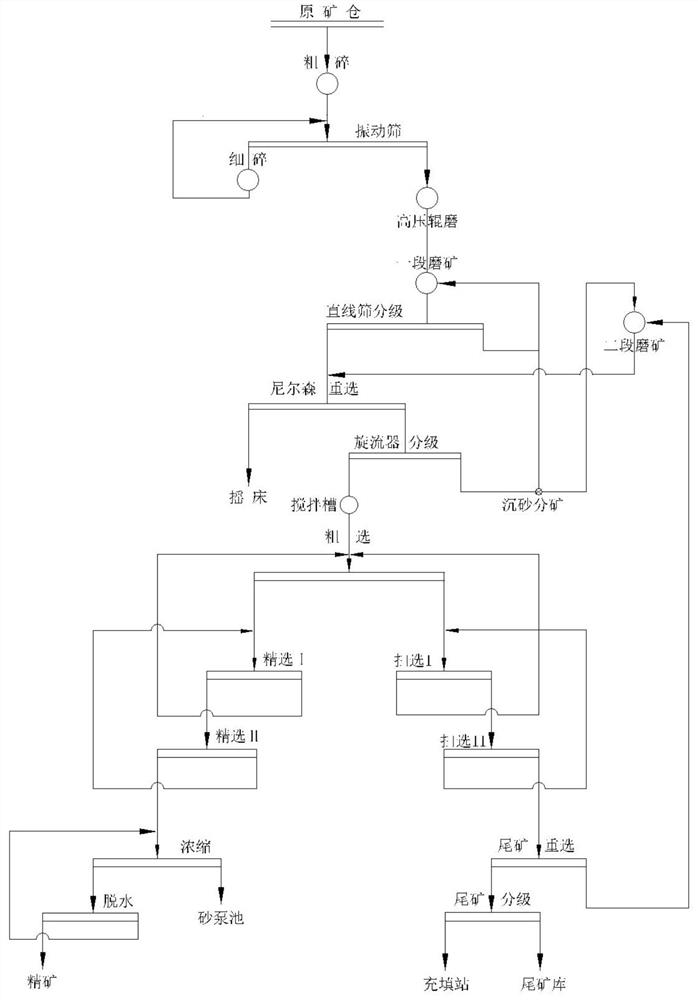

Low-grade mineral separation process

A low-grade, high-tech technology, applied in the direction of solid separation, wet separation, grain processing, etc., can solve the problems of low resource recovery rate, high energy consumption of crushing and grinding, poor environmental protection conditions, etc., and achieve low energy consumption and high crushing efficiency , Improve the effect of recycling indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] The gold ore raw ore is unloaded into the raw ore bin by electric locomotive or car. The upper part of the raw ore bin is equipped with a 450×450mm square grid screen. The ore in the raw ore bin is fed into the jaw type C100 through the GBZ 1750×9000 heavy-duty apron feeder. Crusher performs coarse crushing, the coarse crushing outlet is 90-120mm, the coarse crushed products are sent to the vibrating screen on the upper part of the powder ore bin through the belt conveyor A for screening, and the under-screen products with a particle size of less than 20mm fall directly into the powder ore bin Inside, the on-sieve products with a particle size greater than 20mm are returned to the HP4 cone crusher through the belt conveyor B for fine crushing. Crushing process, vibrating screen hole size is 15×25, 20×25 two specifications;

[0042] The material falling into the powder ore bin is sent to the high-pressure roller mill through the heavy-duty plate feeder. The discharge gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com