Dry-process slag discharge device and method for entrained flow bed

A dry slagging and entrained-flow technology, which is applied in the field of coal gasification, can solve the problems of difficult to achieve engineering scale-up, increase the difficulty of product gas purification section, increase production cost, etc., and achieve the effect of realizing clean conversion and reducing black water discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] For better illustrating the present invention, facilitate understanding technical scheme of the present invention, typical but non-limiting embodiment of the present invention is as follows:

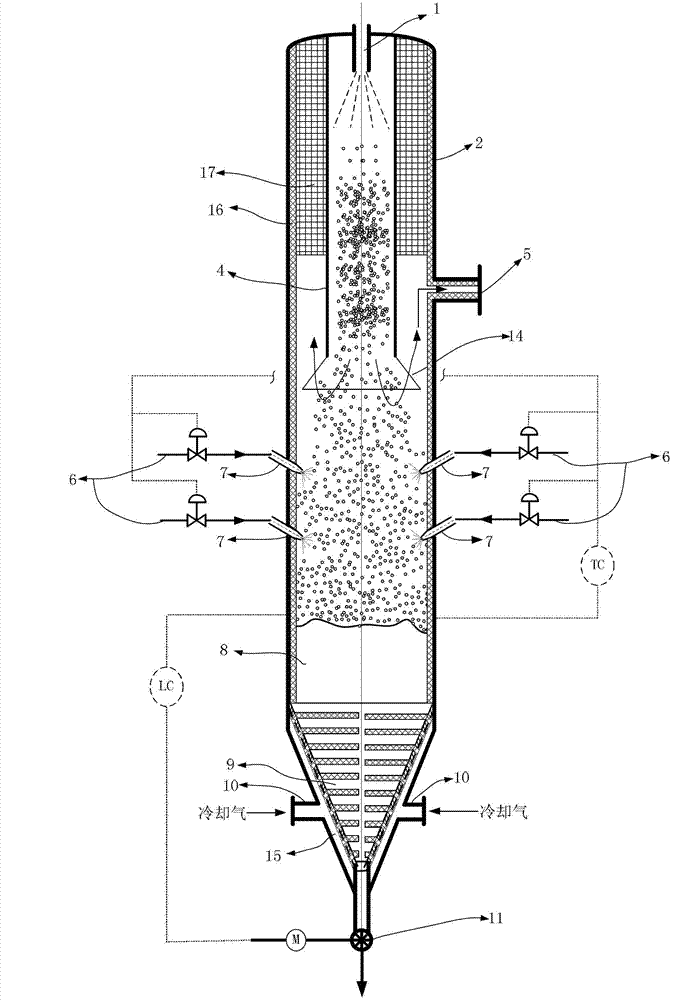

[0039] Such as figure 1 As shown, a dry slagging device for entrained bed, the device is divided into reaction section, cooling section and slagging section from top to bottom;

[0040] The reaction section includes an inner cylinder 4, the inner cylinder 4 is fixed on the top wall of the reaction section and opens downward, and the top wall is provided with a feed nozzle 1 opening to the inner space of the inner cylinder 4; the reaction section A product gas outlet 5 is provided on the side wall 2 . A filter screen 14 is provided at the outlet of the inner cylinder 4 .

[0041] Eight coolant nozzles 7 are arranged symmetrically on the side wall of the cooling section.

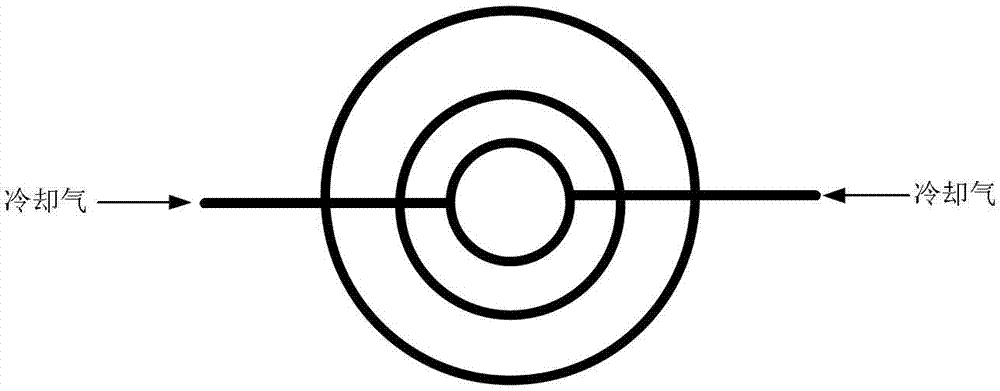

[0042] The slag discharge section includes a moving bed section 8 and a connected conical bottom. A gas dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com