Sorting process for improving beneficiation recovery rate of nonferrous metals

A technology of non-ferrous metals and recovery rate, applied in flotation, solid separation, etc., can solve the problems that old ore concentrators or small concentrators are not applicable, the rapid flotation process system is difficult to implement, and the plant conditions are high, so as to reduce the total flotation The selection time is shortened, the flotation process is shortened, and the separation index is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

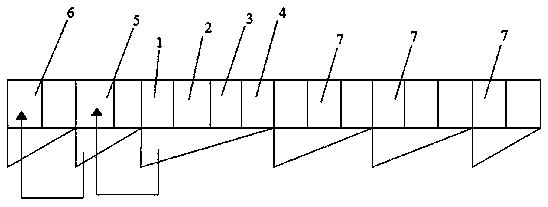

[0027] Such as figure 1 As shown, the prior art lead selection plant roughing operation is equipped with 4 flotation machines, and its technological process is: the foam product of the first groove of the roughing operation and the other three grooves of the roughing operation gather together and enter the selection I operation Sorting is carried out, and the foam products of the selection I operation enter the selection operation again.

[0028] A lead-zinc ore concentrator processes 400,000 tons of lead-zinc ore per year. The main products are lead concentrate, zinc concentrate and sulfur concentrate. The gold and silver in the ore are enriched in the form of associated precious metals to the main products through flotation. middle. The concentrator adopts the process of priority selection of lead, zinc and sulfur mixed separation and separation. Among them, the process of lead selection adopts a process of first roughing, second refining and three sweeping. Zinc inhibitor...

Embodiment 2

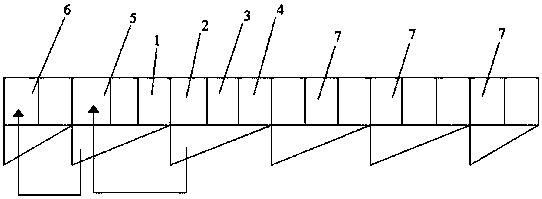

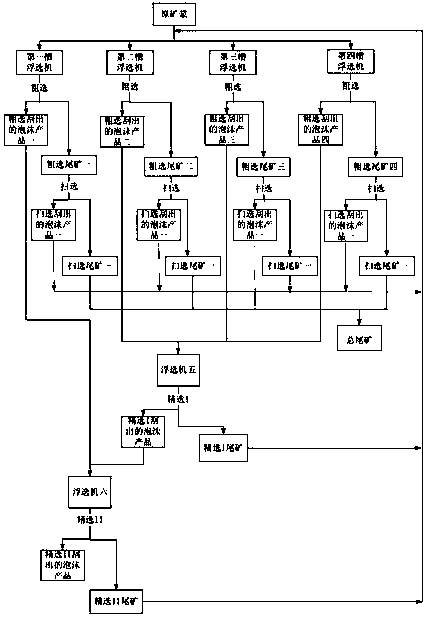

[0030] Please refer to figure 2 and image 3 , a sorting process for improving the recovery rate of non-ferrous metal beneficiation of the present embodiment, comprising the following steps:

[0031] 1) Rough selection: Four parallel flotation machines are used for rough selection, and the raw ore pulp enters the first tank flotation machine, the second tank flotation machine, the third tank flotation machine, and the fourth tank flotation machine for separation. Separation operation, the raw ore pulp enters the separation operation of each flotation machine to obtain their respective foam products and tailings;

[0032] 2) Selection I: the foam product obtained by the rough selection of the second trough flotation machine, the foam product obtained by the rough selection of the third trough flotation machine, the rough selection and scraped foam product obtained by the rough selection of the third trough flotation machine The foam product four scraped out by the rough sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com