Spodumene ore flotation collecting agent, preparation method thereof and beneficiation process of clay mineralized spodumene ore

A technology of clay minerals and spodumene ore, which is applied in flotation, solid separation, etc., can solve the problems of increased chemical dosage, poor buoyancy, and obstruction of the movement path of ore particles, so as to reduce excessive chemical dosage and promote selection Sexual reunion, improve the effect of flotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

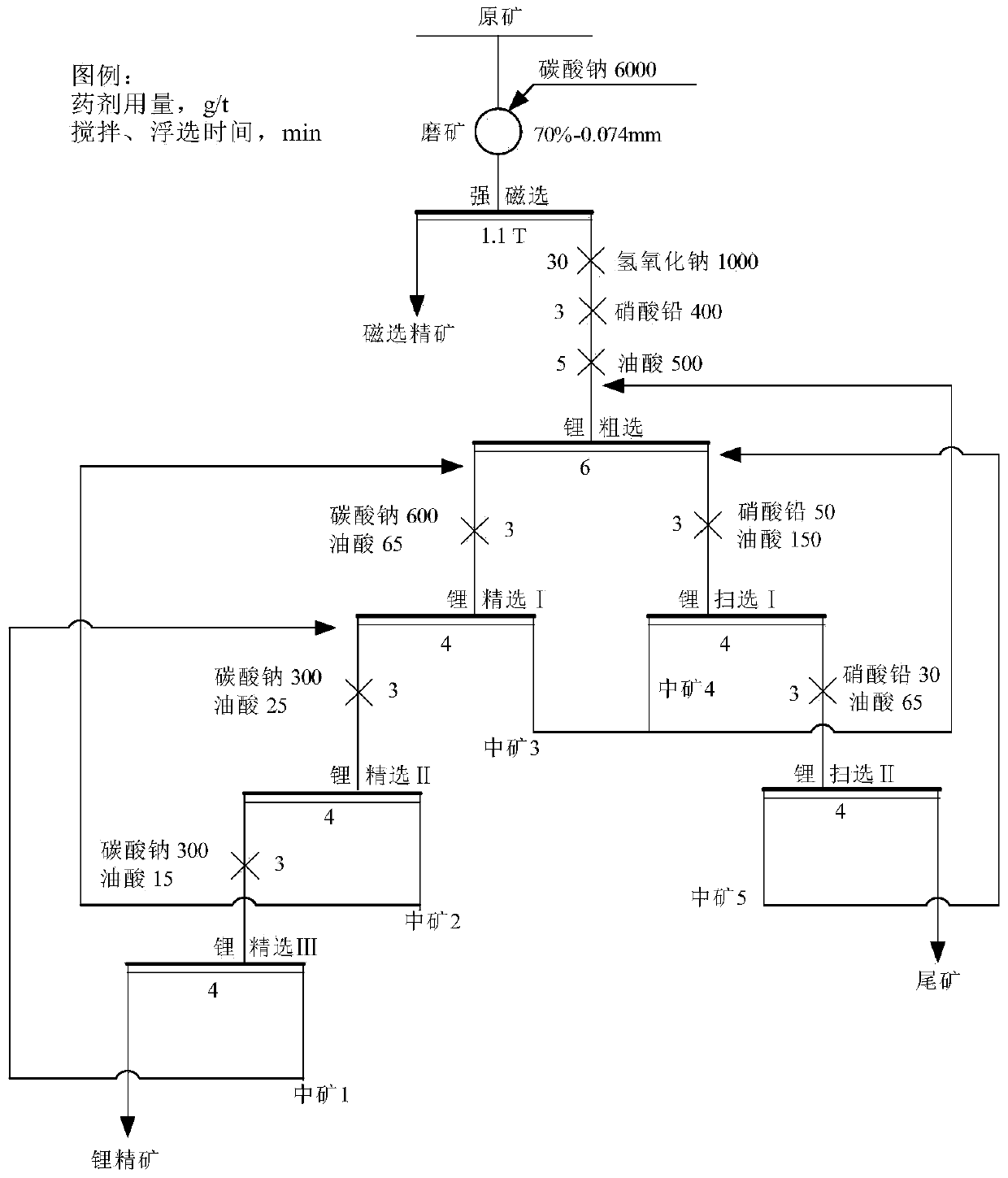

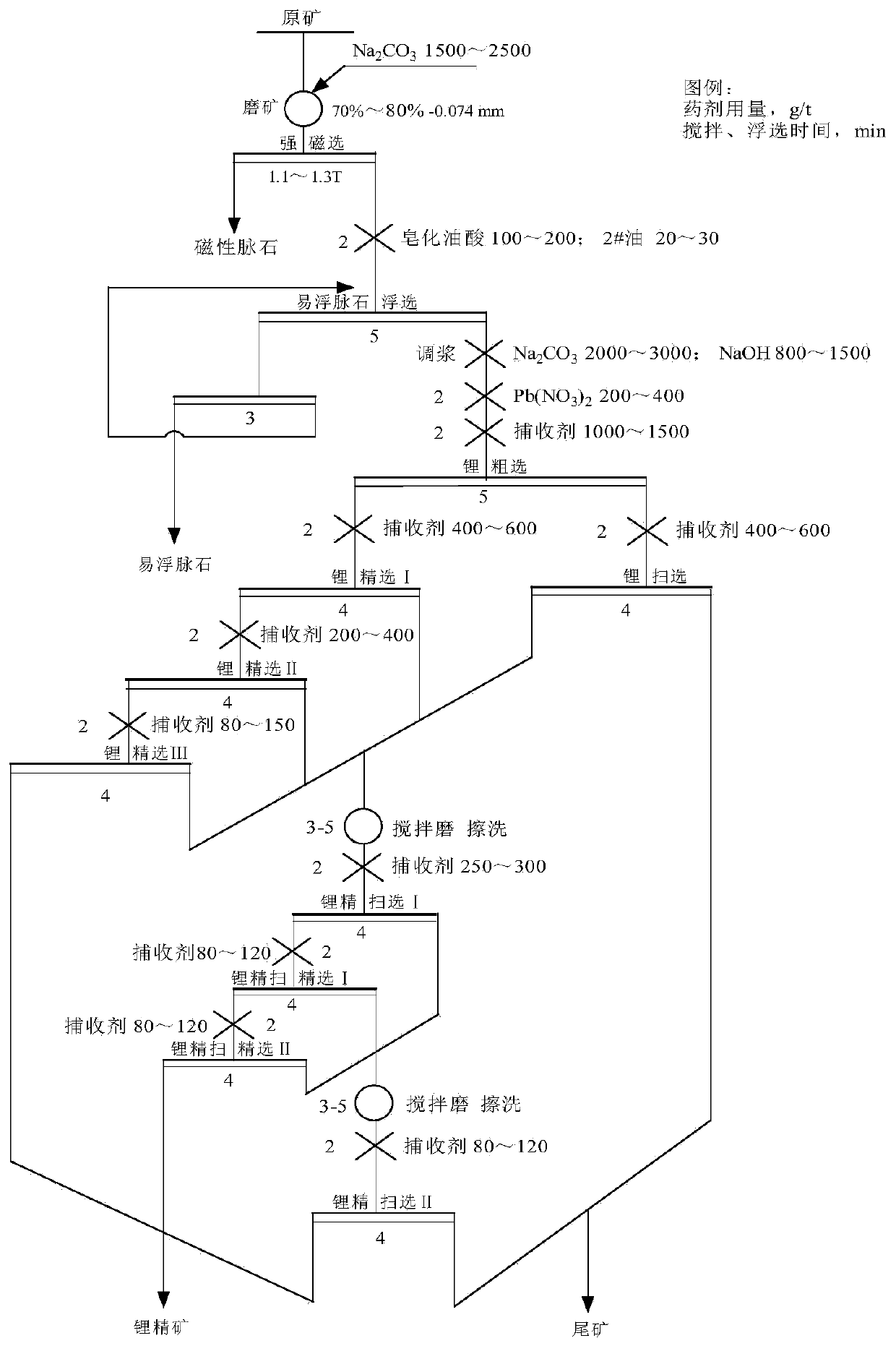

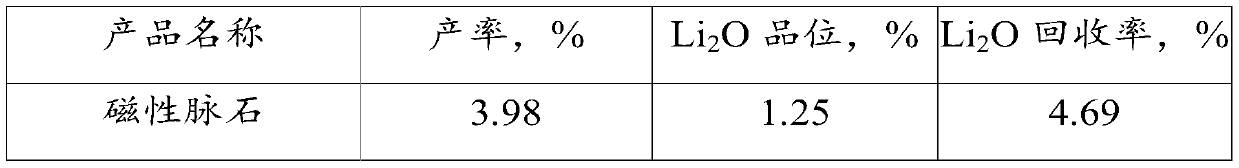

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be described in detail below in conjunction with examples, but those skilled in the art will understand that the following examples are only for illustrating the present invention, and should not be considered as limiting the scope of the present invention. Those who do not indicate the specific conditions in the examples are carried out according to the conventional conditions or the conditions suggested by the manufacturer.

[0040] According to one aspect of the present invention, a spodumene ore flotation collector is provided in at least one embodiment, comprising each component of the following parts by weight: 45-55 parts of sodium oleate, 5-10 parts of gallic acid , 15-25 parts of tartaric acid, 10-20 parts of oxalic acid and 10-20 parts of lignin.

[0041] Sodium oleate can effectively adsorb target minerals, increase the contact of mineral surfaces, promote the agglomeration of fine-grained ores, and thus increase the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com