Method for preenriching and separating lithium and boron from salt lake brine by liquid-liquid-liquid three-phase extraction

A salt lake brine, pre-enrichment technology, applied in chemical instruments and methods, lithium compounds, boron compounds, etc., can solve the problems of high solubility of diisobutyl ketone, high price, low single-stage extraction rate of lithium, etc., to achieve solution The effect of wide pH adaptation range and easy phase formation behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

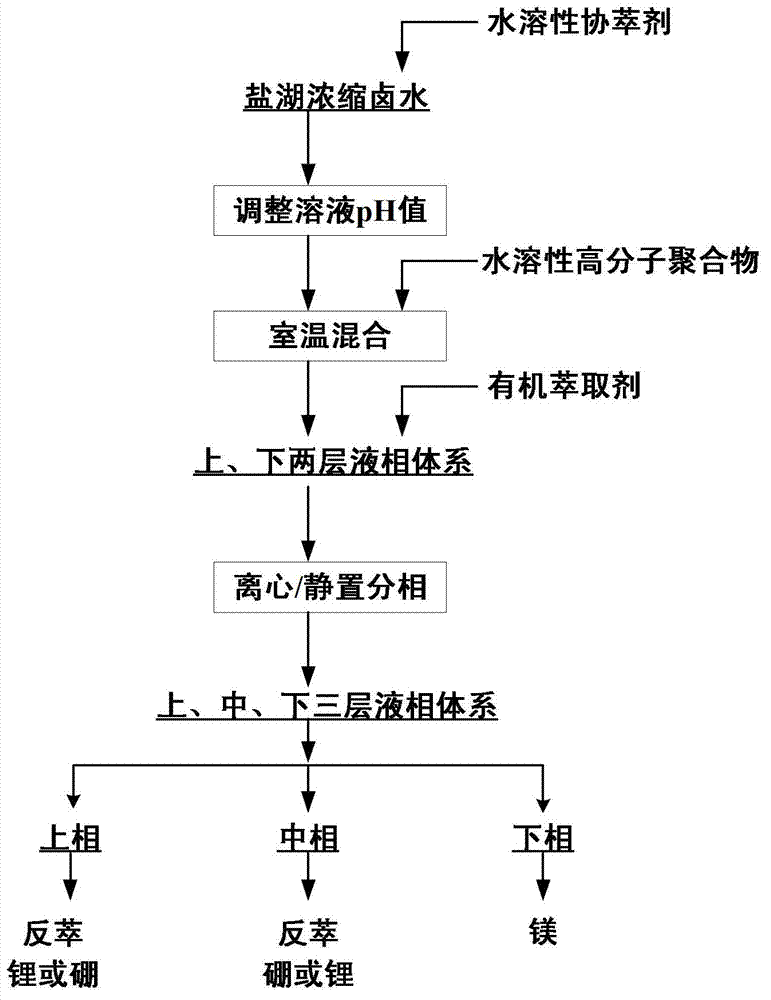

Method used

Image

Examples

Embodiment 1

[0052] Take 50mL of the concentrated brine solution, and the brine composition is: Li + 2.21g / L, B 2 o 3 2.85g / L, Mg 2+ 100.71g / L, Na + 5.53g / L, K + 2.85g / L, the mass ratio of magnesium to lithium is 45.6.

[0053] Add co-extractant FeCl to the above brine 3 , the molar ratio of iron to lithium was 1.2:1, and the pH of the brine was adjusted to 1.5; then 10 g of water-soluble high molecular polymer polyethylene glycol PEG (molecular weight: 2000) was added, thoroughly mixed at room temperature and then centrifuged to separate phases to obtain the above, A two-liquid phase system in which the lower two layers coexist; 25 mL of kerosene solution with a volume percentage concentration of 80% TBP is added to the two-liquid phase system, and the obtained mixture is fully mixed at room temperature and left to separate phases to obtain upper, middle, and A three-liquid phase system in which the lower three layers coexist. The upper and middle two phases of the three-liquid ph...

Embodiment 2

[0055] Take 50mL of the concentrated brine solution, and the brine composition is: Li + 0.48g / L, B 2 o 3 0.89g / L, Mg 2+ 96.21g / L, Na + 9.03g / L, K + 5.48g / L, the mass ratio of magnesium to lithium is 200.4.

[0056] Add the co-extraction agent NaClO in the above brine 4 , ClO 4 - with Li + The molar ratio of the brine is 2:1, and the pH of the brine is adjusted to 7; then 15 g of the water-soluble polymer EOPO (molecular weight: 2500) is added, mixed thoroughly at room temperature, and the phases are separated by centrifugation to obtain a two-liquid phase in which the upper and lower layers coexist. system; add 30 mL of kerosene solution with volume percent concentration of 50% TOPO to the two-liquid phase system, and the obtained mixture is fully mixed at room temperature and left to separate phases to obtain a three-phase liquid phase in which upper, middle and lower layers coexist. system. The upper and middle two phases of the three-liquid phase system were resp...

Embodiment 3

[0058] Take 50mL of the concentrated brine solution, and the brine composition is: Li + 1.80g / L, B 2 o 3 20.89g / L, Mg 2+ 90.51g / L, Na + 6.89g / L,K + 1.85g / L, SO 4 2- 28.82g / L, the mass ratio of magnesium to lithium is 50.3.

[0059] Adjust the pH of the brine to 2, then add 15 g of water-soluble polymer polyethylene glycol PEG (molecular weight: 2000), mix well at room temperature and then centrifuge to separate the phases to obtain a two-liquid phase system in which the upper and lower layers coexist; Add 1,1,2,2,3,3-fluoroheptyl-7,7-dimethyl-4,6-octyldiketone (HFDMOP) with a concentration of 30% by volume to the two-liquid phase system 25 mL of heptane solution, the resulting mixture was fully mixed at room temperature and then allowed to stand for phase separation to obtain a three-phase system in which upper, middle and lower layers coexist. The upper and middle two phases of the three-liquid phase system were respectively taken to analyze the concentration of lith...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com