Flotation method and flotation system of whole-course open circuit floatation for concentrate slurry

A concentrate and flotation technology, which is applied in flotation, solid separation, etc., can solve the problems of difficult control of tailing index, difficulty of stable concentrate quality, difficulty of automatic control, etc., and achieve easy automatic control, easy stable control, Dependency reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

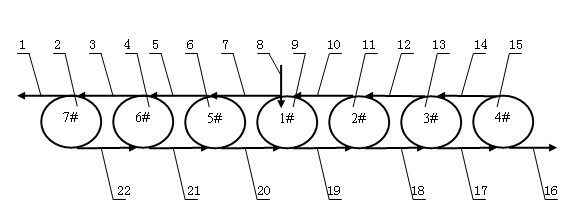

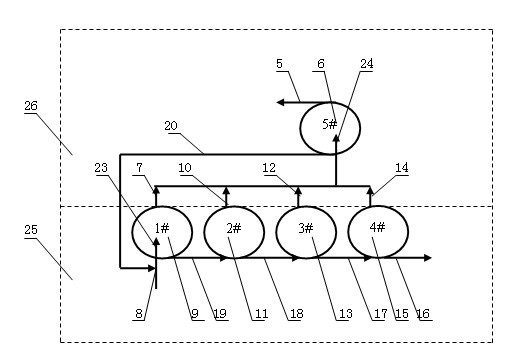

[0044] Embodiment one: A kind of flotation process of whole process open-circuit flotation of concentrate pulp comprising at least two flotation systems

[0045] figure 2 What is shown is a flotation process of full open-circuit flotation of concentrate pulp comprising at least two flotation systems. Wherein the first flotation system 25 is a front flotation system, made up of 1# flotation cell 9, 2# flotation cell 11, 3# flotation cell 13 and 4# flotation cell 15; the second flotation system 26 It is a post-flotation system, consisting of 5# flotation tank 6.

[0046] The course of work of the first flotation system 25 is as follows:

[0047] The inflow ore pulp 23 of the first flotation system can be the raw ore pulp 8 , or a mixed pulp of the raw ore pulp and the tailings pulp 20 of the second flotation system. After the inflow ore pulp 23 of the system enters the first flotation system 25, it is roughed by the 1# flotation cell 9 to produce the concentrate pulp 7 of ...

Embodiment 2

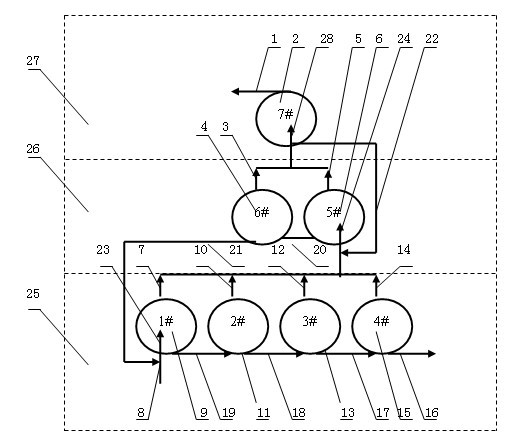

[0052] Embodiment two: A kind of flotation process of open circuit flotation of concentrate pulp including more than three flotation systems, including three flotation systems, wherein, the first flotation system is a front flotation system, which is composed of more than one flotation tank ; The second flotation system is a rear flotation system, which is composed of more than one flotation cell; the third flotation system is a rear flotation system, which is composed of at least one flotation cell; it is characterized in that: the first flotation The system processes the inflow pulp of the first flotation system to produce final tailings pulp and more than one kind of concentrate pulp; the second flotation system processes the inflow pulp of the second flotation system to output system tailings pulp and one The above concentrate pulp; the third flotation system processes the inflow pulp of the third flotation system, and outputs system tailings pulp and final concentrate pu...

Embodiment 3

[0067] Embodiment three:Another kind of flotation process of open-circuit flotation of concentrate slurry including more than three flotation systems

[0068] Figure 4 What is shown is another kind of flotation process of whole process open-circuit flotation of concentrate pulp which includes more than three flotation systems. Its technical principle and working process are basically the same as those in Embodiment 3. The difference is that in the 1# tank concentrate pulp 7, the 2# tank concentrate pulp 10, the 3# tank concentrate pulp 12 and the 4# tank concentrate pulp 14 produced by the first flotation system 25, the 1# tank concentrate pulp The target particle content of the concentrate pulp 7 is close to the final concentrate grade, and is quite different from the grades of the other three concentrate pulps. Therefore, only the other three concentrate pulps are mixed with the tailings pulp in the 7# tank, and they are disposed of as the inflow pulp 24 of the second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com