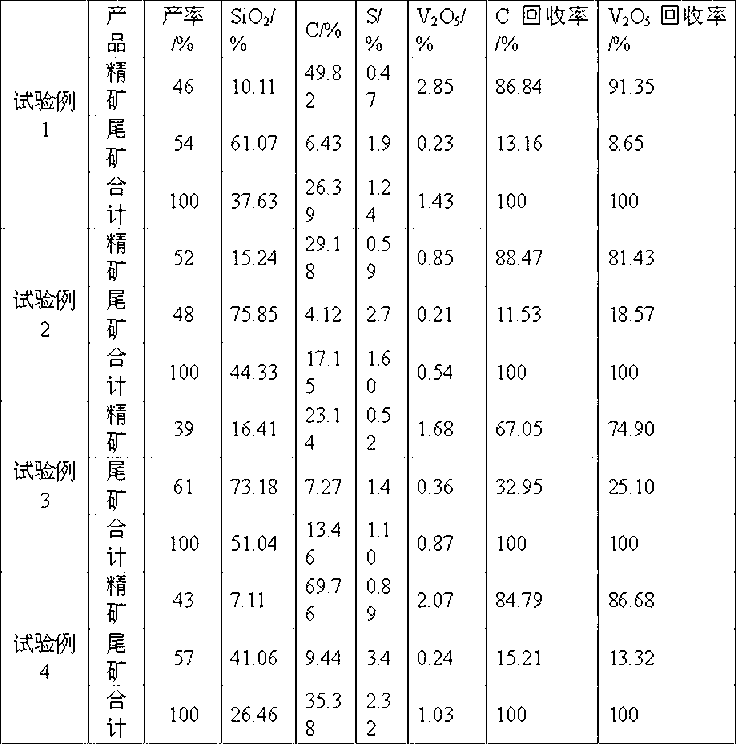

Embodiment 1

[0030] The compound beneficiation reagent for vanadium extraction from stone coal provided in this example is composed of the following components: 5g diesel oil, 0.5g benzyltriethylammonium chloride, 2g terpineol oil, 1g Tween-60, and 200g water.

[0031] The preparation method of the stone coal vanadium extraction compound mineral processing agent provided in this example: weigh 5g of diesel oil and 2g of terpineol oil, mix and stir the two evenly to obtain mixed solution E; weigh 0.5g of benzyltriethyl chloride Add ammonium and 1g Tween-60, add 200g water, stir and dissolve to make a mixed solution F; add the mixed solution E to the mixed solution F while stirring, and stir for 10 minutes to make a uniform emulsion.

Embodiment 2

[0033] The compound beneficiation agent for vanadium extraction from stone coal provided in this example is composed of the following components: 7g diesel oil, 0.3g dodecylamine hydrochloride, 1.5g MIBC, 4g OP-10, and 300g water.

[0034] The preparation method of the stone coal vanadium extraction composite mineral processing agent provided in this example: weigh 7g of diesel oil and 1.5g of MIBC, mix and stir them evenly to obtain mixed solution E; weigh 0.3g and 4g of dodecylamine hydrochloride For OP-10, add 300g of water, stir and dissolve to make a mixed solution F; add the mixed solution E to the mixed solution F while stirring, and stir for 30 minutes to make a uniform emulsion.

Embodiment 3

[0036] The compound beneficiation reagent for extracting vanadium from stone coal provided in this embodiment is composed of the following components: 5g kerosene, 2g dodecyltrimethylammonium chloride, 1g terpineol oil, 2g sodium dodecylsulfonate, 250g water .

[0037] The preparation method of the stone coal vanadium extraction composite mineral processing agent provided in this example: weigh 5g of kerosene and 1g of terpineol oil, mix and stir the two evenly, and prepare mixed solution E; weigh 2g of dodecyl trimethyl chloride Add ammonium chloride and 2g of sodium dodecylsulfonate, add 250g of water, stir and dissolve to make a mixed solution F; add the mixed solution E to the mixed solution F while stirring, and stir for 20 minutes to make a uniform emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com