Inclination pipe type underwater pre-dewatering degassing separation apparatus

A separation device and pre-dehydration technology, applied in the field of marine engineering, can solve the problems of insufficient separation time and small coverage area of oil-water interface, etc., and achieve the effect of light weight, small footprint and low water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

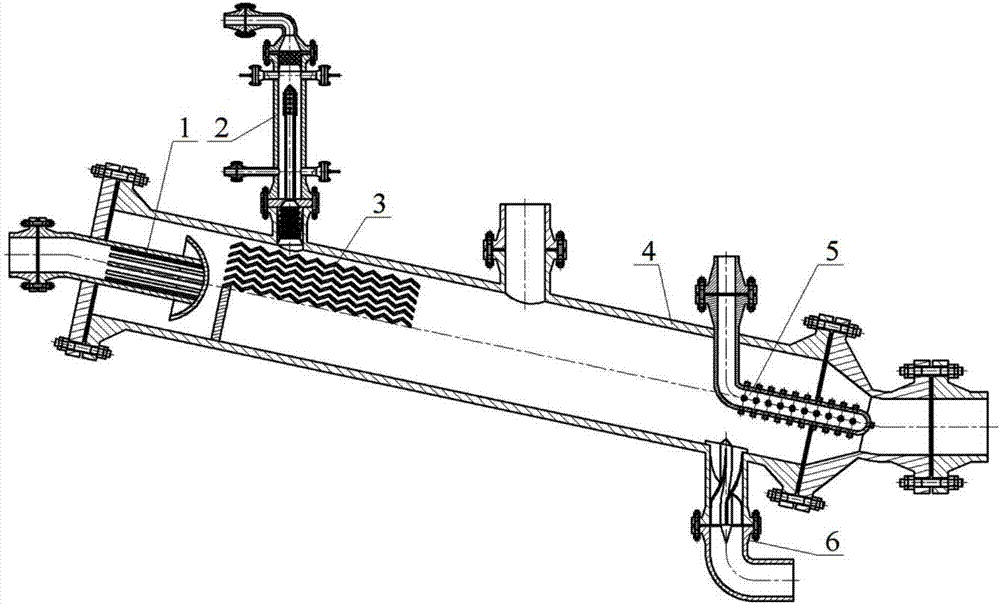

[0036] exist figure 1 Among them, the inclined tube type underwater pre-dehydration and degassing separation device is composed of a shunt pipe 1, an exhaust balancer 2, a corrugated plate group 3, a gas-liquid separation pipe 4, a sand washing pipe 5 and a drainage pipe 6. The inlet pipe of the shunt pipe 1 is connected with the subsea tree and the subsea manifold through a jumper pipe and a flange, the exhaust pipe of the exhaust balancer 2 is connected with the gas pipeline manifold through a flange, and the exhaust balancer The condensate discharge pipe of 2 is connected with the oil pipeline sink through the flange, the oil outlet pipe of the gas-liquid separation pipe 4 is connected with the next stage dehydrator through the flange, and the drain pipe 6 is connected with the water pipeline through the outlet pipe and the flange. The manifolds are connected together, so that the pre-dehydration and degassing separation device is organically combined with the submarine pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com