A method for optimizing feldspar and quartz from tantalum-niobium ore

A technology for tantalum-niobium ore and feldspar, which is applied in the field of feldspar and quartz optimization, can solve the problems of low ore beneficiation efficiency of anion and cation method, restricted efficiency of tantalum-niobium mine, and high cost of hydrofluoric acid treatment, so as to improve the amount of ore selected and reduce the use of chemicals. Toxic and environmental protection, the effect of improving flotation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail now in conjunction with embodiment.

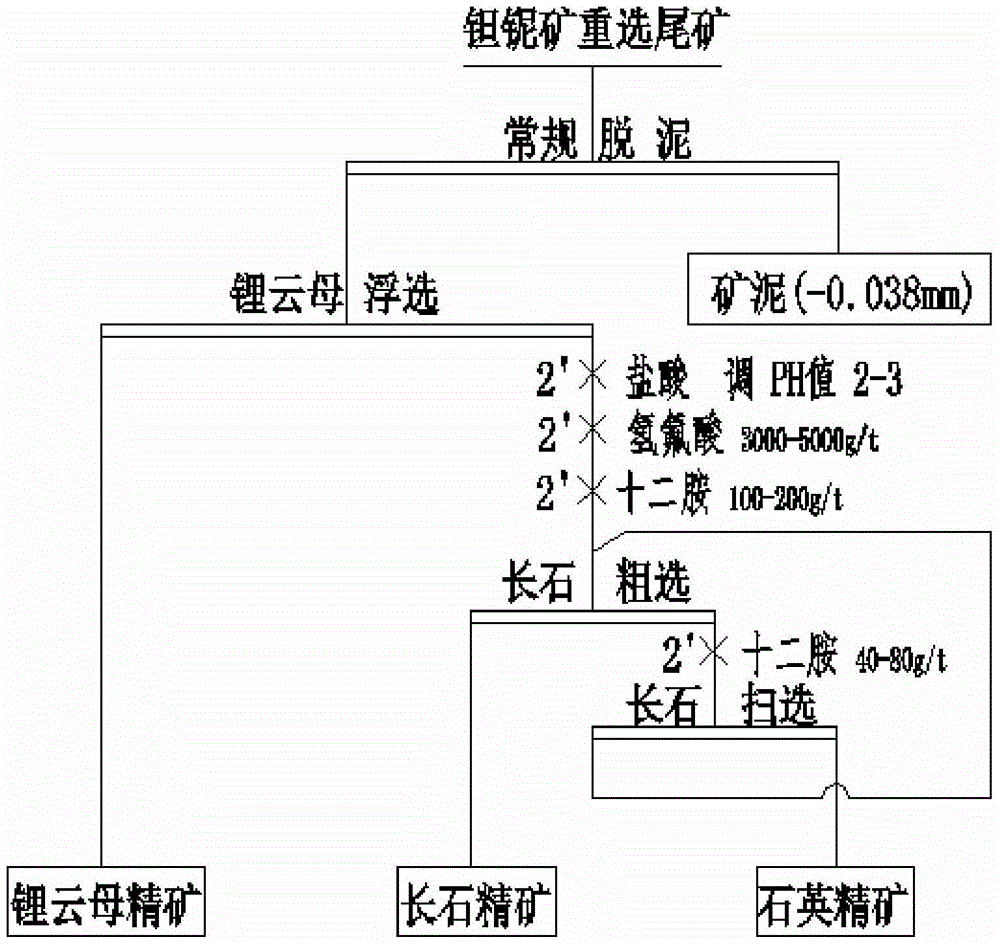

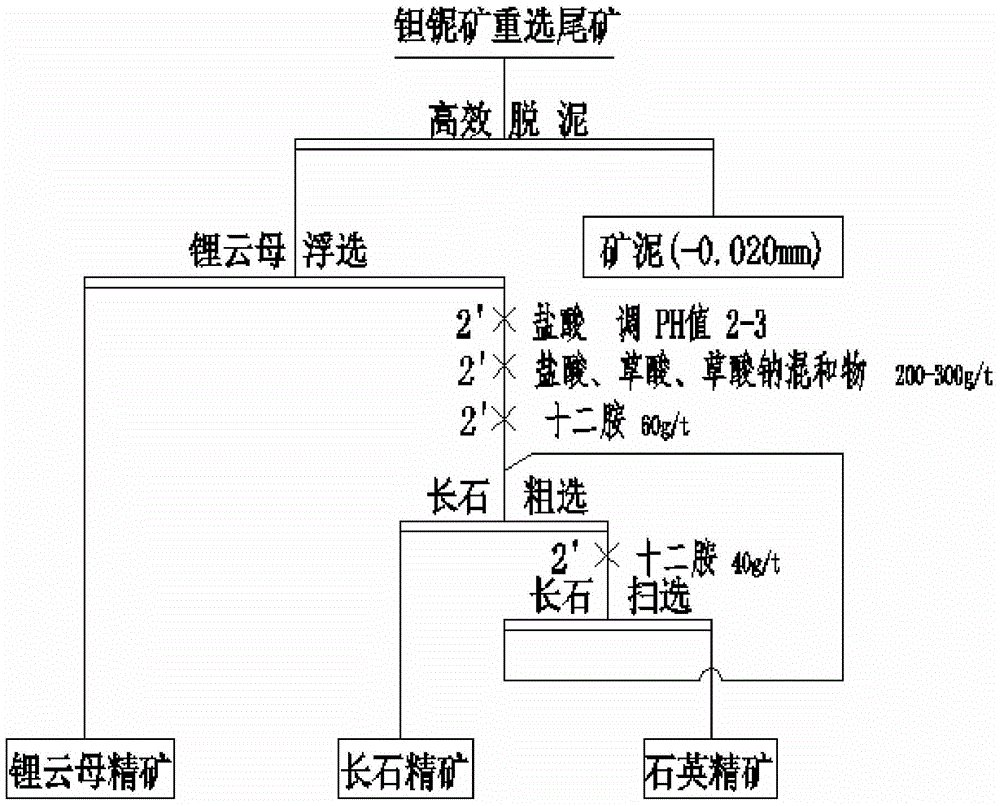

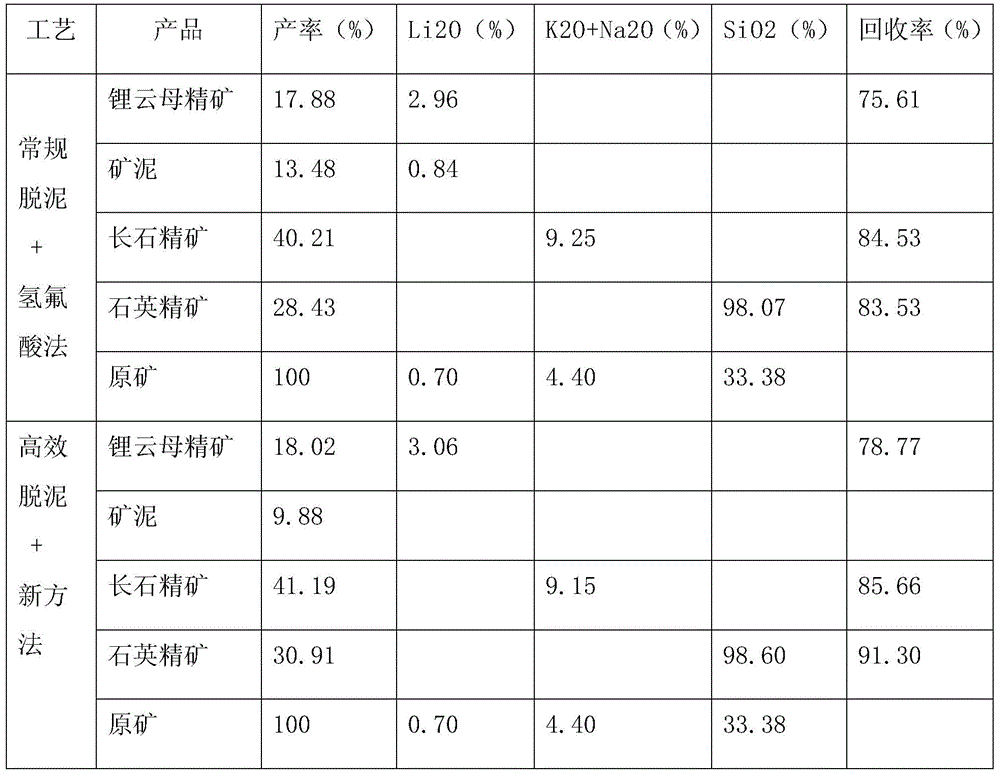

[0031] A method for optimizing feldspar and quartz from tantalum-niobium ore gravity separation tailings, such as figure 2 As shown, the following process steps are included:

[0032] (1) Desliming of tantalum and niobium ore tailings;

[0033] (2) lepidolite flotation, the foam product is lepidolite concentrate;

[0034] (3) Feldspar flotation, the foam product is feldspar concentrate, and the flotation tailings are quartz concentrate.

[0035] Wherein, in step (1) desliming of tailings by gravity separation, the deslimed particle size is 0.020mm, and the content of -0.020mm in the deslimed product is 5.42%;

[0036] Wherein, step (3) feldspar flotation includes a roughing, a sweeping; and in the roughing, hydrochloric acid is added to adjust the pH value to be equal to 2.5 as a regulator; the mixture of hydrochloric acid, oxalic acid and sodium oxalate is added as an activat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com