Ore grinding grading system and method capable of controlling derichment of iron minerals

A grading system and iron ore technology, applied in grain processing, etc., can solve the problems of low gradable particle size of only 0.074, easy blockage of screen, high price of fine screen, etc., to improve mill processing capacity and improve concentrate products Quality, easy-to-handle and implement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

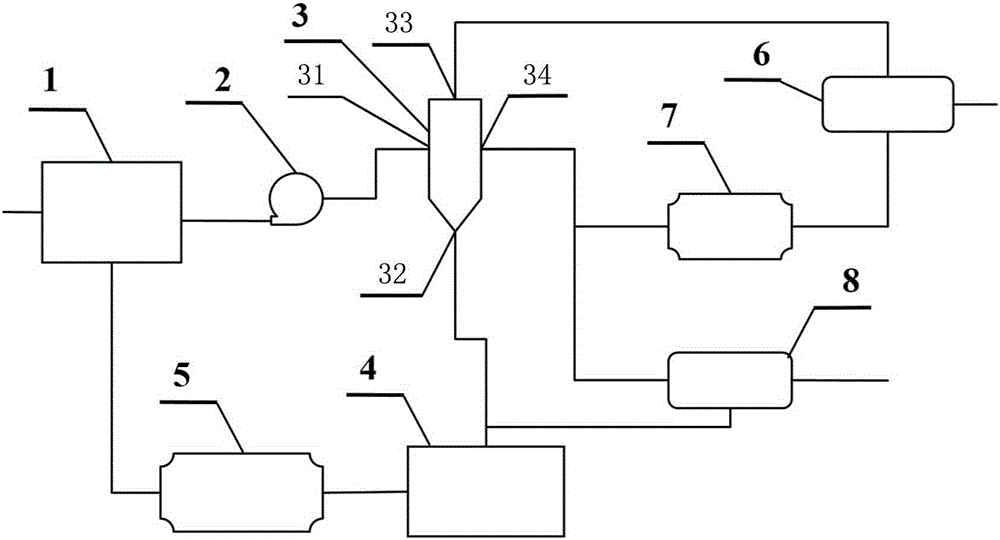

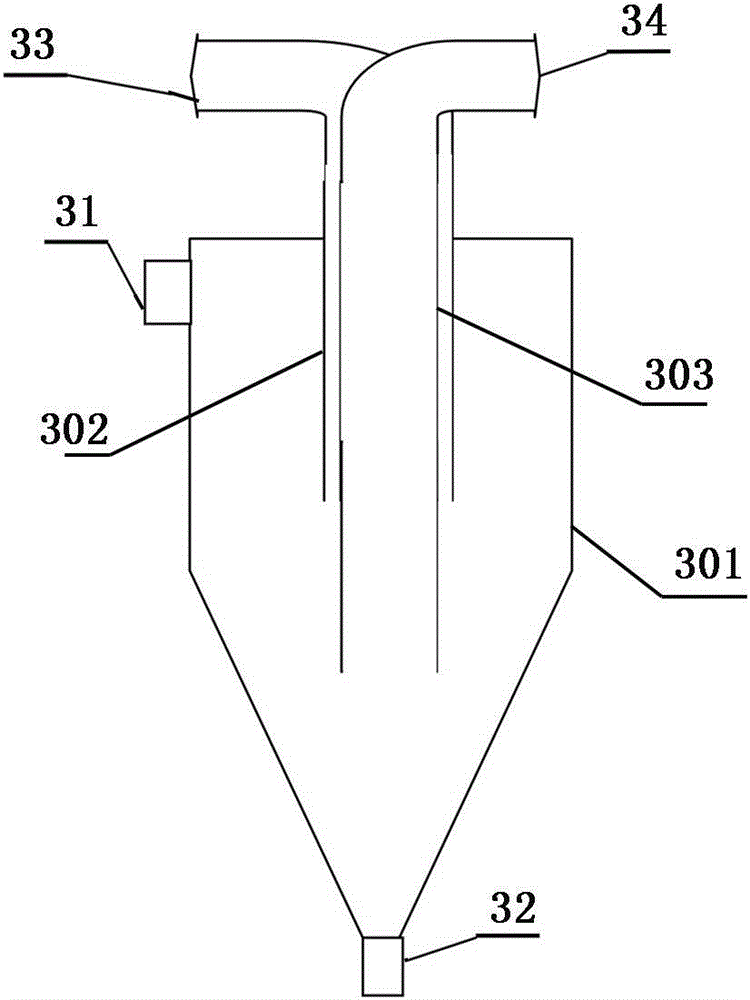

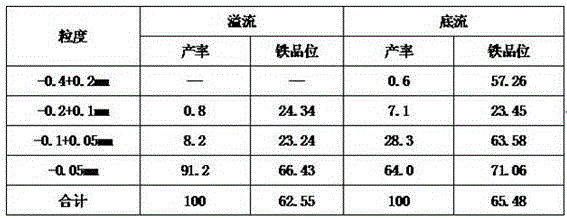

[0032] Such as figure 1 As shown, the present invention can control the anti-enrichment grinding and classification system of iron minerals, including ore feeding slurry tank 1, ore feeding pump 2, double overflow pipe cyclone 3, grit sinking ore slurry tank 4, mill 5, The first sorting equipment 6 and the open-circuit grinding mill 7, the double overflow pipe cyclone 3 is provided with a cyclone inlet 31, a settling outlet 32, an outer overflow outlet 33 and an inner overflow outlet 34, and there are three channels respectively Produce three graded products of grit, overflow and internal overflow, among which, the grit product is composed of coarse and heavy mineral particles (usually large iron mineral conjoint bodies), and the overflow product is composed of fine and light minerals Particles (usually dissociated fine-grained iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com