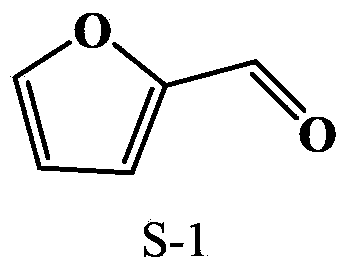

Method for preparation of furfural by biomass microwave mild pyrolysis

A technology of biomass and biomass raw materials, applied in the direction of organic chemistry, can solve the problems of large amount of waste water, high yield, low yield, etc., and achieve the effect of short production cycle, low pyrolysis temperature and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

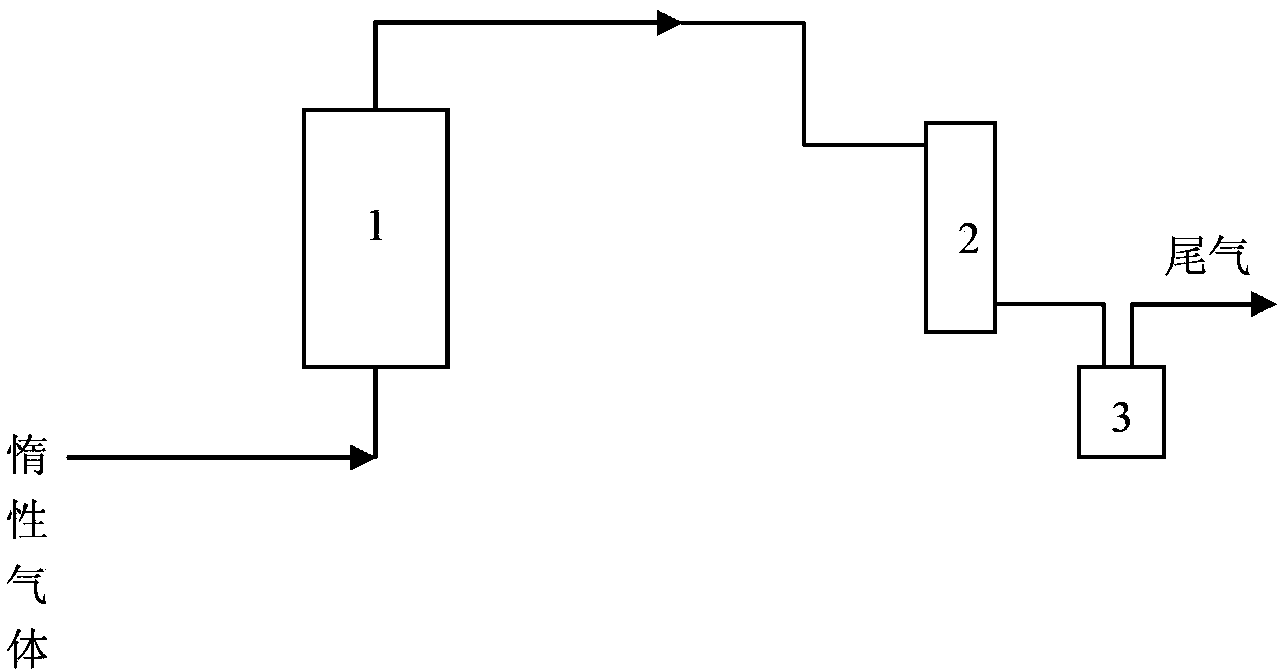

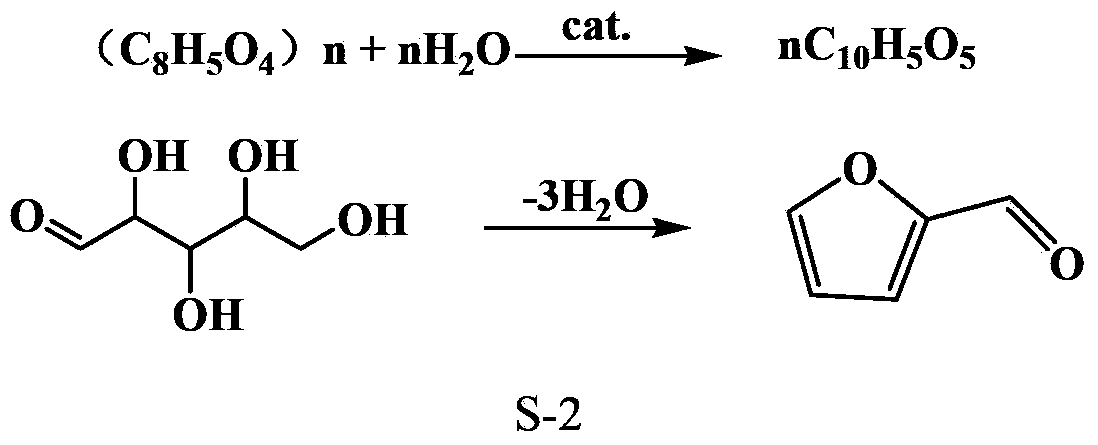

Method used

Image

Examples

Embodiment 1

[0035] Crush the rice straw to about 0.5mm, dip it in a sulfuric acid aqueous solution with a mass fraction of 5% for 10 minutes, dry it at 40°C to remove free water, and carry out charging and microwave gentle pyrolysis according to the above operation process, in which the inert gas used is Nitrogen (flow rate: 100ml / min), the reaction temperature (pyrolysis temperature) of mild pyrolysis is 150°C, stop the reaction after 20 minutes of reaction (pyrolysis), the collected liquid is post-treated as above, and quantified by gas chromatography Analysis shows that the total mass fraction of furfural in the upper and lower layers of liquid product is 38.5%.

Embodiment 2

[0037] Crush the corn stalks to about 1.0 mm, soak them in 8% phosphoric acid aqueous solution for 30 minutes, dry them at 60°C to remove free water, carry out the charging and microwave gentle pyrolysis according to the above operation process, and the inert gas used Argon gas (flow rate: 250ml / min), the reaction temperature (pyrolysis temperature) of mild pyrolysis is 200°C, stop the reaction after 20 minutes of reaction (pyrolysis), and carry out post-treatment on the collected liquid as above, and pass through the gas phase Chromatographic quantitative analysis shows that the total mass fraction of furfural in the upper and lower liquid products is 40.3%.

Embodiment 3

[0039] Crush poplar wood chips to about 1.5 mm, soak them in 10% sulfuric acid aqueous solution for 20 minutes, dry at 50°C to remove free water, and carry out charging and microwave gentle pyrolysis according to the above operation process. Among them, the inert The gas is argon (the flow rate is 200ml / min), the reaction temperature (pyrolysis temperature) of mild pyrolysis is 250°C, the reaction (pyrolysis) is stopped after 15 minutes, and the collected liquid is post-treated as above, after Quantitative analysis by gas chromatography showed that the total mass fraction of furfural in the upper and lower liquid products was 42.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com